Bistable permanent magnetism hydraulic valve for hydraulic pressure spring operating mechanism

An operating mechanism and hydraulic spring technology, applied to engine components, valve details, multi-way valves, etc., can solve problems such as difficult maintenance, complicated operation process and control oil circuit, and influence on valve action, so as to achieve convenient installation, maintenance and debugging, Reliable anti-leakage oil performance, no effect of refusal or misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

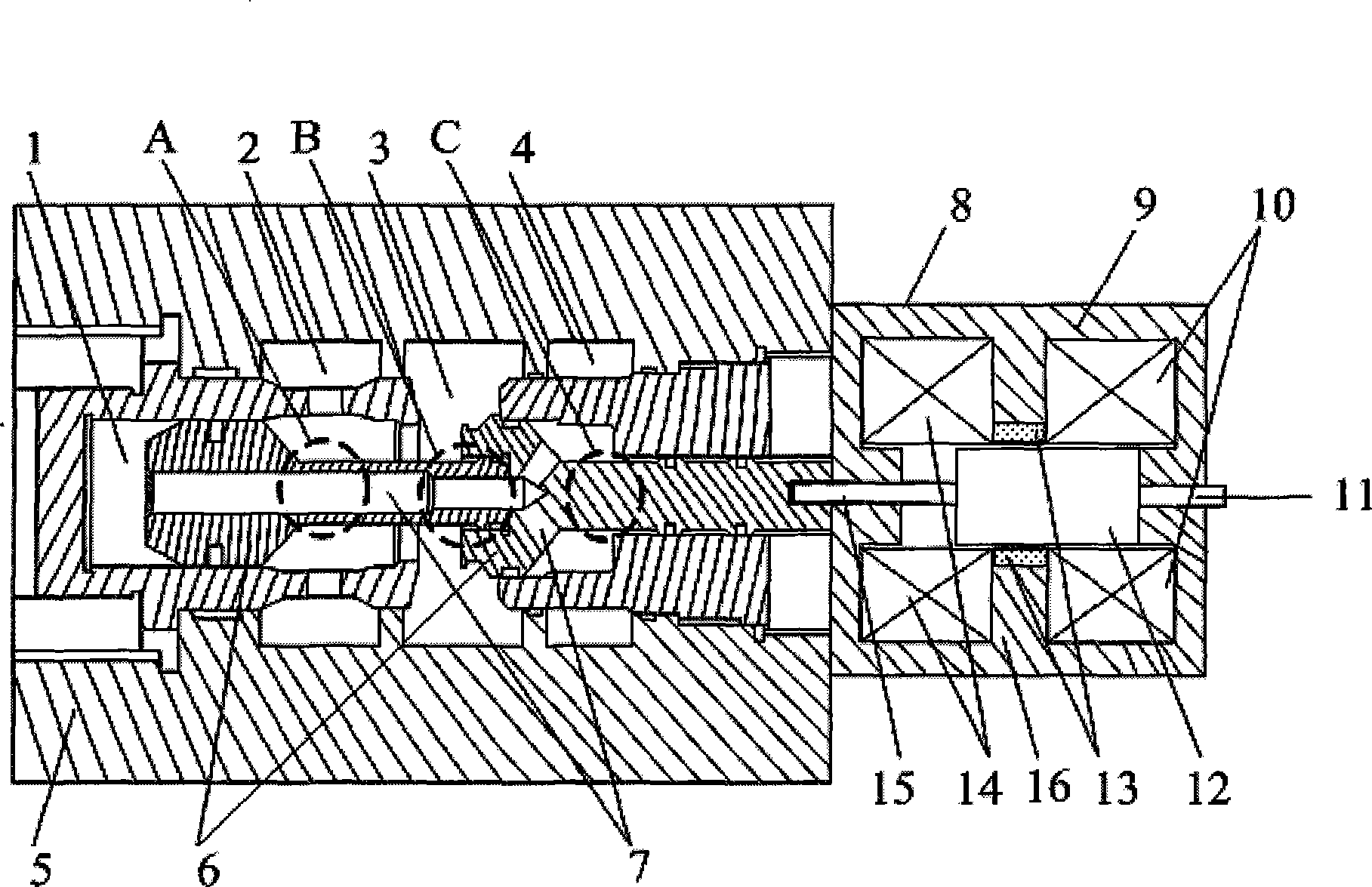

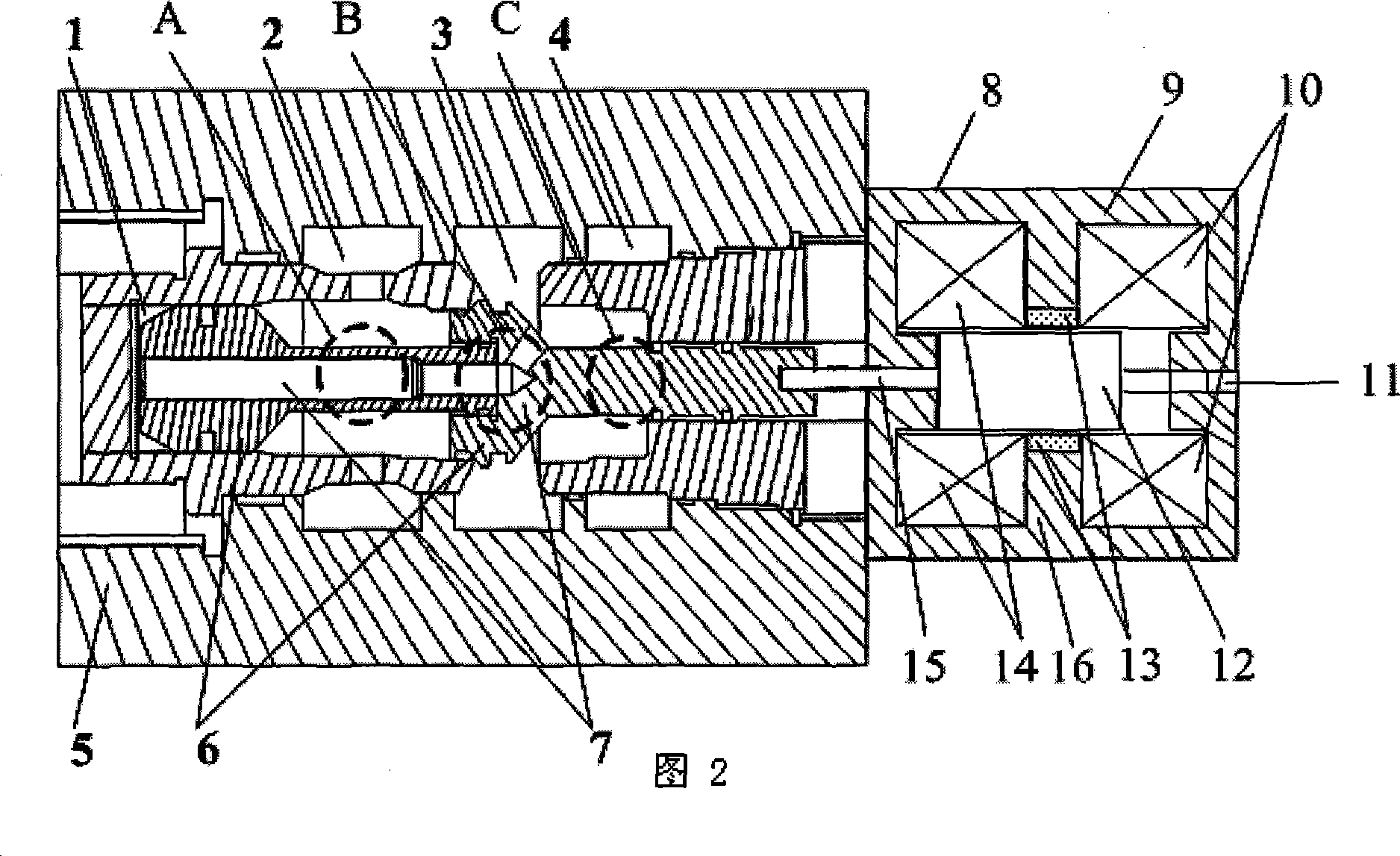

[0014] Embodiments of the present invention are further described below in conjunction with the accompanying drawings: a bistable permanent magnet hydraulic valve for a hydraulic spring operating mechanism, including a valve body 5, which has a normal and low pressure oil zone 2 and a working oil zone 3 , the normal and high pressure oil zone I, the normal and high pressure oil zone II, and the spool 6 located in the valve body 5 are characterized in that: on the right side of the valve body 5, there is a bistable permanent magnet valve 8, and the bistable permanent magnet valve 8 The magnetic valve 8 is provided with a moving iron core 12, and the left connecting rod 15 on the moving iron core 12 is connected with the valve core 6. Among them, the bistable permanent magnet valve 8 includes: a yoke 9, a closing coil 10, a moving iron core 12, a permanent magnet ring 13, and an opening coil 14; wherein: the yoke 9 includes a partition wall 16, and the partition wall 16 left The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com