Ecological transfer printing fabric production system

A transfer printing and production system technology, applied in transfer printing, rotary printing machine, printing, etc., can solve the problems of affecting the transfer printing effect of fabrics, full contamination of fabrics, and incomplete transfer of transfer film groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

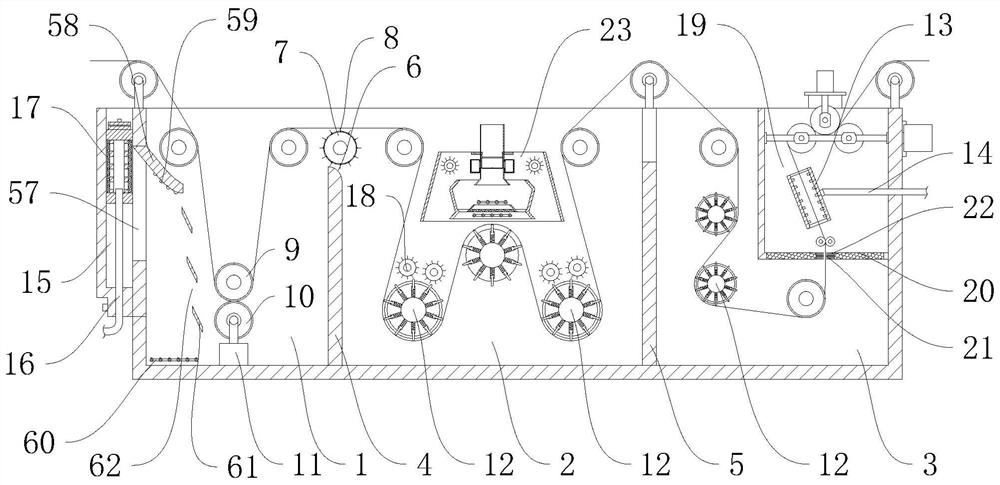

[0027] This embodiment discloses an ecological transfer printing fabric production system, refer to figure 1 As shown, it includes a transfer film printing system, a fabric pretreatment system and a fabric transfer system, which respectively realize the steps of transfer film printing, fabric pretreatment and fabric transfer in the transfer process.

[0028] The interior of the treatment tank is separated from treatment tank 1, treatment tank 2, and treatment tank 3 by partition plate 1 4 and partition plate 2 5. The three treatment tanks are arranged in sequence, and treatment tank 2 is located in treatment tank 1 and treatment tank. Between 3 and 3, an arc-shaped water blocking surface 6 is formed on the upper end of the partition plate 1 4, which gradually rises in the direction of the treatment tank 1 1, and the upper end of the partition plate 2 5 is higher than the upper edge of the arc-shaped water blocking surface 6; Treatment tank two 2 and treatment tank one 1 form a...

Embodiment 2

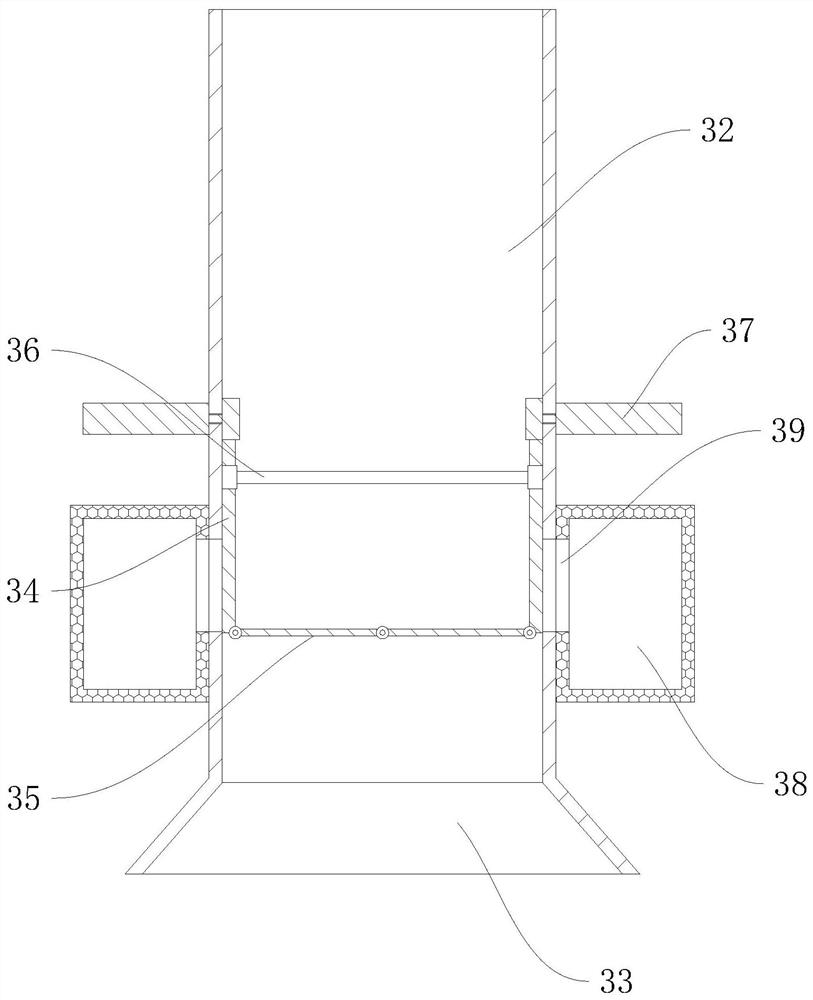

[0046] This embodiment discloses an ecological transfer printing fabric production system. On the basis of Embodiment 1, refer to figure 1 , 5 , 6 to explain in detail, to further optimize the carding and water control in the pre-treatment process of S2 fabrics;

