Centrifugal cooling water pump

A cooling water pump and centrifugal technology, applied in the hydraulic field, can solve the problems of complex and repetitive structure of a dual-pump dual-circulation cooling system, complex implementation of a single-pump dual-circulation cooling system, and high fuel consumption of an internal combustion engine, so as to improve heat transfer efficiency and improve temperature balance. capacity, the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

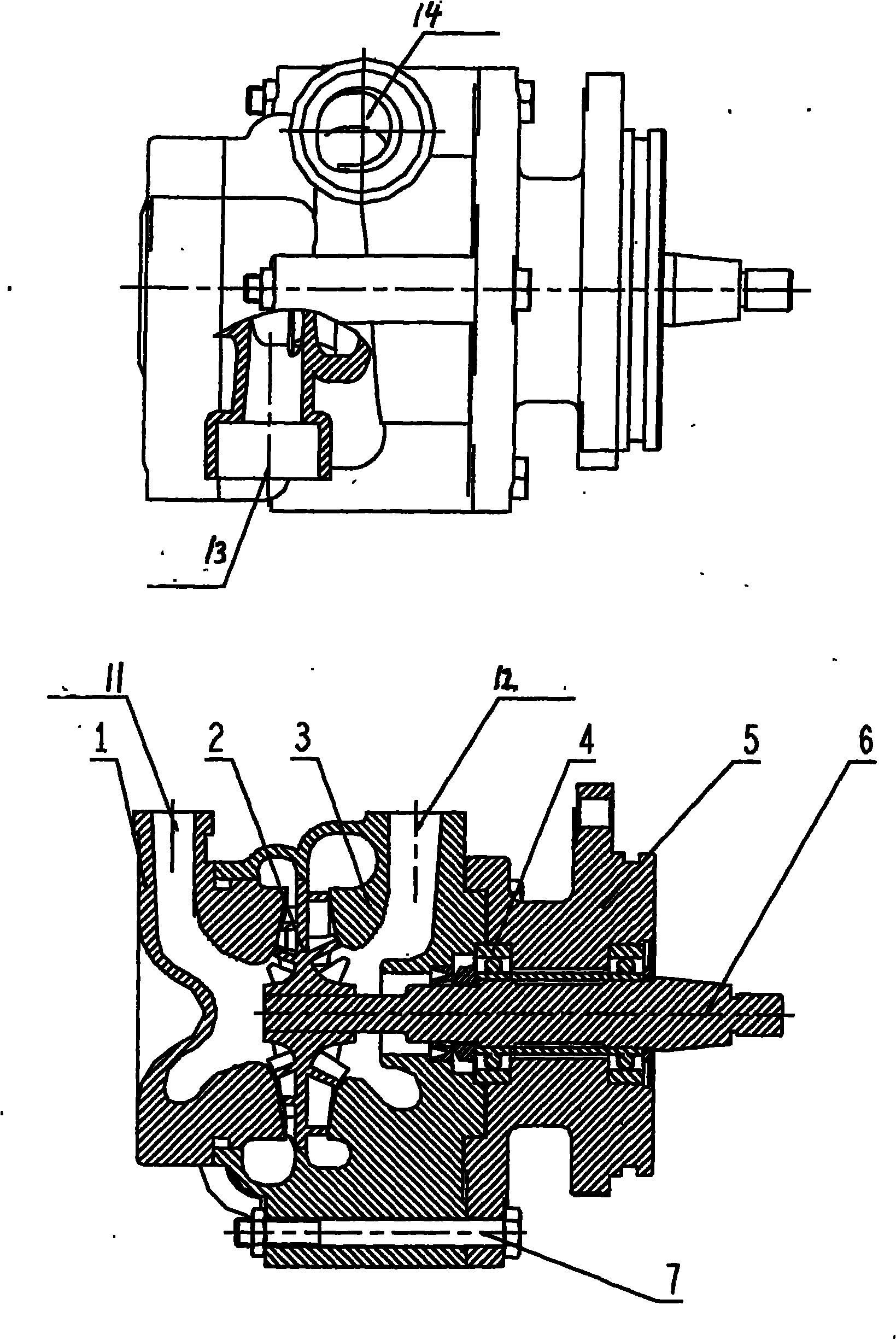

