An electric vehicle controller

An electric vehicle controller and controller technology, applied in the field of electric vehicles, can solve the problems of low mechanical strength of plastic structure shell, poor heat dissipation effect of plastic shell material, loss of sealing and continuous pressing force, etc., so as to improve electromagnetic interference shielding. effect, high waterproof reliability, eliminate the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is further elaborated below in conjunction with all accompanying drawings:

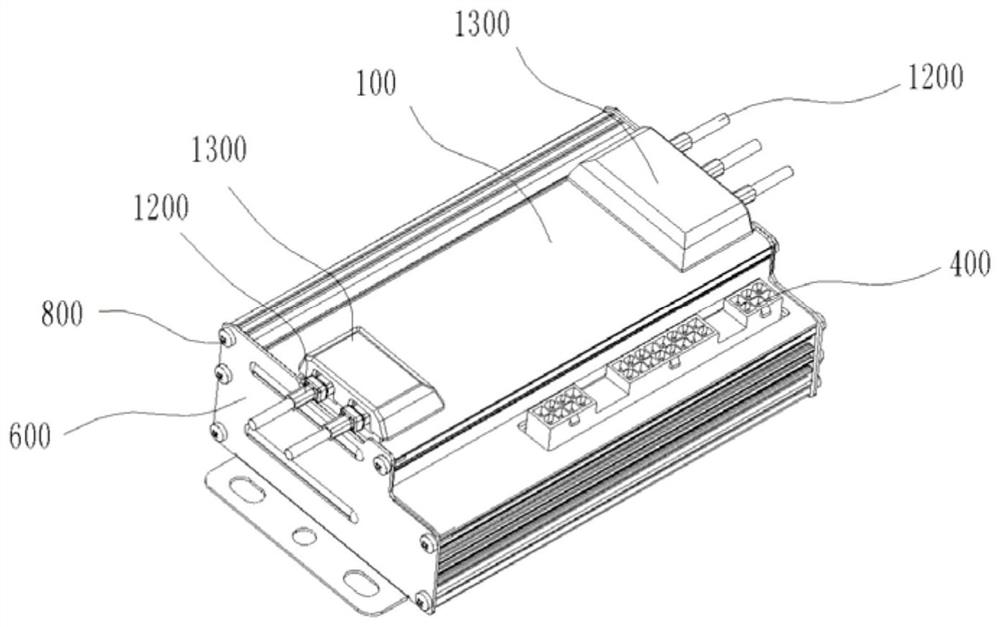

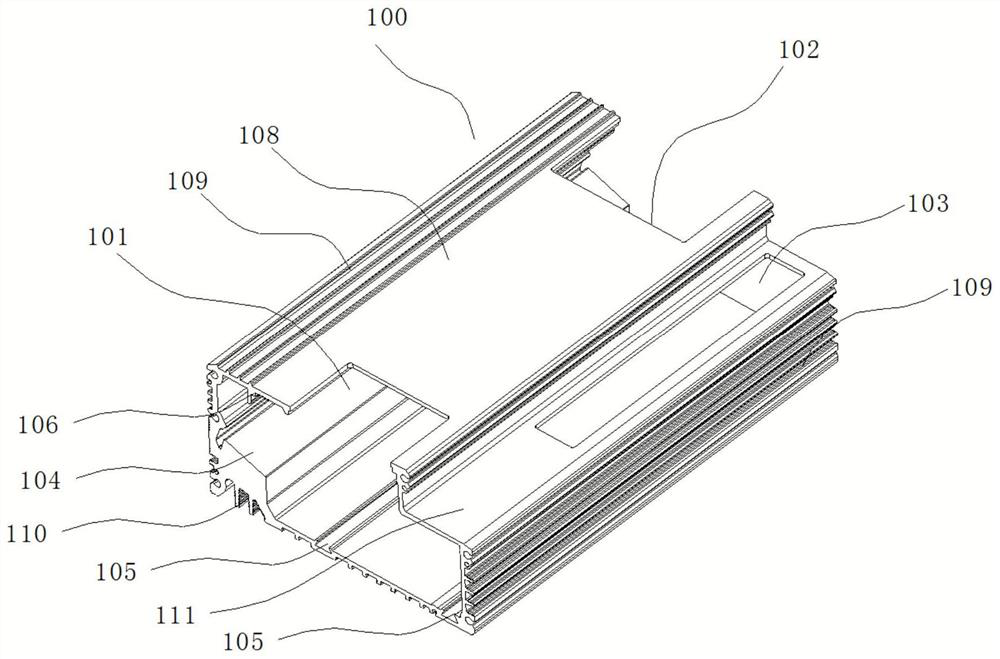

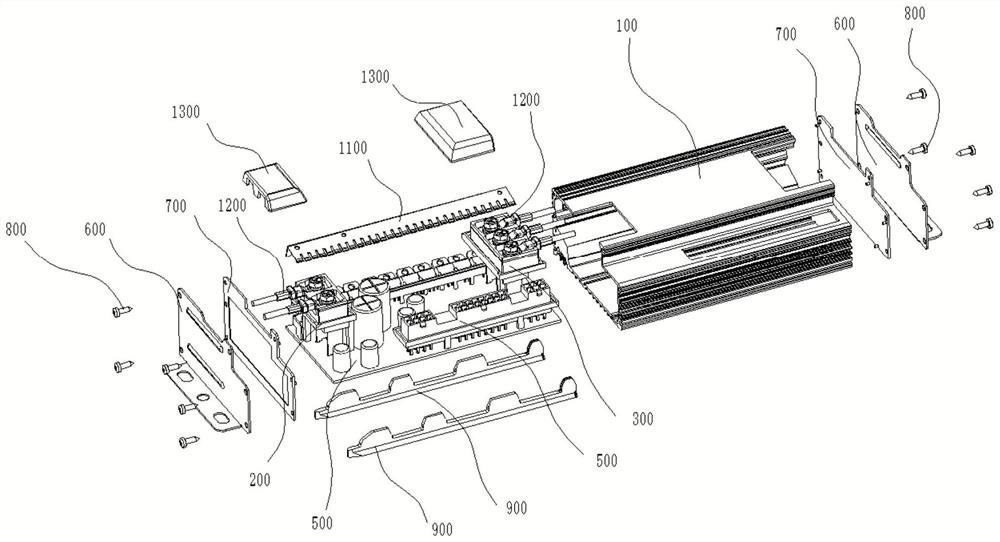

[0049] see in particular Figure 1 to Figure 6 As shown, an electric vehicle controller includes a casing 100, an input terminal block 200, an output terminal block 300, a pin header socket 400, a circuit board 500, and end covers 600 disposed at both ends of the casing 100; The outer surface of the casing 100 is divided into a flat surface 108 and a heat dissipation rib surface 109. On the flat surface 108 of the casing, the upper two ends of the casing 100 are respectively provided with a power supply input terminal socket notch 101 and an output terminal socket notch 102 Install the input terminal block 200 and the output terminal block 300, and the side of the casing 100 is provided with a control wire pin header socket hole 103 Install the pin header socket 400; the casing 100 is provided with a cavity for accommodating a circuit board 107. Corresponding to the notch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com