Coal synthesis gas slurry bed reactor for producing oxygenated fuel

A reactor and synthesis gas technology, applied in the direction of liquid carbon-containing fuels, fuels, chemical instruments and methods, etc., can solve problems such as countercurrent, affecting quality and heat transfer, unfavorable reaction speed, catalyst life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

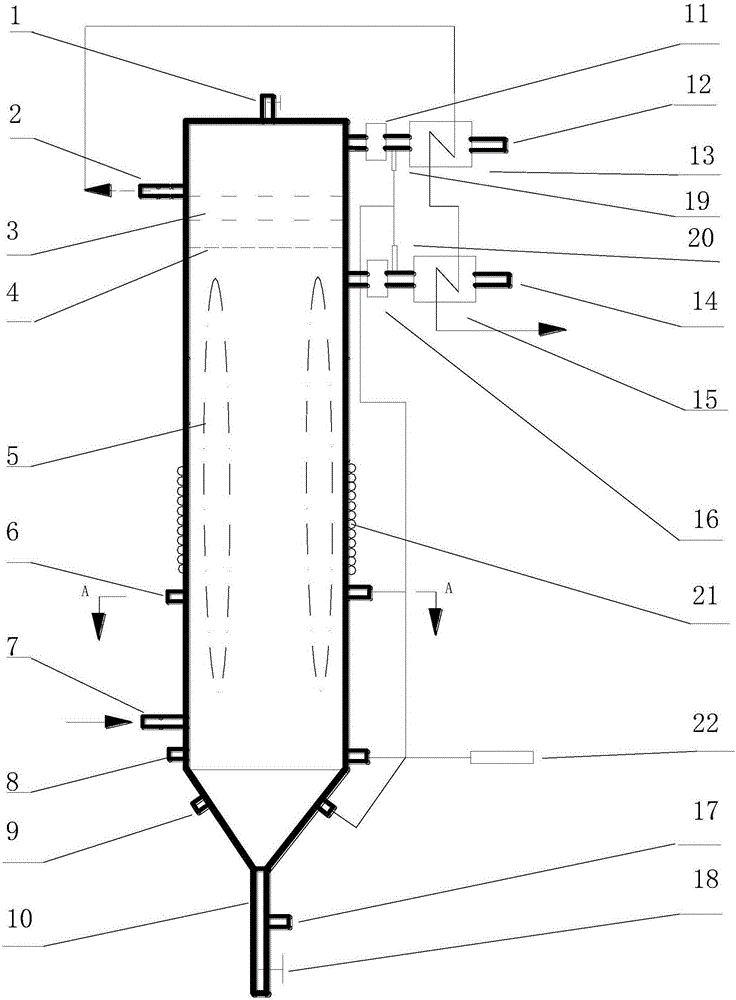

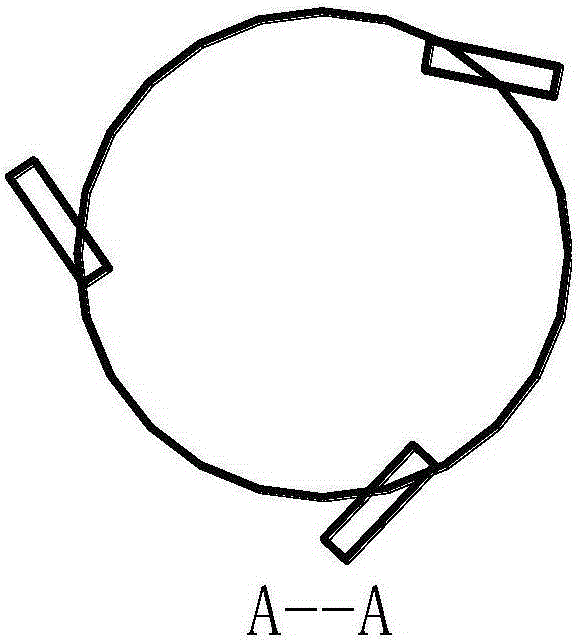

[0033] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

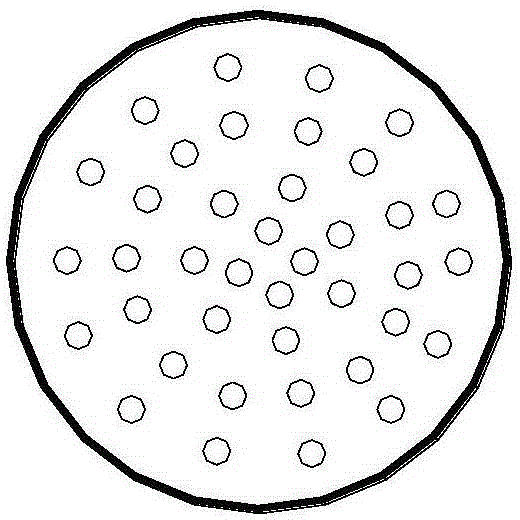

[0034] Implementation of the present invention provides a coal synthesis gas slurry bed oxygenated fuel reactor, which includes a pressure relief safety outlet 1, a multi-layer grate type gas-liquid separator 3, a working medium discharge pipe 10, and a gas phase product Gas-solid filter 11, gas-phase product outlet, gas-phase product liquid-gas surface heat exchanger 13, liquid-phase product liquid-liquid surface heat exchanger 15, liquid-phase product liquid-solid filter 16, working medium discharge pipe recoil gas inlet 17 and the working medium discharge pipe control valve 18, its specific composition relationship is as follows.

[0035] There is a pressure relief safety outlet 1 on the top of the slurry bed reactor, and a reactor high-temperature hot water outlet 2 is installed on the left side of the upper part. And the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com