A kind of solid lithium battery, composite negative electrode and preparation method thereof

A solid lithium and negative electrode technology, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as poor mechanical strength, poor bonding force, and short service life, so as to improve electrical and thermal conductivity and stabilize electrode volume changes , to avoid the effect of lithium dendrite formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

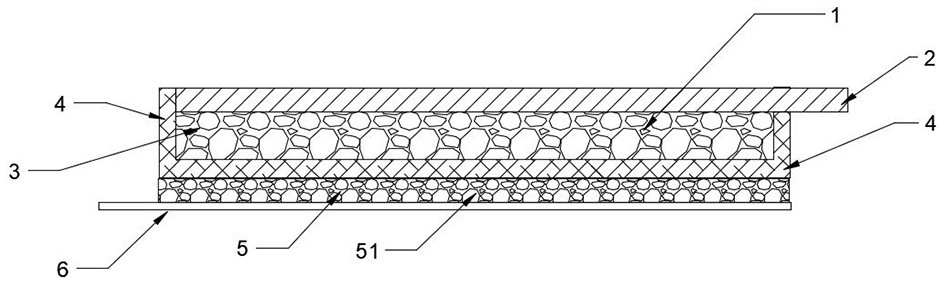

[0060] See attached figure 1 , 3 , 4. The all-solid-state lithium battery provided by the embodiment of the present invention is specifically a layered structure with a stacked positive electrode 5-electrolyte 4-double-sided composite negative electrode 1-electrolyte 4-positive electrode 5, in which there are 4 layers of electrolyte And negative electrode current collector 2 layers completely cover the elastoplastic body 3 and lithium metal 32 layers of the composite negative electrode, avoiding the exposure of lithium metal 32, which is conducive to further preparing it as a battery pack without a module structure, which can increase its weight specific energy Density and safety performance.

[0061] Wherein, the negative electrode current collector copper foil 2 is double-sided roughened copper foil with a thickness of 3-25 μm, and 8 μm is used in this embodiment.

[0062] The solid electrolyte in this embodiment is a sulfide solid electrolyte with a thickness of 10-15 μm...

Embodiment 2

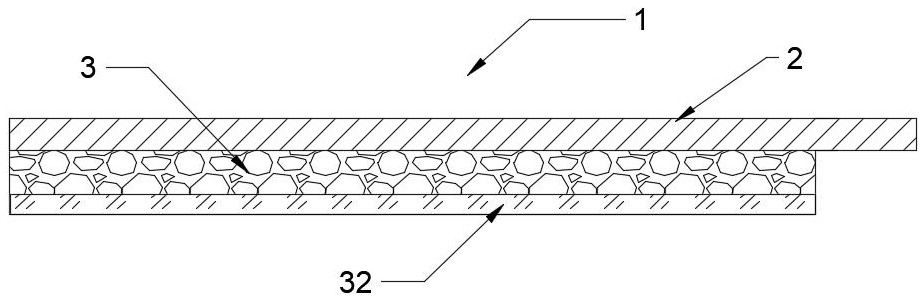

[0090] See attached figure 2 , the all-solid-state lithium battery and composite negative electrode provided in this example, its basic structure, components and preparation method are the same as in Example 1, the difference is that it has a layered structure of positive electrode-electrolyte-single-sided composite negative electrode structure.

[0091] The negative electrode lithium metal 32 used in the solid-state lithium battery of this embodiment is a perforated smooth lithium strip or lithium foil with a thickness of 20 μm, and a plurality of circular through holes 13 are uniformly arranged on the lithium strip or lithium foil. The area of the through hole 13 is 5-10% of the total area of the lithium ribbon or lithium foil, and the diameter of the through hole 13 is 0.1 μm-1 μm.

[0092] In this embodiment, the negative current collector 2 is stainless steel foil with a thickness of 10 μm; the carbon nanotubes 11 are magnetic carbon nanotubes.

[0093] The prepara...

Embodiment 3

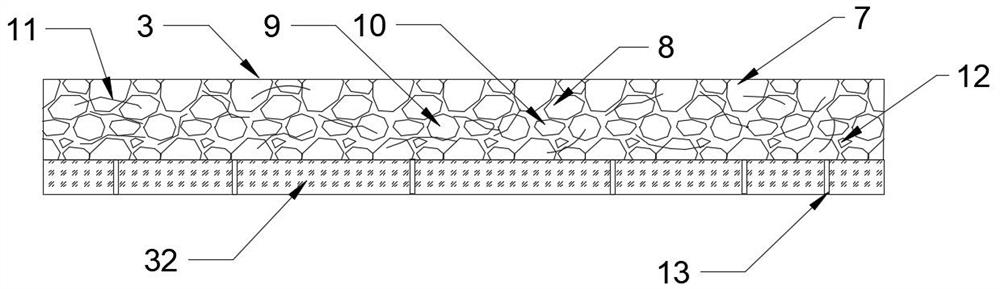

[0108] The basic structure, components and preparation methods of the all-solid-state lithium battery and composite negative electrode provided in this example are the same as those in Examples 1 and 2, except that:

[0109] It is Li / LiFePO 4 system, the cathode of which is LiFeO 4 Electrode (mass load about 3.2mg / cm 2 ); its electrolyte is PEO polymer electrolyte.

[0110] The metal foil base material of the negative electrode current collector used in this embodiment is a copper mesh with a thickness of 6 μm; the lithium metal of the negative electrode is a smooth lithium strip with a thickness of 50 μm.

[0111] In the embodiment of the present invention, the thickness of the negative elastoplastic body 3 after drying is 10 μm, and the active slurry is prepared from the following components in parts by weight: carbon black: graphite: graphene: lithium titanate: nickel balls: organic polymer (specifically polytetrafluoroethylene emulsion): dispersant: thickener: solvent =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com