A cartridge integrated valve group and its working method

A valve group and plug-in technology, which is applied in the field of valve groups, can solve the problems of affecting the actual diameter, large leakage possibility, and many sealing points, so as to reduce the possibility of leakage, flexible flow channel design, and reduce sealing points. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

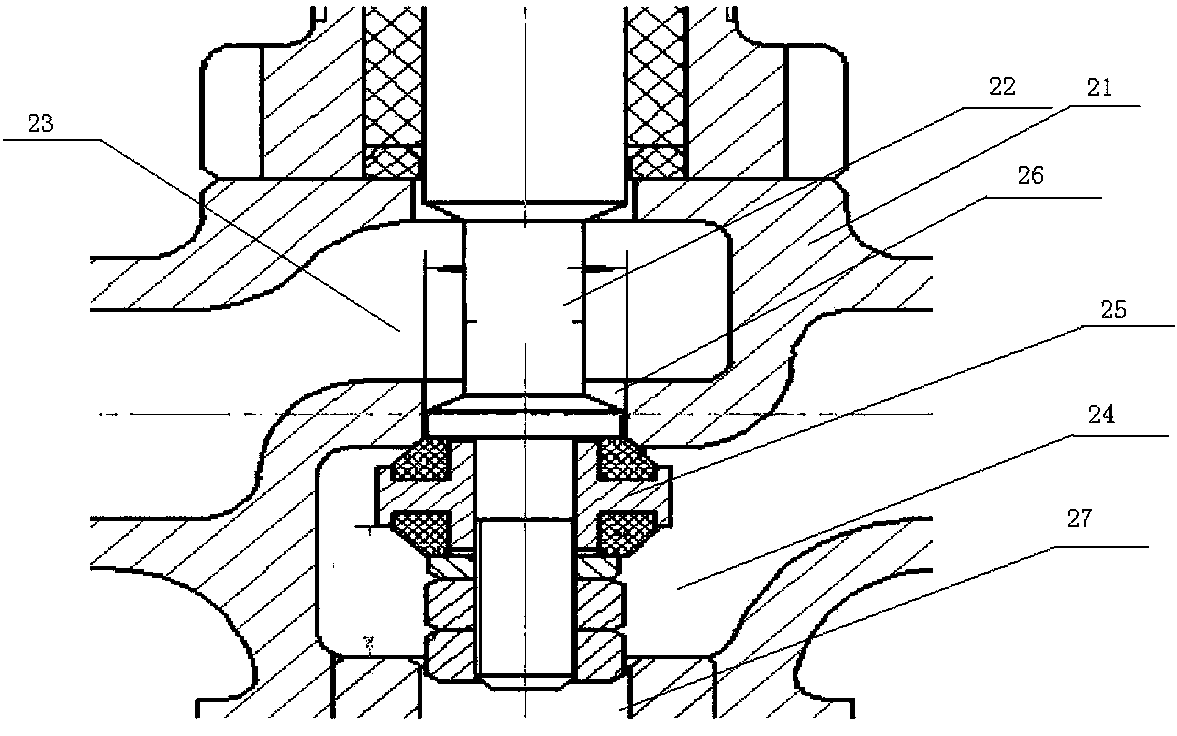

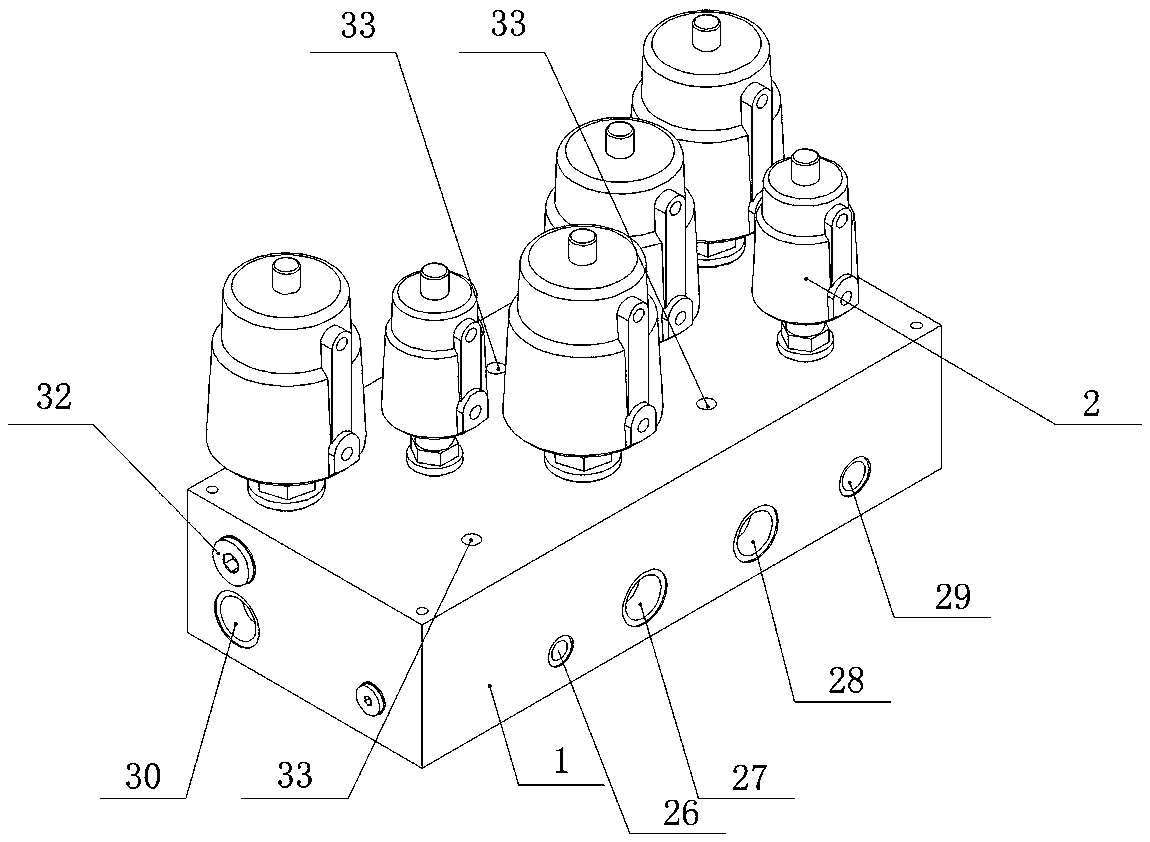

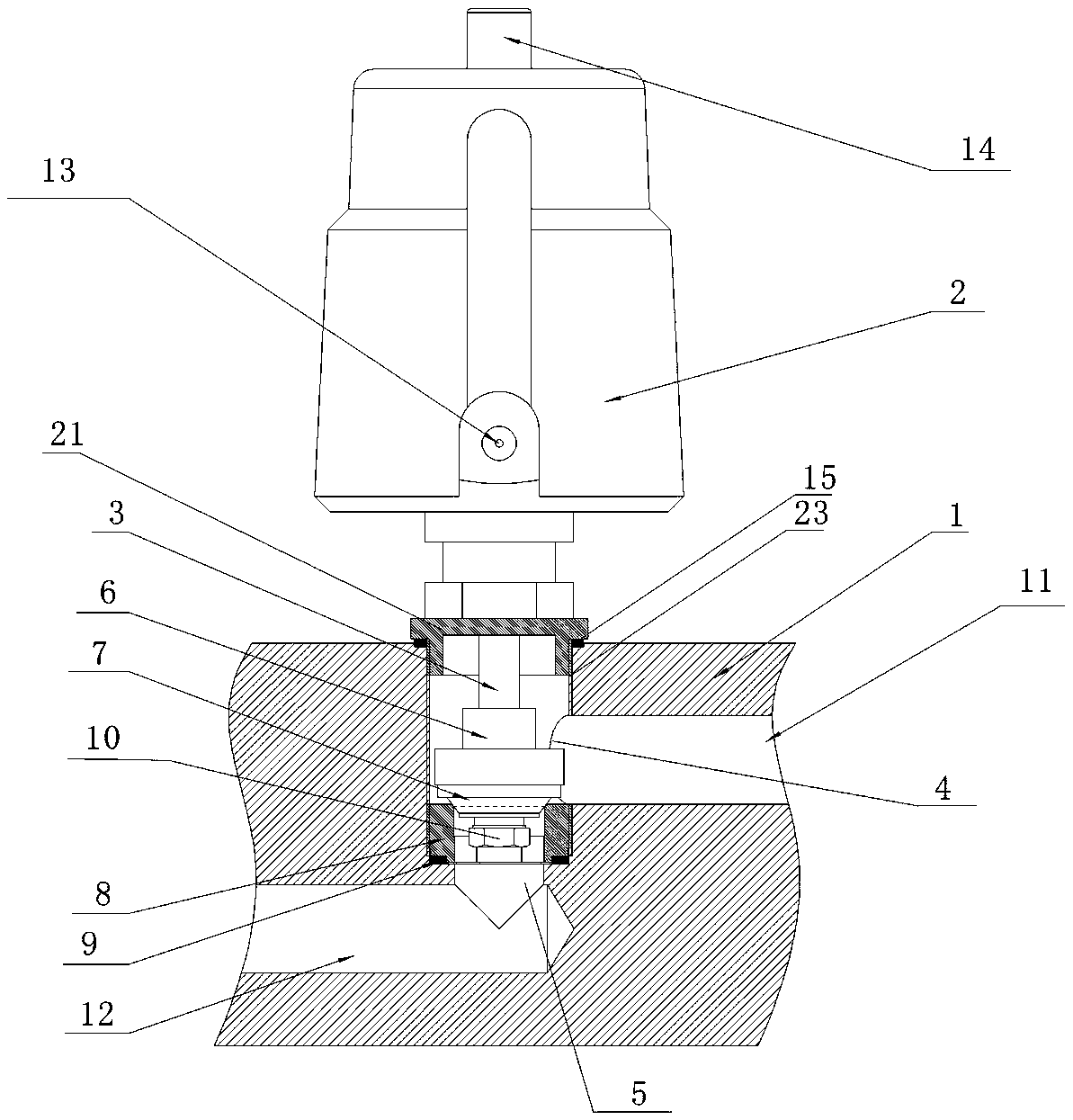

[0043] Such as Figure 2-8As shown, a plug-in integrated valve group includes a valve block 1 and six valves installed on the valve block 1. The valve block 1 is provided with 4 medium inlets and 4 medium inflow channels 12 matching the medium inlets. , and 2 medium outlets and 2 medium outflow channels 11 matching the medium outlets, each medium inlet is connected to the corresponding valve through the corresponding medium inflow channel 12, and the valve corresponding to the medium is connected to the outlet through the medium outflow channel The inlet of the controlled valve is connected to the E outlet 30 or the F outlet 31 through the outlet valve. The valve includes a valve block 1, a valve actuator 2, a valve stem 3, a valve upper port 4, a valve lower port 5, a valve seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com