Patents

Literature

32results about How to "Less sealing points" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

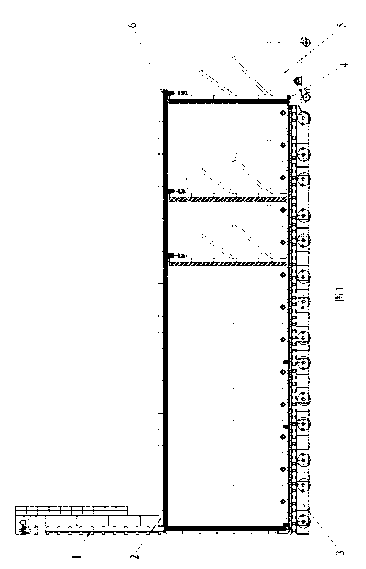

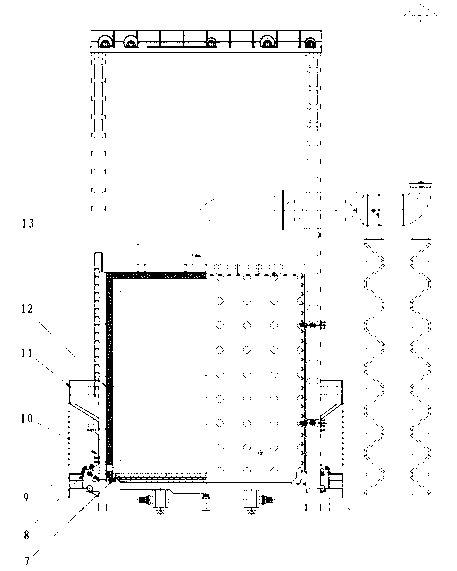

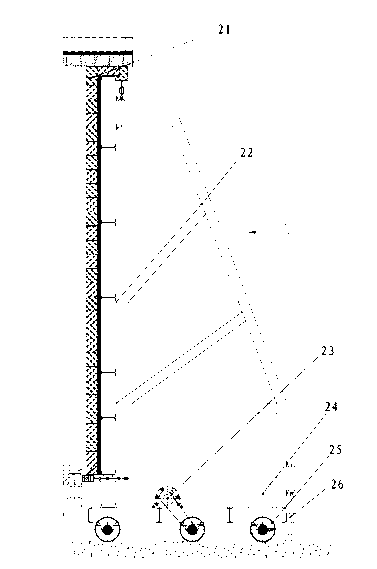

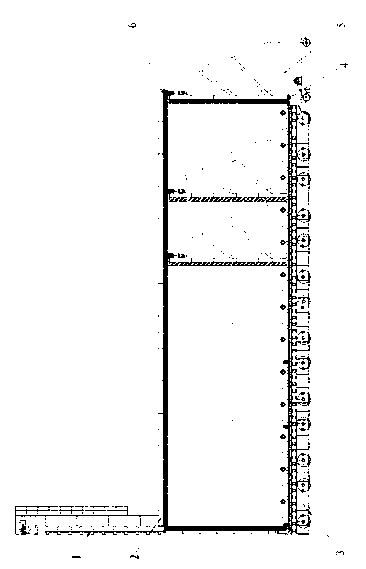

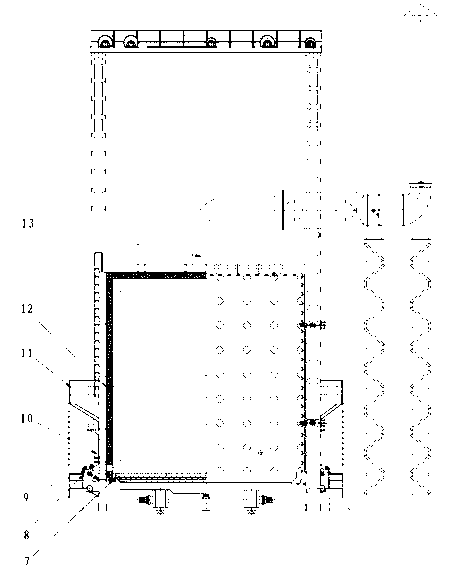

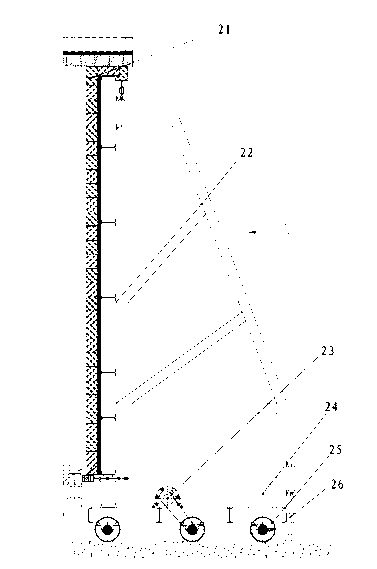

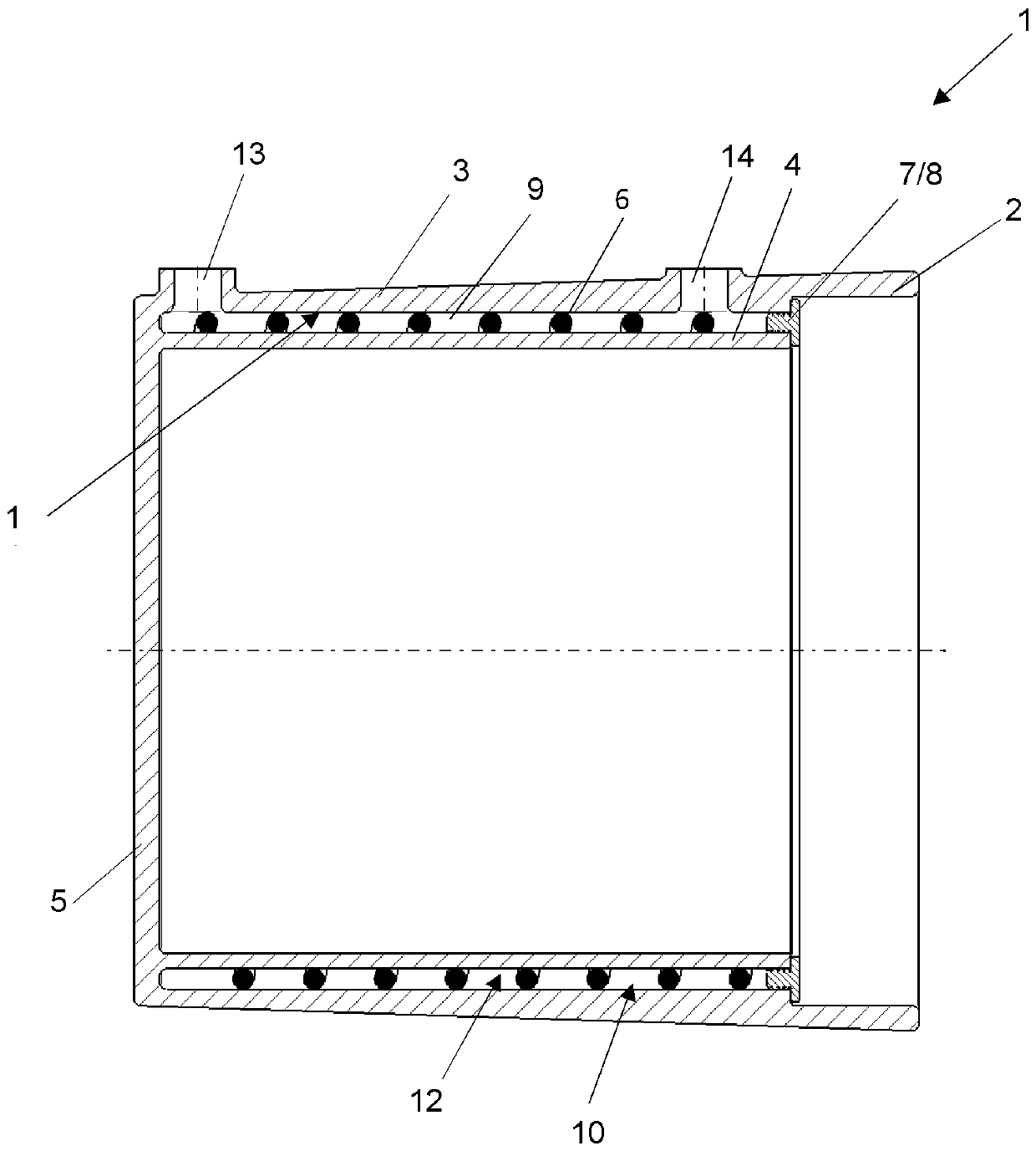

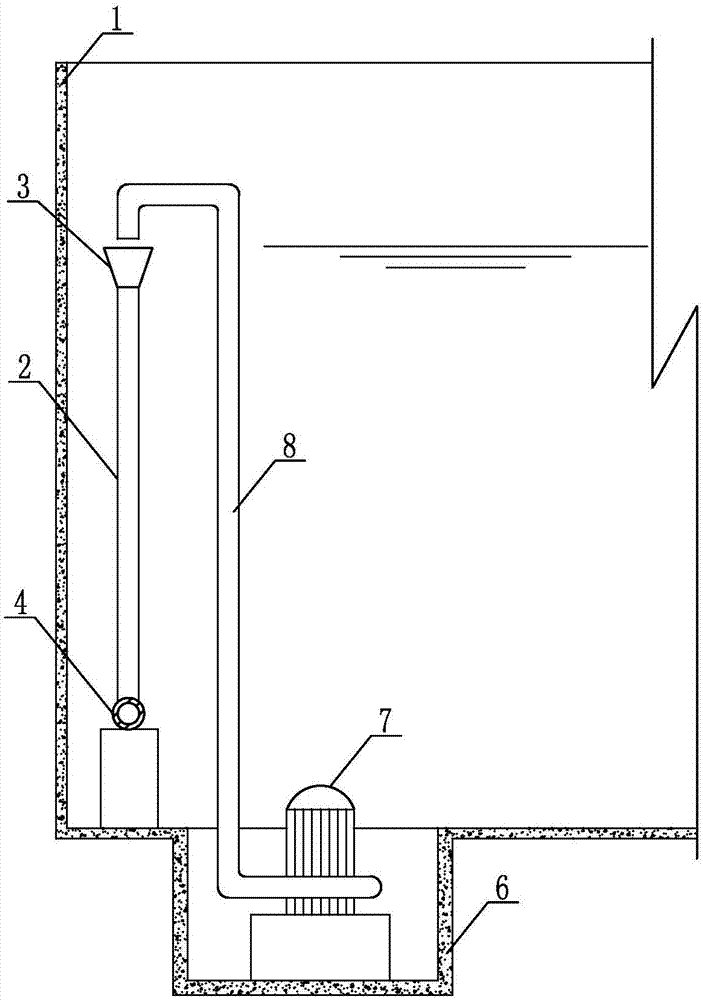

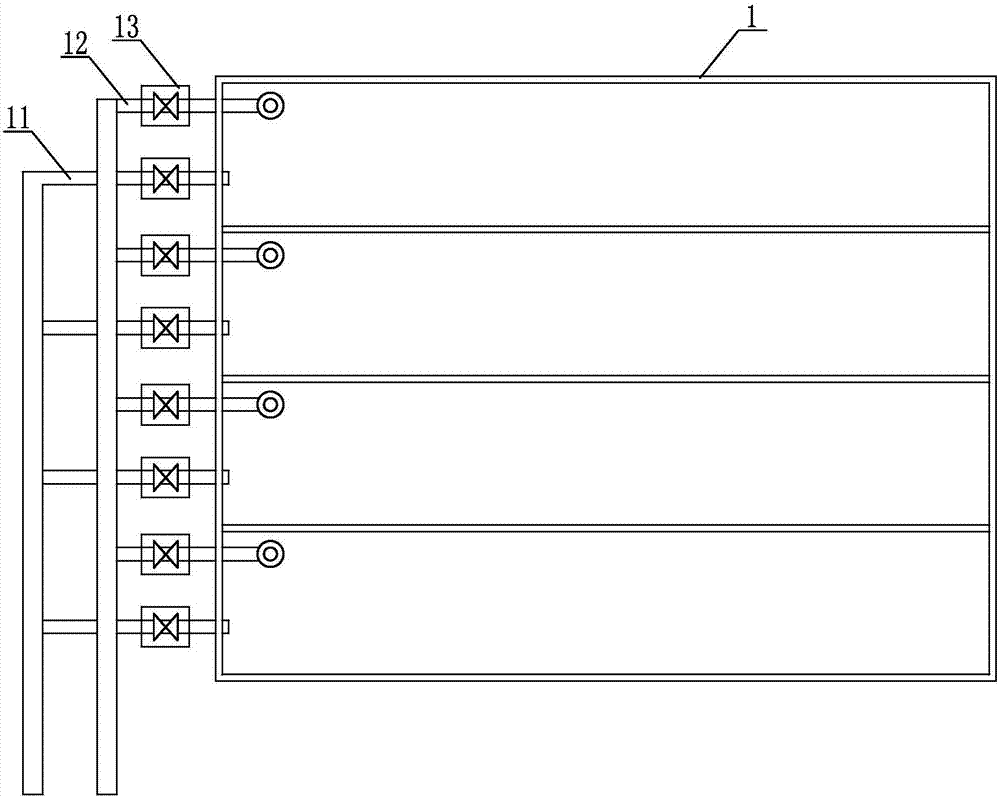

Super-large trolley type gas heat treatment furnace

InactiveCN102703650ASolve the problem of low efficiencyImprove efficiencyFurnace componentsEngineeringMechanical engineering

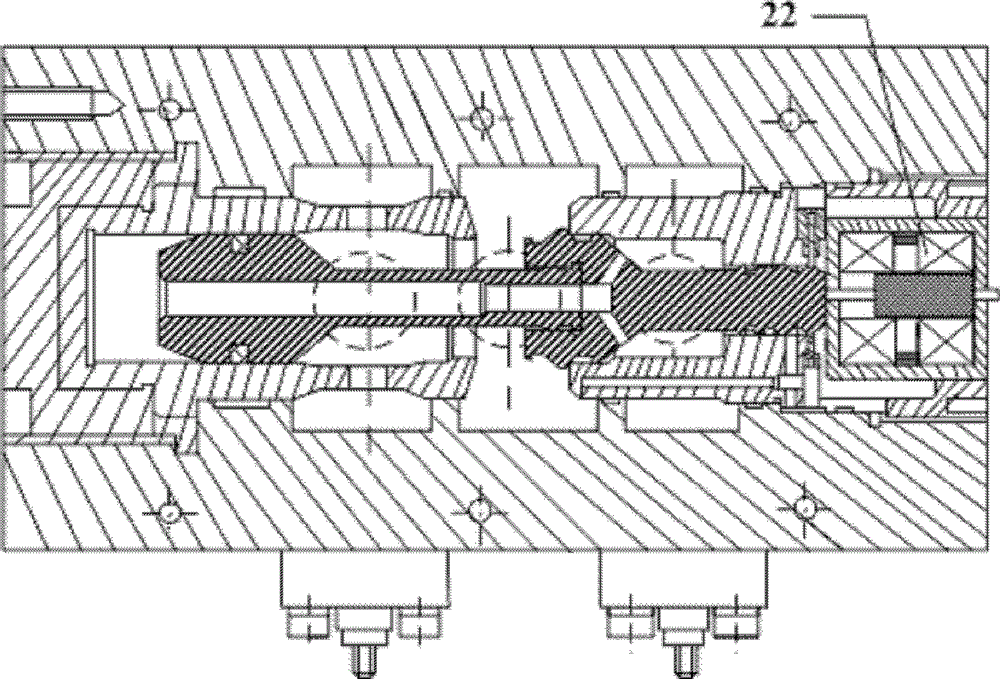

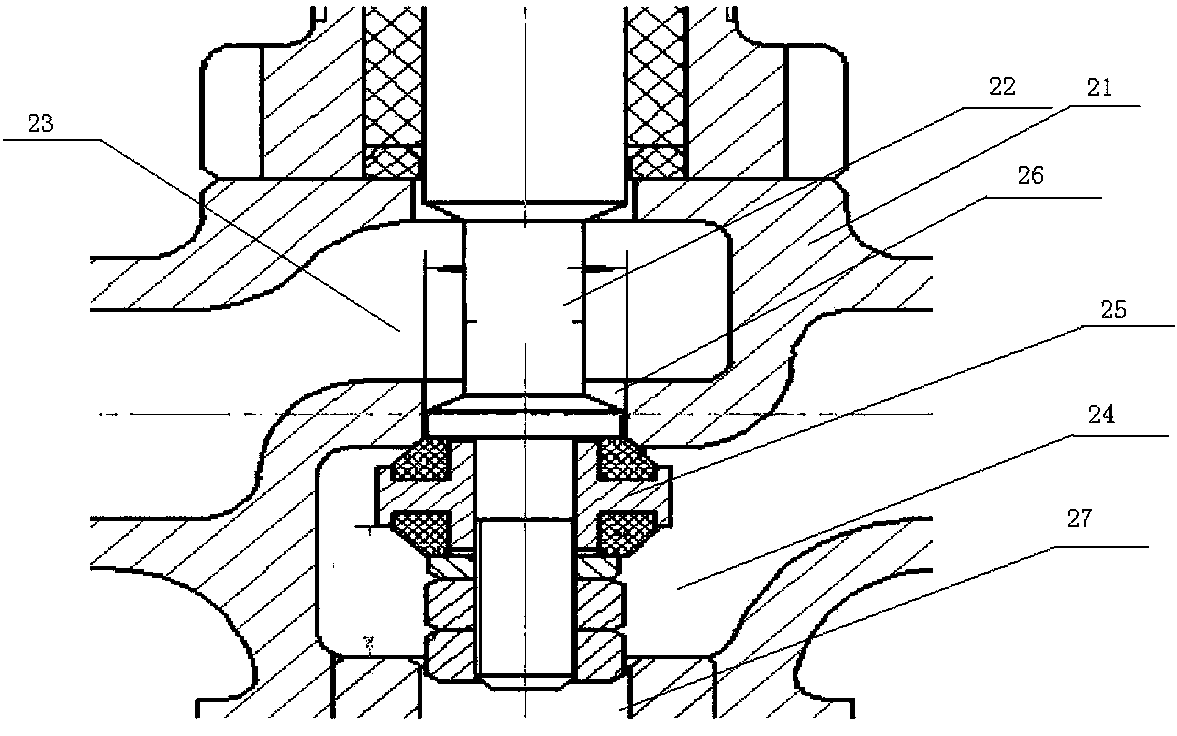

The invention relates to a super-large trolley type gas heat treatment furnace. The gas heat treatment furnace is characterized in that a fixed rear wall of the conventional furnace body is changed into a movable rear wall, a steel member of the movable rear wall is fixed on a travelling mechanism, and a lining is arranged on the lateral surface of the steel member; and a sealing mechanism is arranged on each of the upper, lower, left and right parts of the movable rear wall, so that the movable rear wall, the lining of the furnace body and a trolley are sealed. Moreover, a furnace door dropping preventing device is added in a furnace door and a lifting mechanism and drives a safety pin by means of a reset force of a spring, once the furnace door drops due to loss of pull, the safety pin quickly extends out, and the furnace door is clamped on upright posts on two sides of the furnace door, so that the furnace door is prevented from continuously dropping. The using efficiency of the super-large heat treatment furnace is effectively improved; energy waste caused by ineffective combustion in the redundant space is avoided; the sealing mechanisms of the movable rear wall are reasonable in structure, easy and convenient to operate and convenient to maintain, and can achieve good sealing performance and increase the overall energy-saving effect of the heat treatment furnace; and thefurnace door dropping preventing device promotes the running safety of the furnace body.