[0047] A water control device is arranged in the liquid inlet tank 19, and the water control device can squeeze the passing fabric to control the water. The water control device specifically includes two water control rollers 1 54 and one water control roller 2 55. 19. The screw 51 is installed in the middle, and the screw 51 is threadedly connected with two sliding seats 53, and the sliding seats 53 are rotatably connected with a water control roller 1 54. During the rotation of the screw 51, the first water control roller 54 can form relative or opposite movement; Contrasted all around.

[0048] The screw 51 is driven by the motor 52 to rotate, thereby driving the two water control rollers 54 on the slide 53 to ...

Embodiment 3

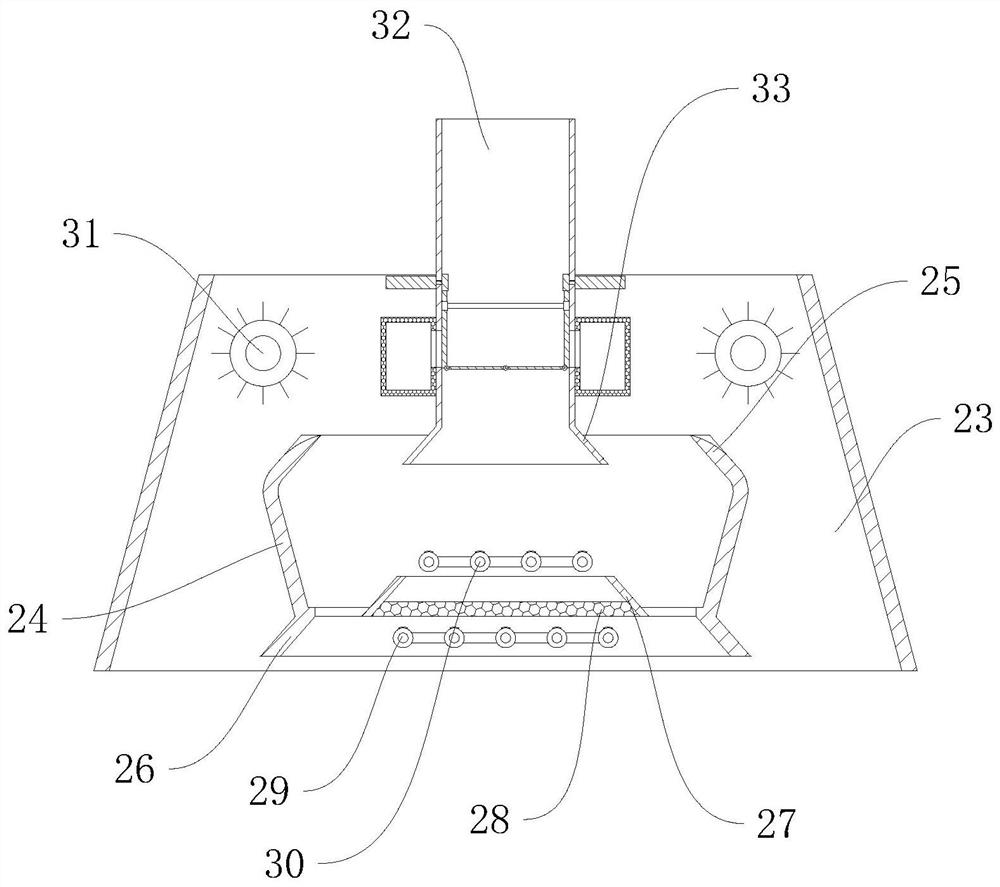

[0053] This embodiment discloses an ecological transfer printing fabric production system. On the basis of the second embodiment, and referring to figure 1 and Figure 4Detailed description; in the pretreatment system, the liquid outlet structure of the liquid outlet tank 1515 is optimized, so as to keep the processing liquid relatively clean and improve the overall transfer quality.

[0054] The liquid outlet tank 15 is communicated with the liquid supply device through the liquid outlet pipe 16, and the section of the liquid outlet pipe 16 extending into the liquid outlet tank 15 is a rigid pipe, forming an upwardly extending columnar structure. The bottom extends upward, and its upper end is lower than the height of the partition plate 1 4, and is located at an upper position in the middle relative to the treatment tank 1 1, so that the liquid at the liquid level above the part can be returned.

[0055] Since the flocs form a suspended structure, and a bubbling pipeline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com