A pressure uniformity detection device and detection method for reverse-wrapped capsules

A detection device and uniformity technology, which is applied in the field of tire molding, can solve the problems of tire carcass cord fabric not being evenly turned up, uneven shape, tire scrapping, etc., to achieve true and effective test results, reduce curing time, and high heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0059] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0060] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

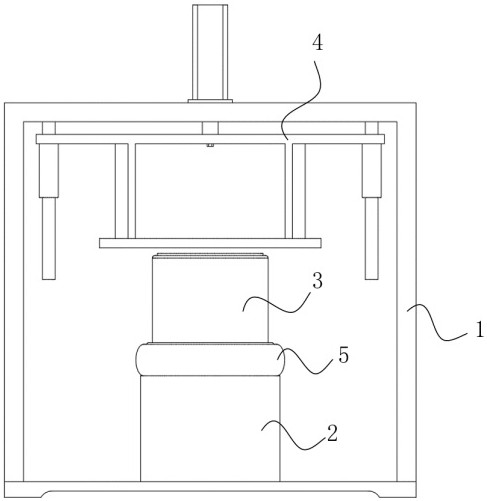

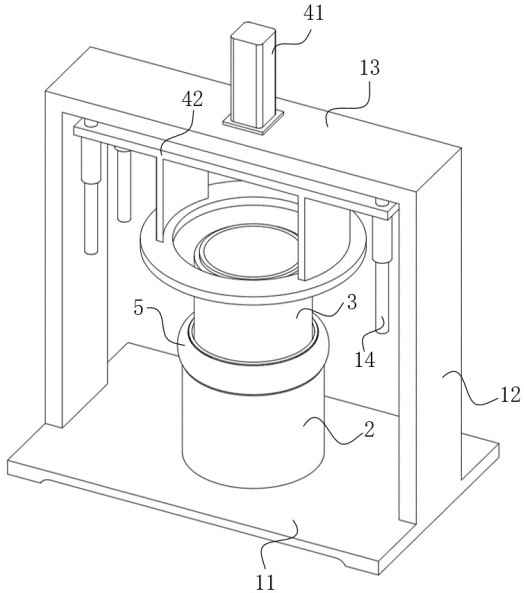

[0062] This embodiment provides a reverse-wrapped capsule pressure detection device, such as Figure 1 to Figure 14 As shown, the pressure uniformity detection device for the reversed capsule includes a frame 1 , a support cylinder 2 , a fixed component 3 for the reversed capsule, a pressure detection component 5 and a control unit 6 .

[0063] The support cylinder 2 is used to install the pressure detection assembly 5 and the fixed turn-up capsule fixing assembly 3. The turn-up capsule fixing assembly 3 is used to install the tested turn-up capsule. The compression degree of the body cord is displayed by the pressure value, and the control part 6 is used to control the action of the pressing plate assembly 4 and the pressure detection assembly 5, and detect the pressure on the pressure assembly, and display the detection result.

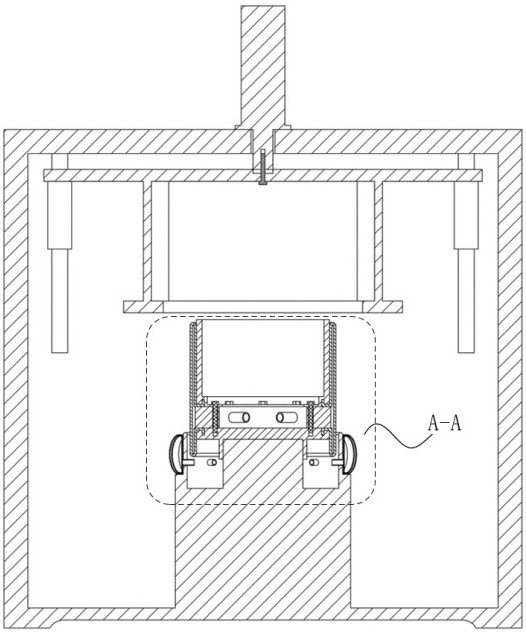

[0064] The pressure detection assembly 5 includes an outer large air bag 51 and a plurality of small air bags 52 arranged in the large air bag 51. ...

Embodiment 2

[0073] In addition to the content of the previous embodiment, this embodiment also provides a pressure uniformity detection device for an inflated turn-up capsule, such as Figure 15 As shown, the pressing plate assembly 4 is used to simulate the pushing effect of the finger plate on the molding machine on the turning-up capsule when the turning-up capsule is working. The pressing plate assembly 4 includes a cylinder 41 and a pressing plate 42. The pressing plate 42 includes a horizontal plate 421, a sleeve 422, The vertical plate 424 and the pressure ring 423, the cylinder 41 is installed above the beam 13, and its telescopic column passes through the beam 13 to connect with the pressure plate 42 below, the four corners of the horizontal plate 421 are provided with mounting holes, the bottom of the mounting hole is connected with the sleeve 422, and the pressure plate 42 is installed on the guide rod 14 through the sleeve 422 and can move up and down. The center of the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com