Owner:DANYANG JIANGNAN INDAL FURNACE

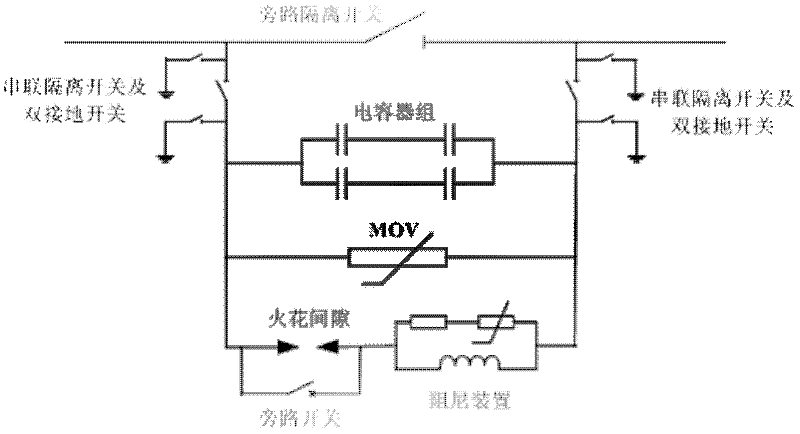

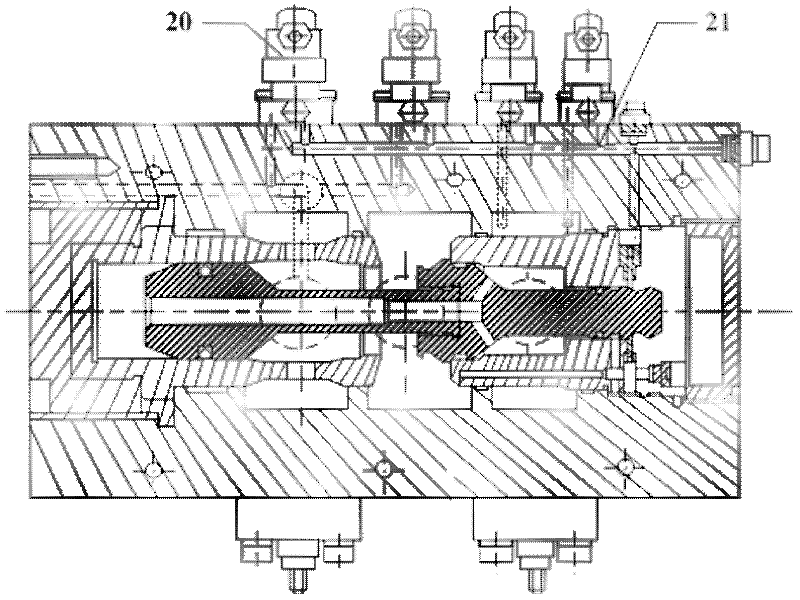

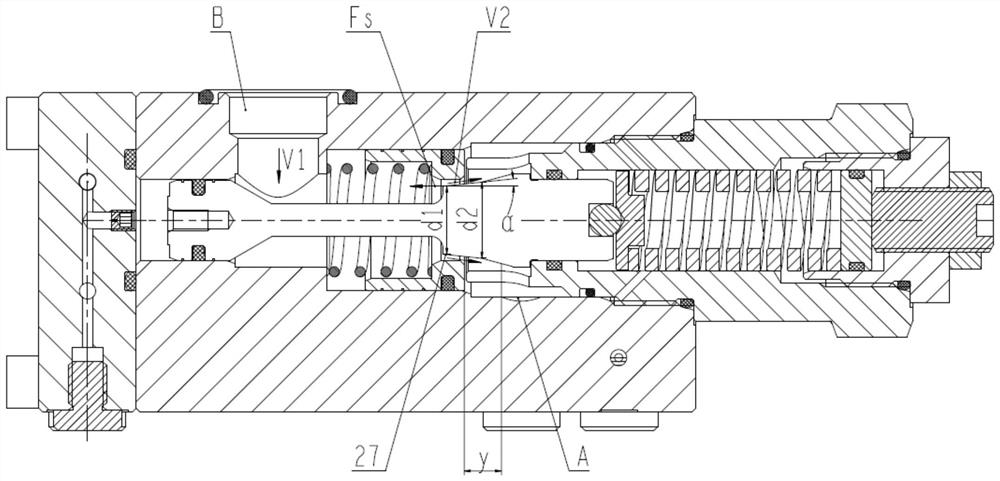

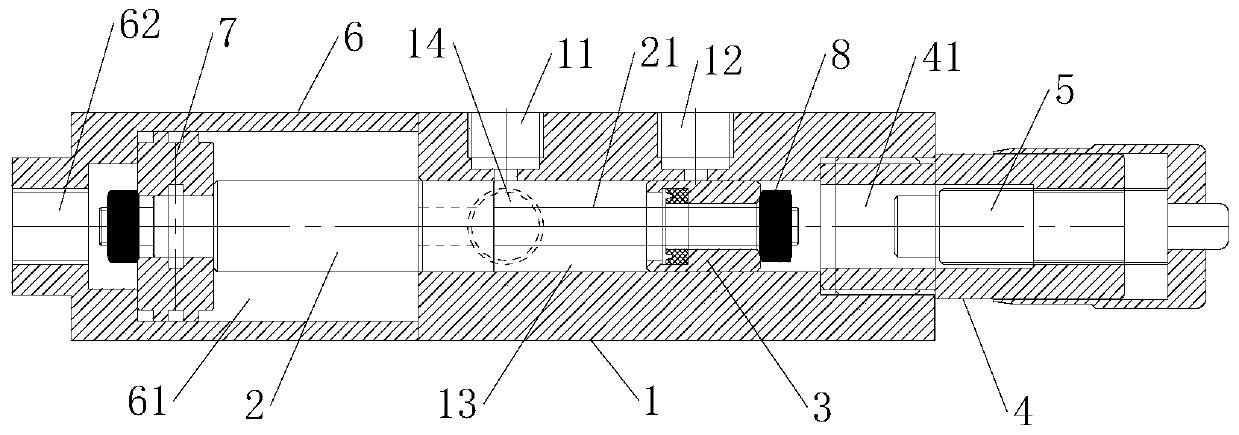

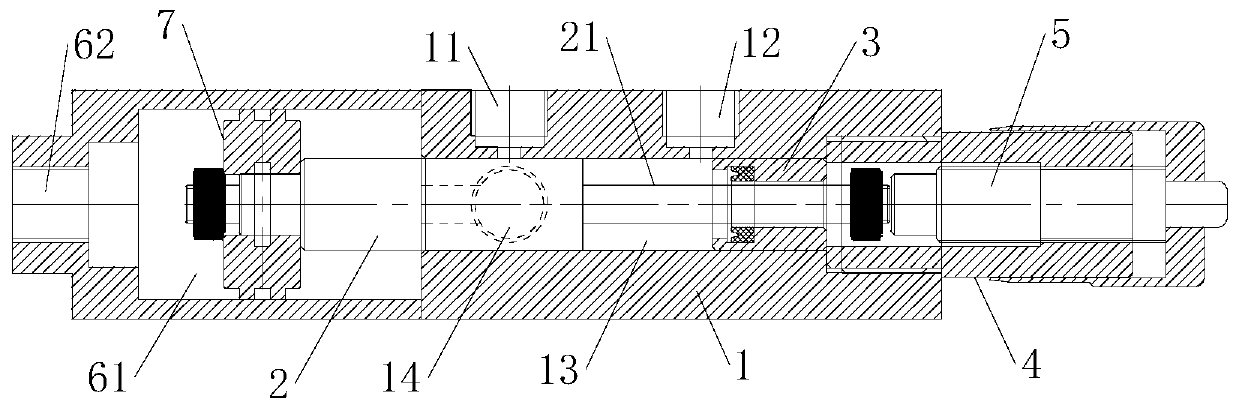

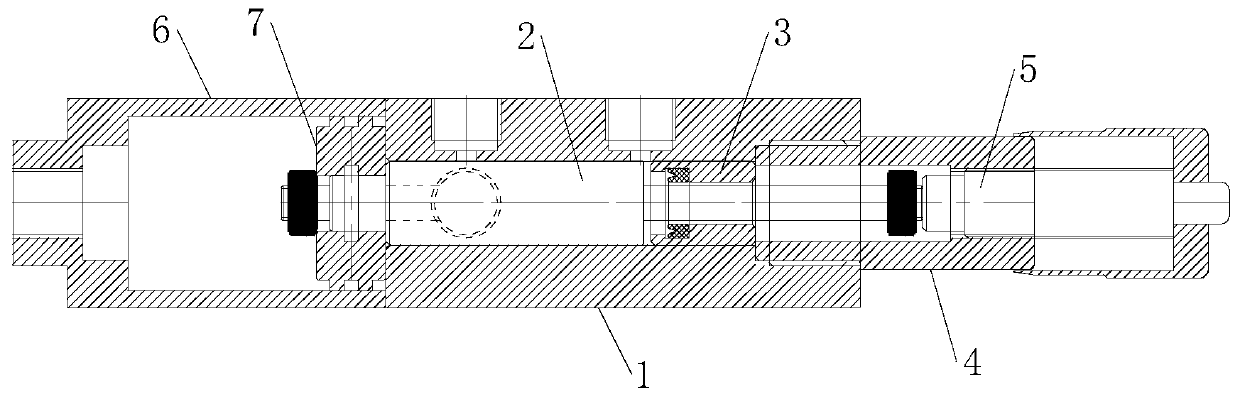

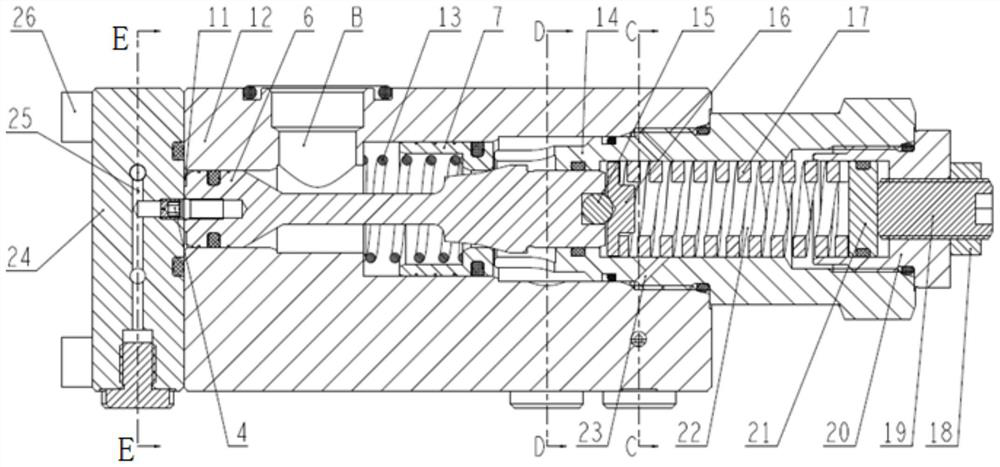

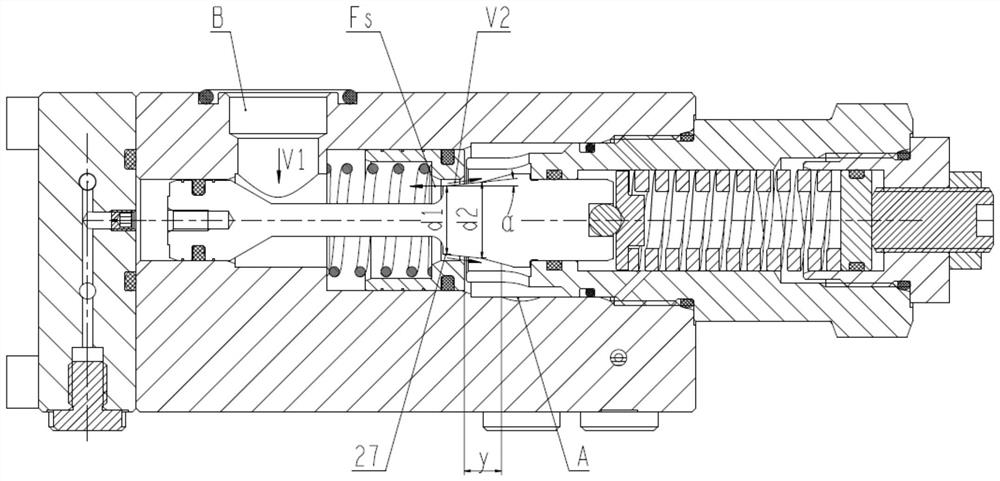

Repulsion reversing valve for extra-high voltage series compensation bypass switch

ActiveCN102403139AMeet technical requirementsFast conversionOperating means/releasing devices for valvesContact driving mechanismsSeries compensationEngineering

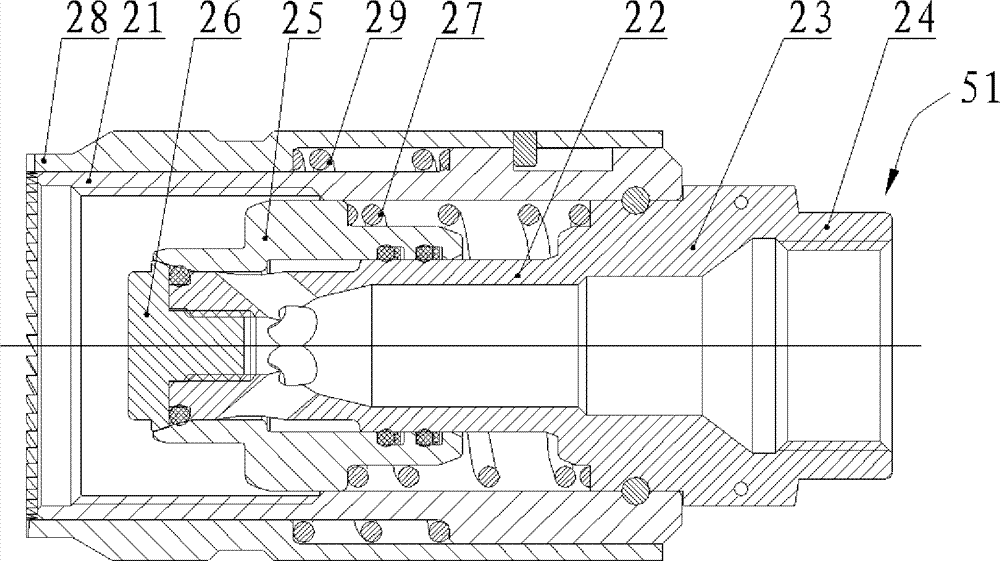

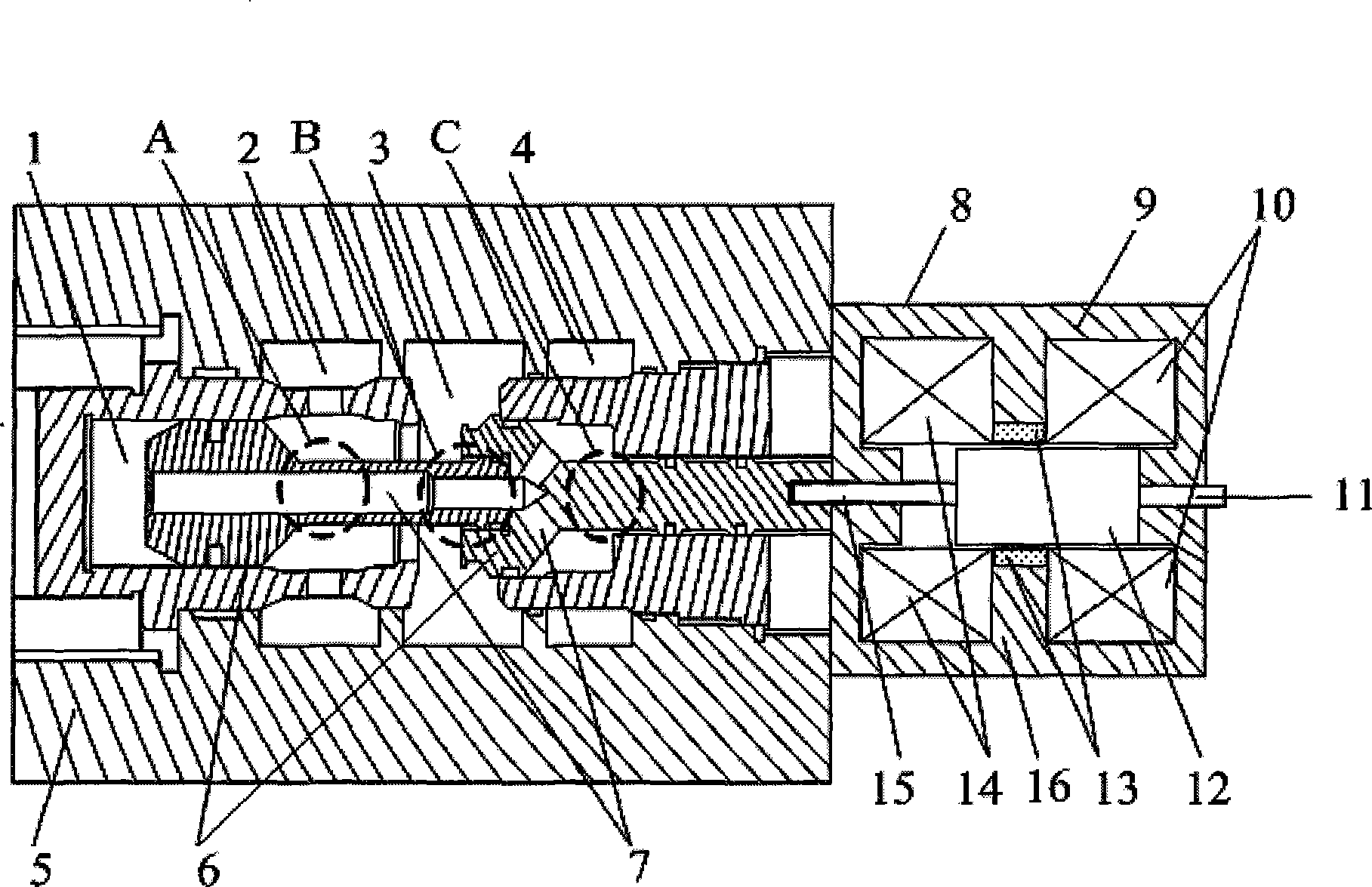

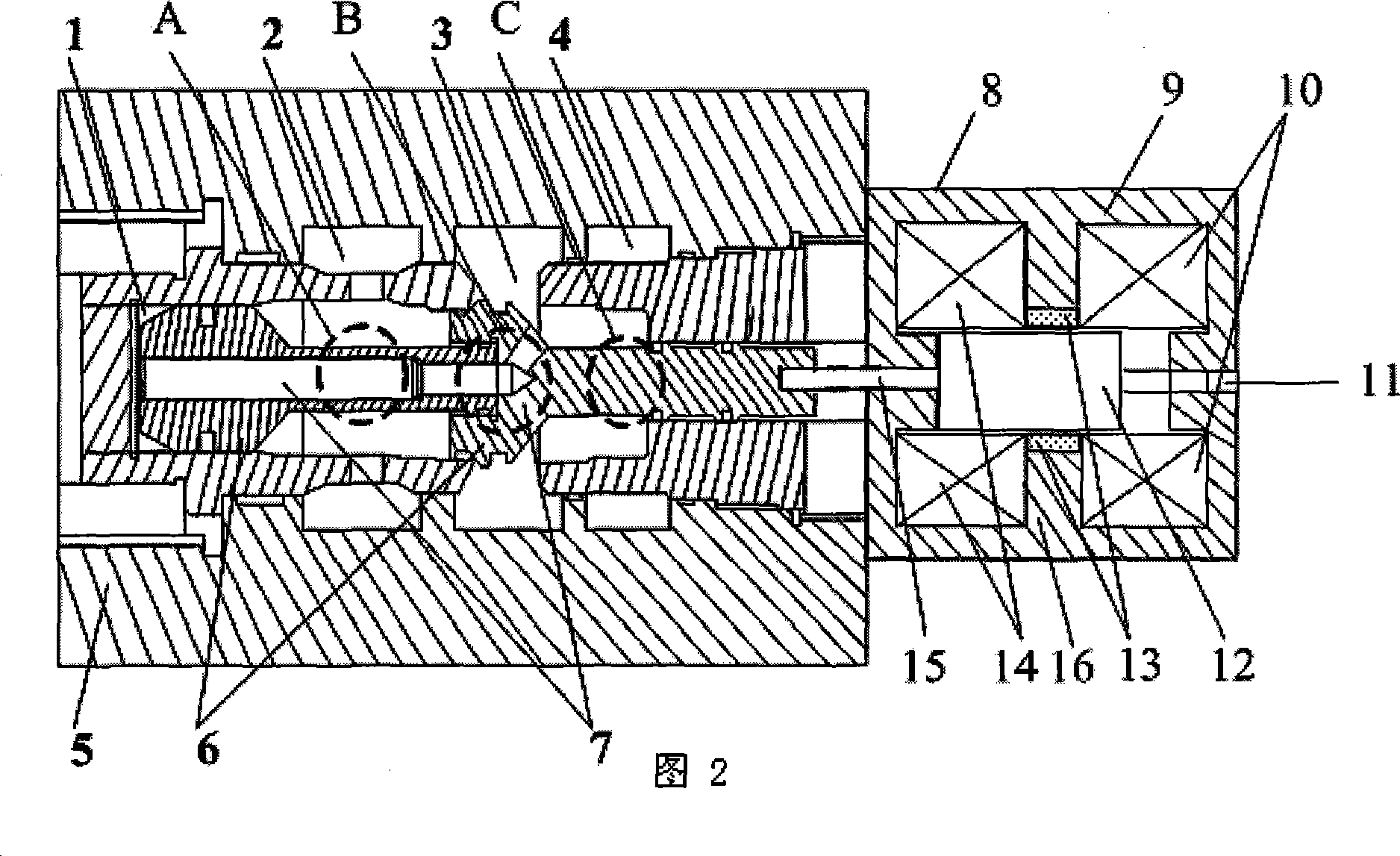

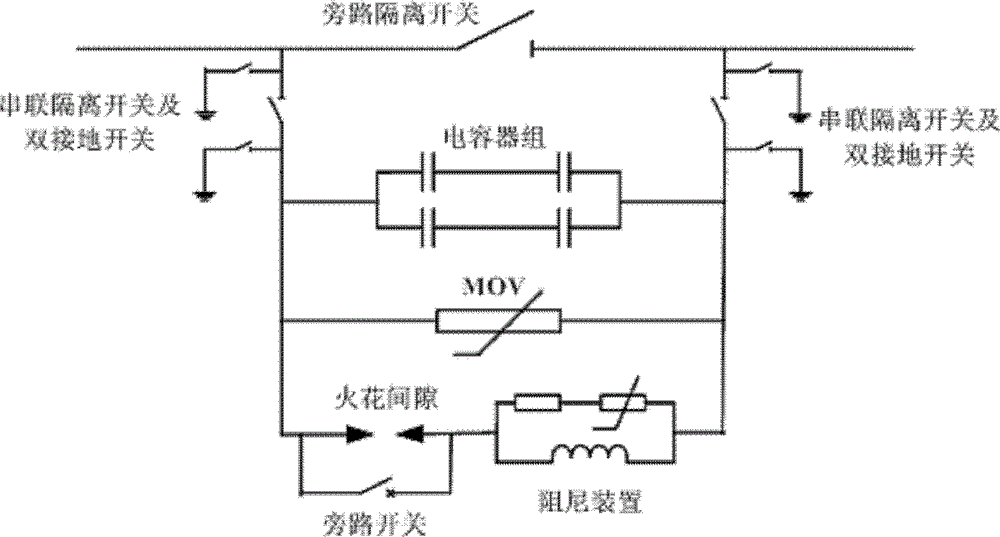

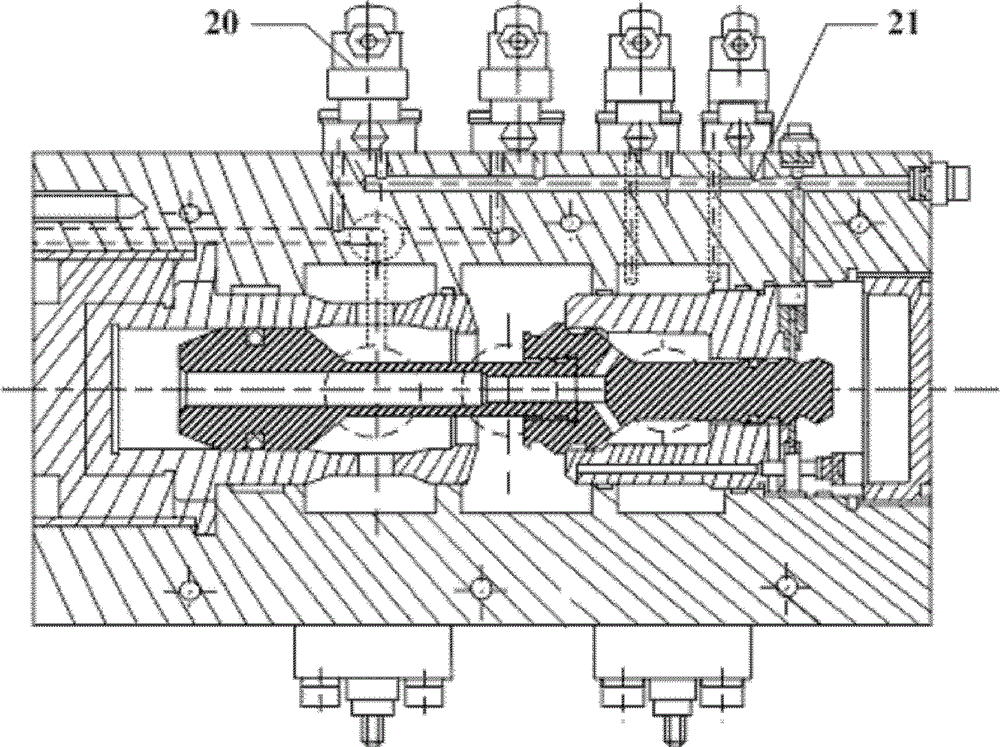

The invention provides a repulsion reversing valve for an extra-high pressure series compensation bypass switch, which comprises a valve body. A valve core is arranged in the valve body. The inside of the valve body is divided into a normally low pressure oil region, a working oil region, a normally high pressure oil region and a valve core moving region. The valve body is provided with a low pressure oil circuit connector, a working oil circuit connector and a high pressure oil circuit connector. A high pressure oil hole is arranged in the valve core. The right part of the valve body is provided with a repulsion valve. A drive rod of the repulsion valve is connected with the valve core. The middle part of the valve core is fixedly provided with a pressure maintenance wing. The pressure maintenance wing is always positioned in the working oil region and is arranged axially with the valve core. The reversing valve has the advantages of simple structure, high reliability, small volume, low cost, long service life and the like. When the reversing valve operates, the switching speed is high and the output characteristic is flexible. The static retentiveness of the reversing valve totally depends on the oil pressure. The bypass switch to which the reversing valve is adopted has closing time of 20ms to 25ms and breaking time of 26ms to 30ms. The technical requirement of an extra-high pressure series compensation device on the bypass switch can be totally met.

