Rotating axis parameter measurement equipment and rotating axis multi-parameter sensor

A parameter measurement and sensor technology, applied in mechanical bearing testing, instruments, signal transmission systems, etc., can solve the problems of large measurement equipment, large volume and weight of toroidal transformers, and high cost, and reduce the interference between the volume and the circuit. , the effect of improving reliability and stability, improving quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

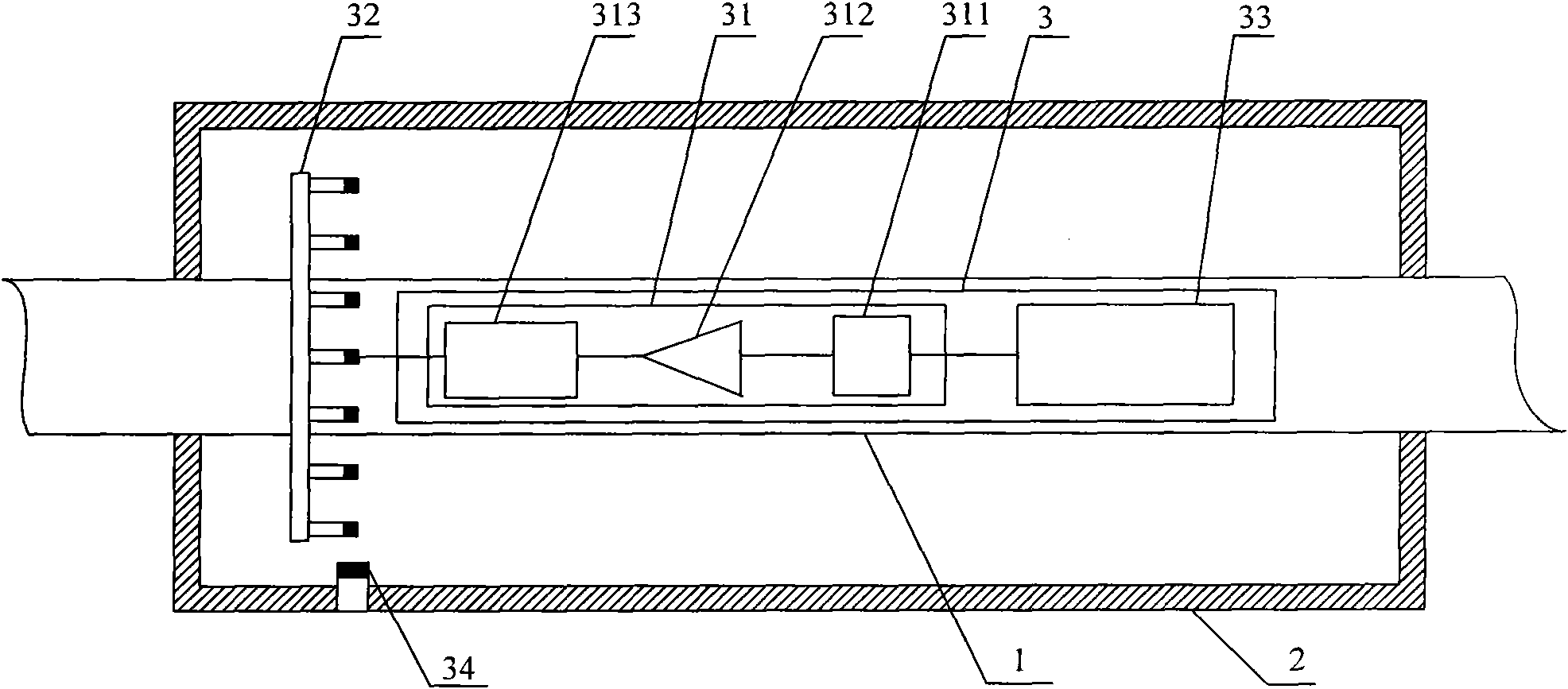

