Method for preparing titanium dioxide films for dye-sensitized solar battery

A technology of solar cells and titanium dioxide, applied in circuits, capacitors, photovoltaic power generation, etc., can solve the problems of complex process, time-consuming and labor-consuming, thin film formation, etc., and achieve the effect of simple process, easy operation, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

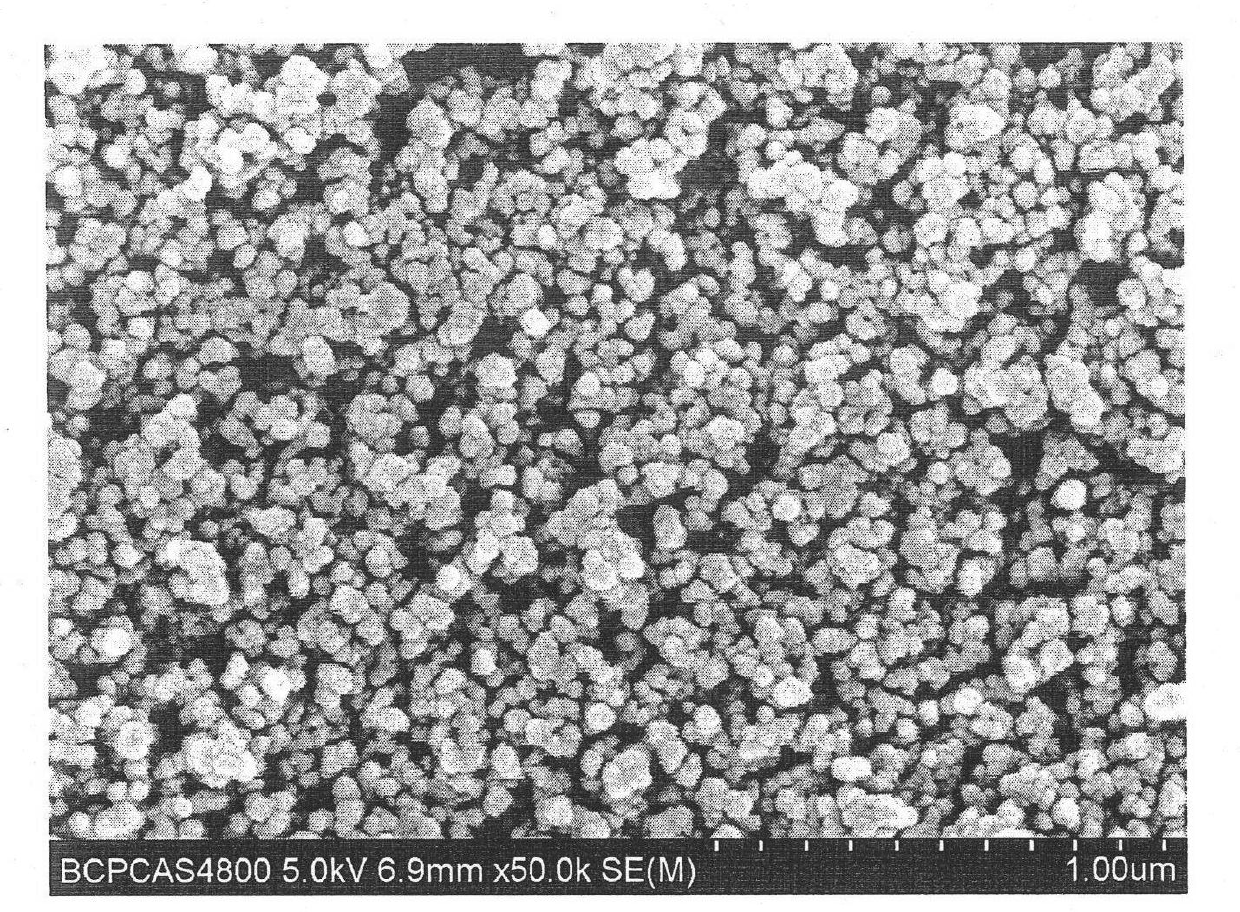

[0032] Heat 12g of ethylene glycol to 60°C, add 2g of isopropyl titanate (Alfa Aesar Company) while stirring, continue to add 10g of citric acid and raise the temperature to 90°C, continue stirring This sol 0.5 hour until it becomes transparent, promptly obtains TiO 2 Sol. As measured by transmission electron microscopy (TEM) (TECNAI-G2, FEI), the TiO 2 Sol TiO 2 The particle size is 5-10nm. 1g of this sol and 6g of titanium dioxide powder (P25 powder, Degussa Company (Degussa Company)) with an average particle diameter of 6g were mixed and ground evenly, and 19g of terpineol (analytical grade, Tianjin Huadong Reagent Factory) and 30g of 10 % by weight ethyl cellulose in ethanol. Continue to grind for 1 hour to get TiO 2 slurry. TiO 2 The slurry was printed on conductive glass (NSG FTO-14, Wuhan Geo Instruments Co., Ltd.) by screen printing, and the effective area of the film was 0.2 cm 2 . After drying the conductive glass at 125°C for 5 minutes, it was placed in a...

