Preparation method of monodisperse Alpha-iron oxide nanosheet

An iron oxide nano, monodisperse technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor cycle performance, and achieve low cost, excellent cycle performance, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Dissolve 1g of P123 in 30ml of ethylene glycol, and stir at room temperature for 24 hours to form a clear solution; take 0.015mol of ferric nitrate nonahydrate and dissolve it in the above-mentioned P123 ethylene glycol solution;

[0037] 2) Dissolve 0.04mol KOH in 10ml of deionized water at the same time, stir well to form a clear solution;

[0038] 3) Slowly add the above KOH aqueous solution dropwise into the ethylene glycol solution of P123 to form a reddish-brown precursor solution, transfer the precursor solution to a 50ml polytetrafluoroethylene reactor for 200°C, 30h hydrothermal reaction, put The hydrothermal reaction product is filtered, washed, and dried to obtain monodisperse α-iron oxide nanosheets.

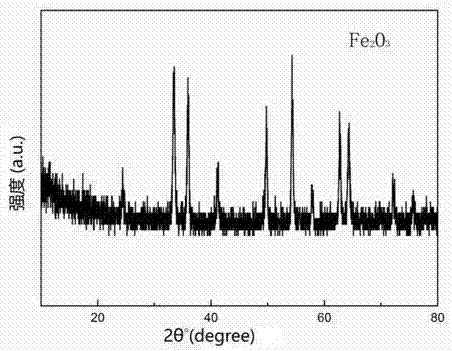

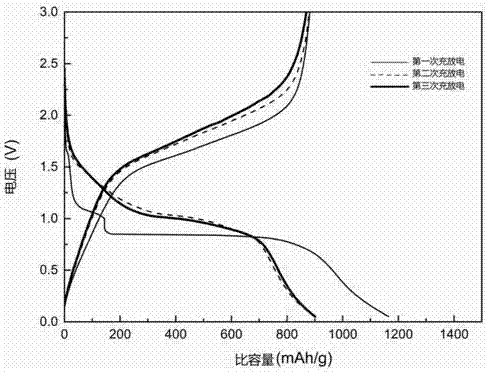

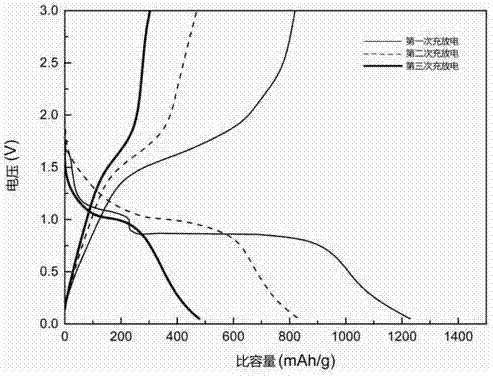

[0039] Carry out XRD characterization to the monodisperse α-iron oxide nanoplate of embodiment 1 gained, as figure 1 As shown, the X-ray diffraction test shows that the product is a pure phase, and there is no heterophase Fe 3 o 4 , confirming that the p...

Embodiment 2

[0042] 1) Dissolve 1g of P123 in 20ml of ethylene glycol, and stir for 20 hours at room temperature to form a clear solution; take 0.02mol of ferric nitrate nonahydrate and dissolve it in P123 ethylene glycol solution;

[0043] 2) Dissolve 0.035mol KOH in 10ml of deionized water at the same time, stir well to form a clear solution;

[0044] 3) Slowly add the above KOH aqueous solution dropwise into the ethylene glycol solution of P123 to form a reddish-brown precursor solution, transfer the precursor solution to a 50ml polytetrafluoroethylene reactor for 200°C, 24h hydrothermal reaction, and water The thermal reaction product is filtered, washed, and dried to obtain monodisperse α-iron oxide nanosheets.

Embodiment 3

[0046] 1) Dissolve 2g of P123 in 25ml of ethylene glycol, and stir for 30 hours at room temperature to form a clear solution; take 0.02mol of ferric nitrate nonahydrate and dissolve it in P123 ethylene glycol solution;

[0047] 2) Dissolve 0.06mol KOH in 10ml of deionized water at the same time, stir well to form a clear solution;

[0048] 3) Slowly add the above KOH aqueous solution dropwise into the ethylene glycol solution of P123 to form a reddish-brown precursor solution, transfer the precursor solution to a 50ml polytetrafluoroethylene reactor for 200°C, 24h hydrothermal reaction, and water The thermal reaction product is filtered, washed, and dried to obtain monodisperse α-iron oxide nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com