Valve lift continuous variable mechanism of engine gas distribution system

A technology of valve lift and engine, which is applied in the direction of engine components, engine control, combustion engine, etc., can solve the problems that the valve cannot be changed, the power performance of the engine cannot be fully exerted, and the valve cannot be controlled, so as to reduce fuel consumption and emission indicators and facilitate Effects of cabin layout and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

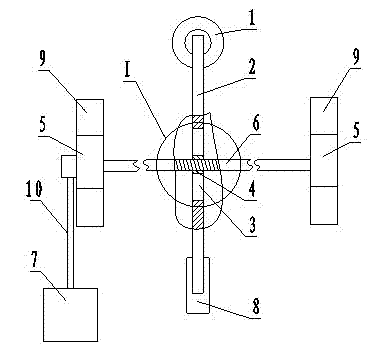

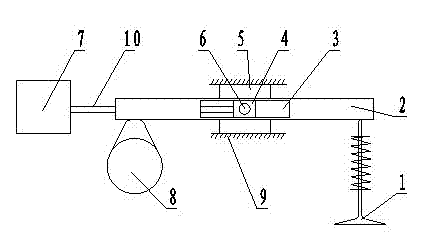

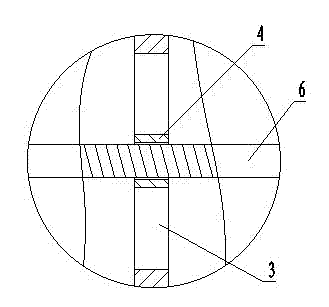

[0017] See Figure 1, Figure 2, image 3 , the present invention includes a group of valve lift continuous change control units whose number matches the number of engine cylinders, wherein each valve lift continuous change control unit is provided with a camshaft 8, a rocker arm 2, a rocker arm shaft 6 and a valve 1, Its special feature is that the slider I4 is installed in the middle of the rocker shaft 6, the slider I4 is hinged with the rocker shaft 6, and the rocker guide rail 3 with a cavity structure is provided in the middle of the rocker arm 2. The slider I4 can slide in the rocker guide rail 3.

[0018] See Figure 1, Figure 2, image 3 , the two ends of the rocker shaft 6 of the present invention are assembled with the slider II5 arranged symmetrically on both sides of the rocker arm 2 respectively, and the slider II5 is assembled with the cylinder head guide rail 9 arranged on the engine cylinder head, and the slider II5 Can slide along cylinder head guide rail 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com