Sewage treatment device and method for synchronously recycling water and electric energy

A sewage treatment device and sewage treatment technology, applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc., can solve complex, pollutant enrichment treatment and other problems, and achieve treatment economy, energy Take advantage of the full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

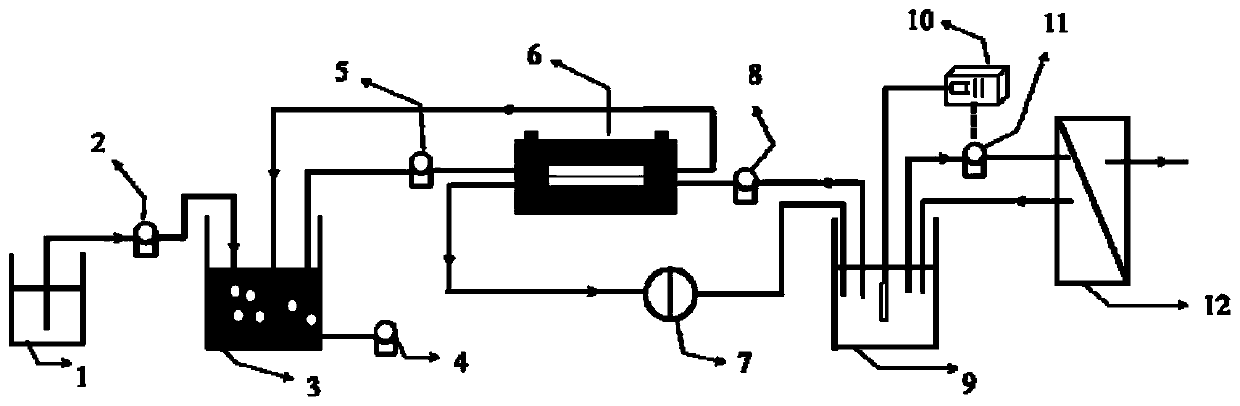

[0036] combine figure 1, specifically introduce a sewage treatment device for synchronously recovering water and electric energy of the present invention. The device of the present invention includes a water inlet tank 1, a bioreactor 3, a FO membrane module 6, a turbine 7, a draw liquid pool 9 and a draw liquid recovery system . The water inlet tank 1 is connected with the bioreactor 3 through a peristaltic pump 2, and the FO membrane assembly 6 includes a draw liquid channel, a feed liquid channel, a gasket and an FO membrane, and the gasket and the FO membrane are placed in parallel and the two connect the draw liquid channel and the feed liquid. The feed liquid channel is separated, the inlet of the feed liquid channel and the outlet of the feed liquid channel are connected to the bioreactor 3, the draw liquid pool 9 is connected to the inlet of the draw liquid channel through the high pressure pump 8, and the outlet of the draw liquid channel is passed through the turbine...

Embodiment 2

[0041] use figure 1 The shown unit treats municipal sewage.

[0042] In view of the structure of FO (one layer is an active layer for interception, and one layer is a support layer for support. The active layer is relatively thin and dense, and has strong anti-pollution ability, while the support layer is thick and porous, which is easy to produce Membrane fouling), and in the present invention, the FO membrane faces the activated sludge containing various pollutants. In order to slow down the FO membrane fouling, the OMBR of the present embodiment adopts AL-FS orientation (active layer faces the feed liquid) during operation.

[0043] The influent is urban sewage, water quality: COD: 350±12.2mg / L, NH 4 + -N: 24.88±1.50 mg / L, TN: 38.24±1.68 mg / L, TP: 2.08±0.13 mg / L. Activated sludge with SS (suspended solids) of 3g / L in the bioreactor, the draw liquid is 2M NaCl, the pressure applied on the draw liquid side is 6bar, and the membrane orientation is AL-FS (active layer faces ...

Embodiment 3

[0047] In order to further increase the average electricity generation power, the inventors tried to use an unconventional FO membrane orientation, ie, AL-DS (active layer oriented to the draw solution), for experiments.

[0048] In the method of this embodiment, the influent is urban sewage, water quality: COD: 350±12.2mg / L, NH 4 + -N: 24.88±1.50 mg / L, TN: 38.24±1.68 mg / L, TP: 2.08±0.13 mg / L. In the bioreactor, the SS is 3g / L activated sludge, the draw liquid is 2M NaCl, the pressure applied on the draw liquid side is 6bar, and the membrane orientation is AL-DS (the active layer faces the draw liquid), and it runs for 4h.

[0049] Effluent water quality: COD: 10±1.51mg / L, NH 4 + -N: 5.12±0.90 mg / L, TN: 5.53±1.21 mg / L, TP: 0. The average water flux is 12.19LML, and the average electricity generation power density is 2.2W / m 2 .

[0050] It can be found that when the active layer faces the draw liquid (the membrane faces AL-DS), the average water flux under the same condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com