Owner:CHINA ELECTRIC POWER RES INST +1

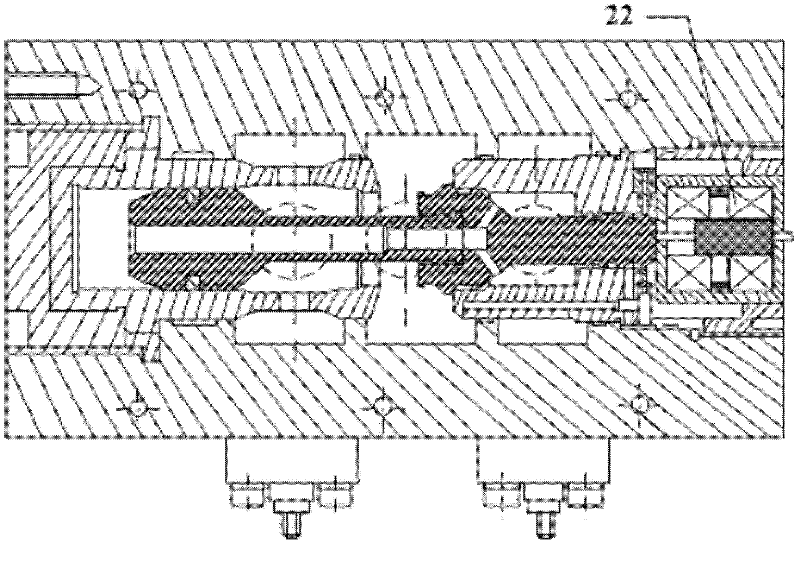

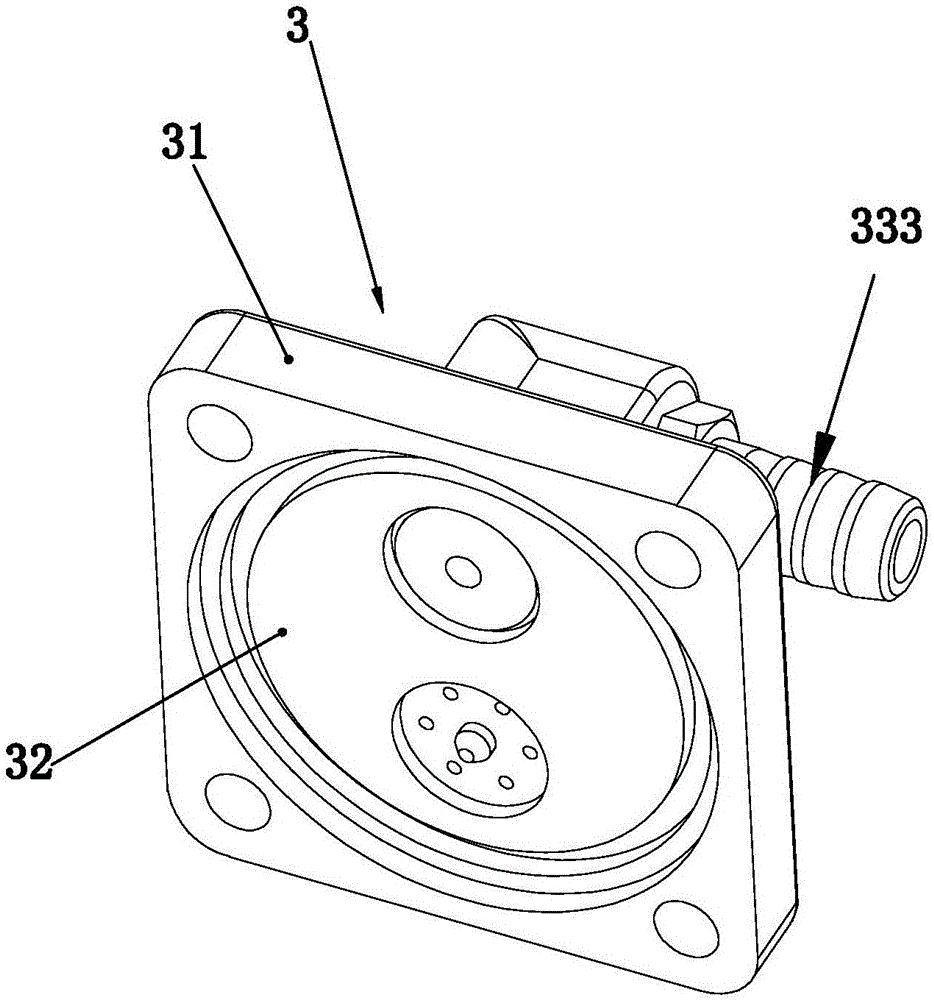

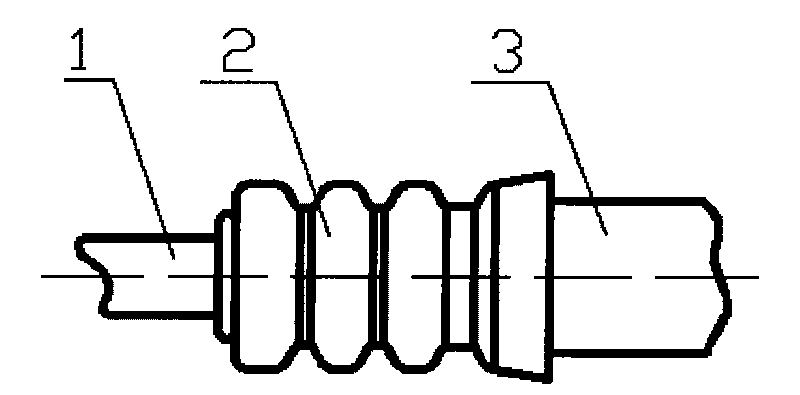

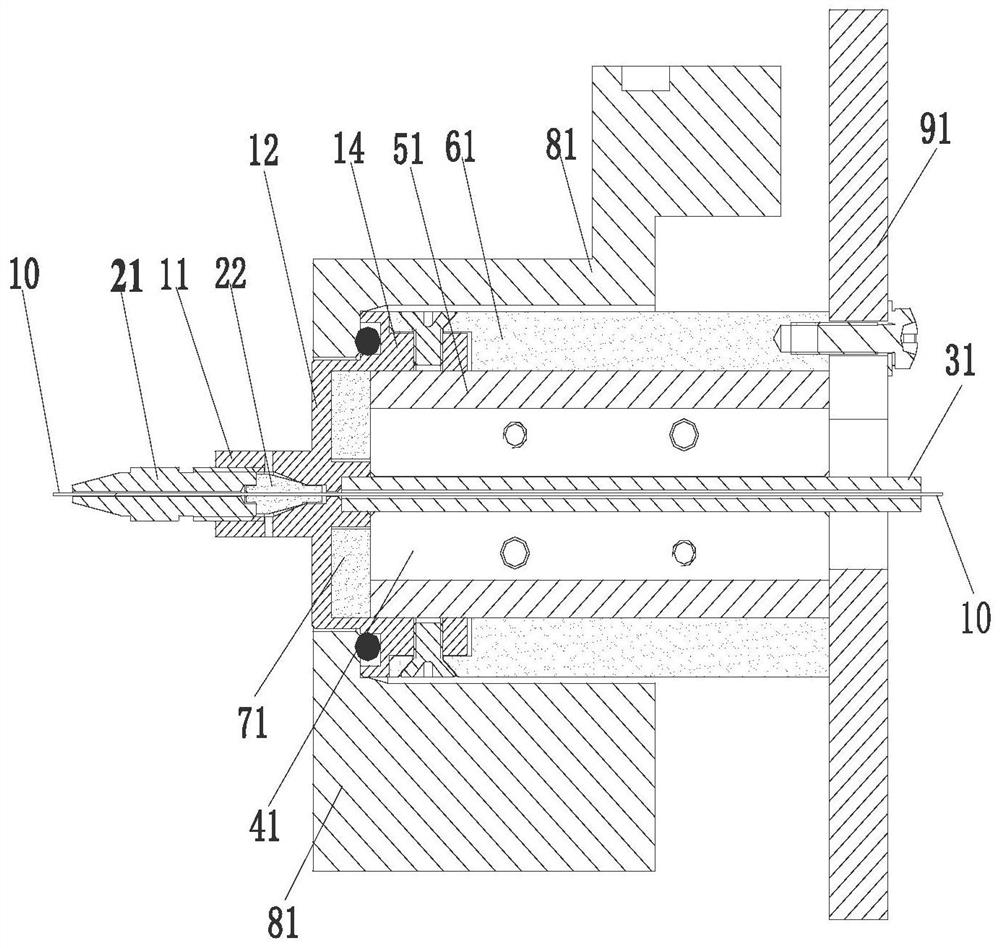

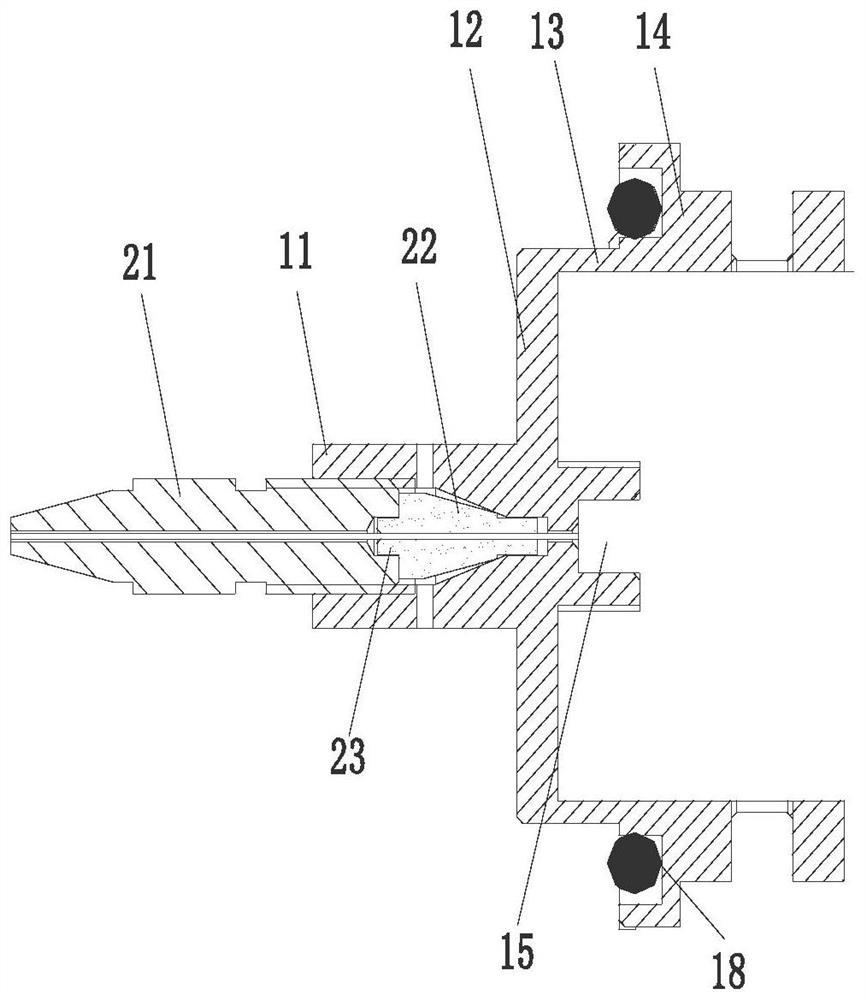

Fixed core adapter valve and self-sealing adapter assembly using same

The invention relates to a fixed core adapter valve and a self-sealing adapter assembly using the same. The fixed core adapter valve comprises a valve body and a valve seat which is assembled at the rear end of the valve body; the valve body is internally provided with a valve core which is fixedly connected to the valve seat; a sliding sleeve is sleeved on the valve core movably in an anti-running mode along the front and back direction; a restoration spring is installed between the rear end of the sliding sleeve and a valve body or a valve seat at the top; the valve core is provided with a valve core seal section; the valve core is internally provided with a medium channel; the medium channel is provided with a medium inlet which is positioned at the rear end of the valve core and is used for receiving media in the corresponding pipeline and a medium outlet which is positioned at the periphery of the valve core seal section; the sliding sleeve is provided with a sliding sleeve seal section which is used for sliding seal coordination with the valve core seal section to seal the medium outlet; and the sliding sleeve is provided with a starting stroke which slides backward to startthe medium outlet. Through the fixed core adapter valve provided by the invention, the seal performance of the fixed core adapter valve is improved greatly, and further the problem of poor seal performance of the prior self-seal adapter is solved.

Owner:新乡平原航空液压设备有限公司

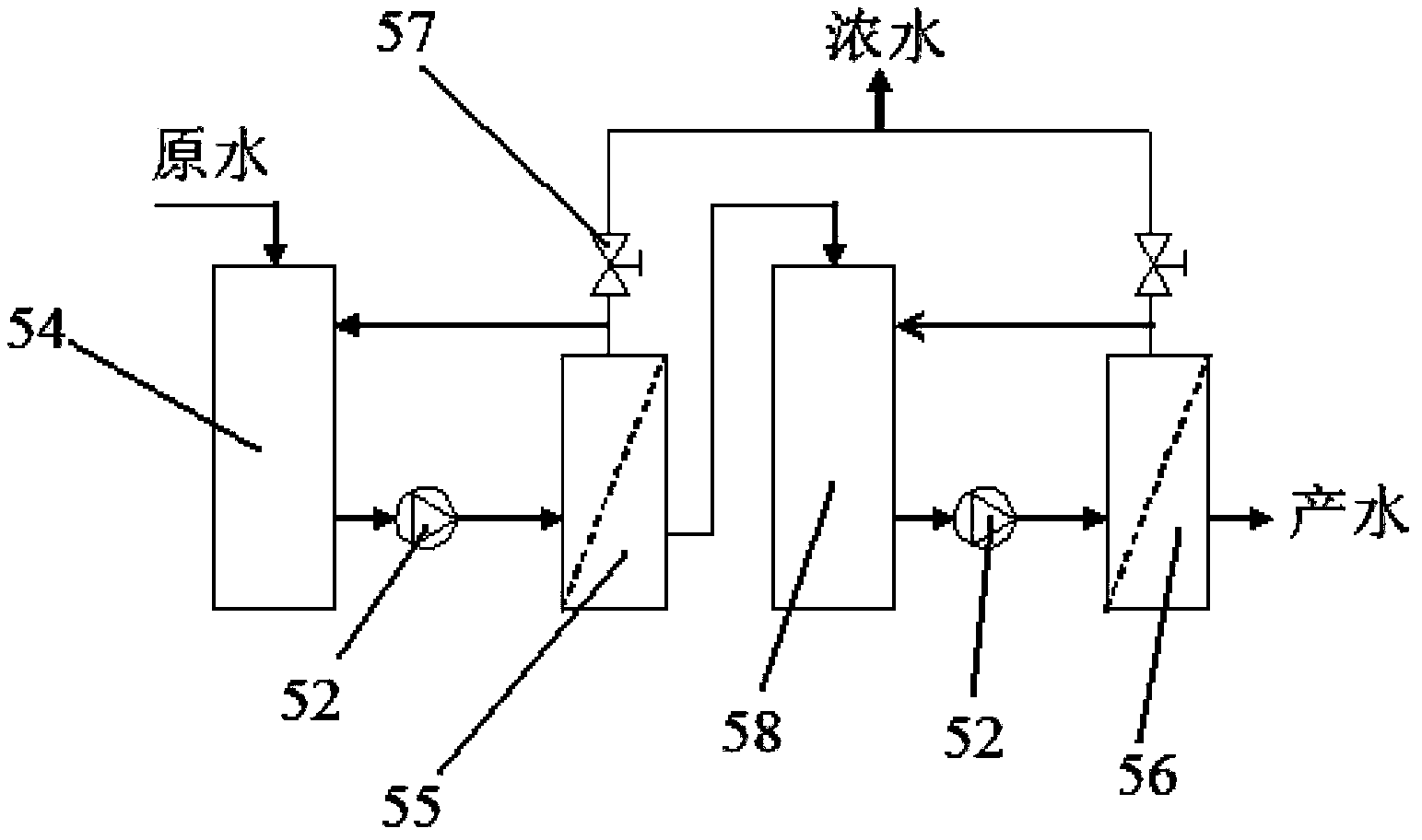

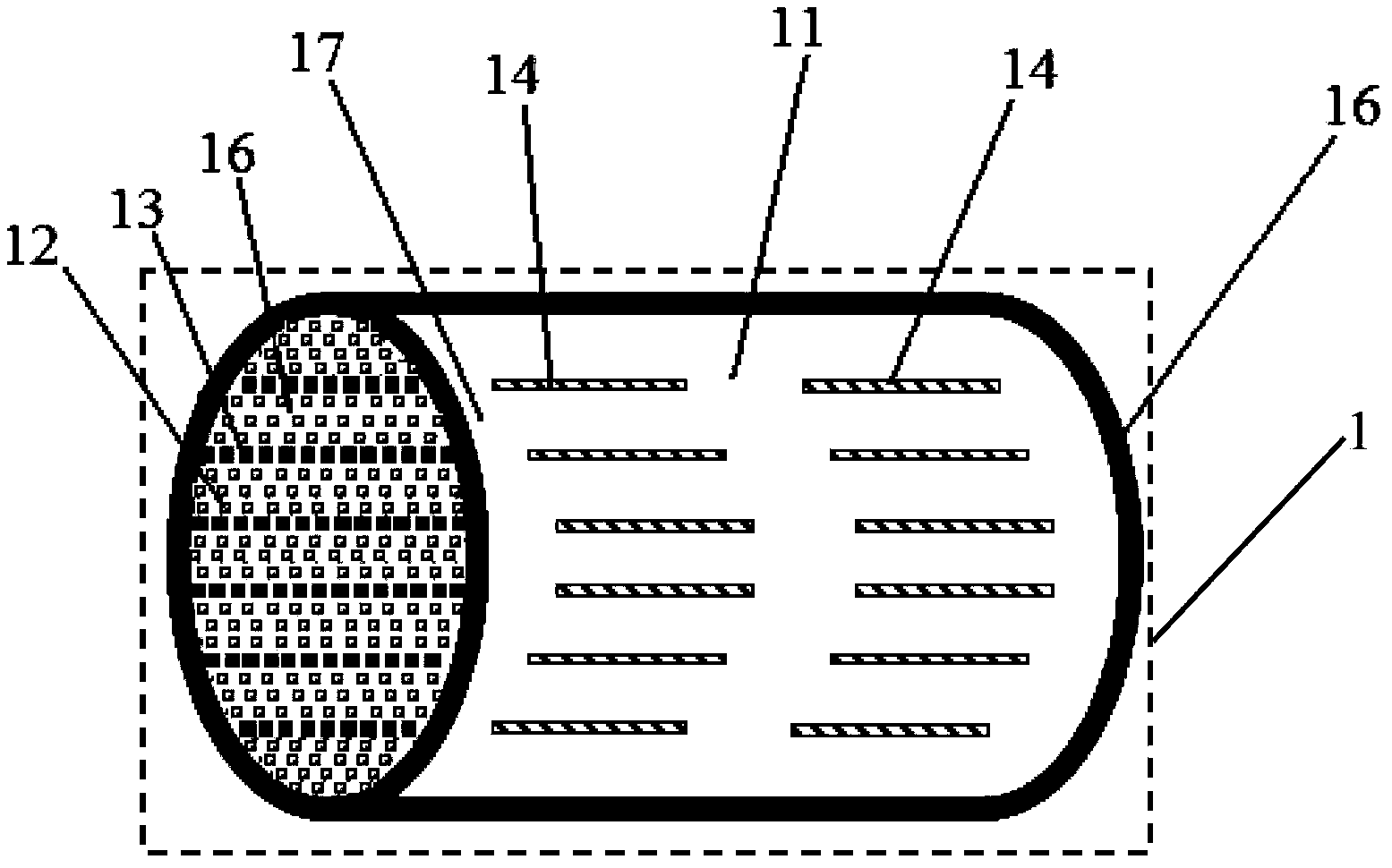

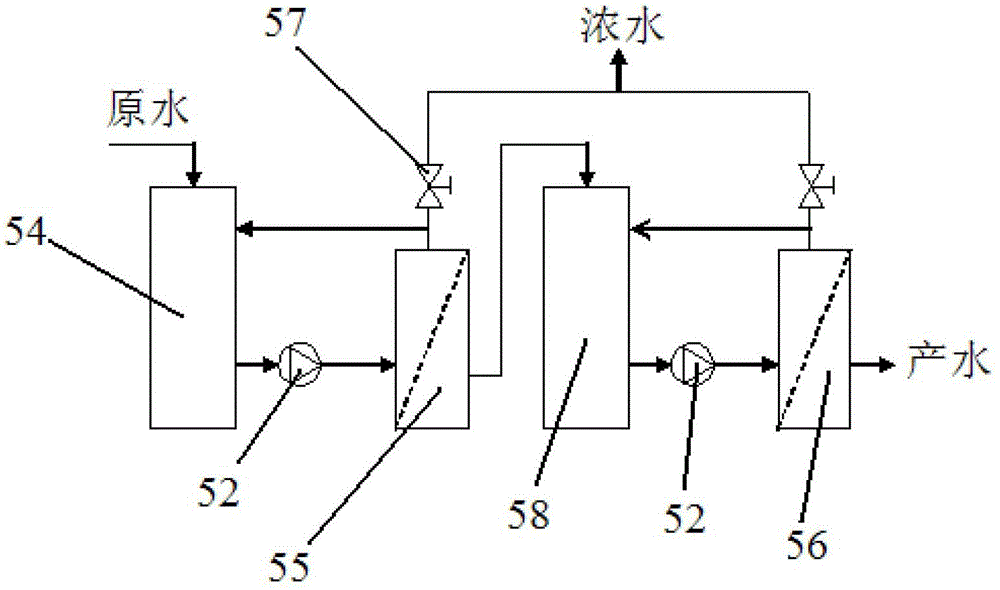

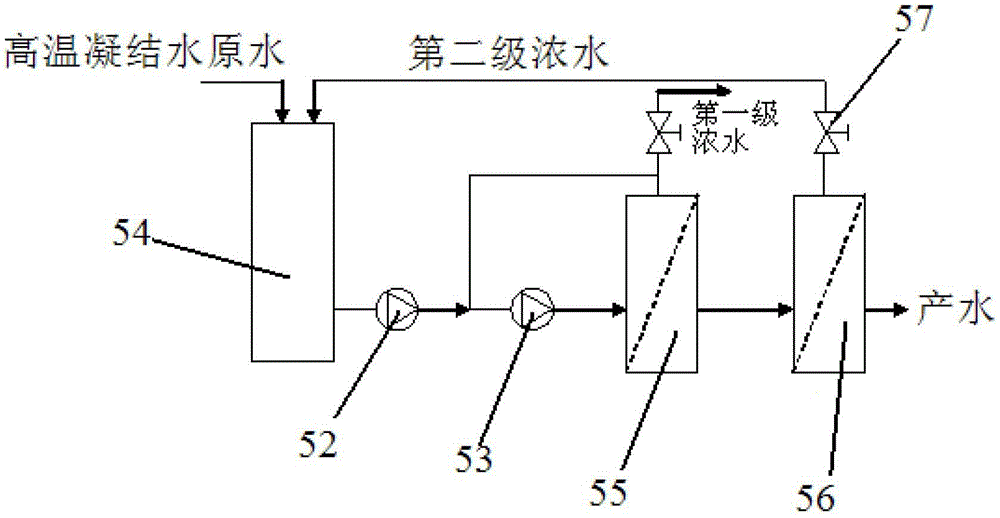

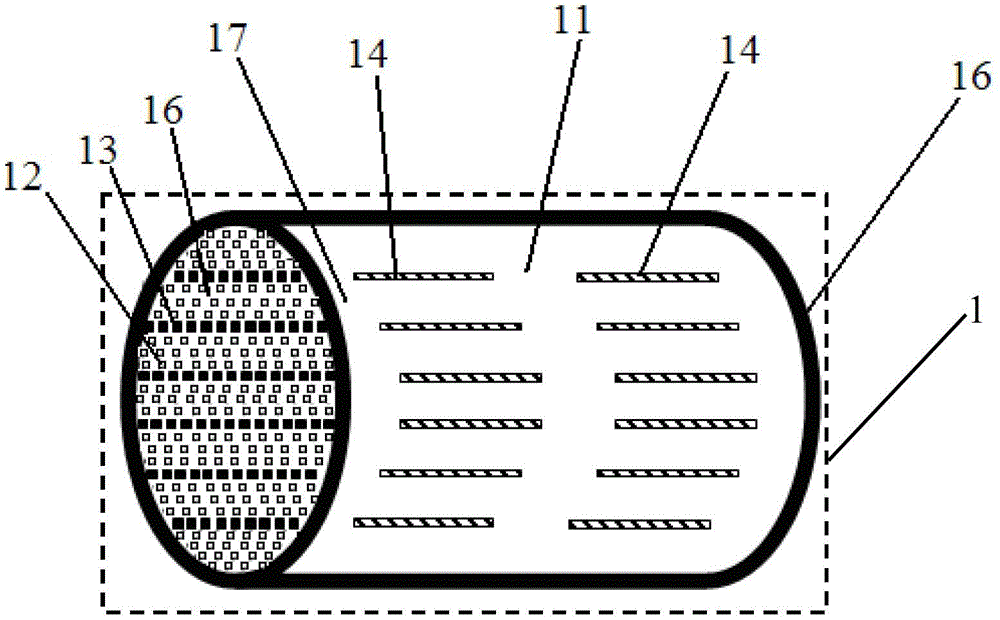

Purifying method of high-temperature condensed water

ActiveCN103657413AIncrease packing densityHigh structural integrationSemi-permeable membranesWater/sewage treatment by ion-exchangeThermal energyWater quality

The invention discloses a purifying method of condensed water. The purifying method comprises the steps of adopting a honeycomb-shaped carrier type inorganic carbon membrane assembly to carry out at least one stage of membrane filtering treatment on high-temperature condensed water, wherein the filtering accuracy of the membrane assembly treated by membrane filtering is 0.001-100mum, and preparing the boiler supplementing water suitable for recycling. The purifying method disclosed by the invention has the advantages that the filtering accuracy is high, the membrane flux of a honeycomb-shaped carrier type membrane core is large, the impact resistance of incoming water is strong, the resistance to oil pollution is strong, the integration level of the membrane core structure is high, the preparation method is simple, a complex online discrimination system is not needed, and the prepared condensed water is stable in quality and high in temperature, meets the requirement on water quality of the boiler supplementing water and saves a great amount of heat.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

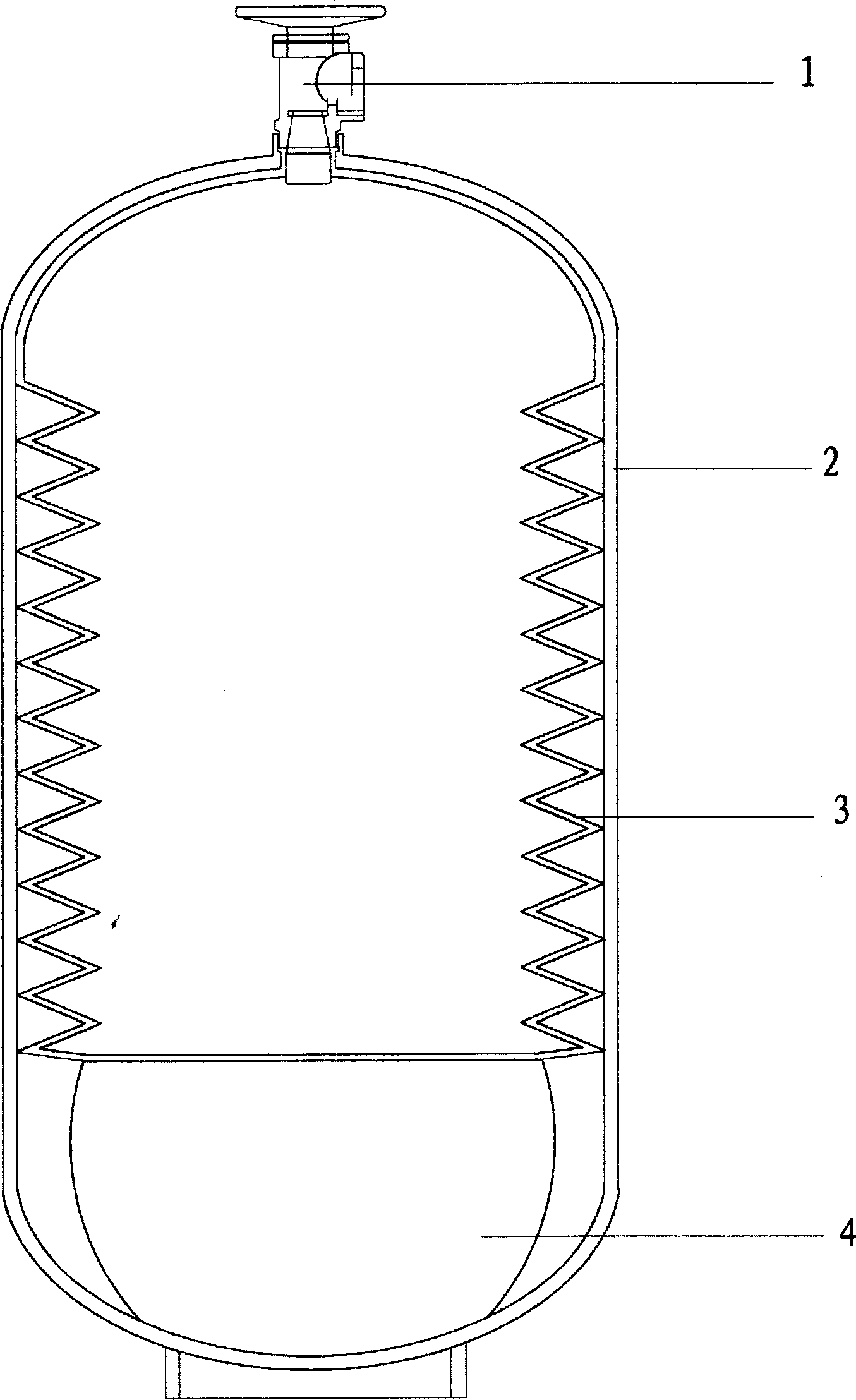

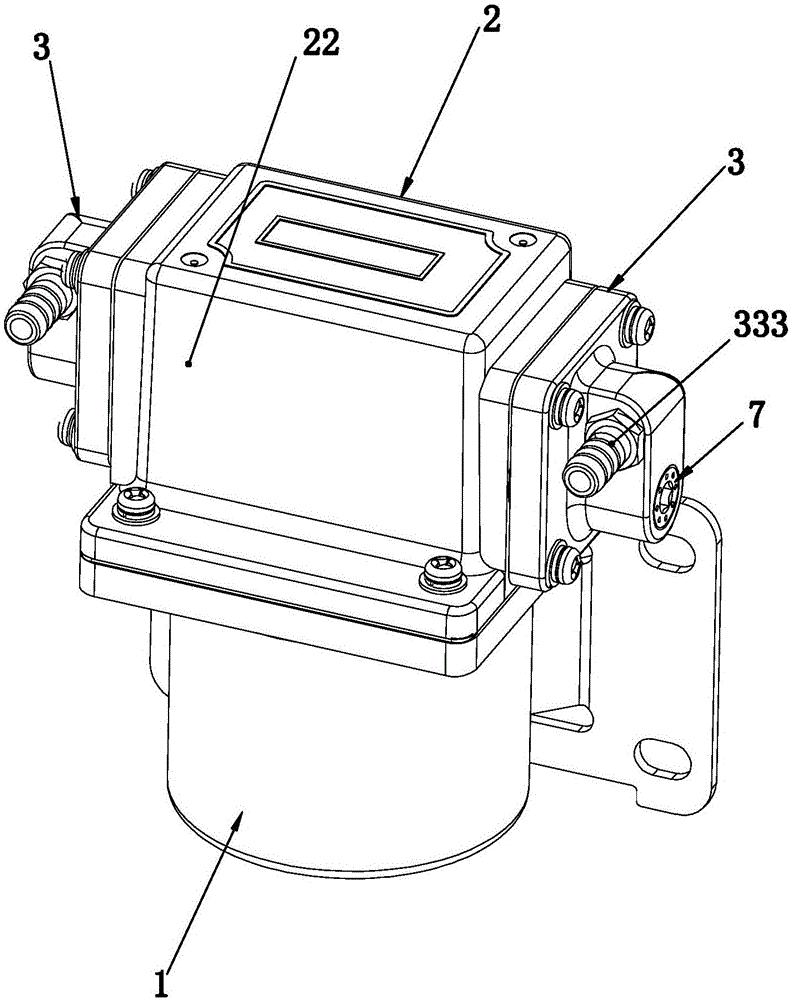

Voltage stabilized storage tank

InactiveCN1919701AStable output pressureSimple structureLarge containersPressure vesselsEngineeringMechanical engineering