Embodiment 2

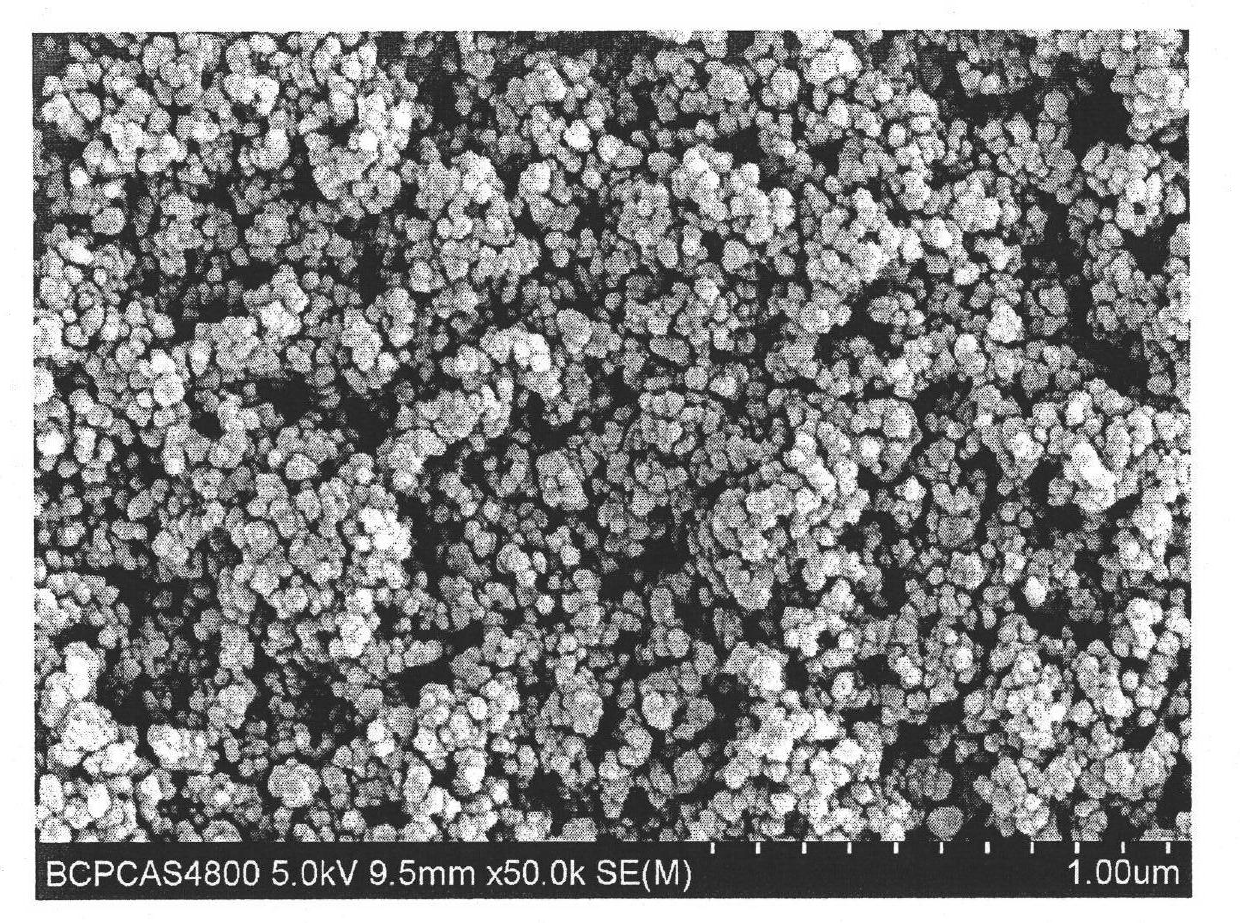

[0036] Heat 12g of ethylene glycol to 60°C, add 2g of isopropyl titanate (Alfa Aesar Company) while stirring, continue to add 10g of citric acid and raise the temperature to 90°C, continue stirring This sol 0.5 hour until it becomes transparent, promptly obtains TiO 2 Sol. As measured by transmission electron microscopy (TEM) (TECNAI-G2, FEI), the TiO 2 Sol TiO 2 The particle size is 5-10nm. 2g of this sol and 6g of titanium dioxide powder (P25 powder, Degussa Company (Degussa Company)) with an average particle diameter of 6g were mixed and ground evenly, and 18g of terpineol (analytical grade, Tianjin Huadong Reagent Factory) and 30g of 10 % by weight ethyl cellulose in ethanol. Continue to grind for 1 hour to get TiO 2 slurry. TiO 2 The slurry was printed on conductive glass (NSG FTO-14, Wuhan Geo Instruments Co., Ltd.) by screen printing, and the effective area of the film was 0.2 cm 2 . After drying the conductive glass at 125°C for 5 minutes, it was placed in a...

