Fixed core adapter valve and self-sealing adapter assembly using same

A joint valve, fixed valve core technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of poor sealing performance of self-sealing joints, and achieve the effect of solving poor sealing performance and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

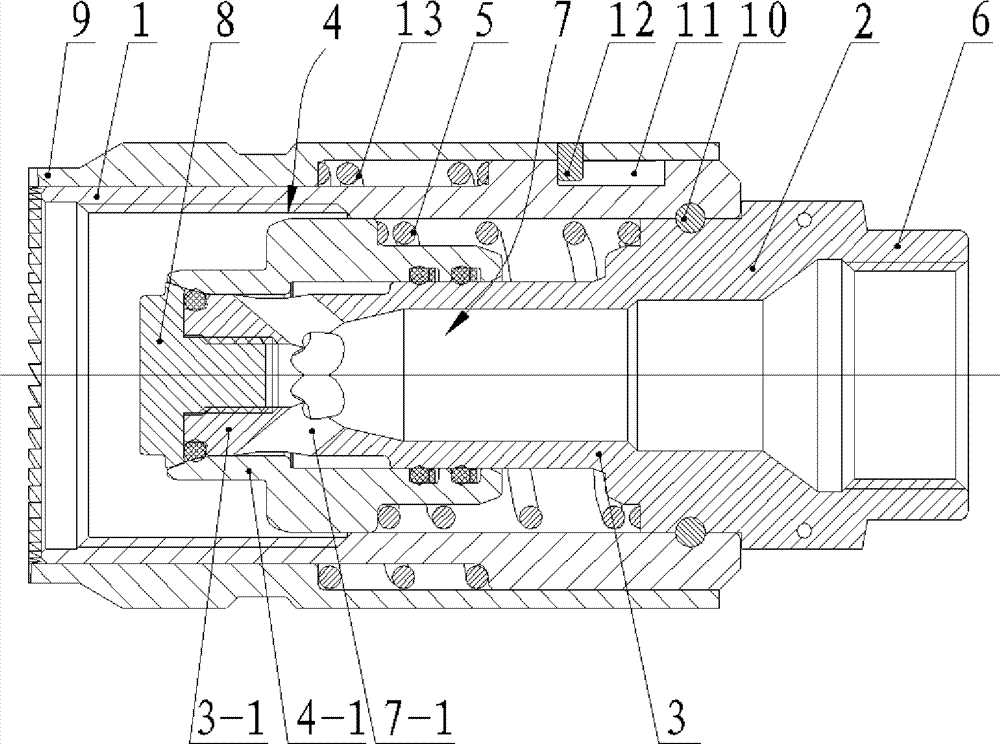

[0023] Embodiment 1 of the fixed core joint valve of the present invention, such as figure 1As shown, it has a valve body 1, a valve seat 2 assembled at the rear end of the valve body 1, a valve core 3 arranged in the valve body 1, a sliding sleeve 4 and a top mounting The return spring 5 between the sliding sleeve 4 and the valve seat 2, the valve seat 2 has a through hole through the front and back, and the rear end is integrally provided with a threaded joint 6 for screwing with the corresponding pipeline. The through hole on the valve seat 2 corresponds to the through hole, the rear end of the valve core 3 is integrally connected to the valve seat 2, and its front end has a valve core sealing section 3-1, and the front and rear ends of the valve core 3 are provided with Medium channel 7, medium channel 7 has a medium inlet located on the rear end surface of the valve core 3 and a medium outlet 7-1 located on the sealing section of the valve core, the medium inlet communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com