Owner:王海金

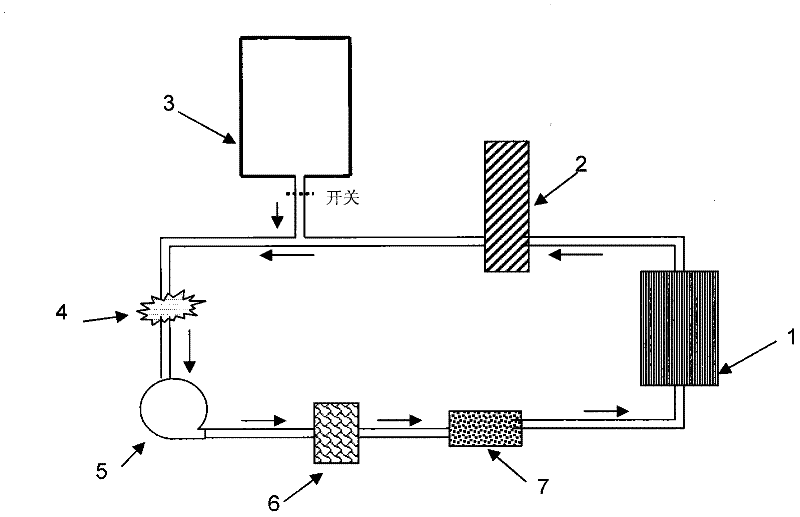

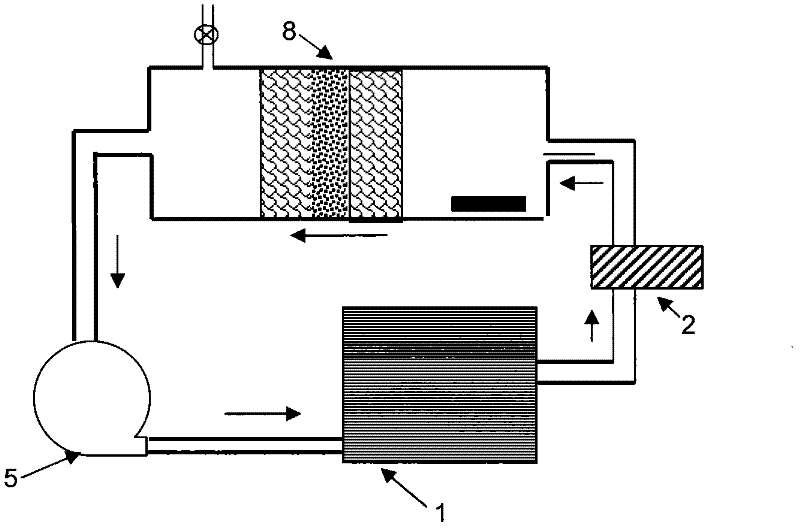

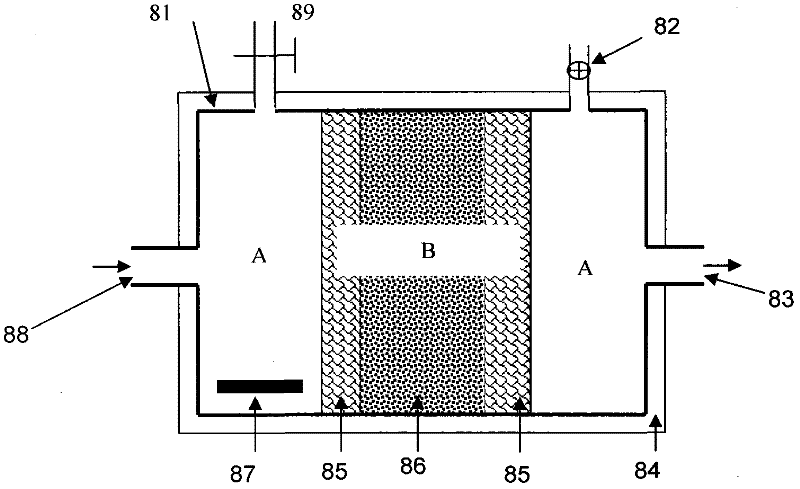

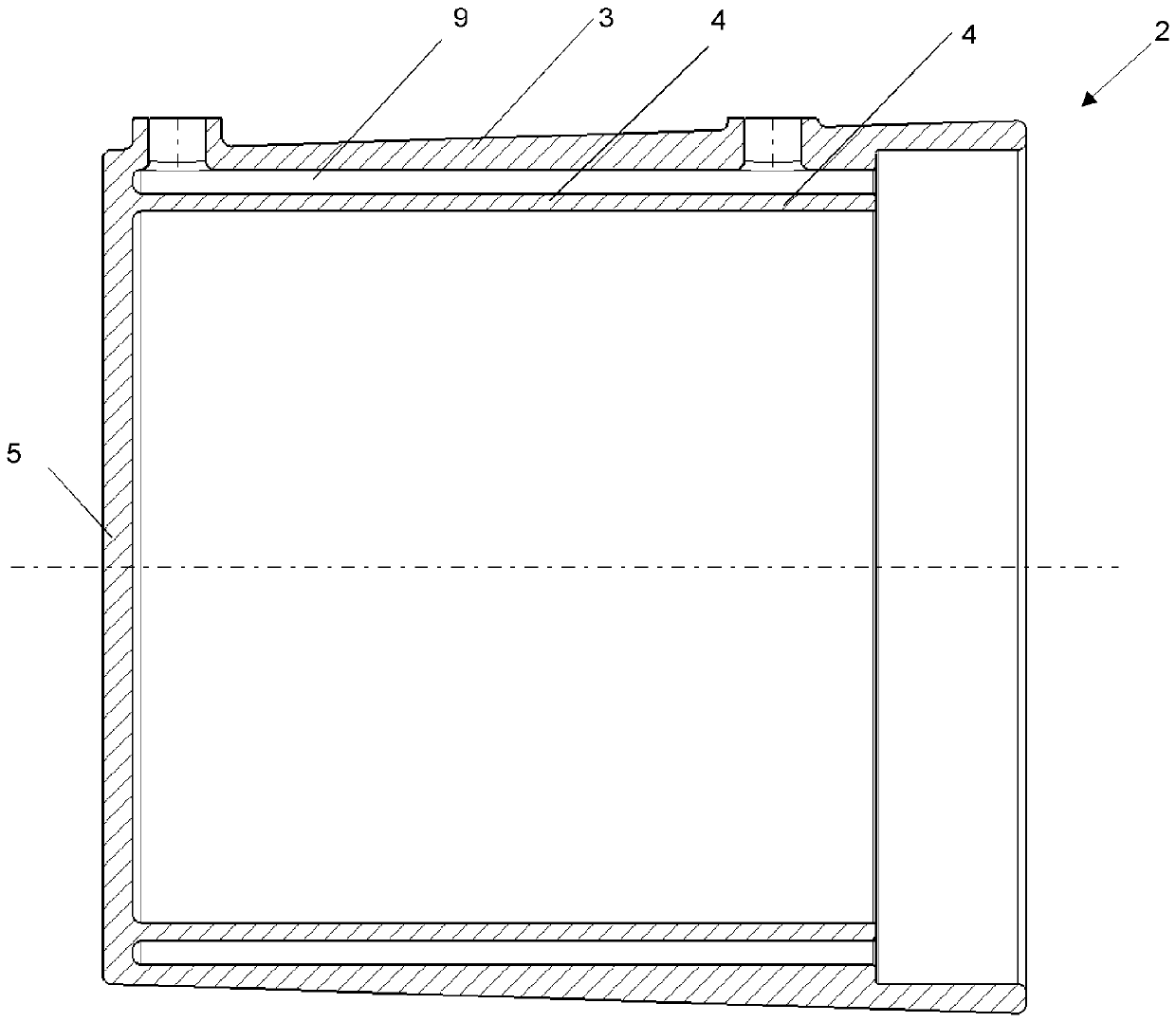

Fluid storage and purification integrated device for fuel cell and fluid cooling system of fuel cell

InactiveCN102403521ALess sealing pointsImprove reliabilityFuel cell auxillariesFuel cellsEngineering

The invention discloses a fluid storage and purification integrated device for a fuel cell and a fluid cooling system of the fuel cell. The fluid storage and purification integrated device comprises a box body, a fluid storage chamber is arranged in the box body and is used for storing cooling fluid, the top part of the box body is provided with a gas release valve, the box body is provided with a cooling fluid inlet and a cooling fluid outlet, the cooling fluid inlet and the cooling fluid outlet are communicated with the fluid storage chamber, the cooling fluid outlet is arranged in the middle lower part of the box body, a porous cooling fluid purification element is also arranged in the fluid storage chamber and between the inlet and the outlet, and the effective volume of the fluid storage chamber non-filled by the purification element can meet fluid storage requirements for supplying the cooling fluid to the cooling circulation system of the fuel cell. Since the fluid storage, purification and even heating are integrated in the integrated device, the pipeline of the cooling circulation system of the fuel cell can be simplified and reduced, the number of sealing points can be reduced, the influence of bubbles on distribution of the cooling fluid in galvanic pile can be reduced, the number of fluid supply control components and operation can also be reduced, all the cooling fluid can be maintained in the fluid state in low-temperature environments, and the operating reliability of the system can be improved.

Owner:武汉银泰科技燃料电池有限公司

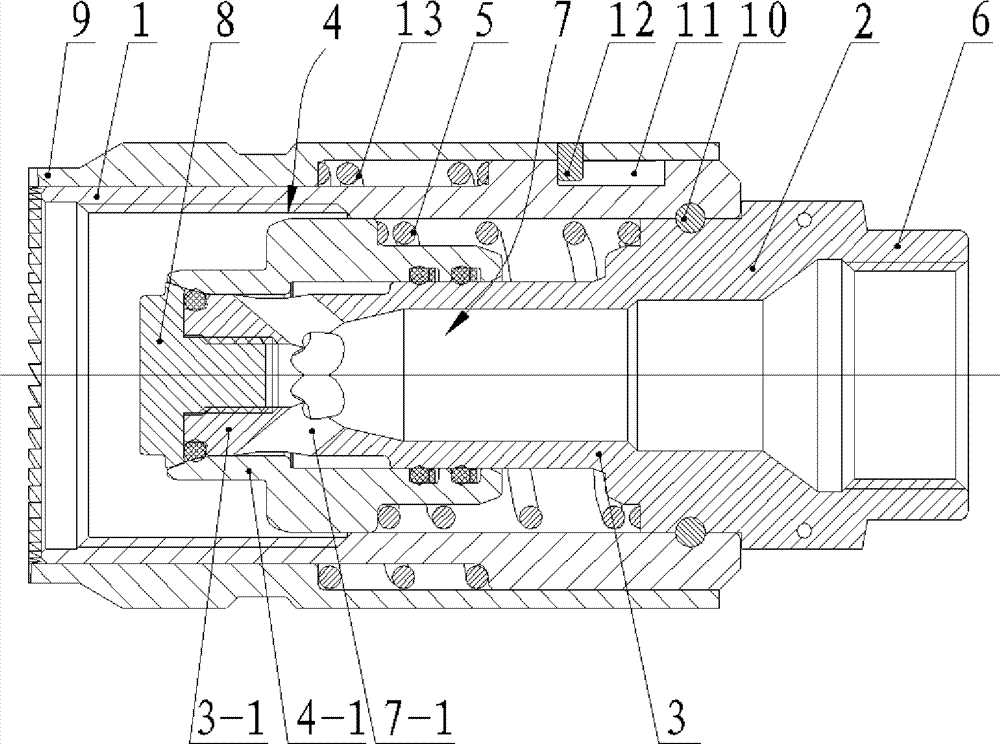

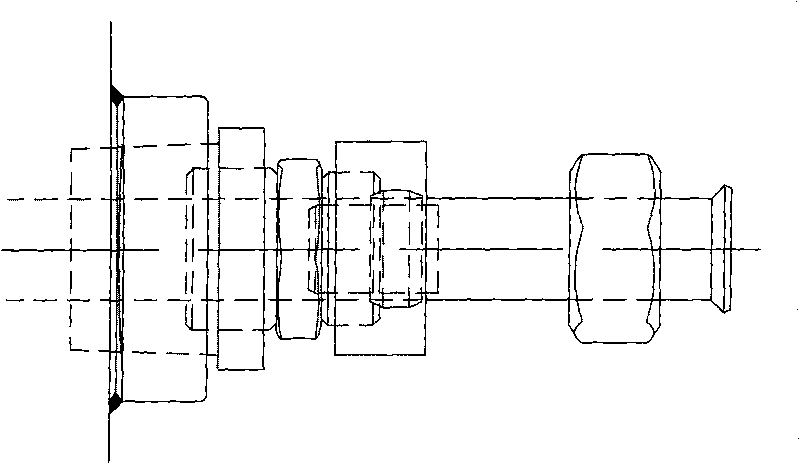

Bistable permanent magnetism hydraulic valve for hydraulic pressure spring operating mechanism

InactiveCN101251198ARegardless of operating characteristicsSimple structureOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

The invention provides a bistable permanent magnet hydraulic valve for a hydraulic spring operation mechanism, belonging to the high pressure breaker switch field; the invention is disclosed aiming at resolving problems existing in the prior hydraulic valve of complicated structure and easy occurrence of refusing operation; the invention consists of a valve body and a permanent magnet valve, wherein the valve body is provided inside with a valve core; the right part of the valve body is provided with a bistable permanent magnet valve which is provided inside with a moving iron core, a driving rod of which is connected with the valve core. The bistable permanent magnet valve comprises a magnetic yoke, a closing coil, the moving iron core, a permanent magnetic ring and a trip coil, wherein the magnetic yoke is provided inside with a separation wall which is provided with the trip coil on the left side, the closing coil on the right side and a permanent magnet in the central part; the central space of the closing coil, the permanent magnet and the trip coil is provided inside with the moving iron core, the left end and the right end of which are provided with a left connecting rod and a right connecting rod respectively; the left connecting rod is connected with the valve core, and the right connecting rod extends out of the magnetic yoke. The lower part of the valve body is provided with oil channels communicated with oil zones in the valve body. The bistable permanent magnet hydraulic valve has the advantages of simple structure, flexible action, safety and reliability and long service life.

Owner:SHENYANG POLYTECHNIC UNIV

Repulsion reversing valve for extra-high voltage series compensation bypass switch

ActiveCN102403139BMeet technical requirementsFast conversionOperating means/releasing devices for valvesContact driving mechanismsSeries compensationEngineering

The invention provides a repulsion reversing valve for an extra-high pressure series compensation bypass switch, which comprises a valve body. A valve core is arranged in the valve body. The inside of the valve body is divided into a normally low pressure oil region, a working oil region, a normally high pressure oil region and a valve core moving region. The valve body is provided with a low pressure oil circuit connector, a working oil circuit connector and a high pressure oil circuit connector. A high pressure oil hole is arranged in the valve core. The right part of the valve body is provided with a repulsion valve. A drive rod of the repulsion valve is connected with the valve core. The middle part of the valve core is fixedly provided with a pressure maintenance wing. The pressure maintenance wing is always positioned in the working oil region and is arranged axially with the valve core. The reversing valve has the advantages of simple structure, high reliability, small volume, low cost, long service life and the like. When the reversing valve operates, the switching speed is high and the output characteristic is flexible. The static retentiveness of the reversing valve totally depends on the oil pressure. The bypass switch to which the reversing valve is adopted has closing time of 20ms to 25ms and breaking time of 26ms to 30ms. The technical requirement of an extra-high pressure series compensation device on the bypass switch can be totally met.