Embodiment 3

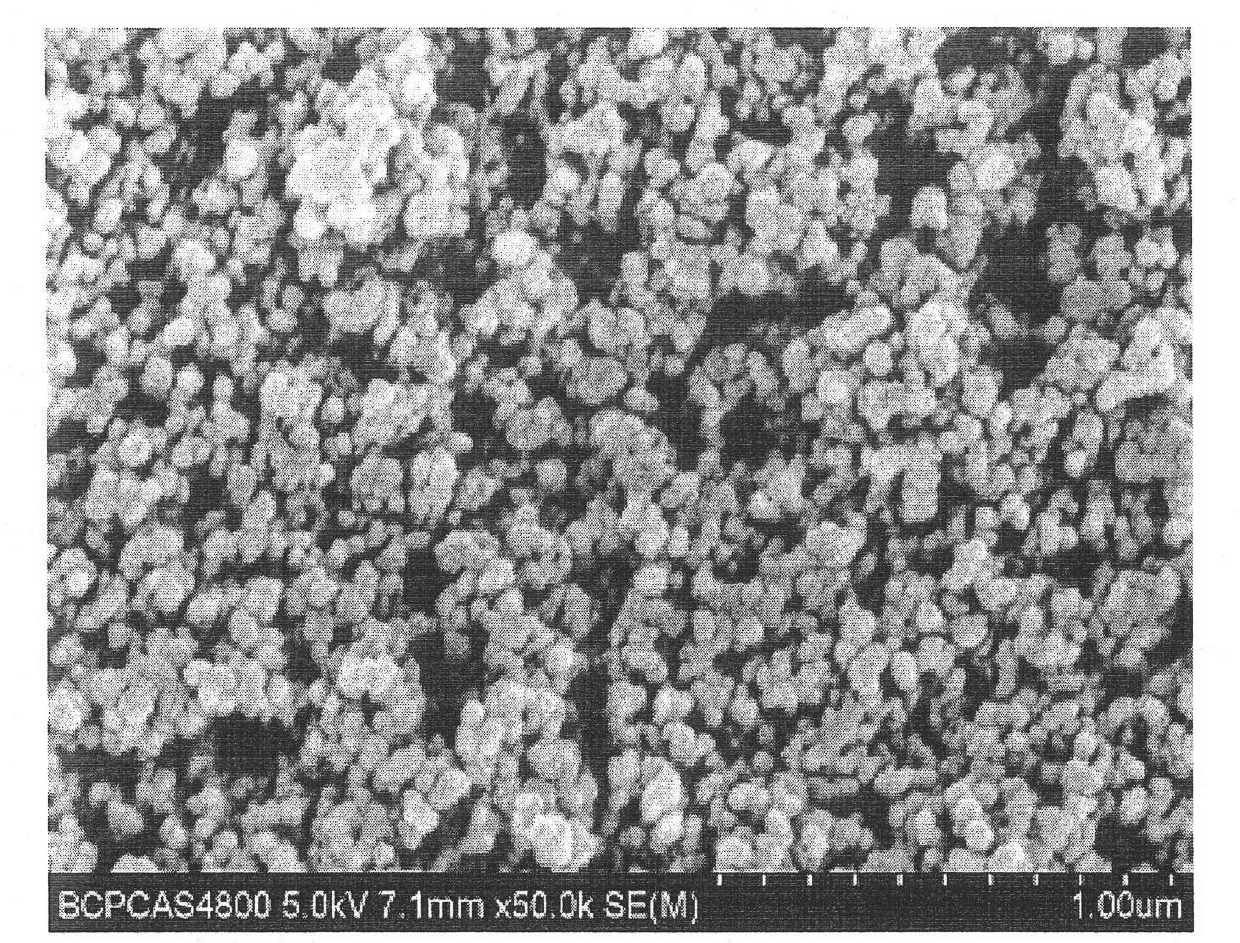

[0039] Heat 12g of ethylene glycol to 60°C, add 2g of isopropyl titanate (Alfa Aesar Company) while stirring, continue to add 10g of citric acid and raise the temperature to 90°C, continue stirring This sol 0.5 hour until it becomes transparent, promptly obtains TiO 2 Sol. As measured by transmission electron microscopy (TEM) (TECNAI-G2, FEI), the TiO 2 Sol TiO 2 The particle size is 5-10nm. 3g of this sol and 6g of titanium dioxide powder (P25 powder, Degussa Company (Degussa Company)) with an average particle size of 6g were mixed and ground evenly, and 17g of terpineol (analytical grade, Tianjin Huadong Reagent Factory) and 30g of 10 % by weight ethyl cellulose in ethanol. Continue to grind for 1 hour to get TiO 2 slurry. TiO 2 The slurry is printed on conductive glass (NSG FTO-14, Wuhan Geo Instruments Co., Ltd.) by screen printing, and the effective area of the film is 0.2cm 2 . After drying the conductive glass at 125°C for 5 minutes, it was placed in a tube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com