Coil pipe mounting and sealing structure for solar water tank

A solar water tank and sealing structure technology, which is applied to solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of high thread processing requirements, cumbersome operations for workers, and high labor intensity, so as to reduce labor intensity, simple operation, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

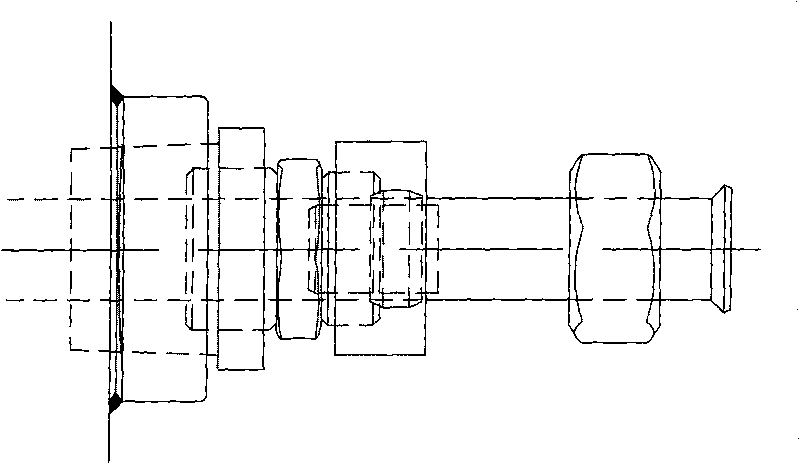

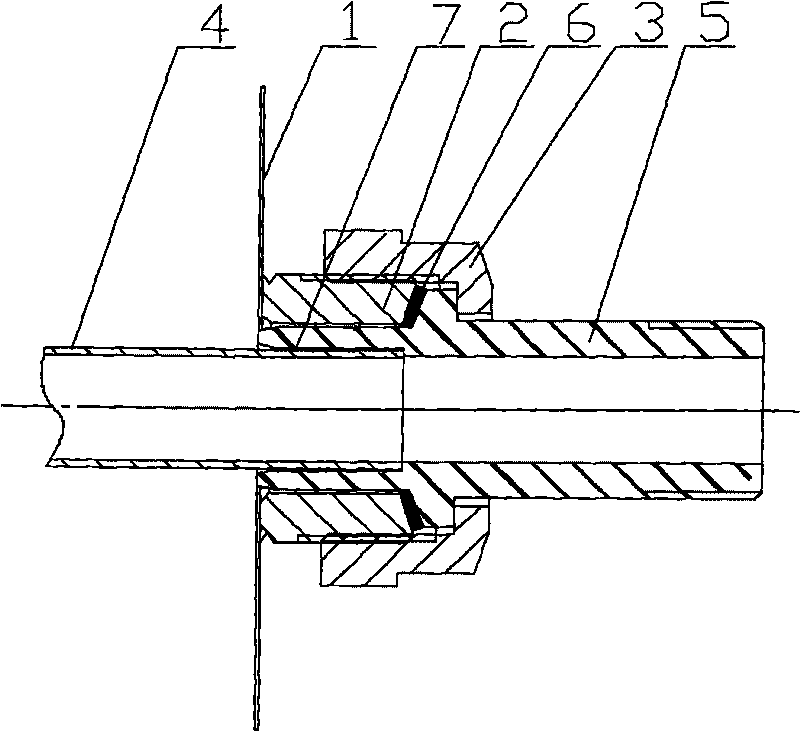

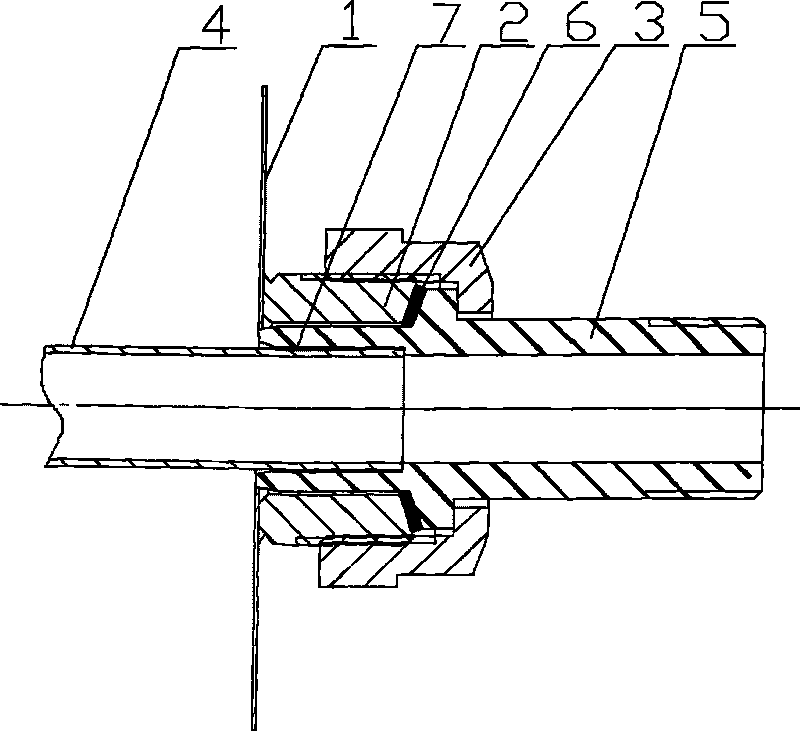

[0010] As can be seen from the accompanying drawings, the coil installation and sealing structure for a solar water tank includes a water tank inner tank body 1, a pipe base 2 and a nut 3, the pipe base 2 is welded on the water tank inner tank body 1, and the coil 4 is connected to the water tank inner tank body 1. There is a sealing joint 5 between the tube bases 2, and the sealing joint 5 is welded with the coil tube 4. The coil tube is made of copper tube material and can be welded by silver soldering. A metal gasket 6 is provided between the butterfly contact surfaces of the seat 2, and a nut 3 is set on the sealing joint 5, and the nut 3 and the pipe seat 2 are fastened and connected by threads. The metal gasket between the sealing joint and the pipe seat can be made of a thin copper sheet, and the metal extrusion is used to ensure that the gasket, the pipe seat and the sealing joint are tightly combined without any gaps to ensure that the surface seal does not leak. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com