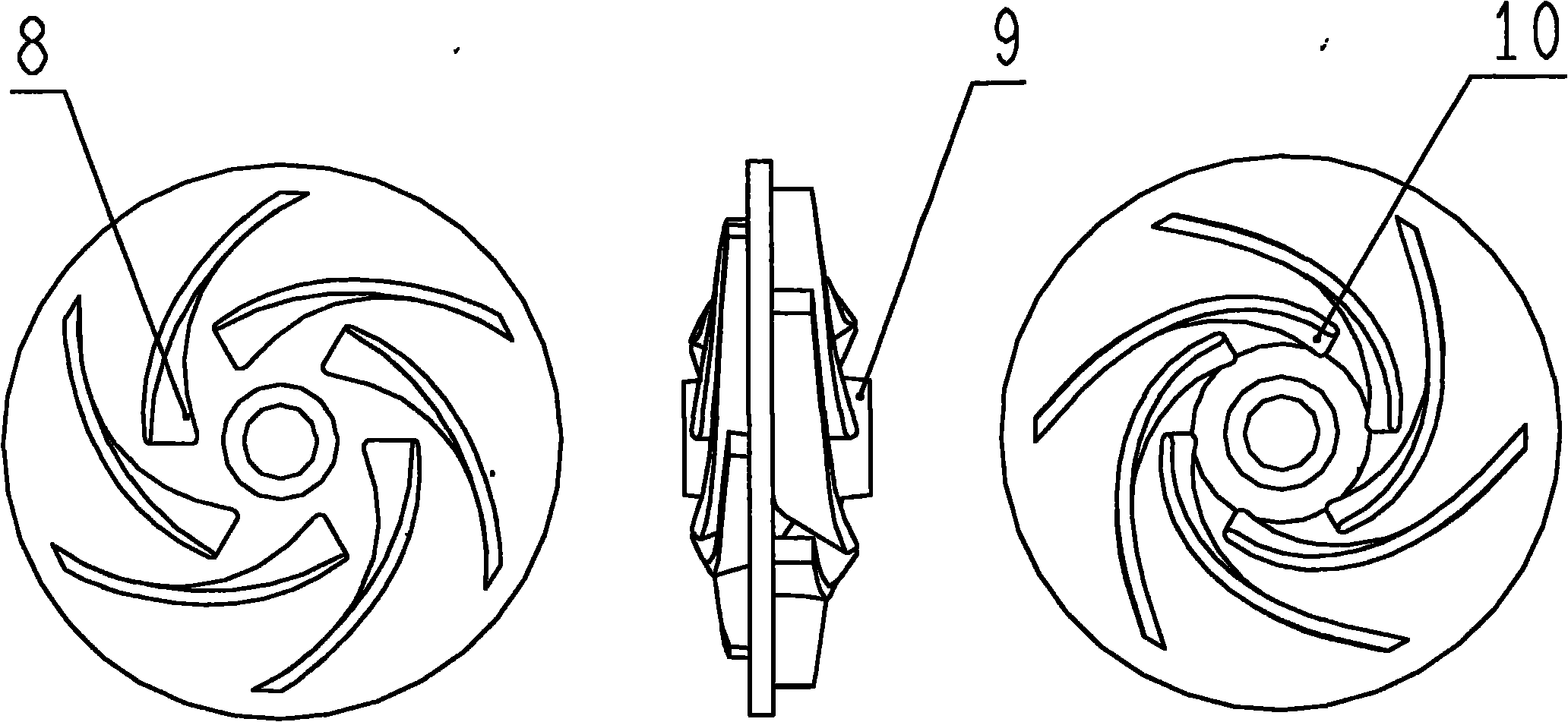

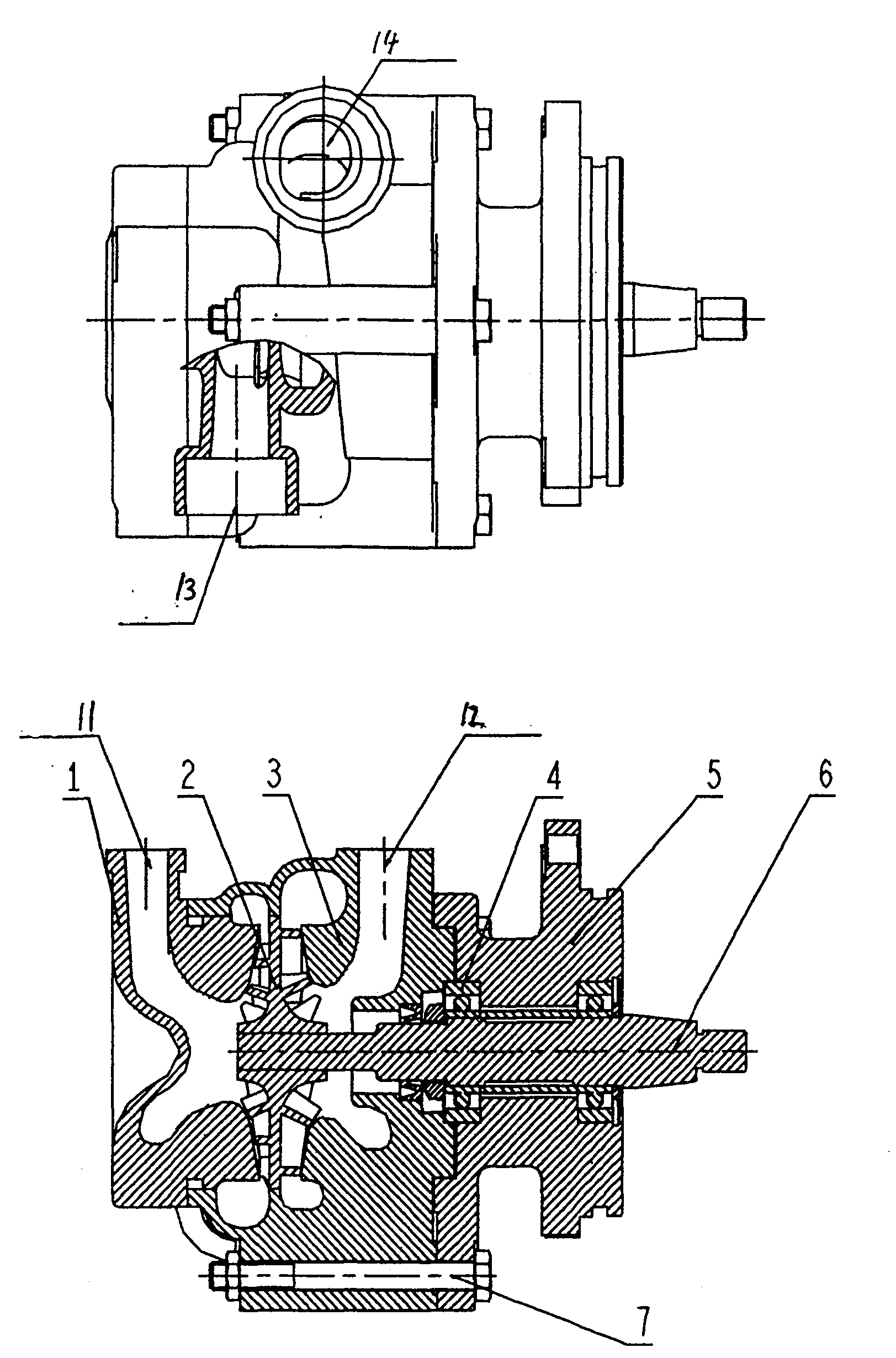

[0010] A centrifugal cooling water pump, comprising a water inlet plate 1, an impeller 2, a volute 3, a bearing 4, a bearing seat 5, a transmission shaft 6, a fastener 7, a high temperature impeller 8, a hub 9, a low temperature impeller 10, and a water inlet 11 , water inlet 12, water outlet 13, water outlet 14; water inlet 11 is provided on the water inlet plate 1, water inlet 12 is provided on the volute 3, and the volute 3 is connected to the water inlet plate 1 and the bearing seat through the fastener 7 5 connection, interference connection bearing 4 on bearing seat 5, interference connection between bearing 4 and inner ring of transmission shaft 6, transmission shaft 6 interference connection with impeller 2, water pump radially provided with water outlet 13 and water outlet 14, impeller 2 One side is provided with a high temperature impeller 8, the other side of the impeller 2 is provided with a low temperature impeller 10, and the impeller 2 is axially provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com