Polaroid, display module and processing method of polaroid

A processing method and polarizer technology, applied in the field of polarizers, can solve the problems of polarizer wrinkles, uneven distribution, and different areas, and achieve the effect of smooth appearance, easy access, and stable optical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

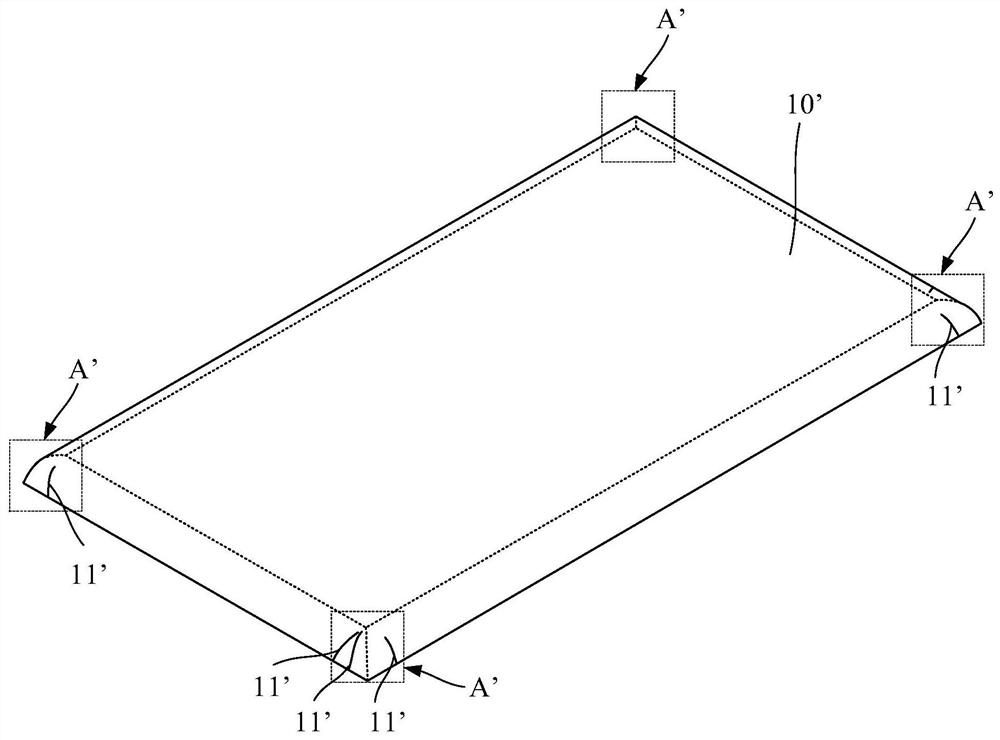

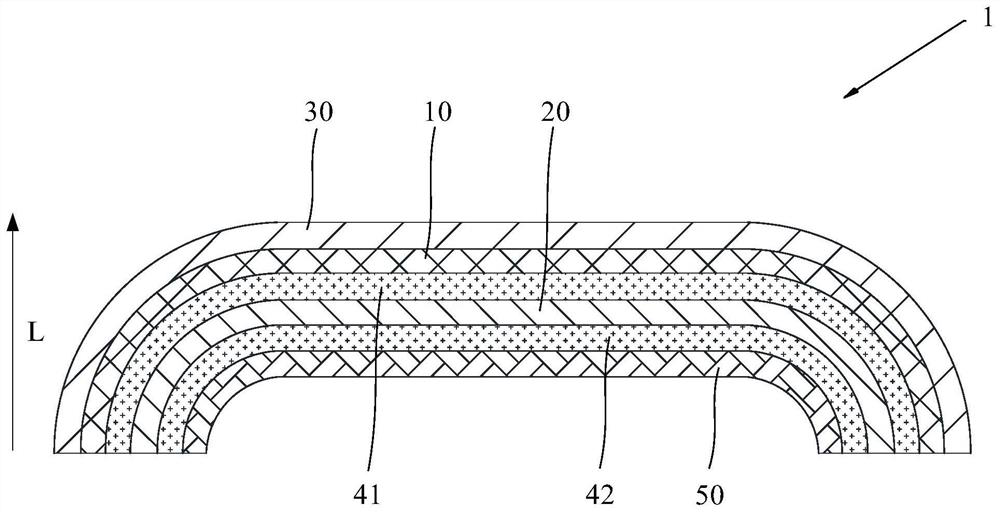

[0034] Such as figure 2 As shown, this embodiment provides a polarizer 10 . The polarizer 10 is made of a stretchable material, and is shaped into a curved shape through a hot pressing process. Wherein, the curved shape includes dihedral curved shape, tetrahedral curved shape, spherical shape and any three-dimensional curved surface shape. The polarizer 10 is a stretchable material, that is, the polarizer 10 has stretchability and shrinkability.

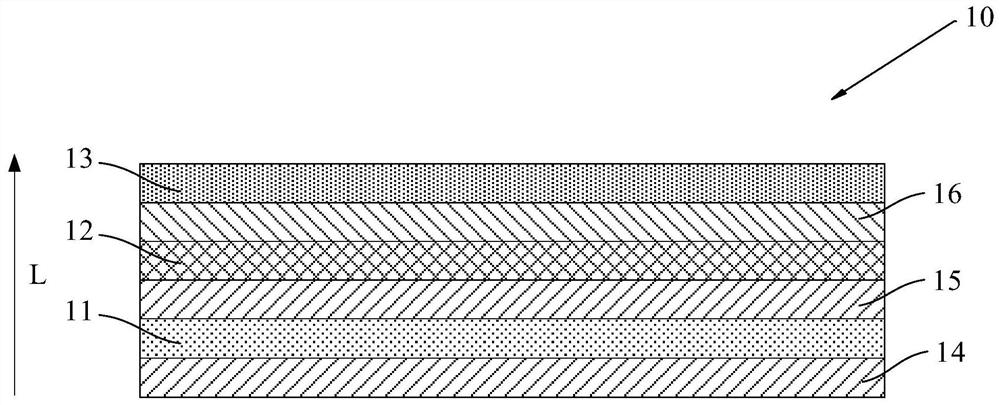

[0035] The polarizer 10 includes a phase difference film layer 11 , a polarizing function layer 12 and a protective layer 13 stacked in sequence along the light emitting direction L.

[0036] The protective layer 13 is used to protect the polarizing functional layer 12 . The protective layer 13 is made of stretchable material. The protective layer 13 is a stretchable material, that is, the protective layer 13 has stretchability and shrinkability. Preferably, the modulus of the protective layer 13 is between 5 MPa and 7000 MPa; ...

Embodiment 2

[0060] Such as Figure 7 As shown, the overall structure of the polarizer 10 of this embodiment is the same as that of the polarizer in Example 1, the difference is that the material of the polarizing functional layer 12 is different from that of Example 1, so The materials of the polarizing functional layer 12 include liquid crystal materials and dichroic dyes. Wherein, the content of the dichroic dye in the polarizing function layer 12 is subject to the realization of its polarizing function, which is not further limited here. Its working principle is: through light-driven alignment, the liquid crystal material has a fixed orientation, and at the same time, the dichroic dyes in the liquid crystal material have the same orientation arrangement to obtain the function of line deviation.

[0061] The polarizing functional layer 12 is formed through a coating process. By means of coating, the polarizing functional layer 12 is lighter and thinner, has better temperature and humi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com