Owner:CHINA ELECTRIC POWER RES INST +1

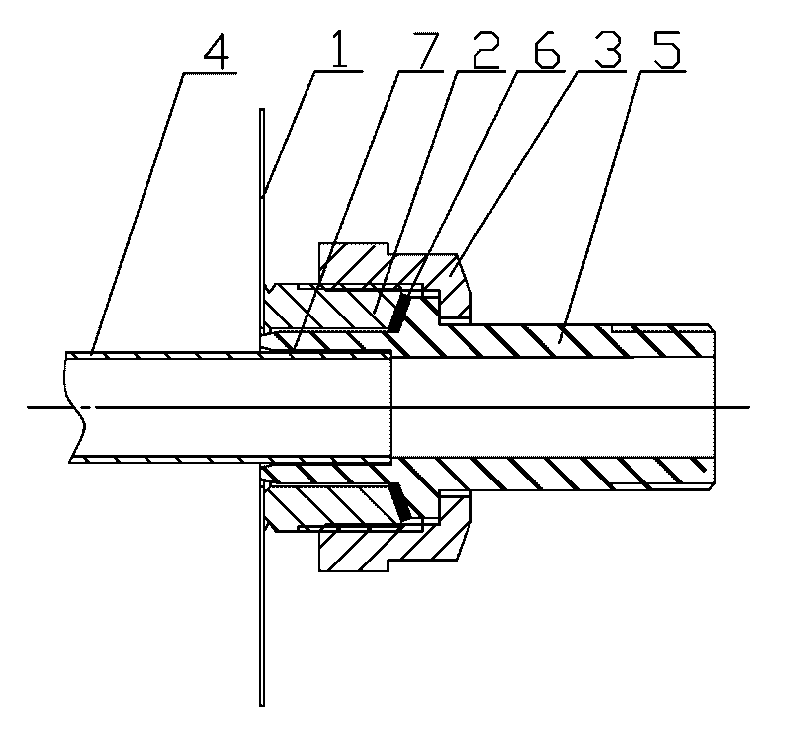

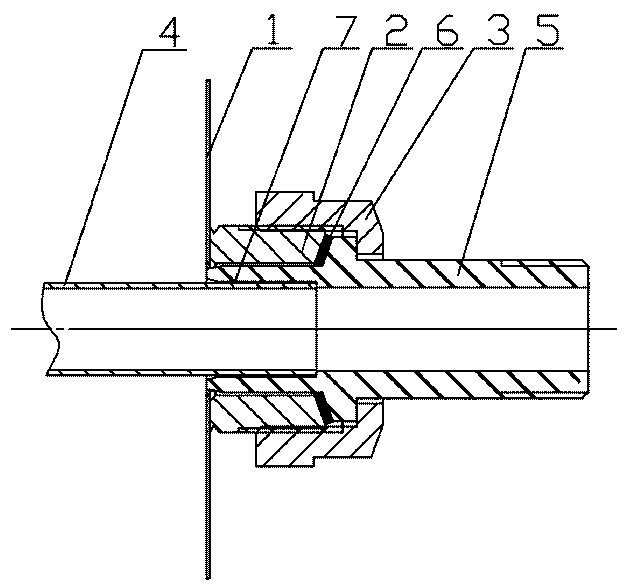

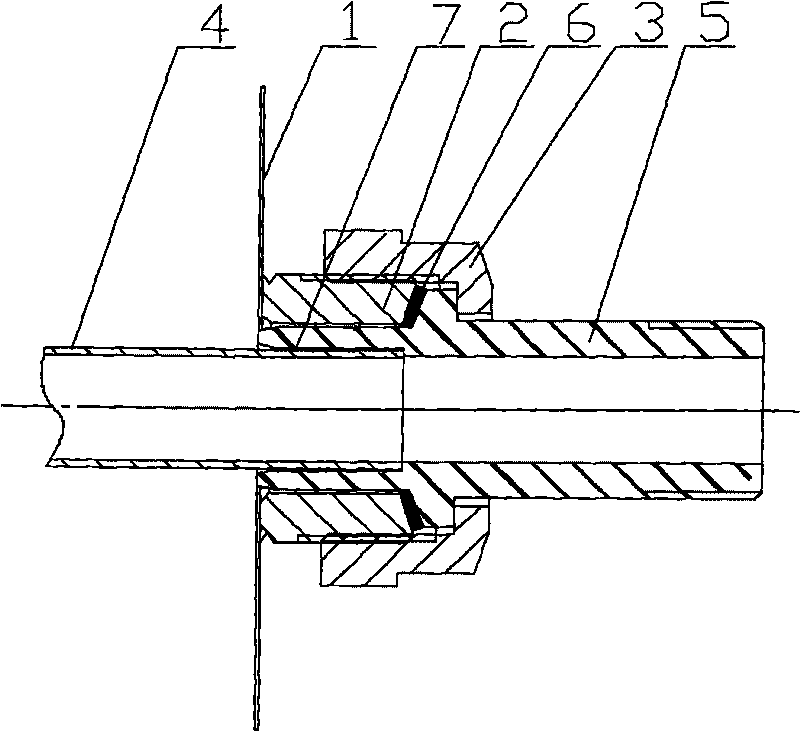

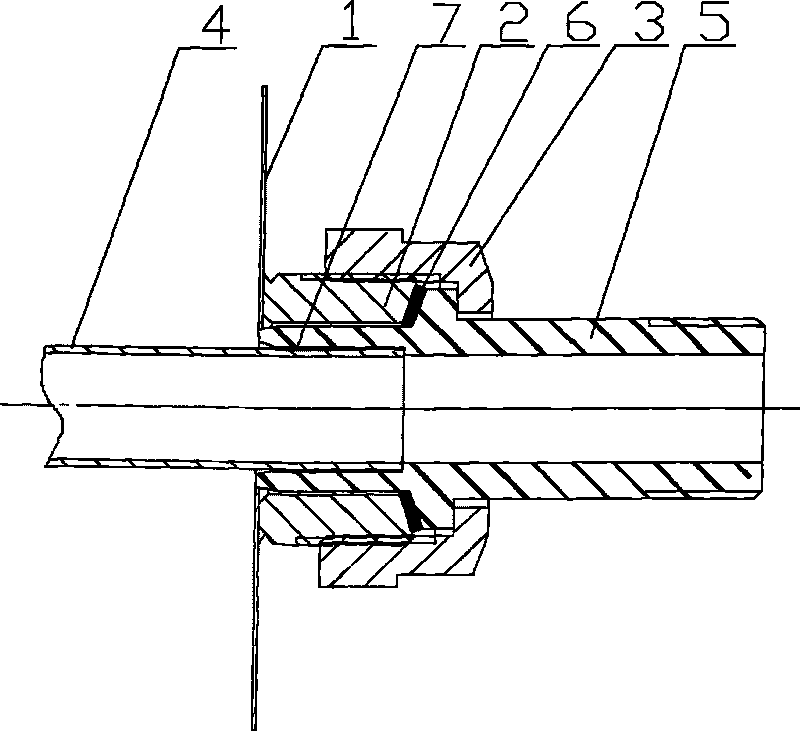

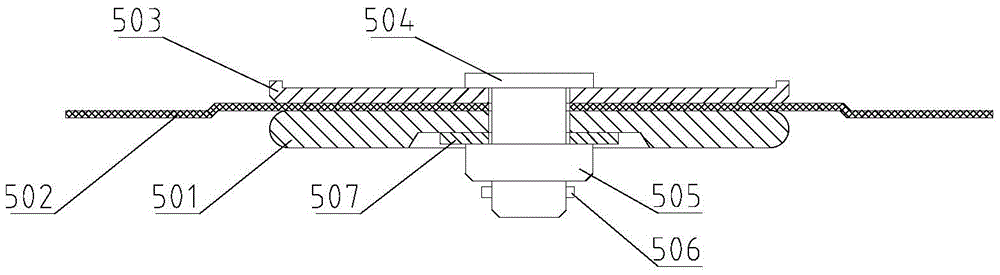

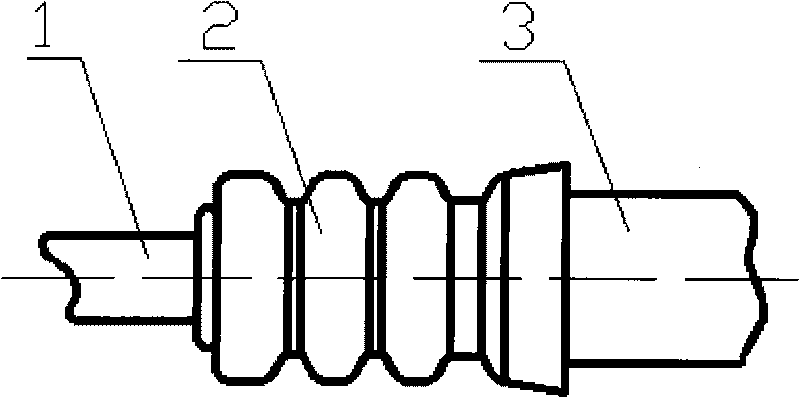

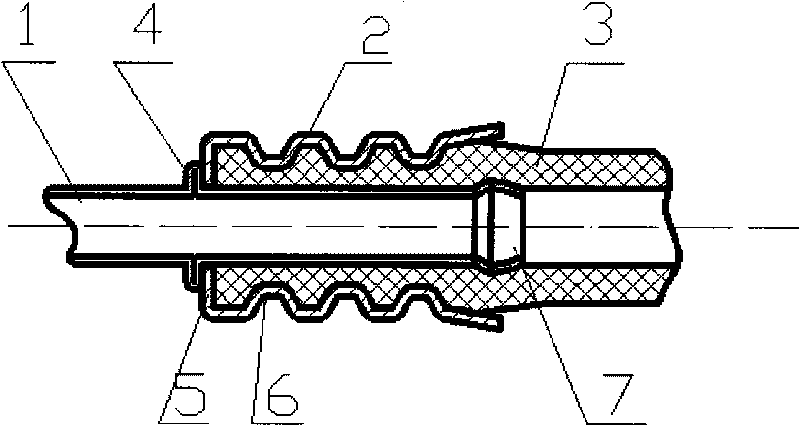

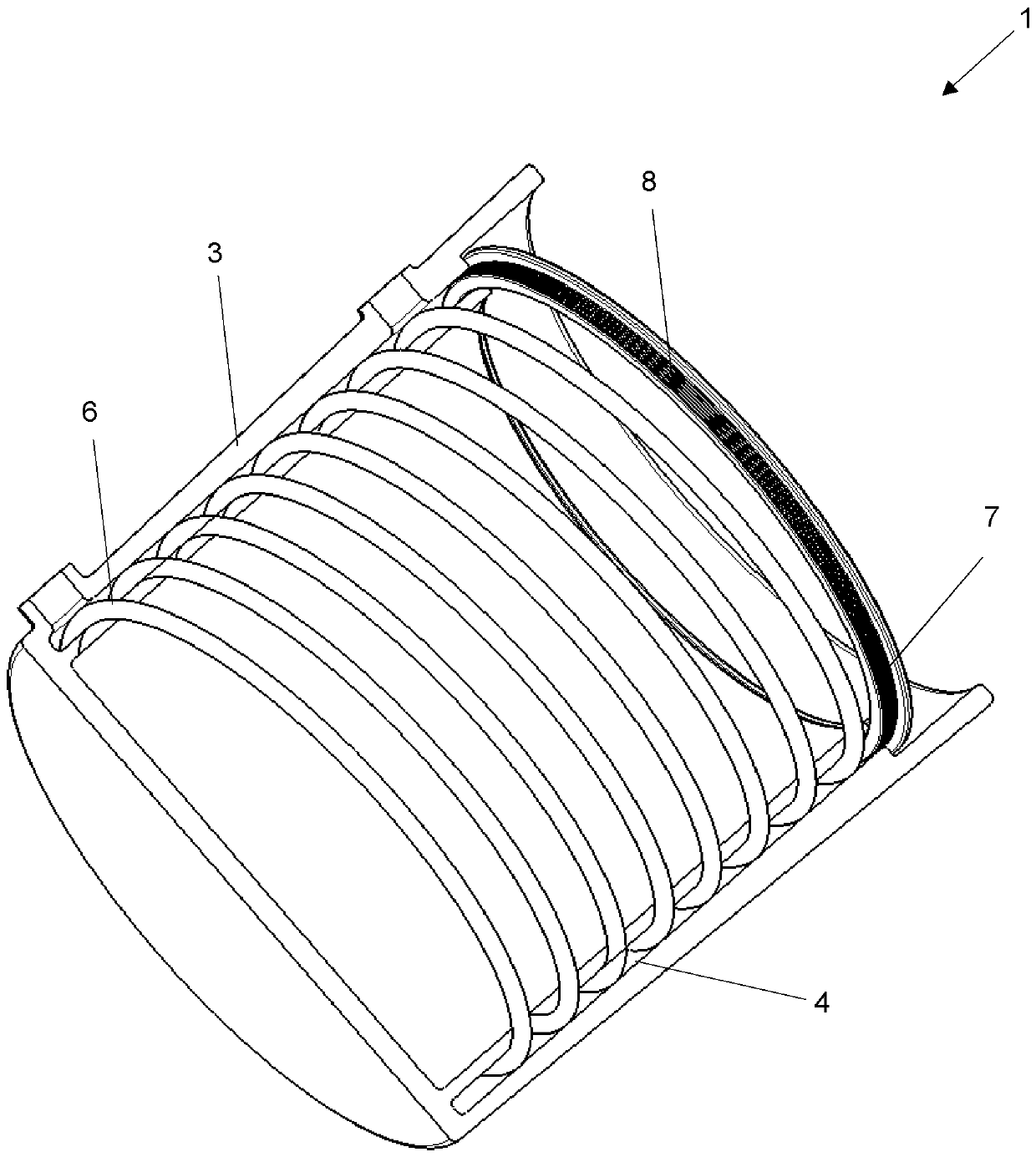

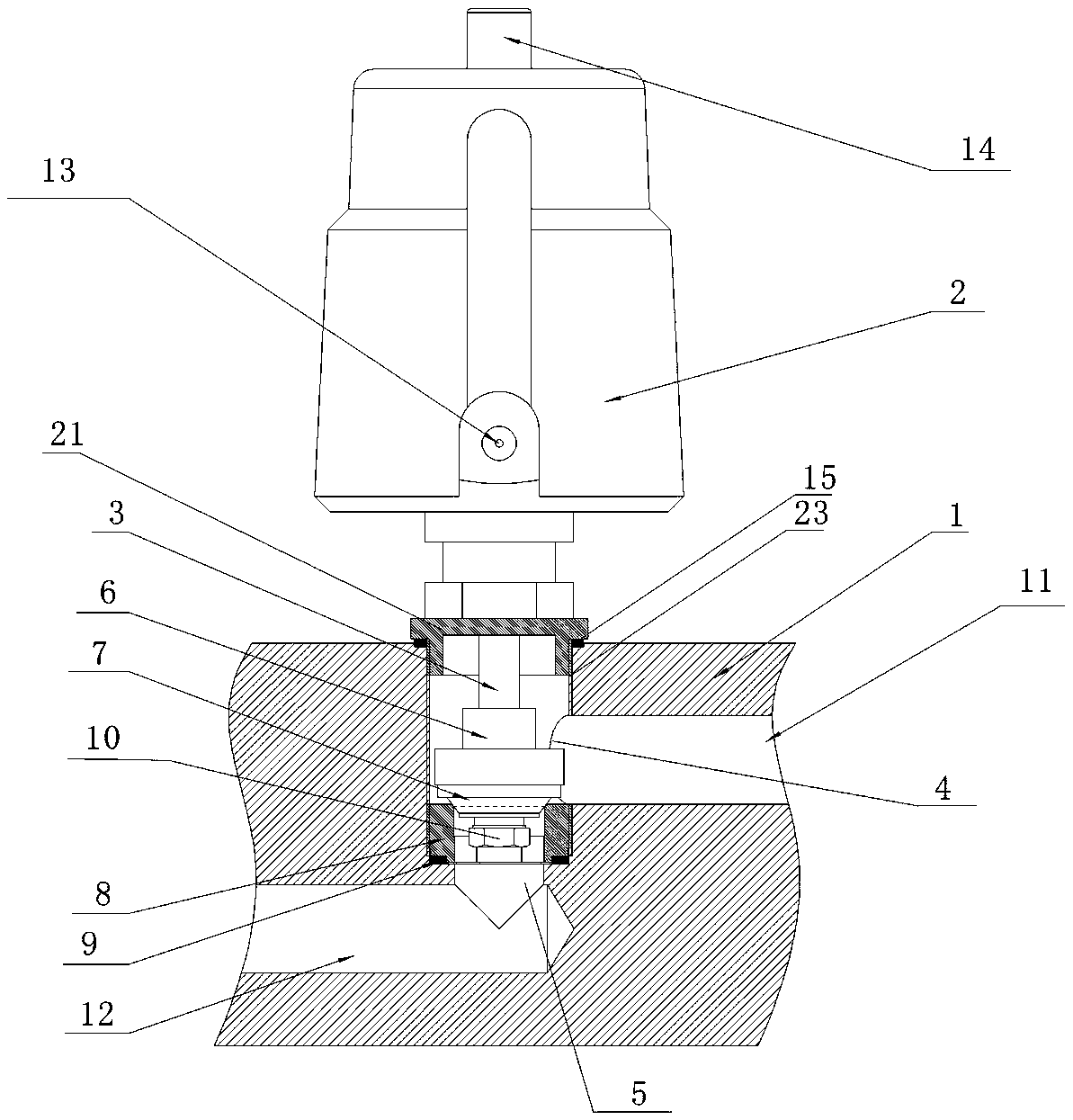

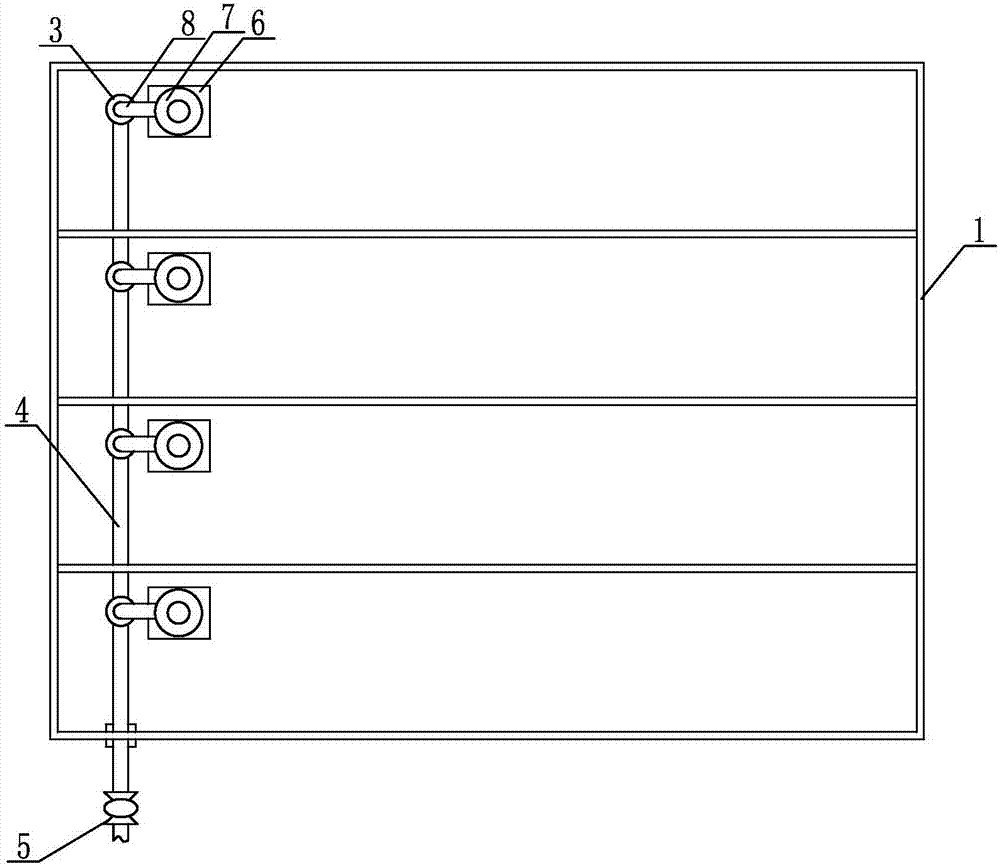

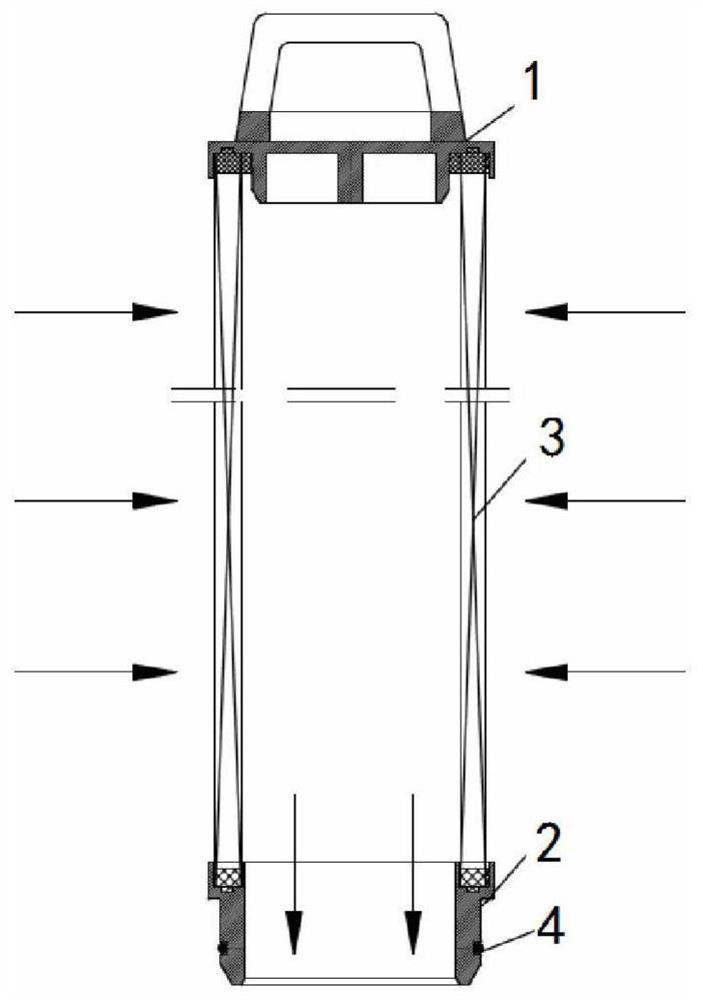

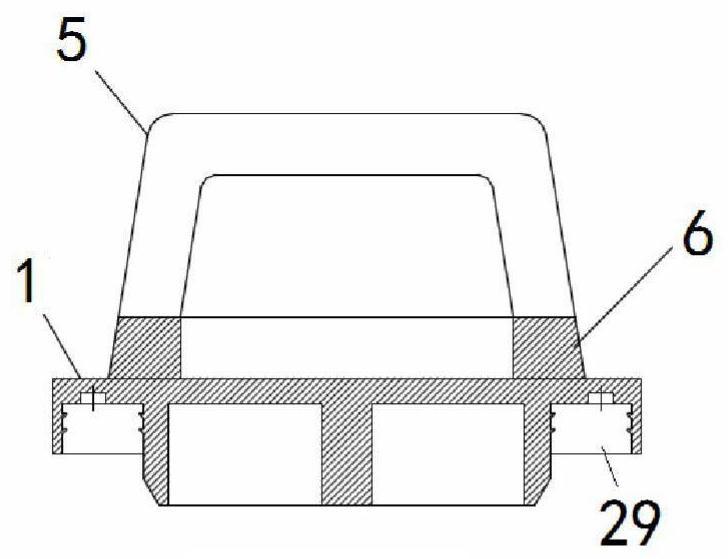

Sealing method for mounting coil pipe of solar water tank

InactiveCN101737980AReduce labor intensityLess sealing pointsSolar heat devicesSolar thermal energy generationSolar waterEngineering

The invention discloses a sealing method for mounting a coil pipe of a solar water tank, which comprises the following steps: extending a copper coil pipe (4) out of a mounting hole position of a water tank liner cylinder body (1), sheathing a sealing joint (5) with a butterfly sealing surface at the pipe end of the copper coil pipe (4), and welding the sheathed parts of the sealing joint (5) and the copper coil pipe (4) by adopting a silver-soldering brazing process; sheathing a sealing gasket (6) machined by a thin copper sheet on the butterfly sealing surface of the sealing joint (5), and inserting the welded sealing joint (5) into an inner hole of a pipe seat (2) for mounting in place; and sheathing a nut (3) on the sealing joint (5), and connecting and fastening the nut (3) and the screw thread on the pipe seat (2). The method of the invention has the advantages of low mounting requirement precision and simple operation, can reduce the labor intensity of workers, has relatively reliable sealing effect, and can prolong the service life.

Owner:JIANGSU GMO HI TECH

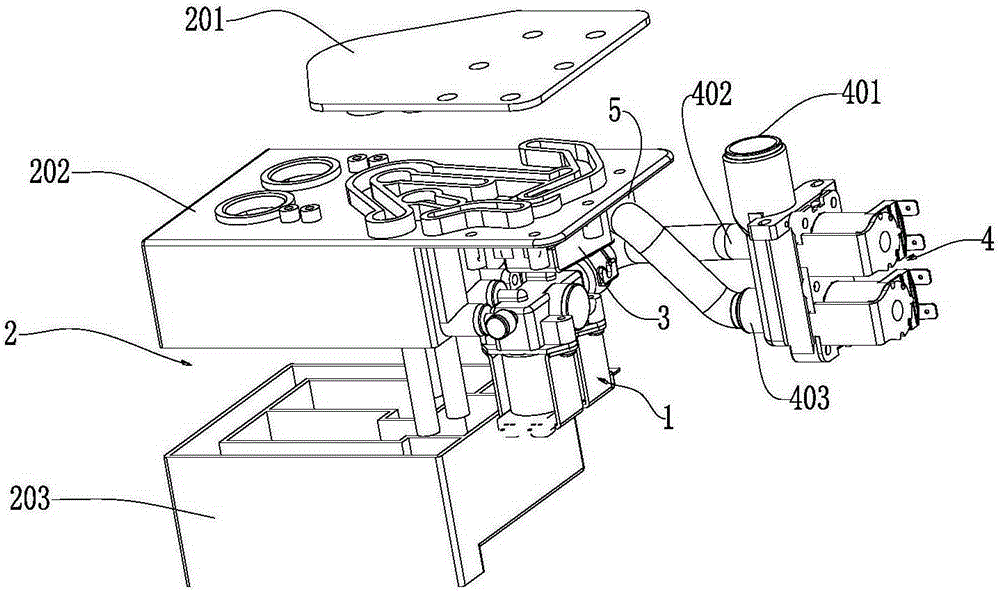

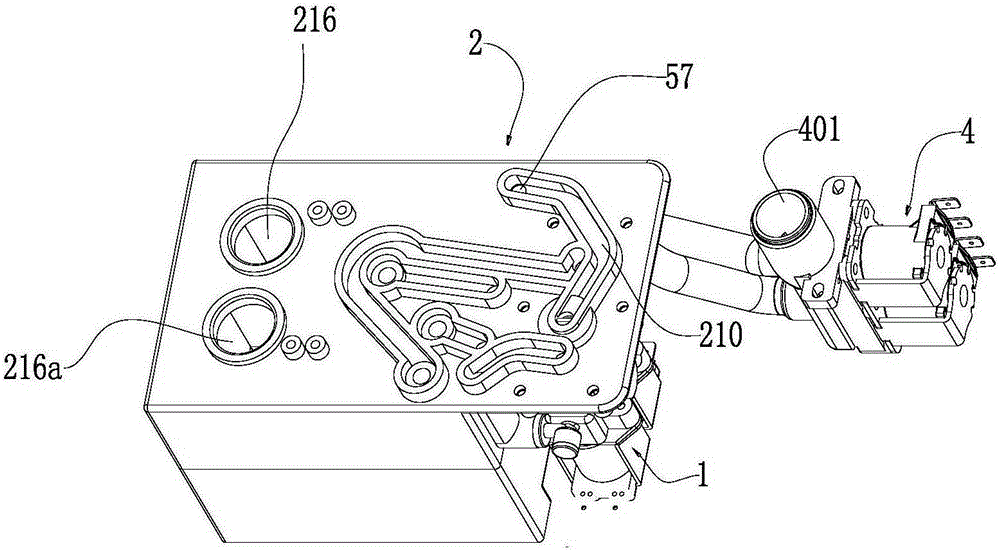

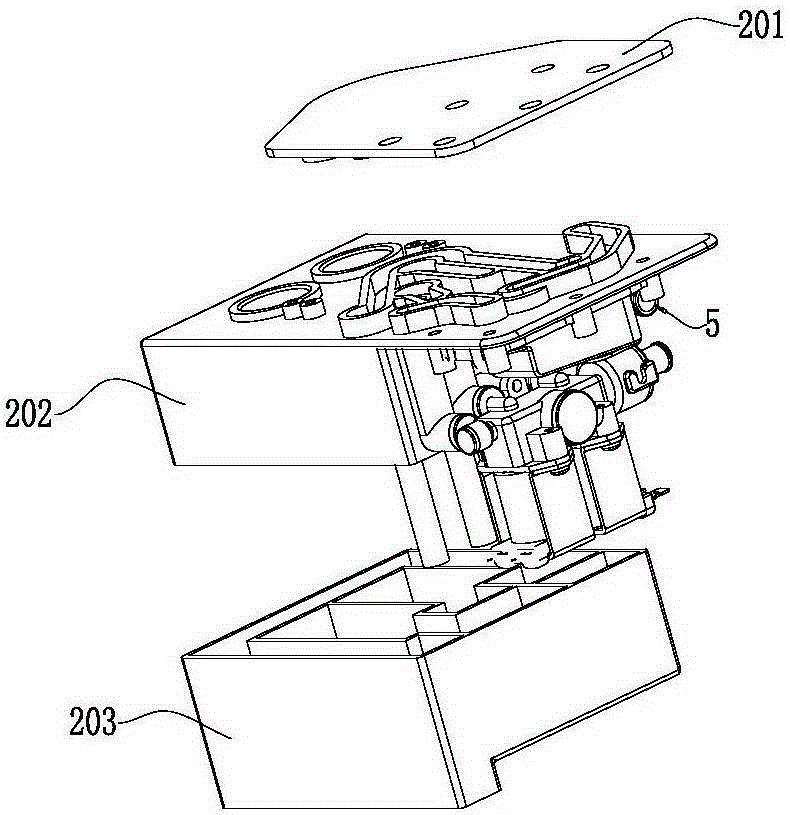

Fabric softener putting device used for washing machine

ActiveCN105239320AReduce complex and bloated structuresNovel and reasonable structureOther washing machinesTextiles and paperLaundry washing machineEngineering

The invention relates to a fabric softener putting device used for a washing machine. The fabric softener putting device used for the washing machine comprises a water inlet solenoid, a liquid storage box, a fixed capacity container, a fabric softener switch valve and a negative pressure generator. The liquid storage box is provided with a water box and a laundry detergent / fabric softener storage chamber. The fixed capacity container is provided with a laundry detergent inlet, a negative port and a drain outlet. The water inlet solenoid is provided with a water inlet, a first water outlet having a solenoid and a second outlet having a solenoid. The second water outlet is connected with the negative pressure generator, and a negative pressure port of the negative pressure generator is connected with the negative pressure port of the fixed capacity container. The fabric switch valve comprises a water inlet, a laundry detergent inlet, a fabric softener inlet, and a liquid outlet. The laundry detergent / fabric softener storage chamber is connected with the fabric softener switch valve. The water inlet solenoid is connected with the water inlet of the fabric softener switch valve. The fabric softener switch valve is connected with the laundry detergent inlet of the fixed capacity container, and the drain outlet of the fixed capacity container is connected with the water box. The putting device is low in manufacturing cost, high in precision, convenient to switch, and the fabric softener hardly jam.

Owner:JINHUA HONGCHANG ELECTRLCAL EQUIP CO LTD

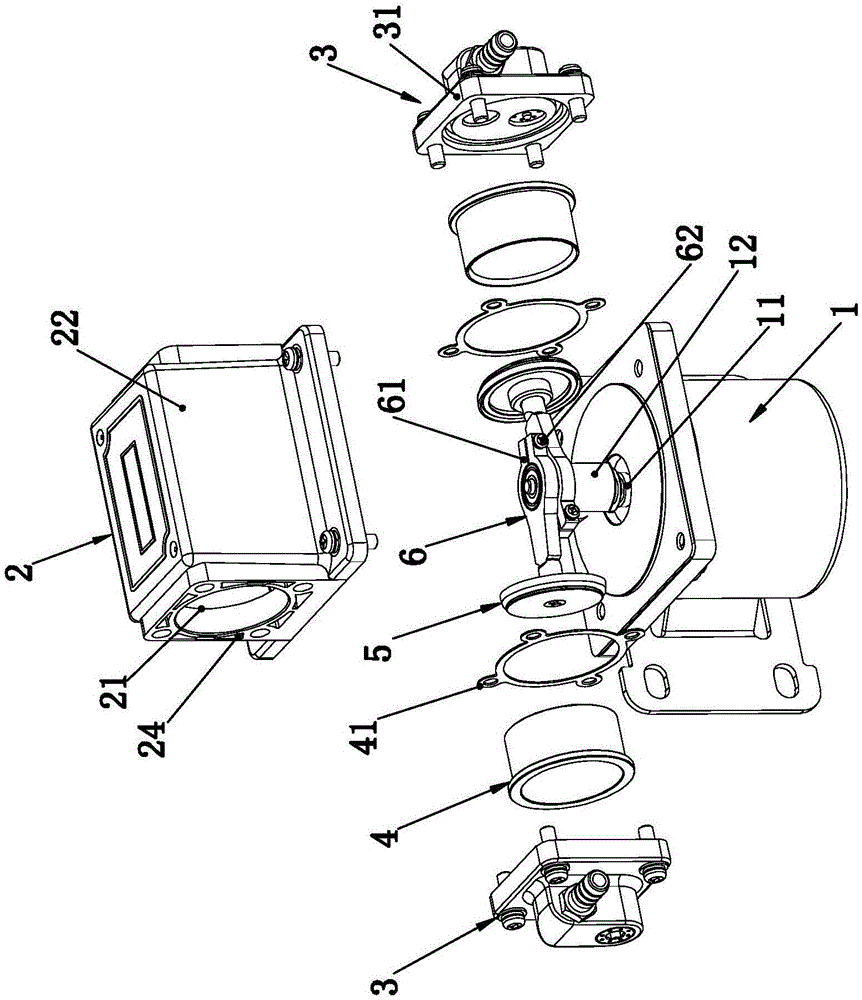

Electric automobile vacuum pump

ActiveCN106224201AImprove sealingEasy to assemblePositive displacement pump componentsPiston pumpsEngineeringVacuum pump

The invention relates to automobile spare parts, in particular to an electric automobile vacuum pump. The invention has the technical scheme that the electric automobile vacuum pump comprises a motor, a pump shell, installation openings arranged on the pump shell, one-way valves and cylinder sleeves arranged on the installation openings, and piston rubber cups arranged in the cylinder sleeves. The piston rubber cups are connected with a motor shaft of the motor through a connecting rod through a crankshaft; the installation openings are arranged on the two ends in a longitudinal direction of the pump shell; the cylinder sleeves and the one-way valves connected with the pump shell are arranged on the installation openings; the two ends in a transverse direction of the pump shell are sealed end faces; one-way valve sealing gaskets with the peripheral surfaces being sealed with inner walls of air inlet passageways and exhaust passageways are clamped in the air inlet passageways and the exhaust passageways of the one-way valves; and air inlet one-way valve plates and exhaust one-way valve plates are arranged on the one-way valve sealing gaskets. By adopting the technical scheme, the invention provides the electric automobile vacuum pump, which is capable of keeping the concentricity when the connecting rod and the installation openings of the pump shell are assembled, good in sealing performance, reduced in noise, and simple in structure.

Owner:浙江品达机动车部件有限公司

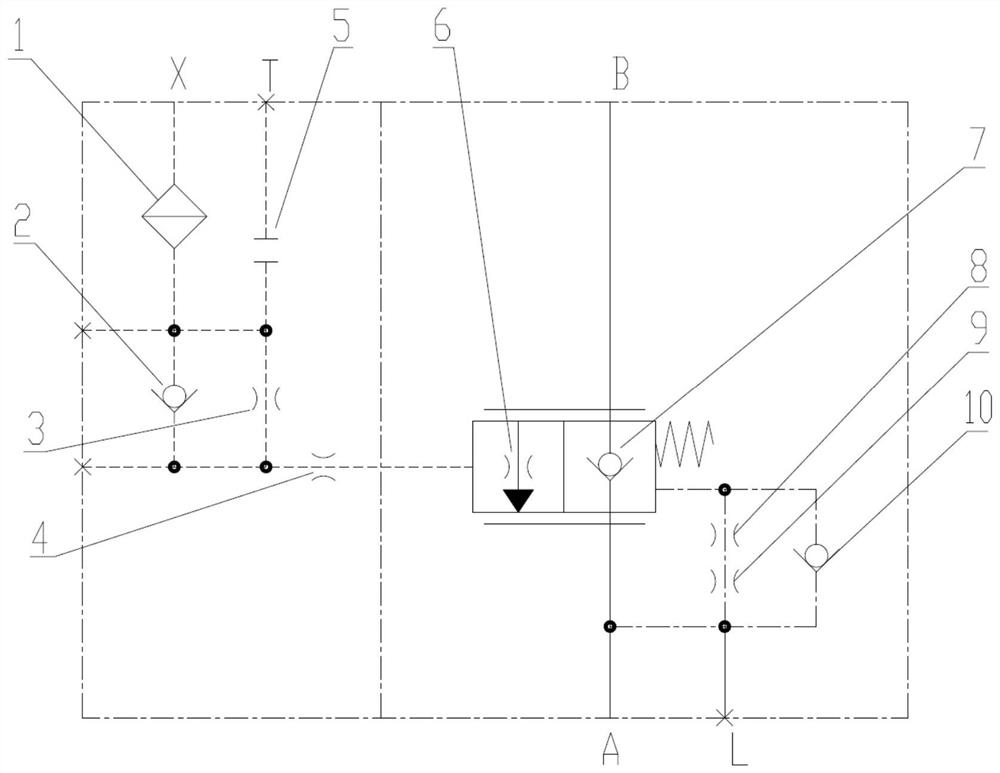

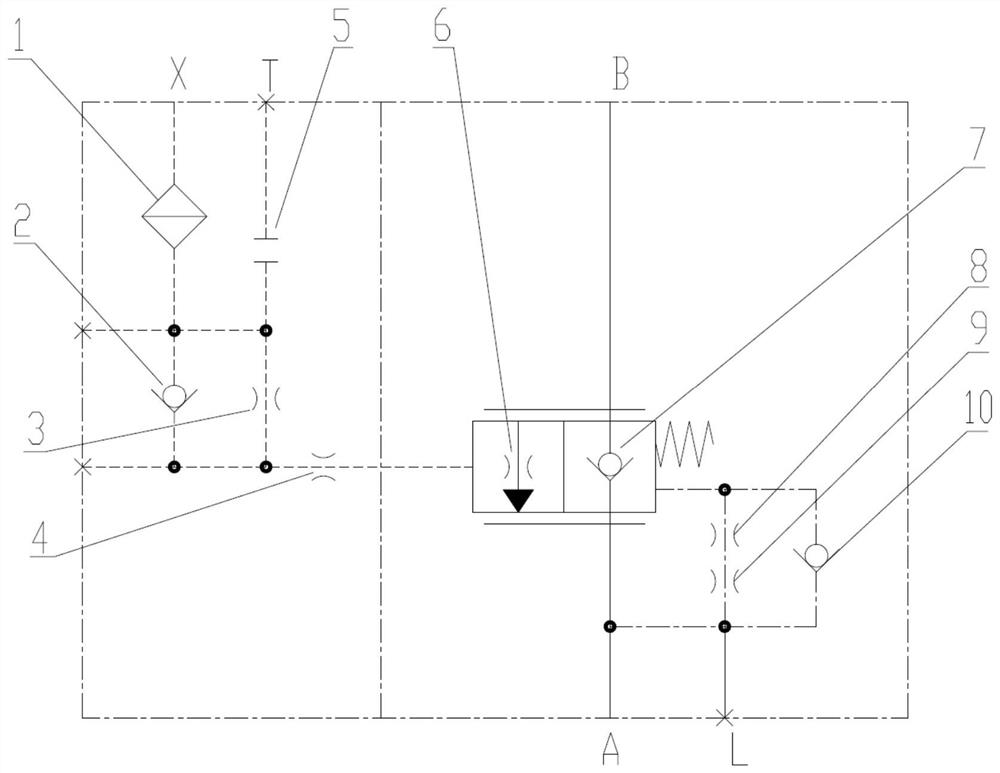

Hydrodynamic compensation balance valve

The invention discloses a hydrodynamic compensation balance valve. A pilot control end cover assembly comprises a control end cover valve body, and a pilot oil channel is arranged on the control end cover valve body; a valve element assembly comprises a throttling valve element, a main spring and an adjusting valve seat; a one-way valve seat assembly comprises a one-way valve and a one-way valve spring; a balance valve body assembly comprises a balance valve body and a valve seat; the throttling valve element is provided with a throttling opening with the angle of alpha; the right end inner wall conical surface of the one-way valve is mutually matched with a throttling opening conical surface of the throttling valve element to form opening and closing sealing; and the one-way valve moves to the left when the amplitude of variation rises, the one-way valve function of the balance valve to an oil opening B from an oil opening A is realized, the throttling valve element is started to theright under the action of pilot control pressure when the amplitude of variation declines, the balance valve function from the oil opening B to the oil opening A is realized, with the increasing of loading pressure, the opening size of the throttling opening of the throttling valve element is controlled by hydrodynamics generated by an annular overcurrent channel with the angle of the throttling valve element of alpha, and load-flow compensation is realized.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

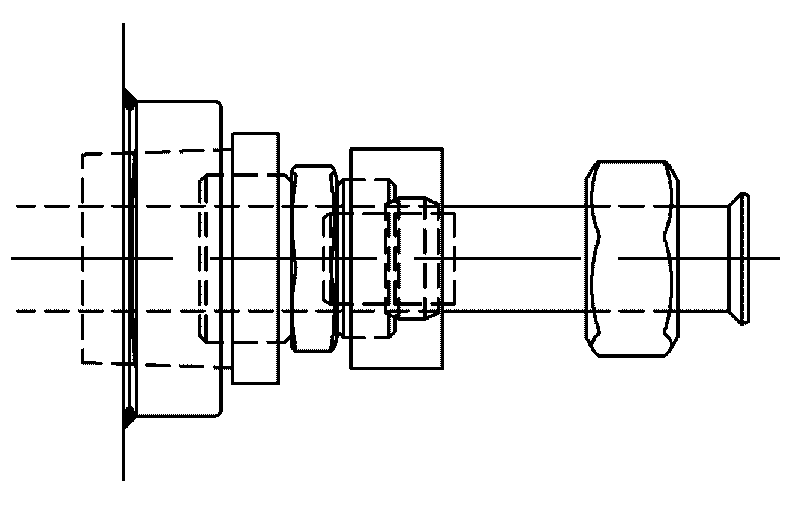

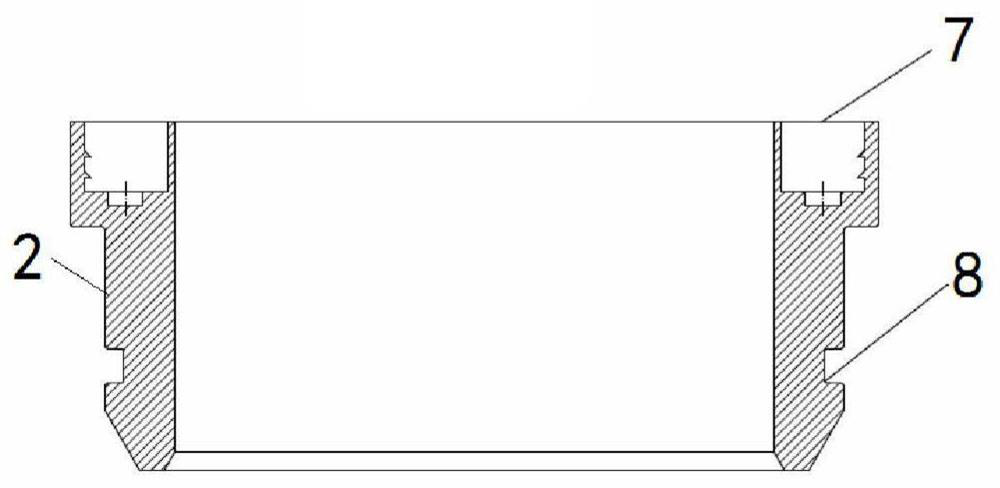

Coil pipe mounting and sealing structure for solar water tank

InactiveCN101737978AReduce labor intensityLess sealing pointsSolar heat devicesSolar thermal energy generationSolar waterEngineering

The invention discloses a coil pipe mounting and sealing structure for a solar water tank. The coil structure comprises a water tank liner cylinder body (1), a pipe seat (2) and a nut (3), wherein the pipe seat (2) is welded to the water tank liner cylinder body (1); a sealing joint (5) is arranged between a coil pipe (4) and the pipe seat (2); the sealing joint (5) is welded with the coil pipe (4) together; a metal sealing gasket (6) is arranged between the butterfly contact faces of the sealing joint (5) and the pipe seat (2); the nut (3) is sleeved on the sealing joint (5); and the nut (3) and the pipe seat (2) are fastened and connected through screw threads. By adopting the structure, because of few parts, the sealing point is few, the mounting requirement precision is low, the operation is simple, and the labor intensity of workers can be reduced; and the sealing effect is comparatively reliable, the possibility of leakage does not exist, and the service life can be prolonged.

