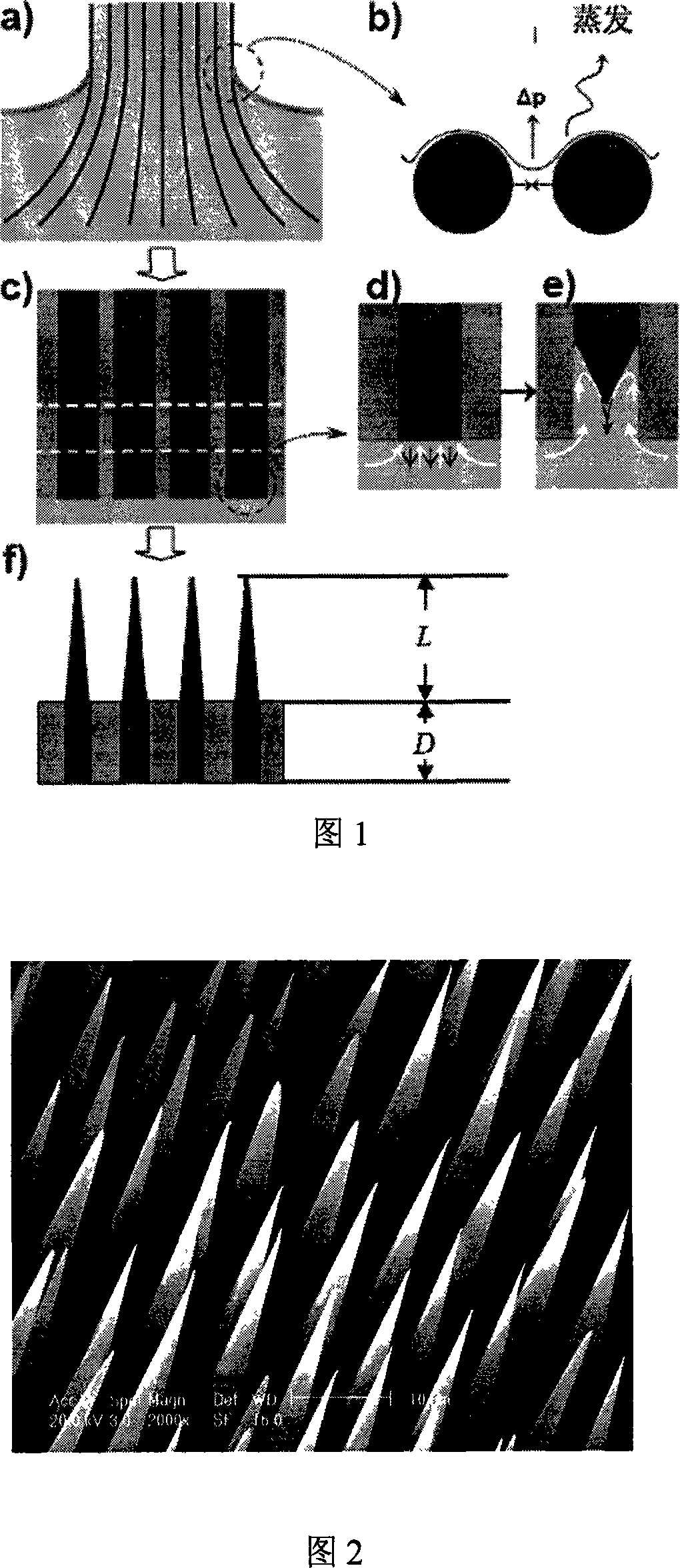

Method for preparing micrometer and submicron probe arrays

A submicron, needle array technology, applied in the field of preparation of nano- and micro-structured materials, can solve problems such as limiting the application field and scope, and achieve the effects of short preparation cycle, simple operation, and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: SiO with a diameter of 8 microns 2 Fiber obtains SiO through self-assembly technology 2 Fiber bundle; then put it into the MMA (polymethyl methacrylate) solution with BPO, place it in a water bath and heat it at 60℃ for 24h to solidify the polymer, SiO 2 The volume ratio of the fiber bundle to the polymer cured product is 0.1; then, it is cut into slices with a thickness of 1 mm, and then corroded with a 40% HF acid solution at a constant temperature of 30°C for 5 minutes, ultrasonically cleaned with deionized water, and dried to obtain a nanoneedle array.

Embodiment 2

[0021] Example 2: SiO with a diameter of 8 microns 2 Fiber obtains SiO through self-assembly technology 2 The fiber bundle; then put it into the styrene solution added with hexamethyleneimine lithium, and heat it in a water bath at 60℃ for 24h to solidify the polymer; SiO 2 The volume ratio of the fiber bundle to the polymer cured product is 0.3; then it is cut into slices with a thickness of 3mm; it is corroded with a 20% HF acid solution at a constant temperature of 30°C for 30 minutes, ultrasonically cleaned with deionized water, and dried to obtain a nanoneedle array;

Embodiment 3

[0022] Example 3: SiO2 fibers with a diameter of 8 microns are obtained by self-assembly technology 2 Fiber bundle; then immerse it in the molten resin at 120℃, and cool the slice after filling, SiO 2 The volume ratio of the fiber bundle to the polymer cured product is 0.6; the slice thickness is 1cm; it is etched with 40% HF acid solution for 10 minutes at a constant temperature of 40°C, and then cleaned with deionized water ultrasonically. After drying, the nanoneedle array can be obtained, as shown in Figure 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com