Preparation method of polymerized iron flocculant

A flocculant and iron-poly technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unstable precipitation, weakening, loss of coagulation performance, etc., and achieve enhanced bonding and bridging ability, improved coagulation effect, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

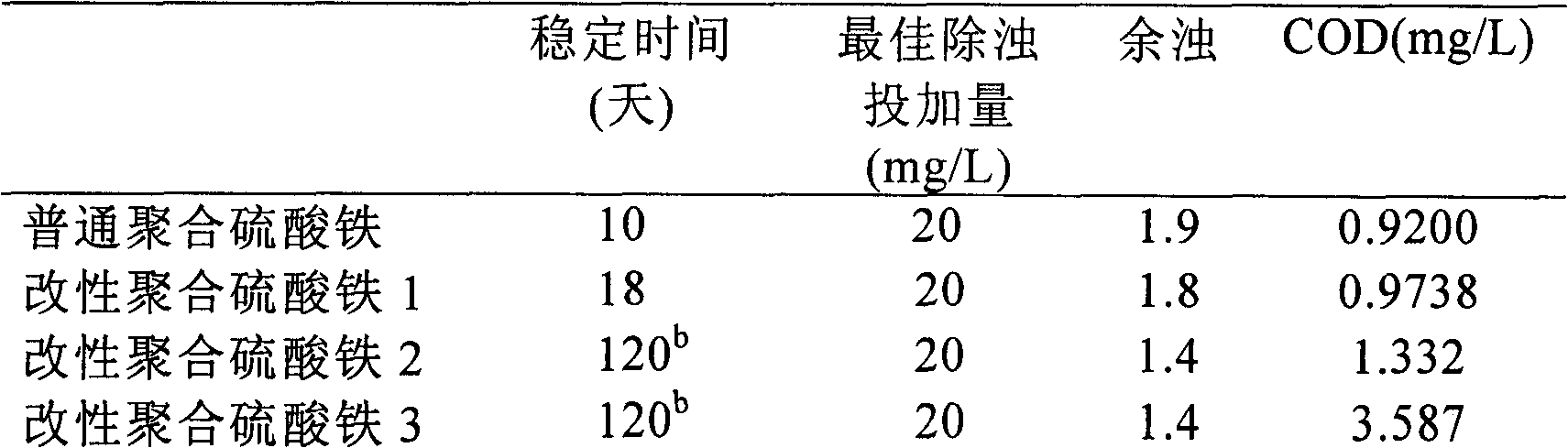

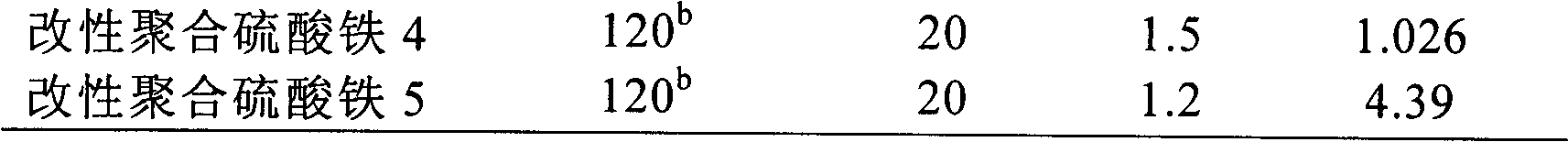

[0027] This implementation case uses the following steps:

[0028] (1) Control the temperature at 20-35°C, add 15.0g of ferrous sulfate and 1.2ml of sulfuric acid to 32.0ml of water, stir magnetically to completely dissolve the ferrous sulfate, and the reaction is exothermic;

[0029] (2) Control the temperature range constant, add 3.0ml hydrogen peroxide (30%) to the ferrous sulfate solution at a speed of 1.0ml / min, stir for 15min, so that the ferrous ions in the solution are completely oxidized to ferric ions;

[0030] (3) Add 32.1ml of 1mol / L sodium bicarbonate solution from the bottom of the beaker at a rate of 1.7ml / min, and then mature at a constant temperature of 50°C for 24h to obtain common polyferric sulfate.

Embodiment 2

[0032] The method described in this implementation case is basically the same as Case 1, the difference is that 3.5ml of sodium acetate solution of 5.0mol / L is added in step (3), the concentration of iron in the polyferric sulfate is kept constant, and the reaction obtains modified polyferric sulfate 1 .

Embodiment 3

[0034] The method described in this implementation case is basically the same as Case 1, the difference is that 10.5ml of sodium acetate solution of 5.0mol / L is added in step (3), the concentration of iron in the polyferric sulfate is kept constant, and the reaction obtains modified polyferric sulfate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com