Owner:JIANGSU GMO HI TECH

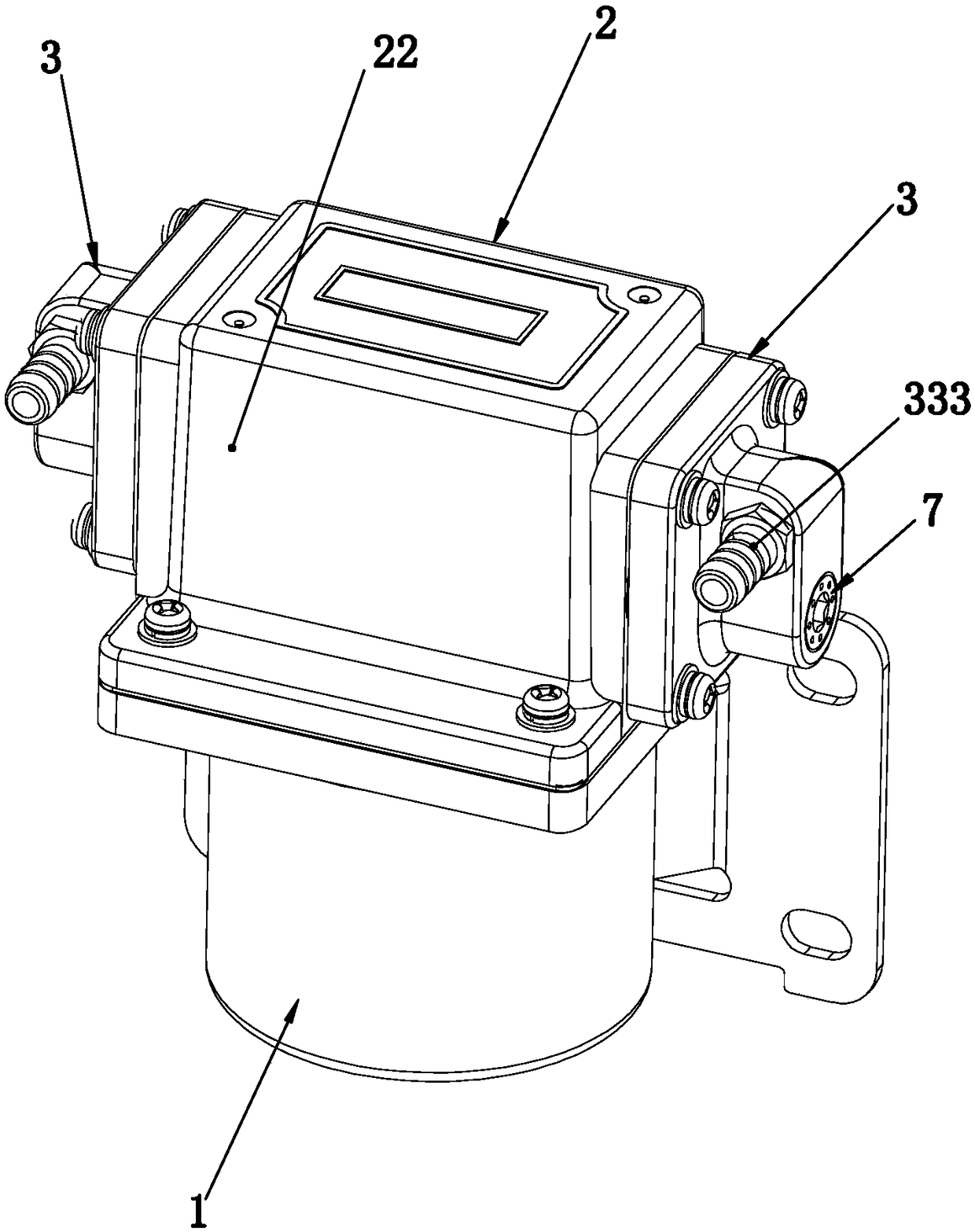

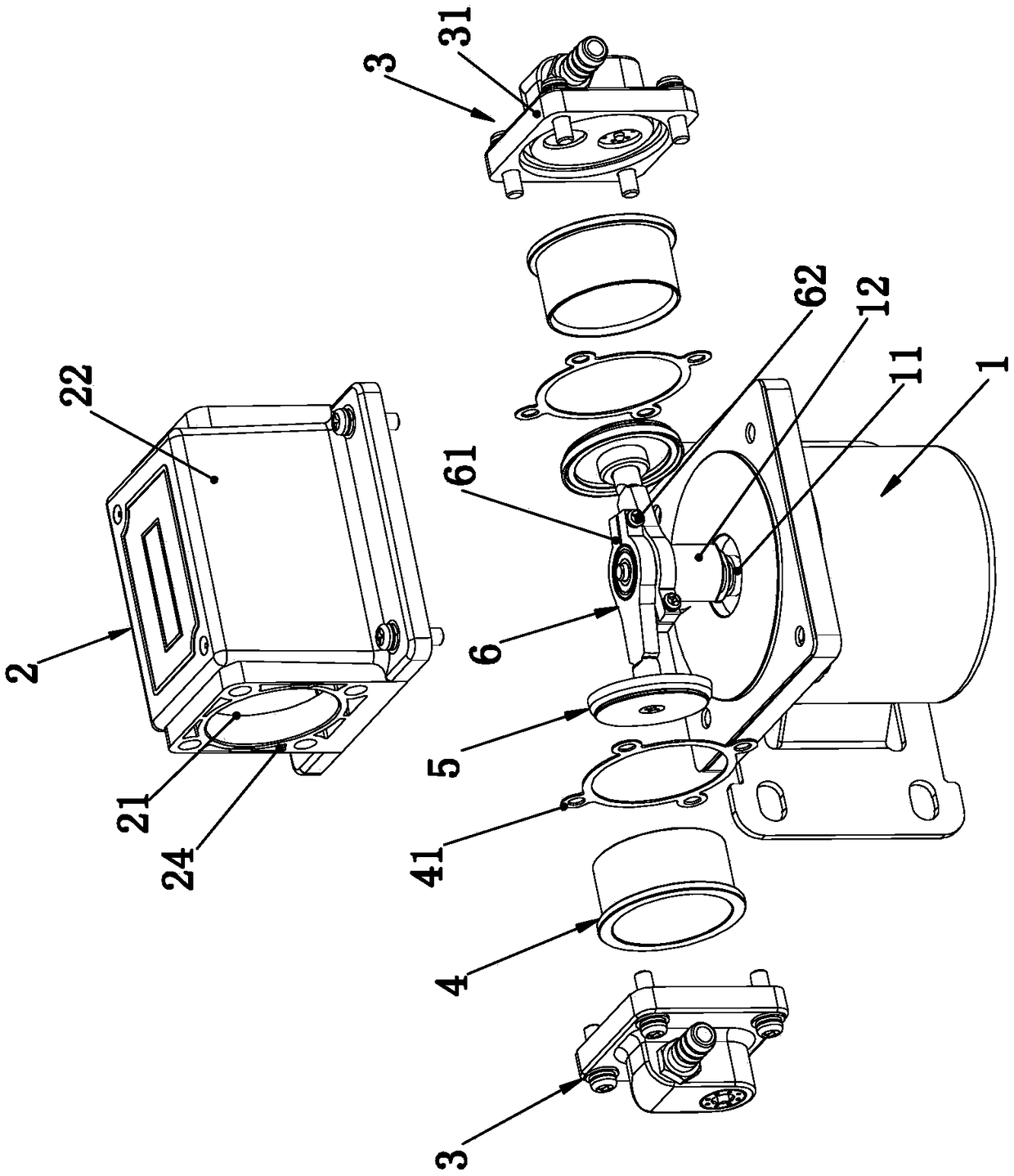

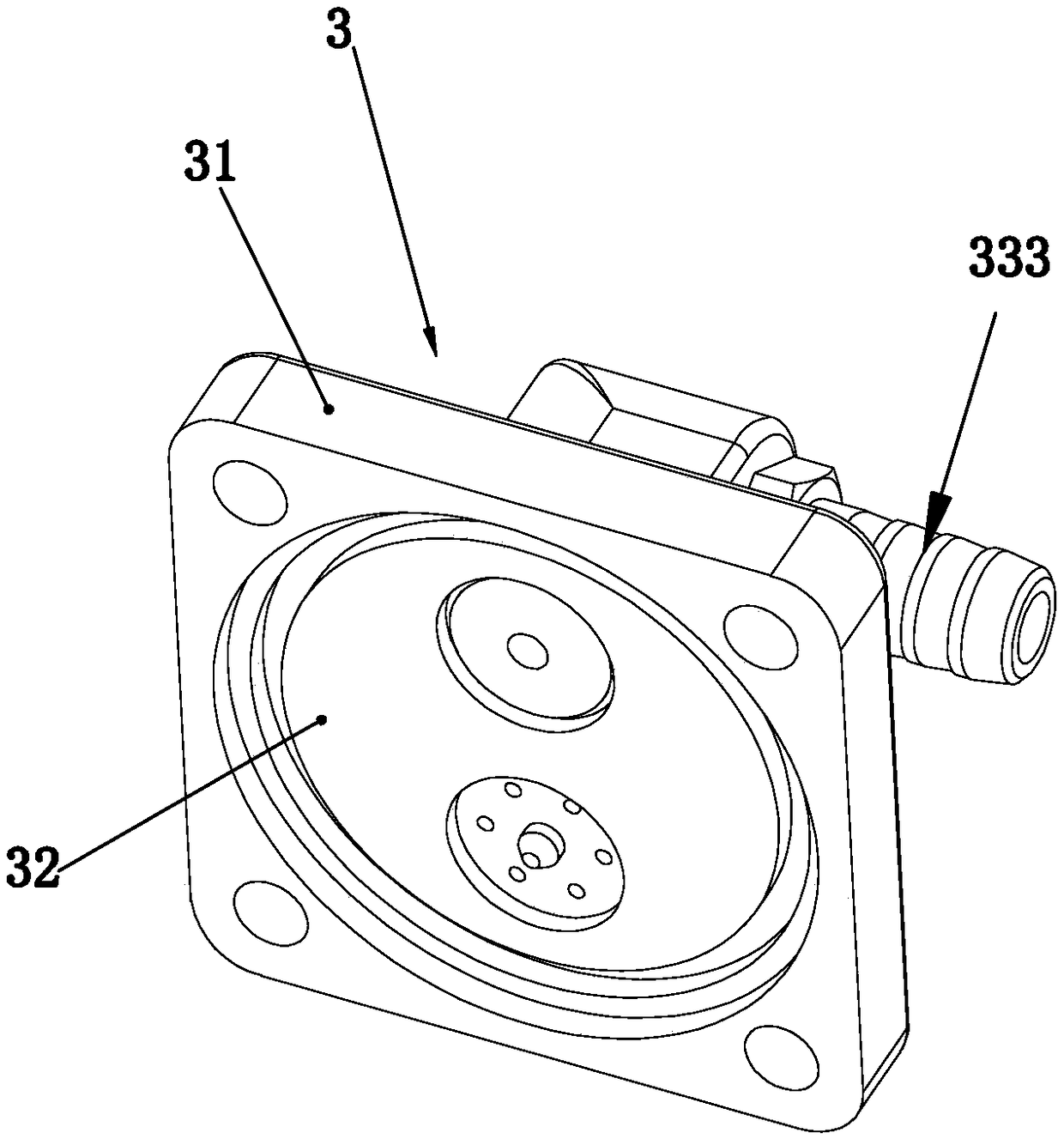

Electric vehicle vacuum pump

ActiveCN106224201BImprove sealingEasy to assemblePositive displacement pump componentsPiston pumpsElectric machineElectric vehicle

The invention relates to automobile spare parts, in particular to an electric automobile vacuum pump. The invention has the technical scheme that the electric automobile vacuum pump comprises a motor, a pump shell, installation openings arranged on the pump shell, one-way valves and cylinder sleeves arranged on the installation openings, and piston rubber cups arranged in the cylinder sleeves. The piston rubber cups are connected with a motor shaft of the motor through a connecting rod through a crankshaft; the installation openings are arranged on the two ends in a longitudinal direction of the pump shell; the cylinder sleeves and the one-way valves connected with the pump shell are arranged on the installation openings; the two ends in a transverse direction of the pump shell are sealed end faces; one-way valve sealing gaskets with the peripheral surfaces being sealed with inner walls of air inlet passageways and exhaust passageways are clamped in the air inlet passageways and the exhaust passageways of the one-way valves; and air inlet one-way valve plates and exhaust one-way valve plates are arranged on the one-way valve sealing gaskets. By adopting the technical scheme, the invention provides the electric automobile vacuum pump, which is capable of keeping the concentricity when the connecting rod and the installation openings of the pump shell are assembled, good in sealing performance, reduced in noise, and simple in structure.

Owner:浙江品达机动车部件有限公司

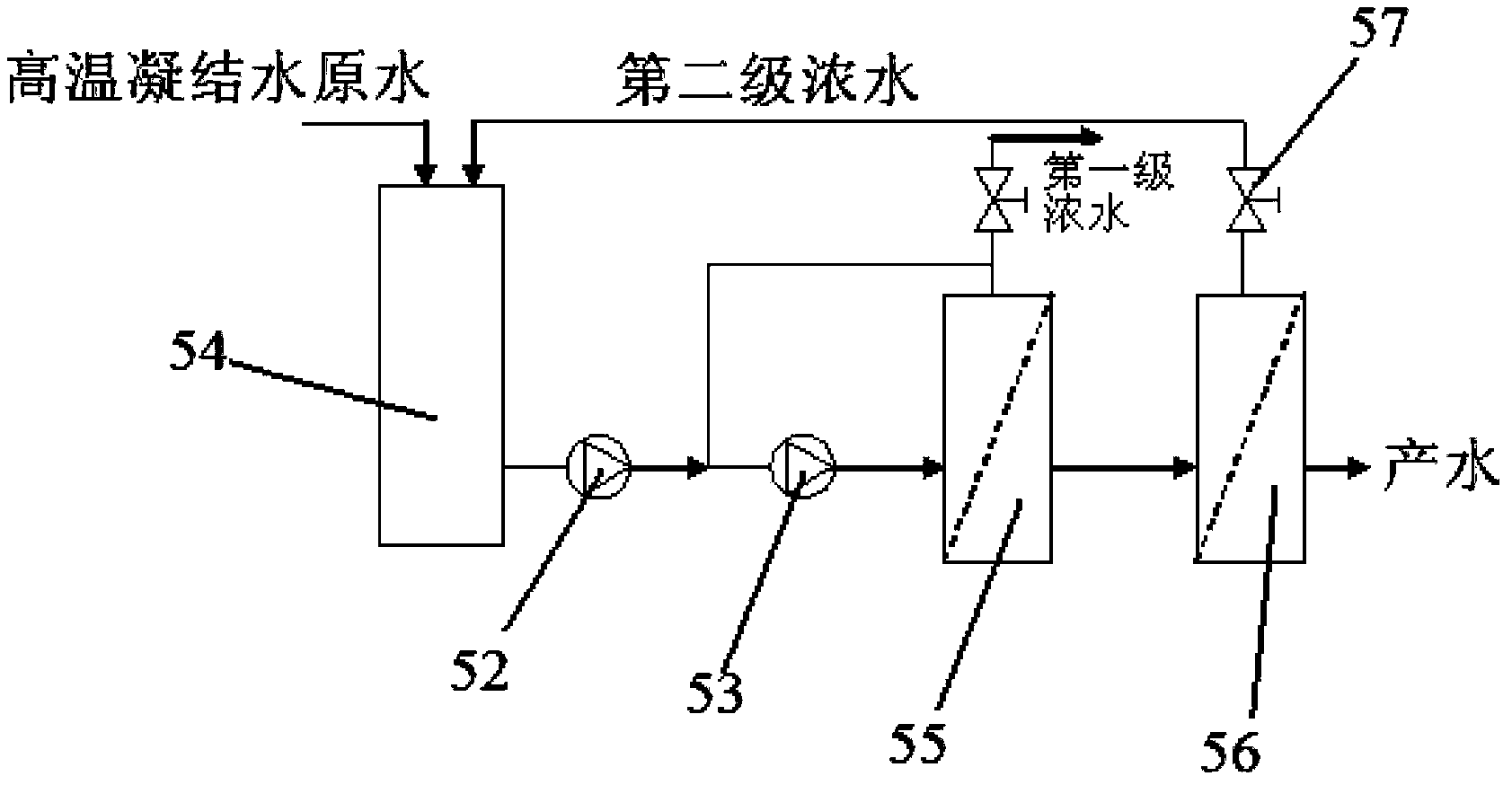

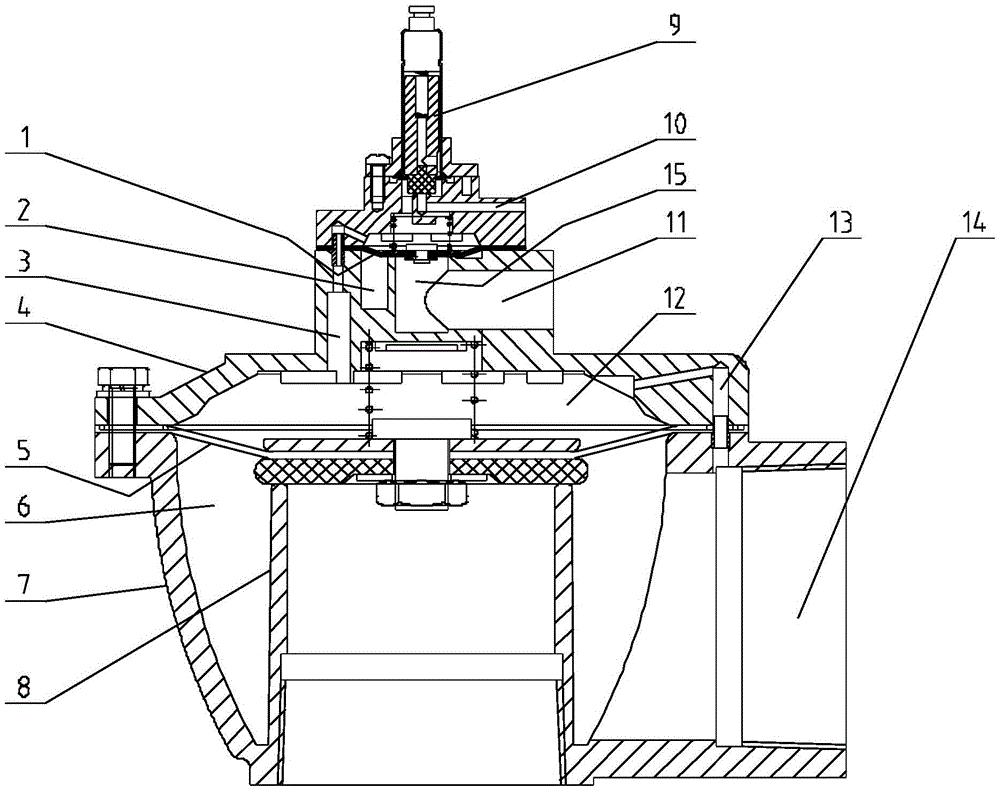

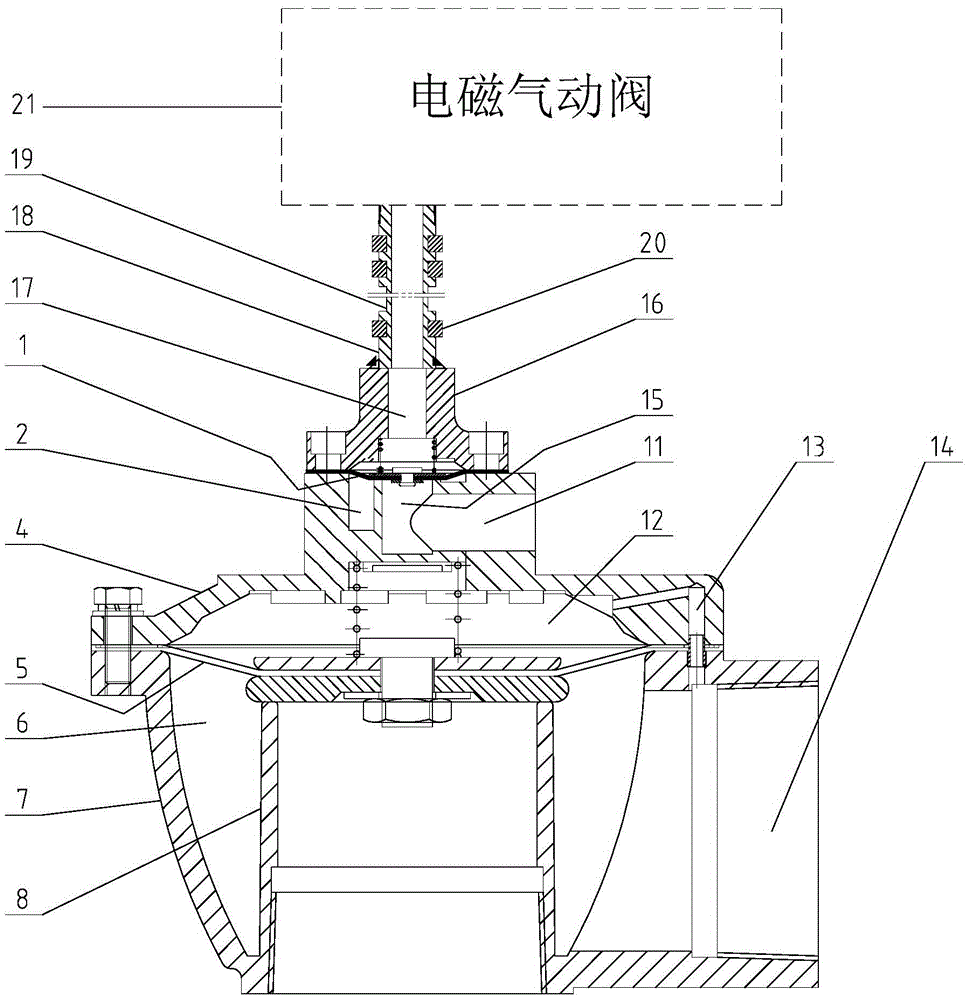

pulse valve

ActiveCN103574092BLess sealing pointsImprove high temperature performanceDiaphragm valvesOperating means/releasing devices for valvesPneumatic valveVALVE PORT

The invention discloses a pulse valve which can improve the use performance in high-temperature gas. The pulse valve comprises a valve consisting of a valve body and a valve deck, wherein a moving diaphragm which can move forward and backward is mounted between the valve body and the valve deck; a valve port which can be closed by the moving diaphragm in forward movement position is formed in the valve body; an upper moving diaphragm which can move forward and backward is arranged at the top of the valve deck, and a gland whose gas path is independent from the valve is mounted at the top of the valve deck; the upper moving diaphragm is mounted between the gland and the valve deck and maintained by a spring located between the upper moving diaphragm and the gland, and a return chamber which is adaptive to the upper moving diaphragm is formed in the bottom of the gland; when the upper moving diaphragm moves backwards toward the return chamber, a gas inlet chamber and a gas exhaust chamber are communicated; and a gas vent communicated with the return chamber is formed in the gland and connected with an electromagnetic pneumatic valve, so that control gas controlling the upper moving diaphragm to move forward and backward is input into the gas vent or discharged from the gas vent through the electromagnetic pneumatic valve.

