Film coating method of filling material in biological contact oxidation pond

A film-hanging method and biological contact technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as complex operation, poor microbial growth, and low impact load resistance, and achieve The effect of increasing the microbial biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The test uses a biological contact oxidation tank with a volume of 13 liters to treat domestic wastewater. The filler is a suspended semi-soft spherical plastic filler. The temperature of the test environment is 26°C, the pH of the wastewater is 6.8, and the sludge is taken from the secondary sedimentation tank of a domestic sewage plant. The return sludge in the SV after acclimatization 30 =30%, the mass density is 7000mg / L.

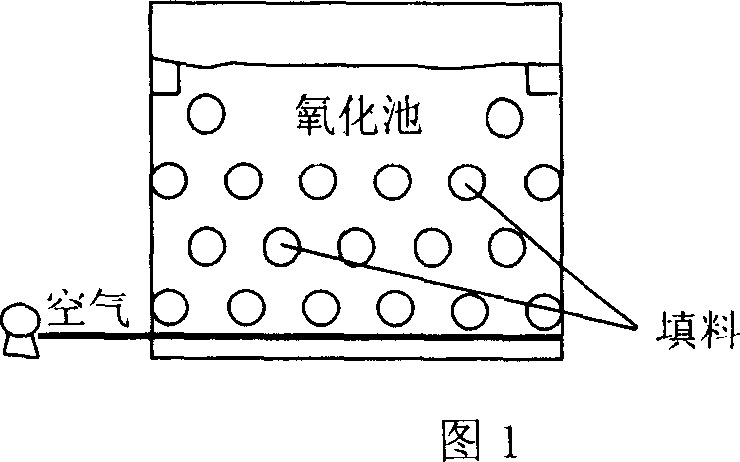

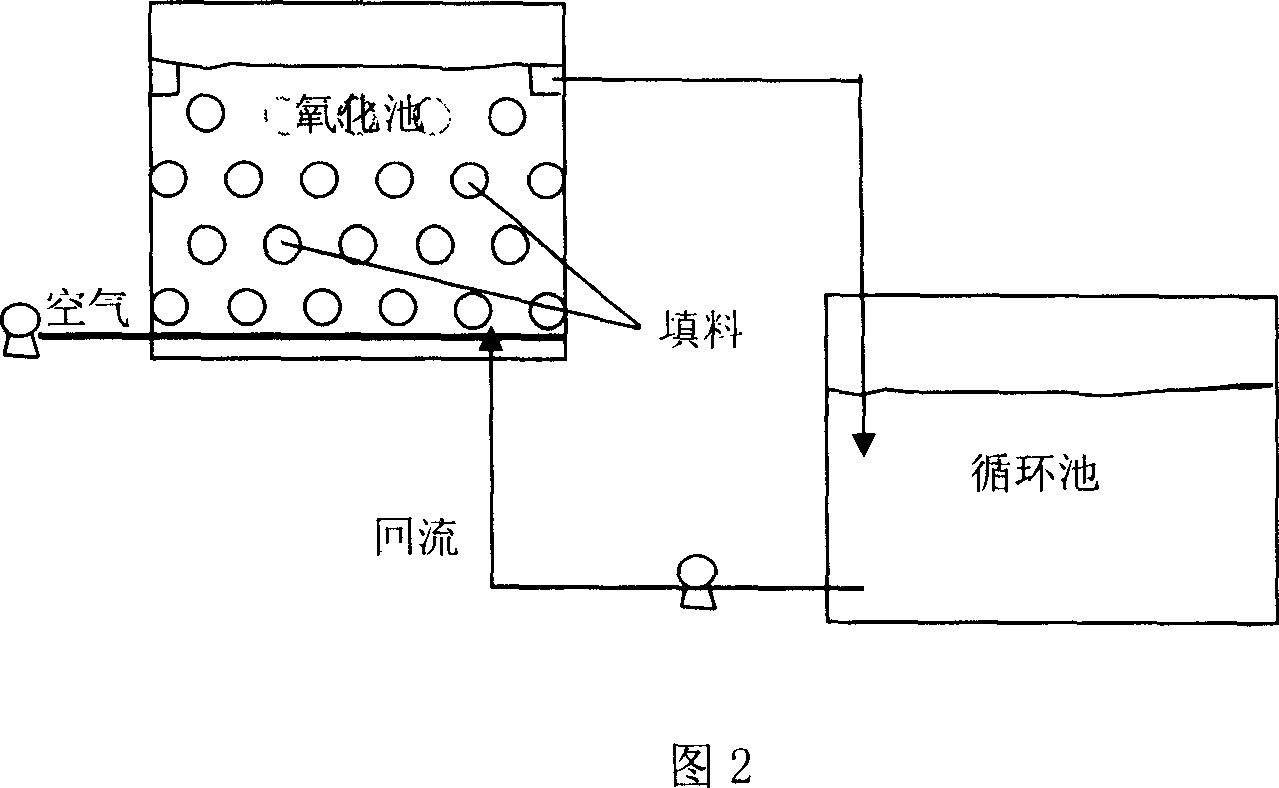

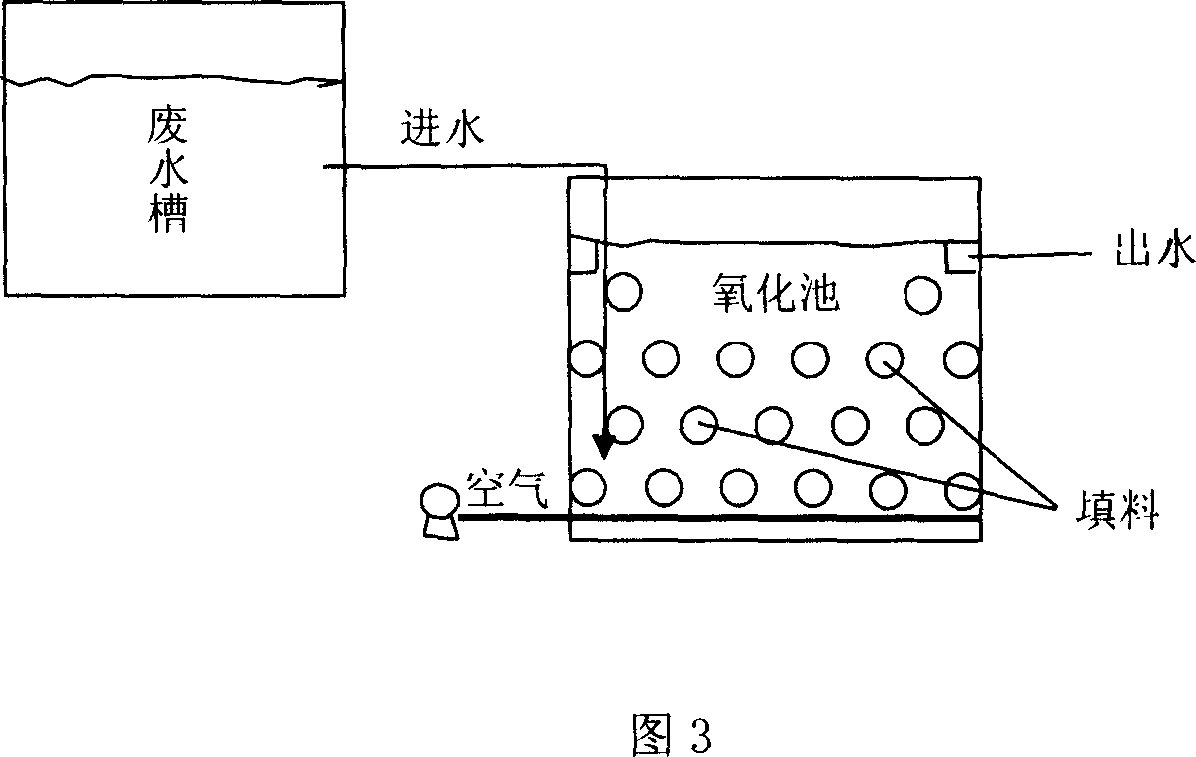

[0027] Mix the cultivated sludge with domestic waste water at a volume ratio of 1:3, and add 300ml of nutrients according to the ratio of C:N:P=100:5:1 (see Table 1 below for the formula of the nutrient solution), and then mix the mixture Inject into the oxidation tank to fully submerge the filler, pour the rest into the circulation tank, control DO=1.0mg / L in the oxidation tank at room temperature, and aerate for 6 hours as shown in Figure 1. Then connect the oxidation tank to the circulation tank, keep the aeration rate unchanged, and after 24...

Embodiment 2

[0031] The industrial waste water from the anaerobic tank of a certain coking plant is used as test water, and the test operating conditions and steps are the same as in Example 1.

