Super-large trolley type gas heat treatment furnace

A super-large table and heat treatment furnace technology, which is applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., to achieve the effects of convenient maintenance, avoiding energy waste, and improving energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

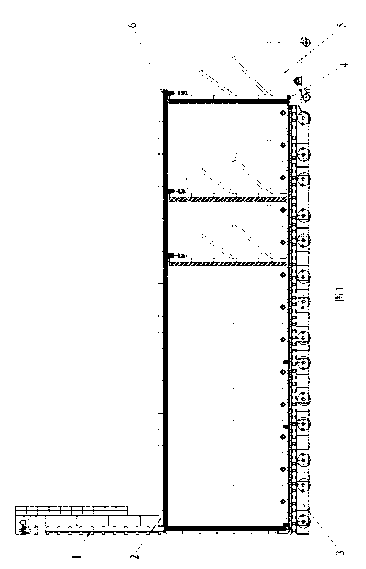

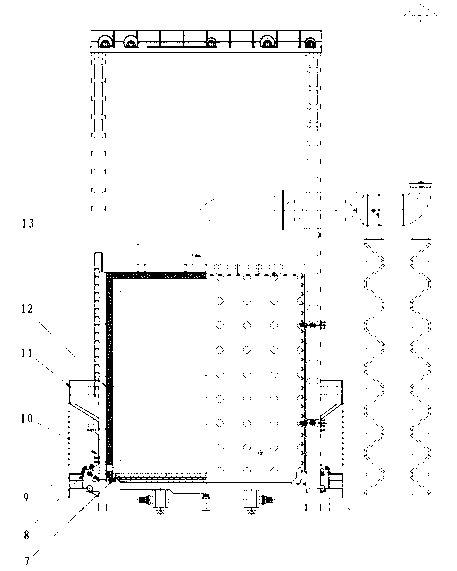

[0028] The overall structure of this embodiment is as figure 1 and figure 2 As shown, the furnace door and the furnace door lifting mechanism 1 are located at the left end of the furnace body. The furnace body is composed of a furnace body steel structure 2 and an inner lining 6. The trolley device 3 can move in the furnace body, and the moving back wall device 5 can move from the furnace body right end. into any position in the furnace body (such as figure 1 The position of the moving back wall depicted by the dotted line in the middle), the moving back wall device 5 realizes the sealing with the furnace body and the trolley device 3 through the rear sealing device 4, and the furnace body realizes the sealing with the trolley device 3 through the side sealing device 7 and the furnace door seal.

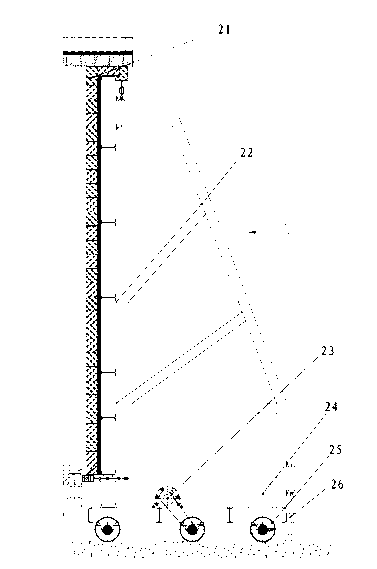

[0029] The structure of the mobile back wall device in this embodiment is as follows: image 3 with Figure 4 As shown, the mobile rear wall device is composed of a rear wall lini...

Embodiment 2

[0034] The structure of this embodiment is basically the same as that of Embodiment 1, and the adjustment steps and sealing process of the moving rear wall are also the same as Embodiment 1. The only difference is that in order to improve the sealing effect at the furnace door, this embodiment is vertically provided with a fire wall on the surface of the trolley. , the position of the fire-retaining wall is set at 10 meters and 20 meters according to user requirements, and the lower edge of the outer side of the fire-retaining wall is laid with 30mm refractory 1260°C fiber. The fire-retaining wall is a seal before the furnace door falls, and the furnace door falls by its own weight It is tight to the refractory fiber on the surface of the trolley to form a secondary seal to achieve a good sealing effect.

Embodiment 3

[0036] In this embodiment, the furnace door anti-falling device is installed on the lifting furnace door of the super-large trolley gas heat treatment furnace on the moving back wall.

[0037] The overall structure of this embodiment is as figure 1 with figure 2 shown. figure 1 It is a cross-sectional schematic diagram of a super large trolley-type gas heat treatment furnace with a moving back wall in this embodiment. This heat treatment furnace changes the fixed back wall of the traditional furnace body into a movable structure, and at the same time ensures that the moving back wall and the top of the furnace body, The reliable sealing between the side walls and the trolley realizes the effective length of multi-section furnace. figure 2 A schematic diagram of the local structure of the lifting furnace door without the anti-fall device is given in this embodiment.

[0038] In this embodiment, an anti-fall device is installed on the left and right sides of the lifting fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com