Owner:CHENGDU INTERMENT TECH

Straight-through proportional valve

PendingCN110107796ASimple structureReduce volumeProportioning devicesOperating means/releasing devices for valvesEngineeringPiston

The invention relates to a proportional valve, in particular to a straight-through proportional valve. The proportional valve comprises a proportional valve body, and a proportional hole, an oil inlethole and an oil outlet hole are formed in the proportional valve body, wherein both the oil inlet hole and the oil outlet hole communicate with the proportional hole; a proportional valve rod is arranged at one end of a proportional valve core, the proportional valve core is inserted into the proportional hole in a sliding mode, proportional pistons are respectively inserted into the proportionalvalve rod and the proportional hole in a sliding mode, and an oil storage cavity is formed by the proportional pistons and the proportional valve core; a limiting nut is fixed at the tail end of theproportional valve rod; a proportional seat is fixed at one end of the proportional hole, a valve rod hole is formed in the proportional seat, and the proportional valve rod and the limiting nut are movably inserted into the valve rod hole; a valve core driving device is connected with the proportional valve core, and the valve core driving device is used for driving the proportional valve core tomove in a reciprocating manner in the proportional hole; when the proportional valve core and the proportional pistons move in a reciprocating mode in the proportional hole, the oil storage cavity communicates with the oil inlet hole and the oil outlet hole. The straight-through proportional valve is simple in structure, small in size and convenient to use, is provided with few sealing points, can reduce leakage points and is convenient to maintain.

Owner:XINTAI JIAXING HYDRAULIC MACHINERY CO LTD

Pipe expanding connection structure of vehicle high-pressure oil pipe

InactiveCN101758806AReach molding size requirementsLow costElectric/fluid circuitMachine partsHigh pressure

The invention relates to a pipe expanding connection structure of a vehicle high-pressure oil pipe. The structure comprises a metal pipe, wherein a rubber hose is sleeved outside the front end of the metal pipe, and a metallic sheath is sleeved outside the rubber hose; the front end of the metal pipe is directly expanded and molded; a circular bulge and a circular check ring are molded in sequence at the position near the end of the metal pipe; the rubber hose is sleeved correspondingly outside the circular bulge of the metal pipe, and the end of the rubber hose closes to the circular check ring of the metal pipe; the metallic sheath is sleeved outside the rubber hose, and the end of the metallic sheath is provided with a circular blocking edge to be pressed on the circular check ring of the metal pipe; and the part of the metallic sheath correspondingly closing to the position between the circular check ring and the circular bulge of the metal pipe is locked in the radial direction to form a contraction part. Compared with the connection structure of the prior art, the combination of the parts such as machining parts and the like can be reduced, and the sealing risk and the production cost are lowered, therefore, the pipe expanding connection structure improves the flexibility, the variety and the reliability of connection, so as to be more applicable to more extensive product forms and higher design requirements.

Owner:邱强

Super-large trolley type gas heat treatment furnace

InactiveCN102703650BSolve the problem of low efficiencyImprove efficiencyFurnace componentsEngineeringMechanical engineering

The invention relates to a super-large trolley type gas heat treatment furnace. The gas heat treatment furnace is characterized in that a fixed rear wall of the conventional furnace body is changed into a movable rear wall, a steel member of the movable rear wall is fixed on a travelling mechanism, and a lining is arranged on the lateral surface of the steel member; and a sealing mechanism is arranged on each of the upper, lower, left and right parts of the movable rear wall, so that the movable rear wall, the lining of the furnace body and a trolley are sealed. Moreover, a furnace door dropping preventing device is added in a furnace door and a lifting mechanism and drives a safety pin by means of a reset force of a spring, once the furnace door drops due to loss of pull, the safety pin quickly extends out, and the furnace door is clamped on upright posts on two sides of the furnace door, so that the furnace door is prevented from continuously dropping. The using efficiency of the super-large heat treatment furnace is effectively improved; energy waste caused by ineffective combustion in the redundant space is avoided; the sealing mechanisms of the movable rear wall are reasonable in structure, easy and convenient to operate and convenient to maintain, and can achieve good sealing performance and increase the overall energy-saving effect of the heat treatment furnace; and thefurnace door dropping preventing device promotes the running safety of the furnace body.

Owner:DANYANG JIANGNAN INDAL FURNACE

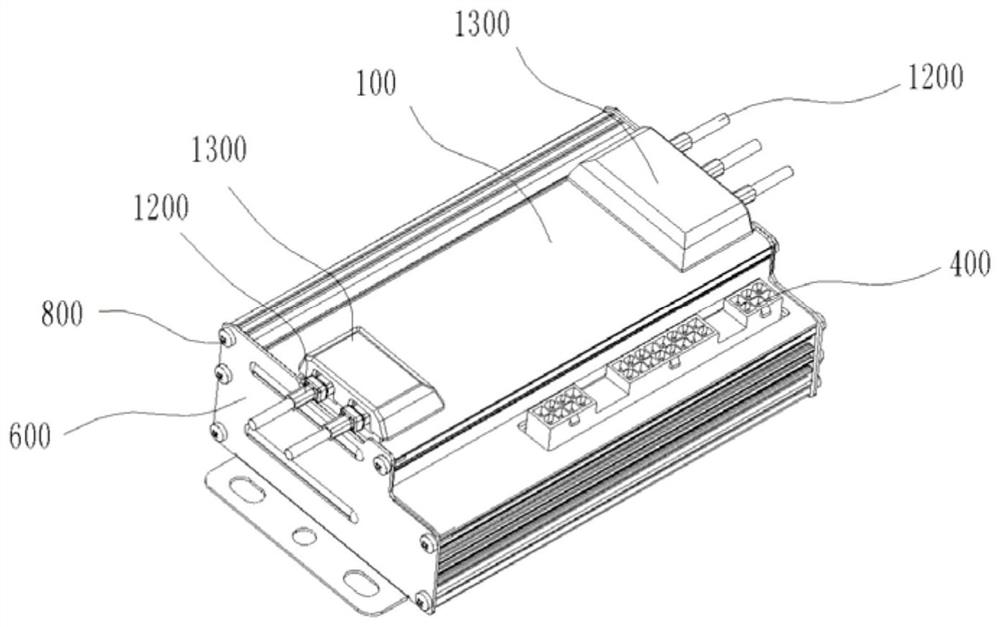

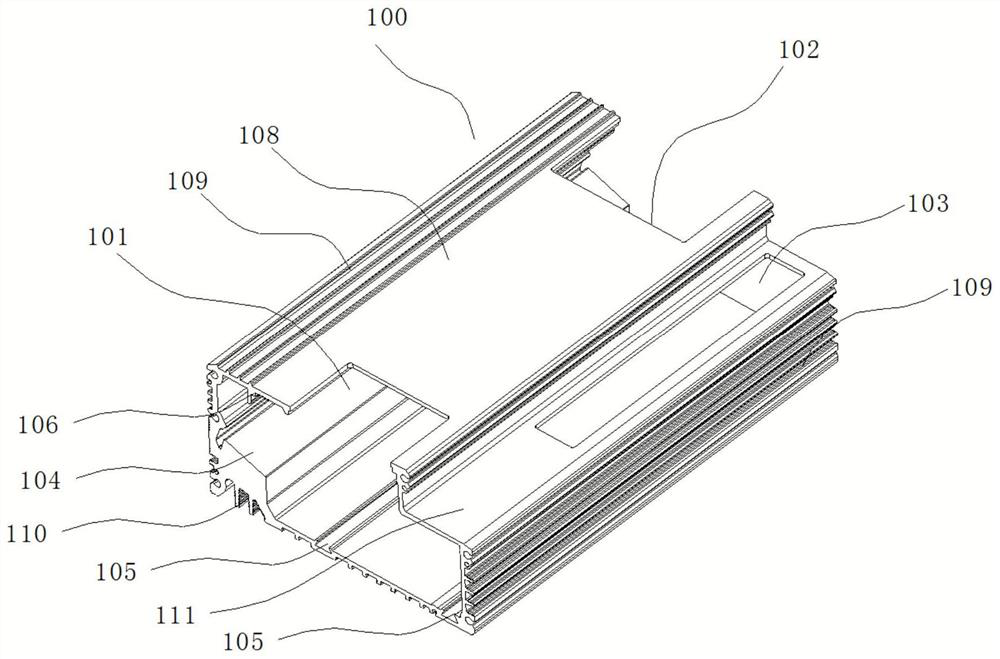

An electric vehicle controller

ActiveCN112291952BGood processing consistencySimple structureCasings with connectors and PCBCasings/cabinets/drawers detailsManufacturing technologyControl line

An electric vehicle controller provided by the present invention includes a casing, a terminal block, a pin socket, a circuit board and an end cover; the casing is made of stretched profiles, and the outer surface of the casing is divided into a flat surface and a heat dissipation rib surface. On the flat surface of the body, the upper two ends of the housing are respectively provided with a wiring seat gap to install the wiring seat, and the side of the housing is provided with a control line pin header socket hole to install the pin header socket; The cavity, corresponding to the notch side of the terminal block in the upper part of the shell, is provided with a rib for positioning the terminal block, and in the bottom or two sides of the shell, there is a perforated channel for installing the positioning member of the circuit board; The body is provided with a heat-conducting surface that fits the power tube; most of the exterior of the shell is provided with heat dissipation ribs. This structural design solves the contradiction between the two existing technologies, with simple and ingenious structure, good workmanship, high heat dissipation performance, low cost, and waterproof. It is reliable, and also plays the role of electromagnetic shielding; it improves the quality and standardization of electric vehicles, reduces the cost of the whole vehicle manufacturing process, and facilitates future maintenance.

Owner:WENLING JIUZHOU ELECTROMECHANICAL

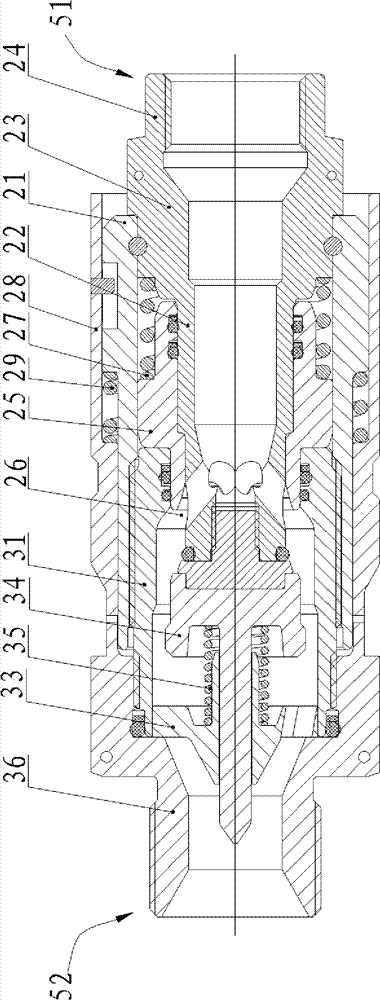

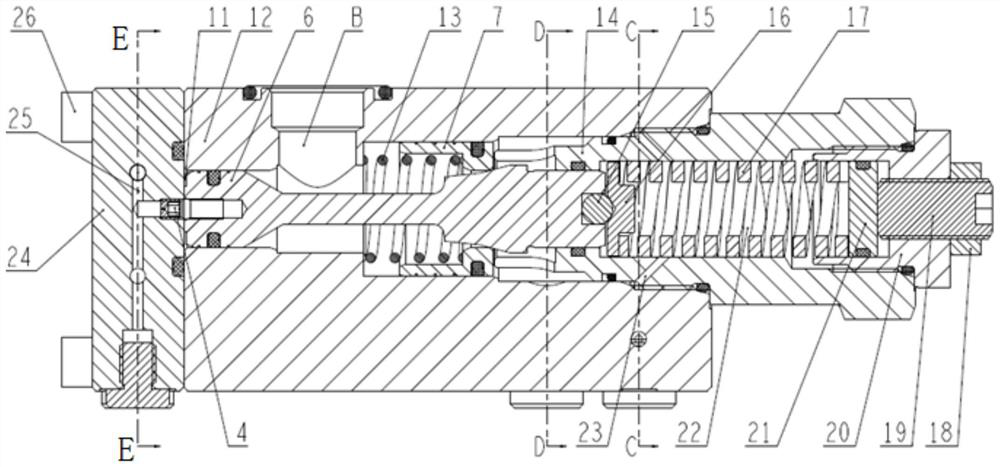

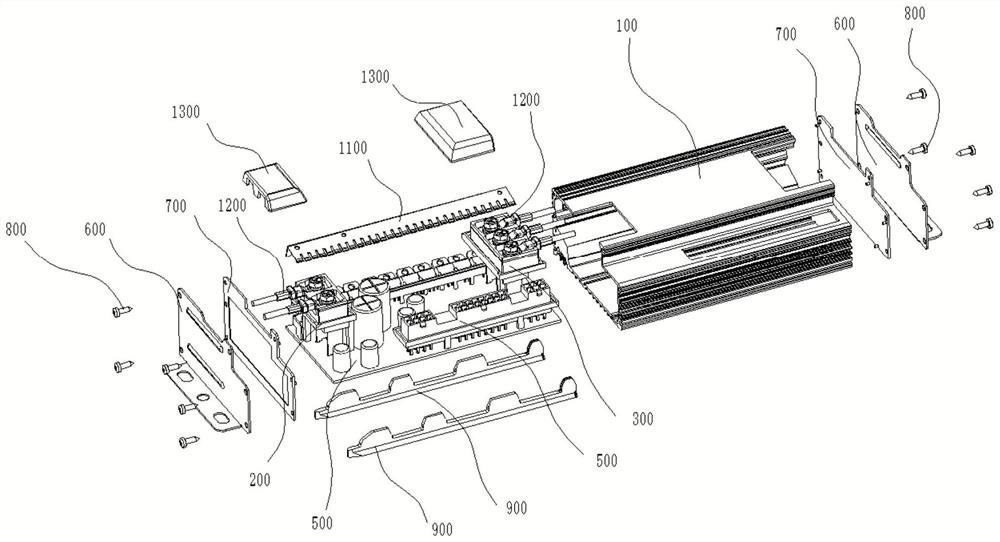

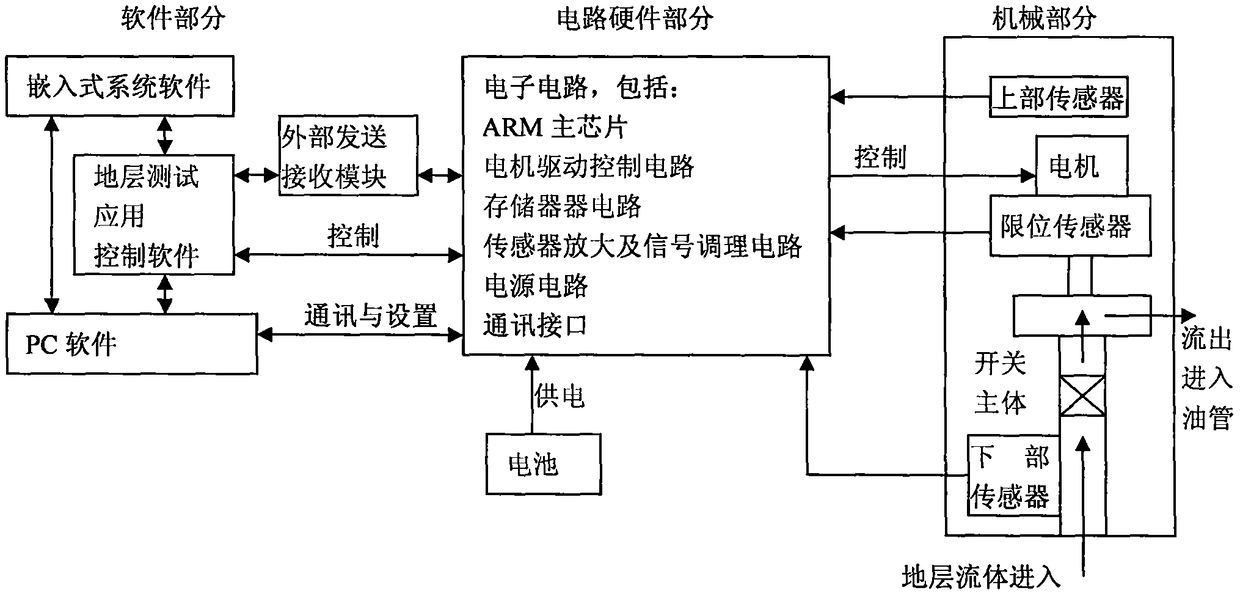

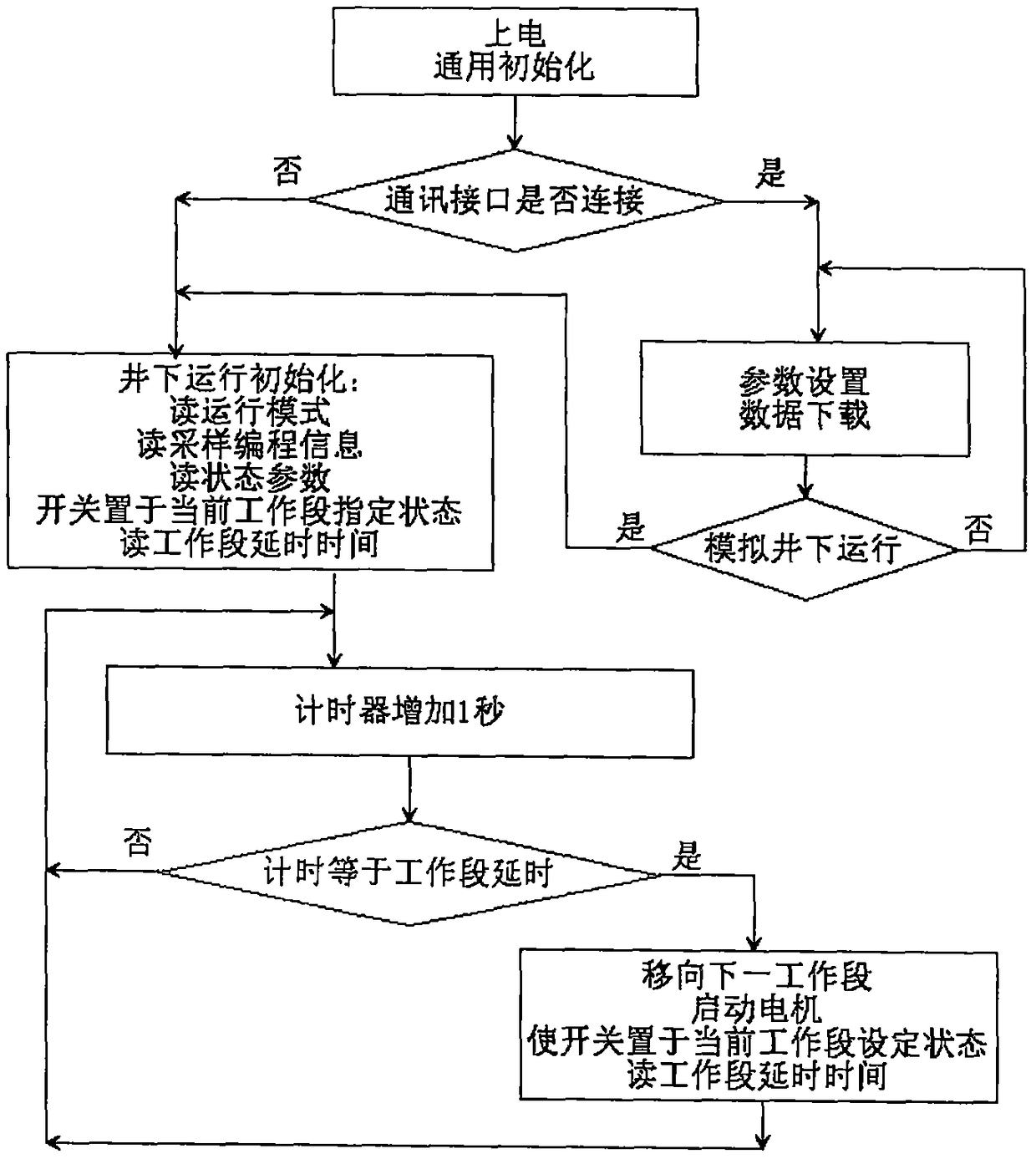

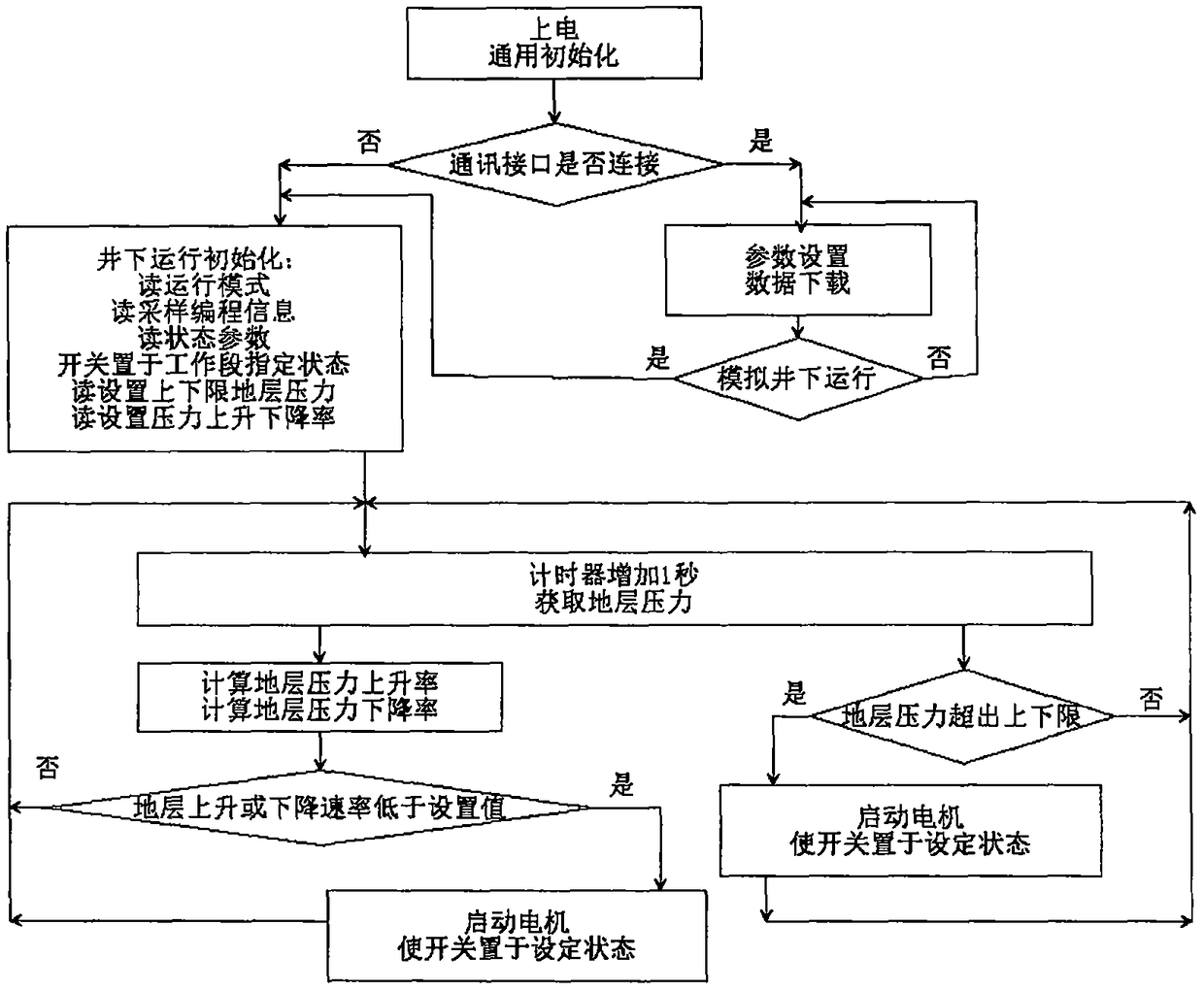

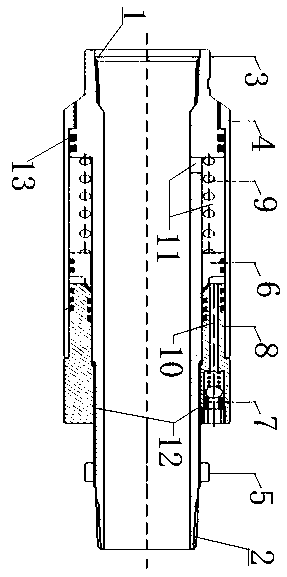

An electronically controlled formation tester

ActiveCN105134192BMiniaturizationReduce volumeBorehole/well accessoriesElectronic switchMultiple sensor

The invention relates to a petroleum exploration and development formation test method and equipment, in particular to an electrically controlled formation test method and a formation tester used by the same. The electrically controlled formation test method applies an electronic switch controlled by programmable software to replace a mechanical switch which is manually operated to achieve the function of the formation tester; meanwhile, multiple control modes are introduced, by means of setting which is conducted on parameters through the software and data which are detected by multiple sensors, the switch is opened or closed automatically at the right time, and therefore intellectualization of formation test is achieved; multiple electronic manometers which are separately equipped for an original formation tester are integrated in a system, and integration of the formation tester is achieved. The introduced electrically controlled switch is small in size and light in weight; in addition, due to the fact that all the manometers used in the test are integrated in the formation tester, the whole test tool is made to be small in size and light in weight, and micromation of the formation tester is achieved.