[0032] Four days after entering the water, the COD removal rate of the wastewater is ≥60%, and the NH 3 -N removal rate ≥ 50%, good microscopic growth of microorganisms. One week later, it was found that there were filamentous bacteria growing on the edge of the filler, and there were many protozoa and metazoans such as paramecia, rotifers, nematodes, bell worms and so on. The biofilm close to the center of the filler was observed through a microscope and found to have more cocci, bacilli, bacterial gelatinous groups and a large number of bell worms. All the indicators prove that the biofilm obtained by this method is stable and has good wastewater treatment capacity.

Embodiment 3

[0034] The test adopts a biological contact oxidation tank with a volume of 24 liters to treat domestic wastewater, and the test operating conditions and steps are the same as in Example 1.

[0035] Three days after entering the water, the film was successfully formed, and the COD removal rate of the wastewater reached 80%, and the NH 3 -N removal rate ≥ 70%, microscopic examination of the biological phase on the surface of the filter material, found that the sticky sludge on it is mainly protozoa or metazoans such as bellworms, rotifers, paramecium, and cladidae, etc., indicating that the filter material The growth of biofilm on the surface has been relatively perfect. And in the later stage of the test, the amount of water inflow was increased (HRT was reduced from the initial 12h to 4h), and the degree of erosion of the biofilm on the filler by the water flow was increased. Tests have shown that waste water has no effect on COD, NH 3 The removal rate of -N did not change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com