Preparation method of iron disulfide microspheres

A technology of ferrous disulfide and microspheres, applied in the direction of iron sulfide, etc., to achieve the effects of cheap and easy-to-obtain raw materials, simple equipment, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

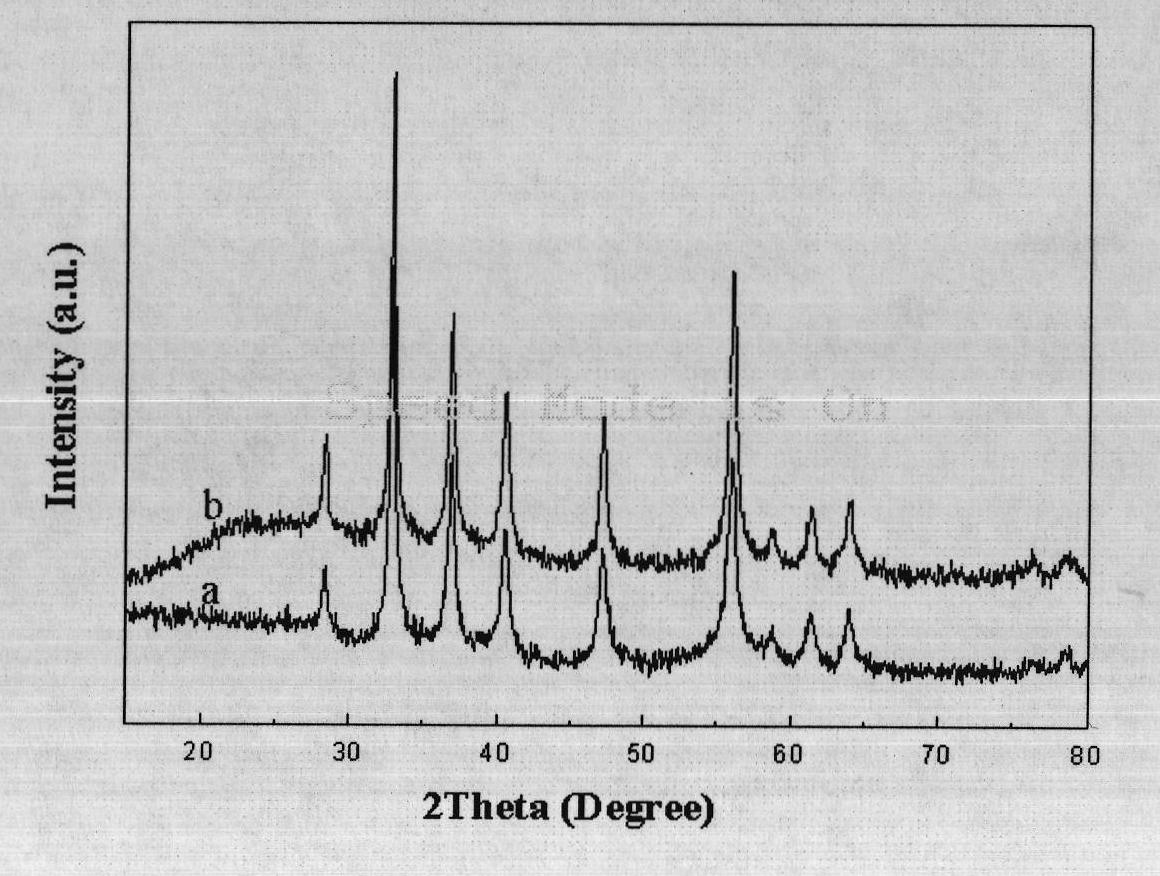

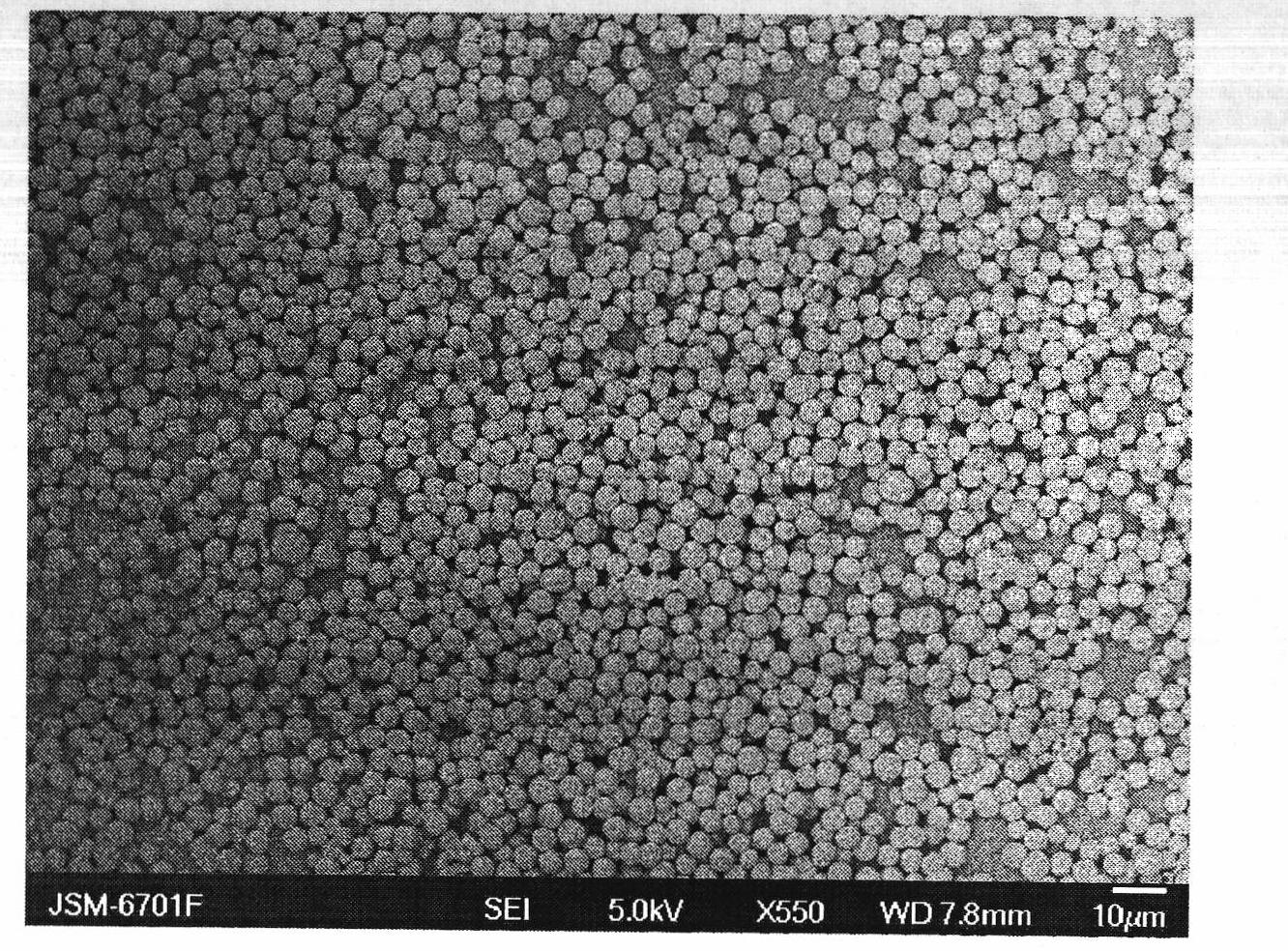

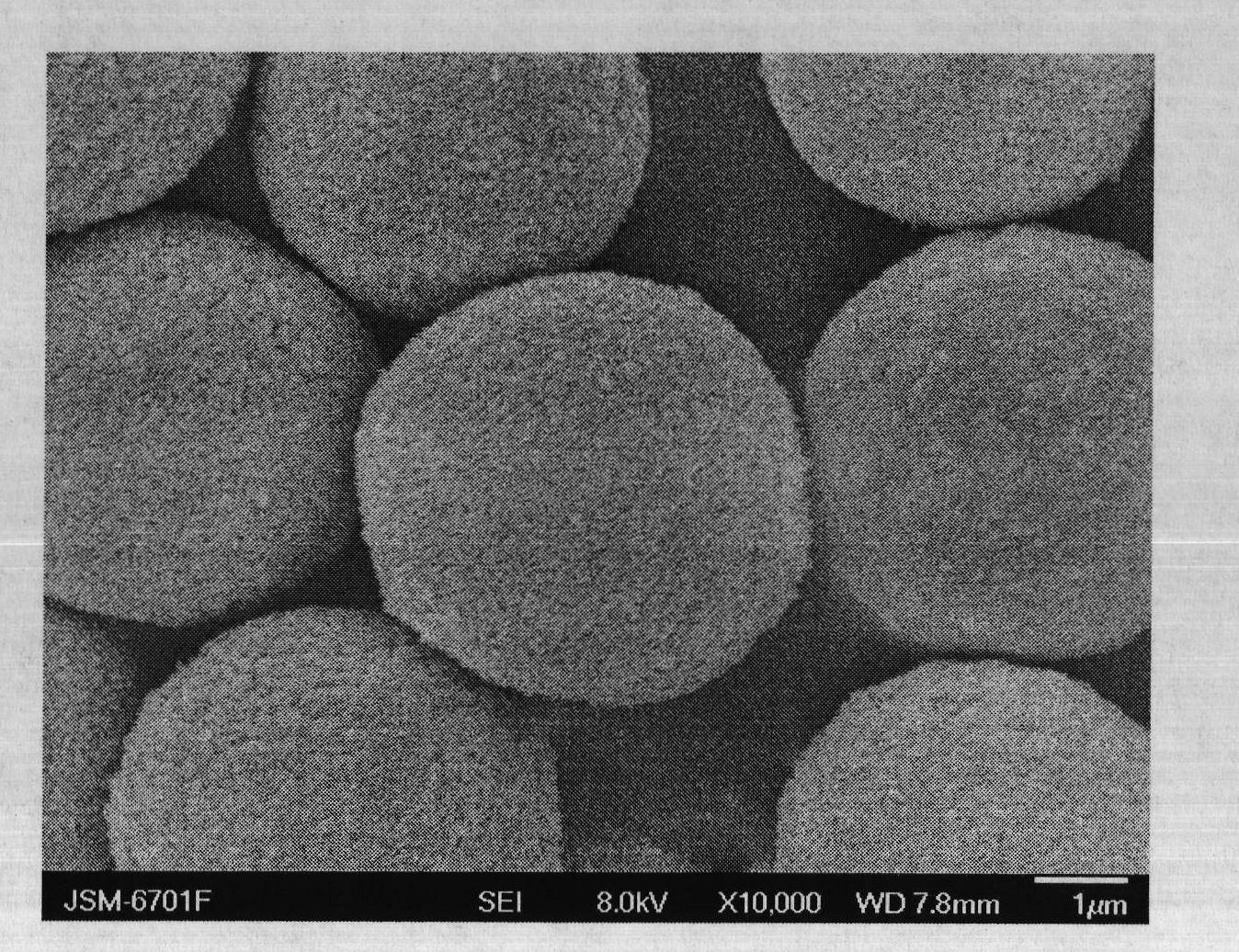

[0016] Take by weighing 1mmol analysis pure ferric trichloride hexahydrate, 0.3g urea joins in the stainless steel pressure-resistant reactor of the polytetrafluoro liner of the mixed solution that 35mL ethylene glycol and nitrogen, nitrogen dimethylformamide are formed in 50 mL), stirred to obtain a clear homogeneous solution. Then react at 160° C. for 12 hours in a closed reactor. Then cool to room temperature, open the reactor, centrifuge the black precipitate at the bottom of the reactor, wash with deionized water, and dry to obtain