Owner:邱万成

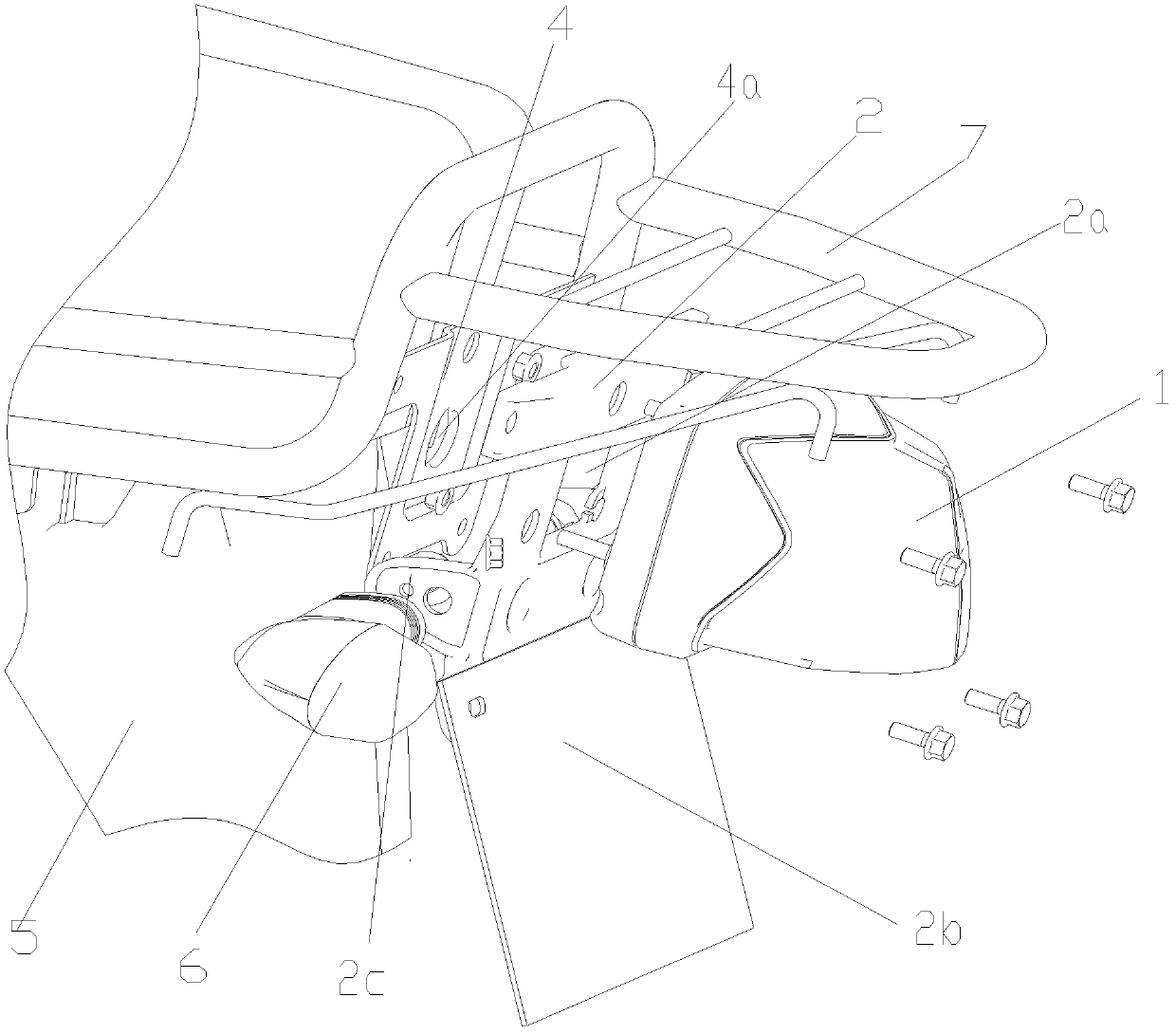

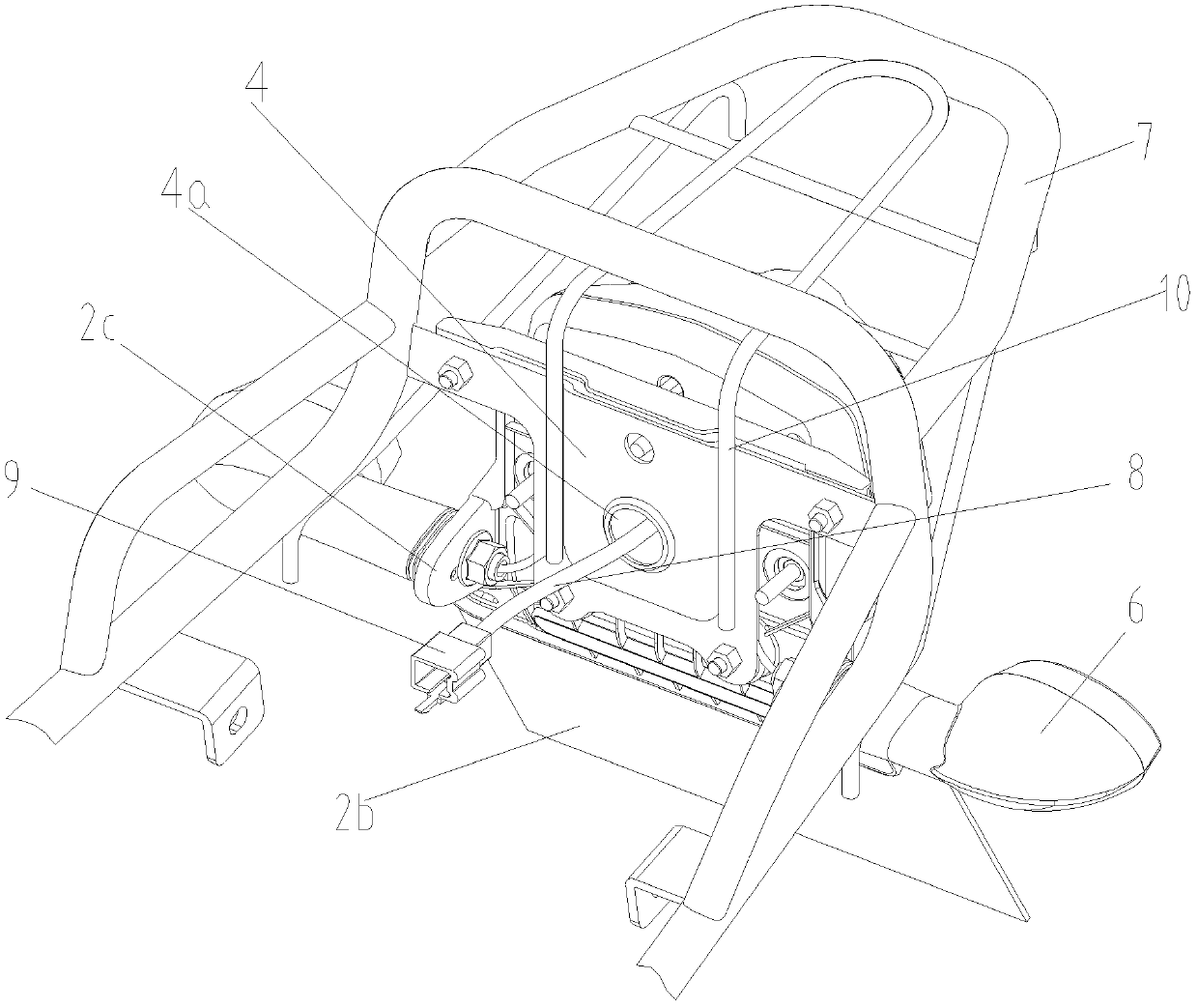

Motorcar tail lamp and rear steering lamp mounting assembly and motorcar thereof

The invention discloses a motorcar tail lamp and rear steering lamp mounting assembly and a motorcar thereof. The mounting assembly comprises a tail lamp assembly, a steering lamp assembly and a tail part bracket fixedly connected to a back carrying frame of the motorcar, wherein both the tail lamp assembly and the steering lamp assembly are fixedly connected to the tail part bracket; and the tail part bracket extends downwards and forms a number plate mounting part used for mounting a motorcar number plate frame. The motorcar tail lamp is high in integrity and more attractive in appearance. Due to the structure, a rear mud-baffling plate can be manufactured into a plastic component; and rear mud-baffling plates with different shapes can be manufactured according to needs, so the whole weight of the motorcar and the cost are reduced, the motorcar is more attractive in appearance, the vibration of the tail lamp assembly and the rear steering lamp assembly during a travelling process can be reduced, noise caused by vibration in the motorcar travelling process is reduced, the service life of the tail lamp assembly and the rear steering lamp assembly is prolonged, and light is easy to distribute for a rear lamp; and a tail lamp assembly lampshade can be integrally manufactured, sealing points are reduced, the water-preventing and dust-preventing ability of the tail lamp assembly is enhanced, and the appearance commodity of the tail lamp assembly is improved.

Owner:广东隆鑫机车有限公司

A hydraulic power compensation balance valve

The invention discloses a hydraulic power compensation balance valve. The pilot control end cover assembly includes a control end cover valve body, and a pilot oil channel is arranged on the control end cover valve body; the valve core assembly includes a throttle valve core, a main spring, a regulating valve Seat; one-way valve seat assembly includes one-way valve and one-way valve spring; balance valve body assembly includes balance valve body and valve seat; throttle valve core is provided with a throttle port with an angle of α; the inner wall of the right end of the one-way valve The conical surface and the conical surface of the throttle port of the throttle spool cooperate with each other to form an openable seal; the one-way valve moves to the left during the luffing operation to realize the function of the one-way valve from the oil port A to the oil port B of the balance valve. During the luffing operation, the throttle spool opens to the right under the action of the pilot control pressure to realize the balance valve function from oil port B to oil port A, and as the load pressure increases, the angle through the throttle spool is α The hydraulic force generated during the annular flow channel controls the size of the throttle opening of the throttle spool to achieve load-flow compensation.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Mass spectrum and chromatography interface device and mounting method thereof

PendingCN112834676AReliable sealing methodSimple structureComponent separationEngineeringStructural engineering

The invention provides a mass spectrum and chromatography interface device and a mounting method thereof. The mass spectrum and chromatography interface device comprises a chromatographic column, the end cover is provided with a first axial extension part, a radial part, a second axial extension part and a third axial extension part which are arranged in sequence; a hollow inner diameter expansion section is arranged in the first axial extension part, and a through hole is formed in the radial part; the second axial extension part is connected with the circumferential direction of the radial part, and the outer diameter of the second axial extension part is smaller than that of the third axial extension part; the pressed part is arranged in the inner diameter expansion section and is extruded by the extrusion part; a protective tube is arranged on one side of the radial part; the chromatographic column sequentially penetrates through the protective tube, the through hole of the radial part, the through hole of the pressed part and the through hole of the extrusion part; and a sleeve is arranged on the outer side of the protection pipe, one end of the sleeve is connected with the third axial extending part, and the other end of the sleeve is provided with a mounting position. The sealing piece is arranged on the outer side of the second axial extrusion part in a sleeving mode. The device has the advantages of good sealing, small error and the like.

Owner:HANGZHOU PUYU TECH DEV CO LTD

A kind of purification method of high temperature condensate water

ActiveCN103657413BIncrease packing densityHigh structural integrationSemi-permeable membranesWater/sewage treatment by ion-exchangeThermal energyWater quality

The invention discloses a purifying method of condensed water. The purifying method comprises the steps of adopting a honeycomb-shaped carrier type inorganic carbon membrane assembly to carry out at least one stage of membrane filtering treatment on high-temperature condensed water, wherein the filtering accuracy of the membrane assembly treated by membrane filtering is 0.001-100mum, and preparing the boiler supplementing water suitable for recycling. The purifying method disclosed by the invention has the advantages that the filtering accuracy is high, the membrane flux of a honeycomb-shaped carrier type membrane core is large, the impact resistance of incoming water is strong, the resistance to oil pollution is strong, the integration level of the membrane core structure is high, the preparation method is simple, a complex online discrimination system is not needed, and the prepared condensed water is stable in quality and high in temperature, meets the requirement on water quality of the boiler supplementing water and saves a great amount of heat.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

Cooled housing

PendingCN111435802AEnsure continuous coolingLess sealing pointsManufacturing dynamo-electric machinesCooling/ventillation arrangementMotronicCooling channel

Owner:乔治费歇尔金属成型科技股份公司

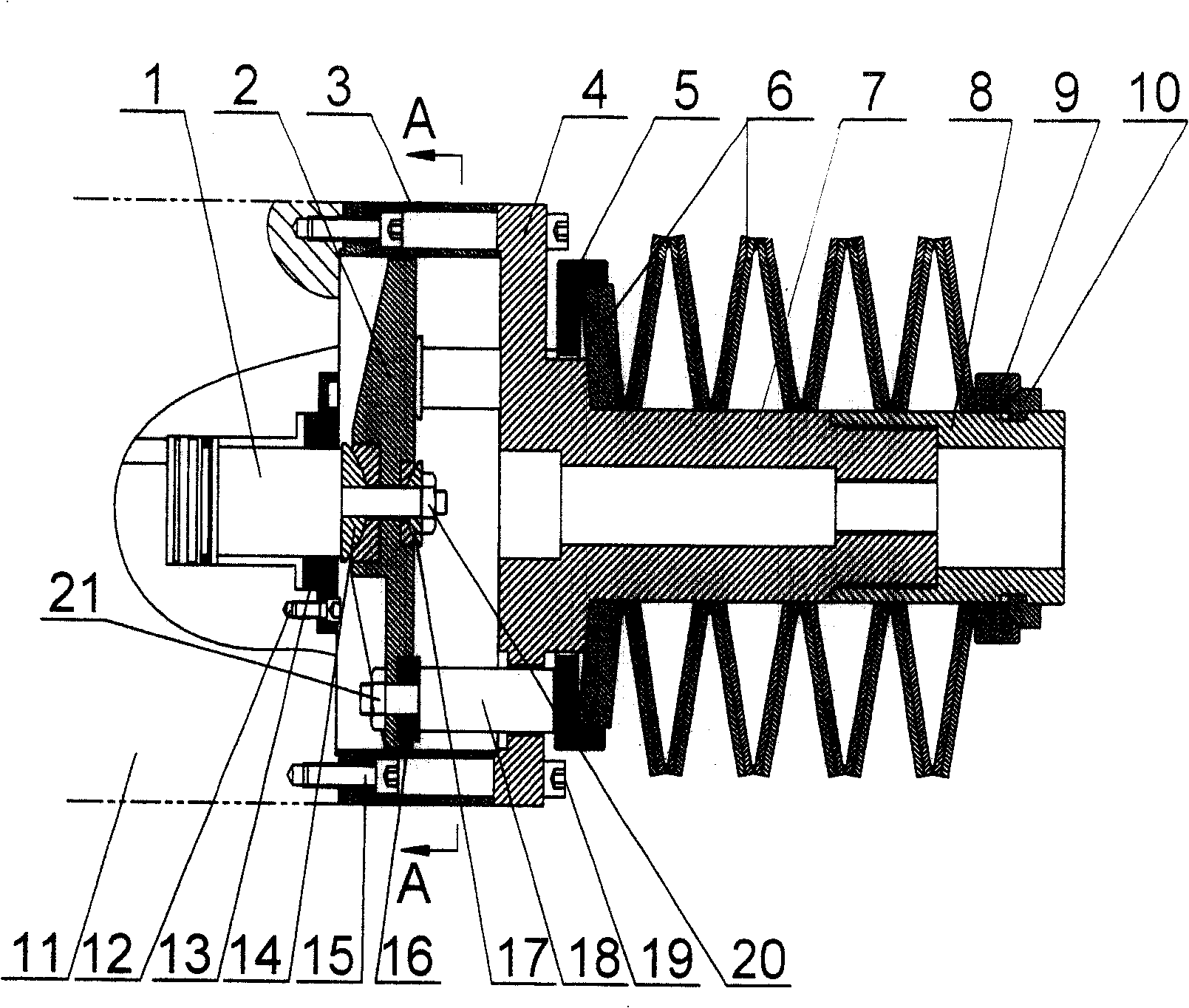

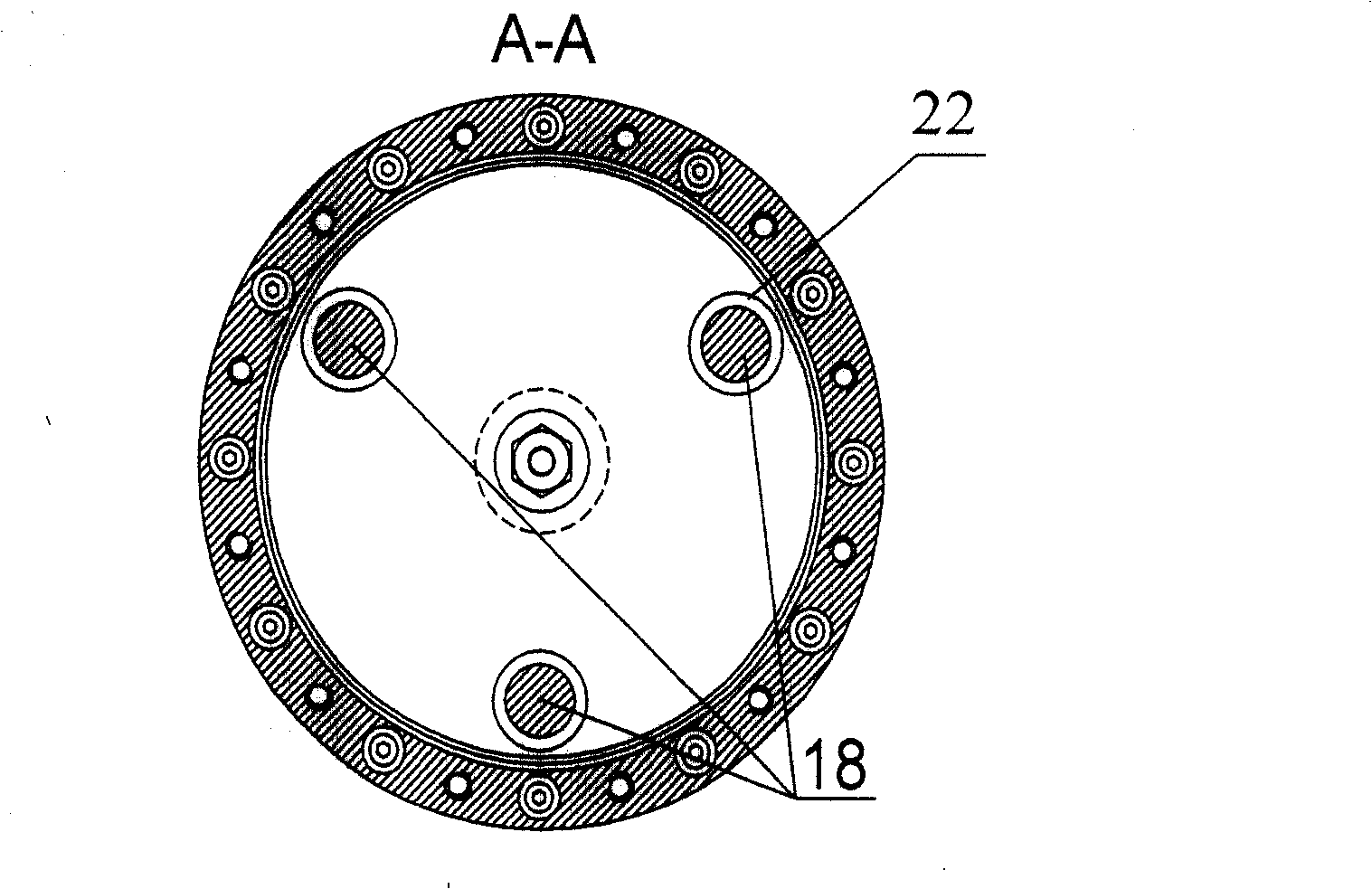

Hydraulic pressure disc spring energy storing device for high-voltage breaker

ActiveCN100517539CNot easy to strainLess sealing pointsSwitch power arrangementsSnap-action arrangementsHydraulic cylinderBall bearing

In order to overcome the structural defects of the hydraulic disc spring multi-accumulator of the traditional high-voltage circuit breaker operating mechanism, the present invention discloses a single-cylinder hydraulic disc spring energy storage device, which includes a piston in a hydraulic cylinder, a force transmission flange and a disc The disc spring is arranged in a separate disc spring mechanism, which is fixedly connected to the hydraulic cylinder body through a transition flange, and connected to one end of the piston through a central ball bearing on the piston side of the force transmission flange. In the radial direction on the other side of the force transmission flange, three dowel rods are uniformly distributed along its circumferential surface. One end of the dowel rod is connected to the force transmission flange through a circumferential ball bearing, and the other end is connected to the disc spring mechanism. The hydraulic disk spring energy storage device of the present invention has convenient installation of the disk spring, can automatically compensate processing errors within a certain range during use, has few leakage points, and will not strain the cylinder body during pressurized operation.

Owner:西安西电高压开关操动机构有限责任公司 +1

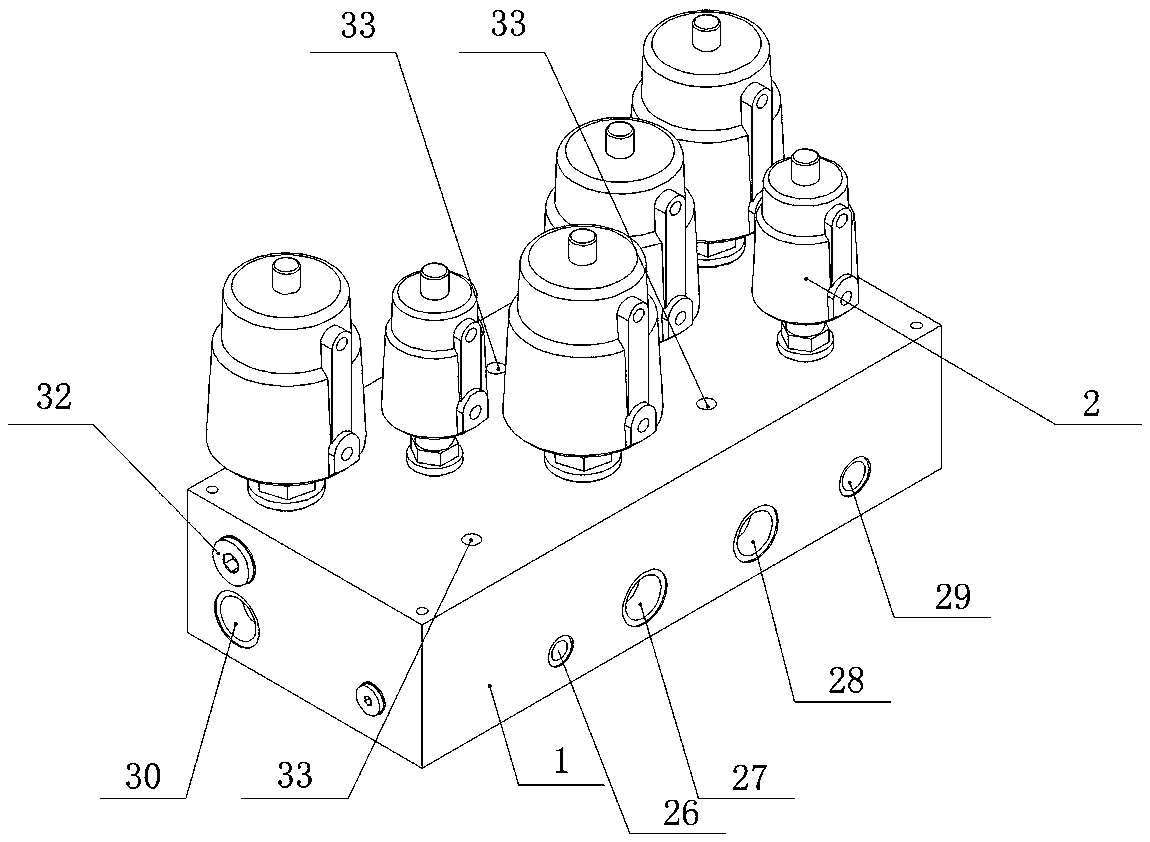

A cartridge integrated valve group and its working method

InactiveCN105736764BImprove sealingStrong circulationMultiple way valvesLift valveActuatorValve opening

The invention discloses a plug-in mounting type integration valve set. The plug-in mounting type integration valve set comprises a valve block and a plurality of valves, the valve block is provided with a plurality of medium inlets, a plurality of medium flowing-in runners, a plurality of medium outlets and a plurality of medium flowing-out runners; each medium inlet is connected with the corresponding valve through the corresponding medium flowing-in runner, and all valves are connected with the corresponding medium outlets through the corresponding medium flowing-out runners; and each valve comprises a valve executor, a valve rod, an upper valve opening, a lower valve opening, a valve sealing disc and a valve sealing holder, wherein each valve sealing holder is located between the corresponding upper valve opening and the corresponding lower valve opening, a V-shaped sealing head is arranged at the bottom of each valve sealing disc, an arc-shaped chamfer is arranged at the top of each valve sealing holder, and valve connecting bases are arranged at the top of the valve block. According to the plug-in mounting type integration valve set, the multiple medium flowing-in runners can be controlled to be on or off to conduct confluence; the sealing effect is good when the valves are closed, and the flow capacity is high when the valves are opened; and meanwhile, sealing points for pipe connection are fewer, and the leakage possibility is reduced.

Owner:JIANDE XINANJIANG PNEUMATIC COMPONENT CO LTD

Pipeline distribution structure of hydrolysis acidification pool

InactiveCN107352645AReduce layoutReduce usageBiological treatment apparatusTreatment with anaerobic digestion processesEngineeringControl valves

The invention discloses a pipeline arrangement structure of a hydrolysis acidification tank, which comprises a plurality of overflow risers arranged in the hydrolysis acidification tank, overflow outlets are installed on the upper ends of the overflow risers, and the bottom ends of each overflow riser are respectively connected to overflow horizontal pipes, and the overflow The horizontal pipe extends to the outside of the hydrolysis and acidification tank, and expansion joints are installed on the overflow horizontal pipe located outside the hydrolysis and acidification tank, and at least one side of the overflow riser is equipped with an emptying device; the overflow system only includes several overflow risers and One overflow horizontal pipe, when emptying, just pull the water outlet end of the emptying device into the overflow port, and it will be discharged from the overflow vertical pipe and overflow horizontal pipe, so the overflow vertical pipe and overflow horizontal pipe are also used as part of the emptying pipeline. The use of pipelines and related control valves and expansion joints is reduced, and valve wells outside the pool are omitted. In addition, the layout of pipelines outside the pool can be reduced, and the sealing points between the pipeline and the hydrolysis acidification tank are reduced, which simplifies the project and reduces engineering difficulty.

Owner:CHANGYI HAIYANG WATER IND

Frameless natural gas filter element structure and mounting and fixing method

PendingCN111957117AReduce workloadReduce risk of leakageDispersed particle filtrationGaseous fuelsEngineeringStructural engineering

The invention discloses a frameless natural gas filter element structure and a mounting and fixing method and belongs to the technical field of machinery. An upper end cover of the filter element is in a blind cover form; a lower end cover of the filter element is in a circular hole form; the lower end cover is provided with a sealing ring groove; the sealing ring groove is connected with an O-shaped sealing ring; a lower bonding groove is formed in the upper end surface of the lower end cover; the lower end cover and the filter layer are bonded by the lower bonding groove; and the lower end cover is connected with a core base. The upper end cover of the filter element comprises a handle, an end cover and a filter element positioning disc, wherein the handle is connected with the filter element positioning disc; the other surface of the filter element positioning disc is connected with the end cover; an upper bonding groove is formed in the lower end surface of the upper end cover; theupper end cover is bonded with the filter layer through the upper bonding groove in a hot melting manner; a pipe plate is connected with a branch pipe; the outer circumference of the other end of thebranch pipe is connected with the core base and the framework, and an inner cavity of the other end of the branch pipe is connected with a rear supporting rib plate; a central screw hole of the rearsupporting rib plate is connected with a pull rod; an inner cavity of the framework is connected with a front supporting rib plate, and a central circular hole of the front supporting rib plate is connected with the other end of the pull rod; and a center connecting tie rod is connected to the front supporting rebar plate through a fastening nut

Owner:北京承天倍达过滤技术有限责任公司

Constant-pressure gas collecting device and method for recycling casing pipe associated gas inside oil field wellbore

PendingCN111365556AHighly integratedHigh technology superiorityEqualizing valvesPipe elementsThermodynamicsExhaust valve

The invention provides a constant-pressure gas collecting device and method for recycling casing pipe associated gas inside an oil field wellbore. The constant-pressure gas collecting device comprisesa body and an outer barrel connected to the outside of the body in a sleeving mode. The upper end of the outer barrel is fixedly connected with the body. An exhaust valve with the exhaust pressure being adjustable is further connected between the outer barrel and the body. An annular part among the outer barrel, the body and the exhaust valve forms an exhaust passage, and the exhaust passage communicates with an inner cavity of the body. The constant-pressure gas collecting device and method for recycling the casing pipe associated gas inside the oil field wellbore are designed in order to achieve the technical aims that the pressure of the casing pipe associated gas is higher than return pressure inside an oil pipe, when the differential pressure reaches a set value, the exhaust valve can be opened without other extra dynamic effects, and the associated gas enters the oil pipe to form oil and gas mixed fluid with oil flow; and when the differential pressure value approaches the opening pressure of the exhaust valve, the exhaust valve can be closed automatically, the gas collecting process is ended and oil leakage inside the oil pipe can be prevented in oil well production. Due tothe fact that the associated gas can absorb a large amount of heat when being released to be in a low-pressure state from a high-pressure state quickly, low-temperature freezing can happen easily.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com