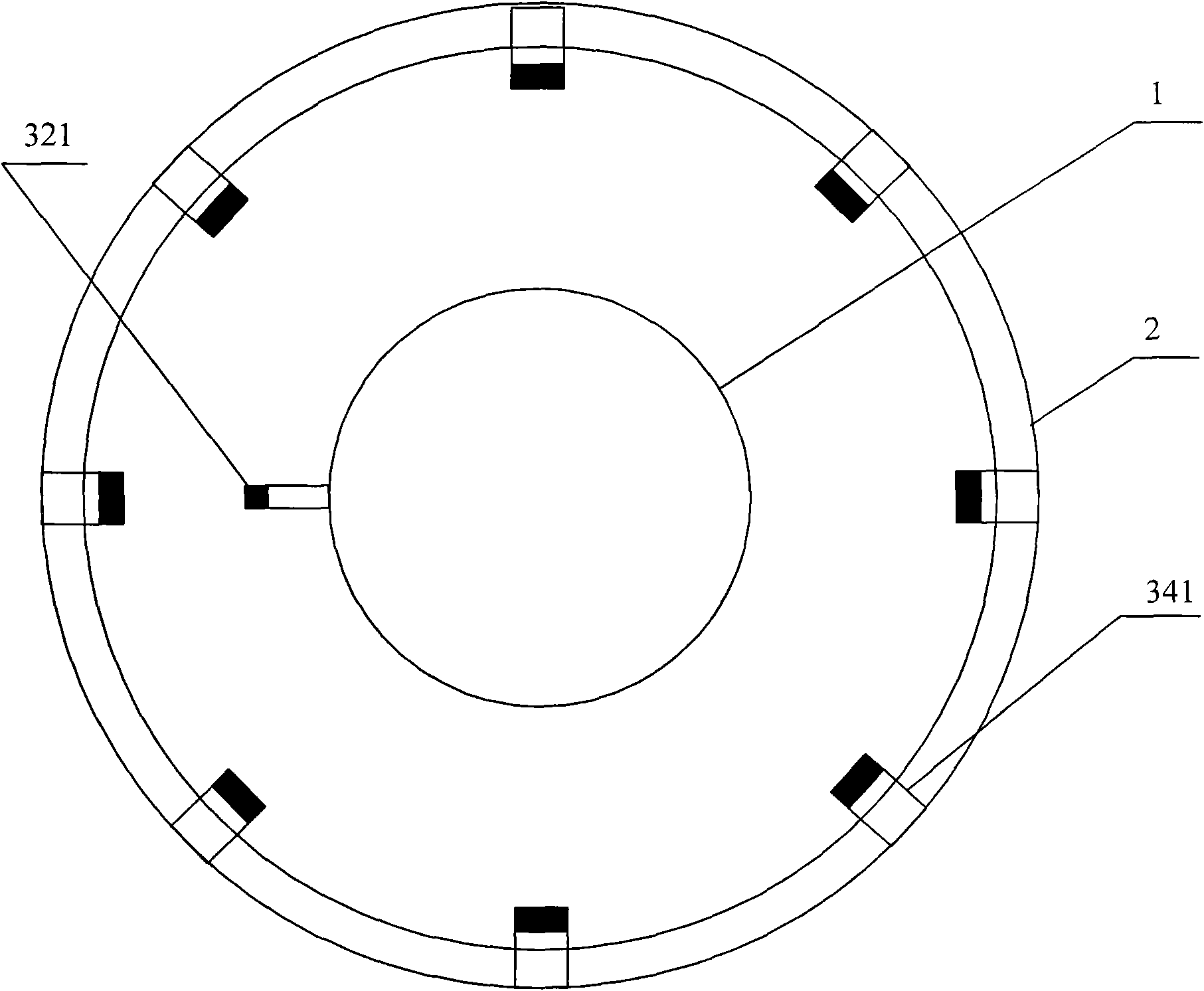

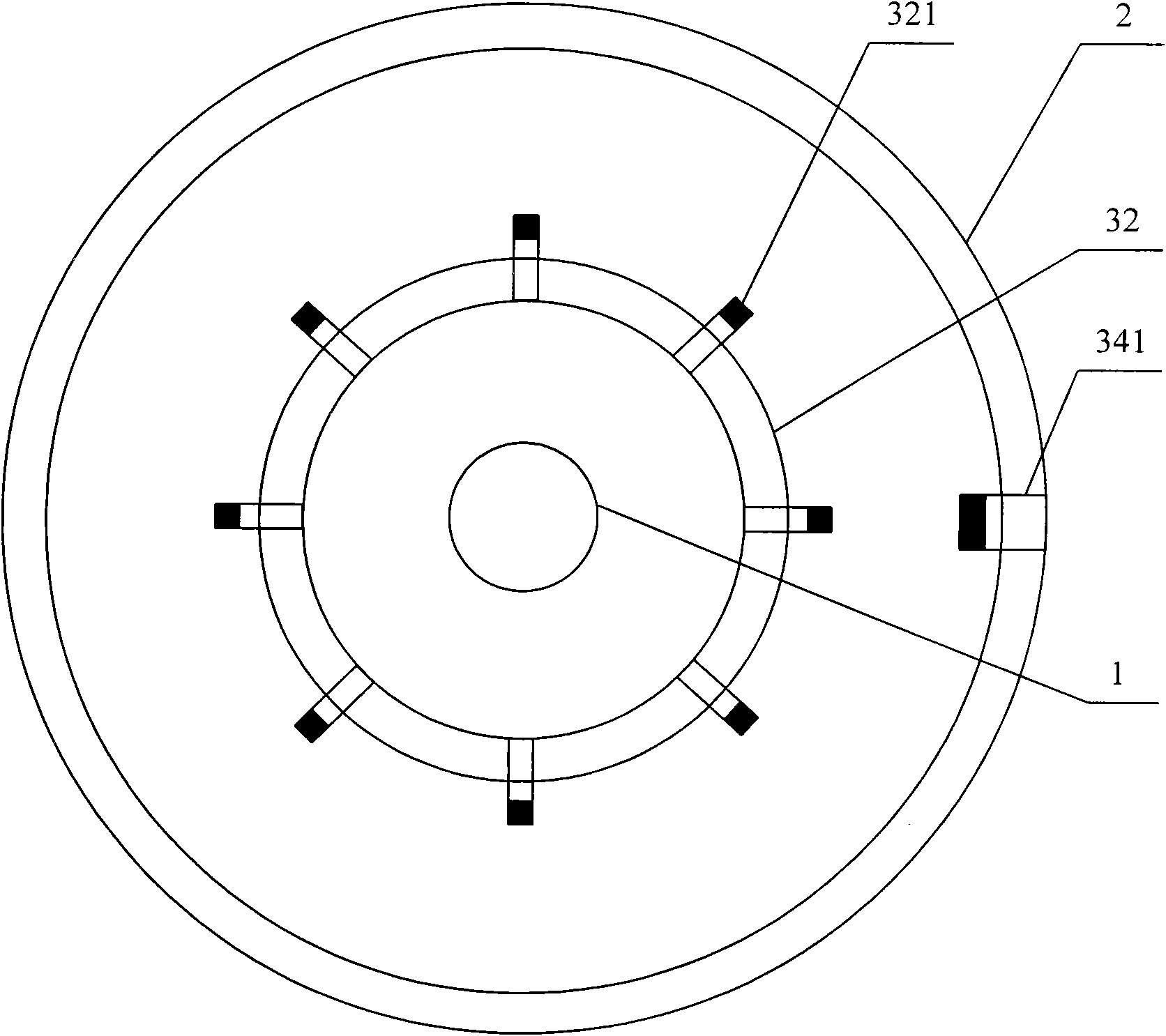

[0019] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the rotary axis multi-parameter sensor of the present invention. The sensor includes a digital measurement circuit 31 and an optocoupler transmitter 32 . The digital measurement circuit 31 is fixed on the rotor 1 for measuring and obtaining the digital signals of the parameters of each rotor; the photoelectric coupler transmitter 32 is connected with the digital measurement circuit 31 and fixed on the rotor 1 to receive the output of the digital measurement circuit 31. The digital signal of the rotor parameter is sent out.

[0020] The digital measurement circuit 31 in this embodiment can measure various parameters in the process of rotor rotation, such as the measurement of parameters such as rotational torque, axial force, vibration, temperature, pressure, and rotational speed, and the measured The obtained rotor parameters are converted into digital signals. When measuring multiple parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com