a black powder. The product is identified as cubic phase by X-ray powder diffraction; characterized by field emission scanning electron microscopy, the product is in the shape of uniformly dispersed microspheres, and the particle size is about 4 microns.

Embodiment 2

[0018] Weigh 1mmol of analytically pure ferric chloride hexahydrate, and add it to a stainless steel pressure-resistant reactor with a polytetrafluoro liner (volume 50mL) that contains 35mL of a mixed solution of ethylene glycol, nitrogen, and nitrogen dimethylformamide. , stirred to obtain a clear homogeneous solution. Then react at 160° C. for 12 hours in a closed reactor. Then cool to room temperature, open the reactor, centrifuge the black precipitate at the bottom of the reactor, wash with deionized water, and dry to obtain a black powder. The product is identified as cubic phase by X-ray powder diffraction; characterized by field emission scanning electron microscopy, the product is in the shape of uniformly dispersed microspheres, and the particle size is about 4 microns.

Embodiment 3

[0020] Weigh 1mmol of analytically pure ferric chloride hexahydrate, and add it to a stainless steel pressure-resistant reactor with a polytetrafluoro liner (volume 50mL) that contains 35mL of a mixed solution of ethylene glycol, nitrogen, and nitrogen dimethylformamide. , stirred to obtain a clear homogeneous solution. Then react at 170° C. for 12 hours in a closed reactor. Then cool to room temperature, open the reactor, centrifuge the black precipitate at the bottom of the reactor, wash with deionized water, and dry to obtain a black powder. The product is identified as cubic phase by X-ray powder diffraction; characterized by field emission scanning electron microscopy, the product is in the shape of uniformly dispersed microspheres, and the particle size is about 4 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com