Magnetic carrier iron ordered mesoporous carbon, preparation method and application thereof

A mesoporous carbon and iron-carrying technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as application limitations of nano-scale iron particles, and is suitable for large-scale production and application, wide application range, stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

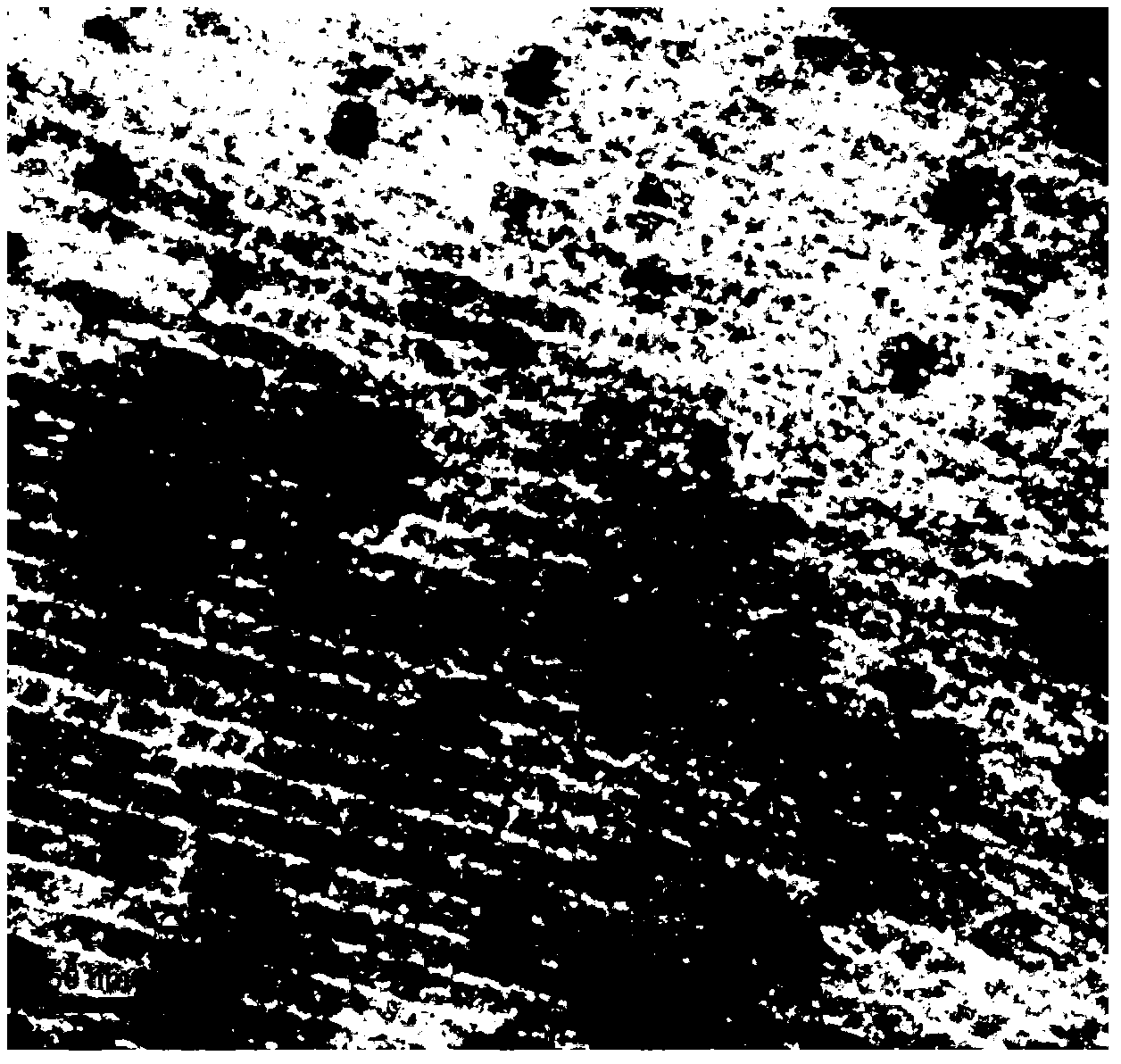

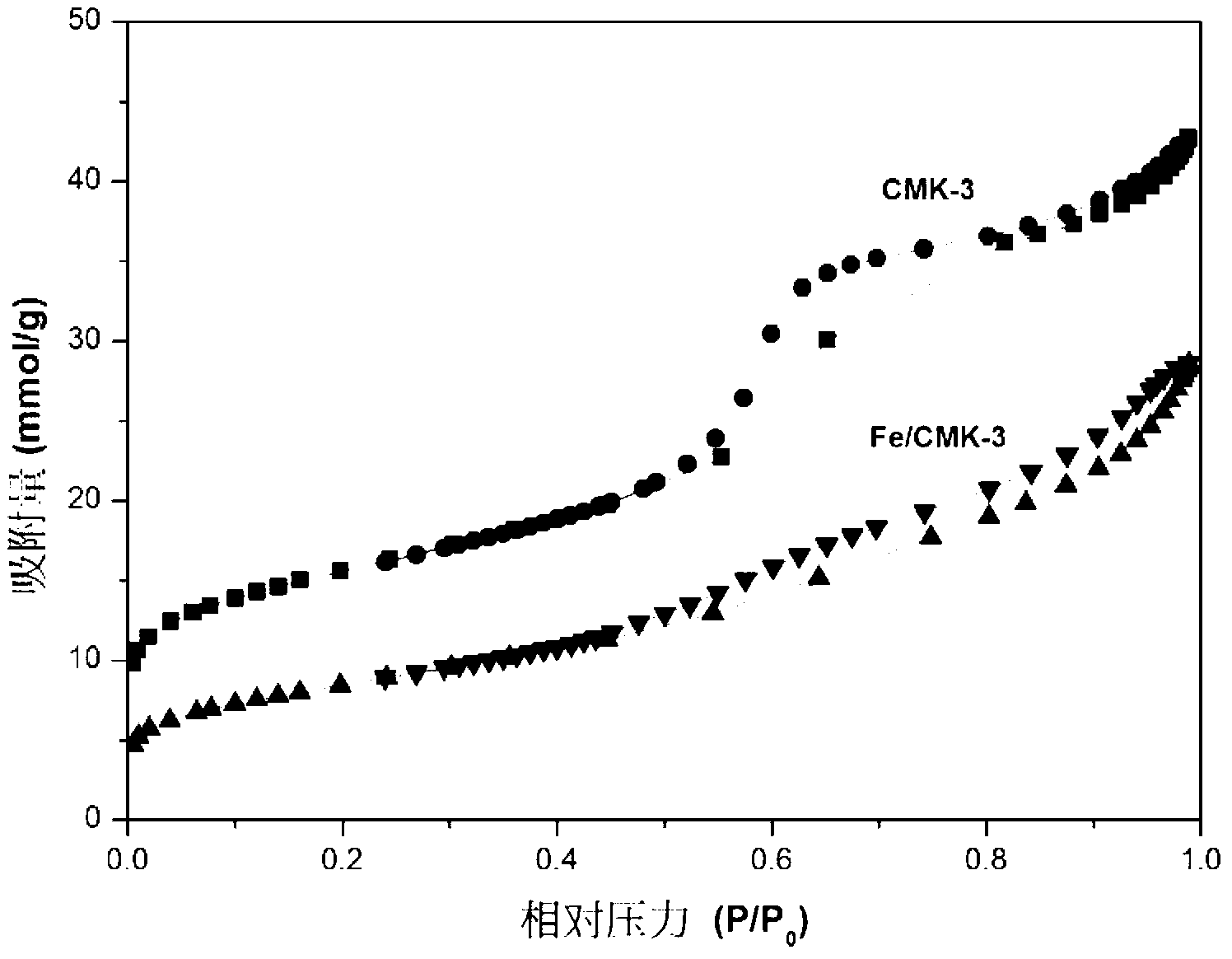

[0036] a kind of like figure 2 The magnetic iron-loaded ordered mesoporous carbon (Fe / CMK-3) of the present invention is shown, which uses ordered mesoporous carbon as a carrier, and the specific surface area of ordered mesoporous carbon is as high as 679.4m 2 / g, magnetic nanoparticles are loaded on the carrier by nano-casting method, and magnetic nano-iron nanoparticles are embedded inside and outside the pores of ordered mesoporous carbon; the magnetic nanoparticles are mainly composed of zero-valent iron and iron oxides, and the iron The oxide contains ferric iron tetroxide and / or γ-ferric oxide, and the amount of iron in the magnetic nanoparticles is based on 1 mmol of iron per gram of mesoporous silicon template raw material in the hard template method. The magnetically loaded iron in this embodiment The pore size distribution of ordered mesoporous carbon is mainly concentrated at about 5nm, and at the same time, a new peak appears at about 3.8nm. The particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com