pulse valve

A technology of pulse valve and valve cover, applied in the field of pulse valve, can solve the problems of short service life, valve port sealing, vulnerability, etc., and achieve the effect of improving high temperature service performance and reducing sealing points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

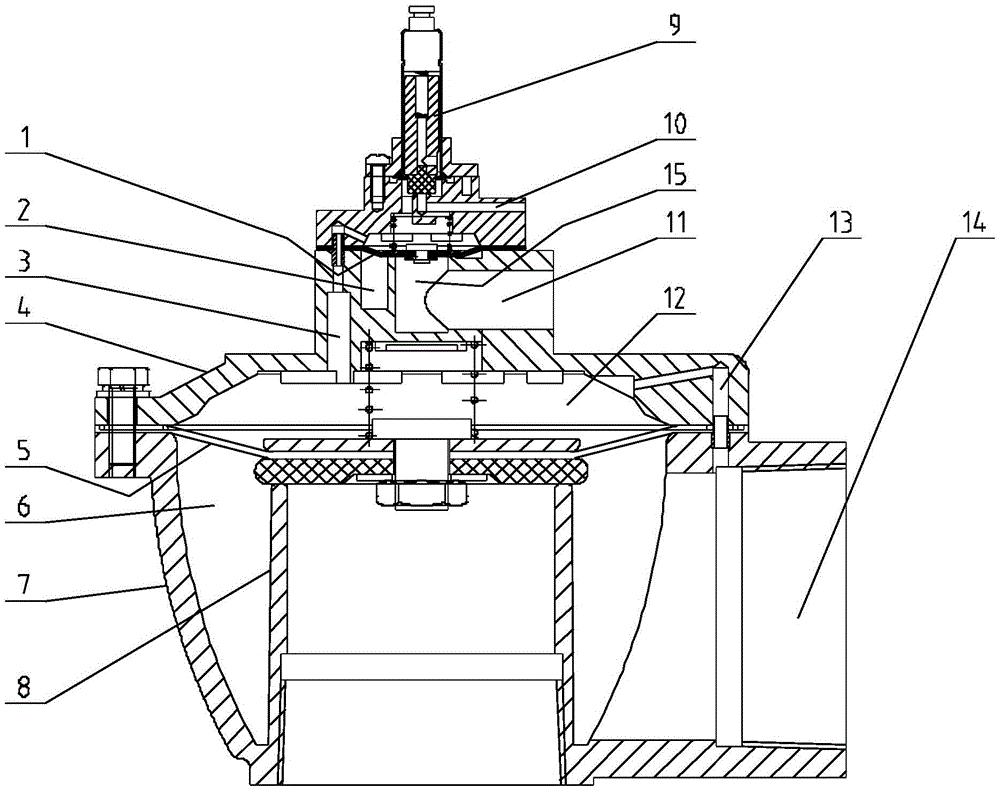

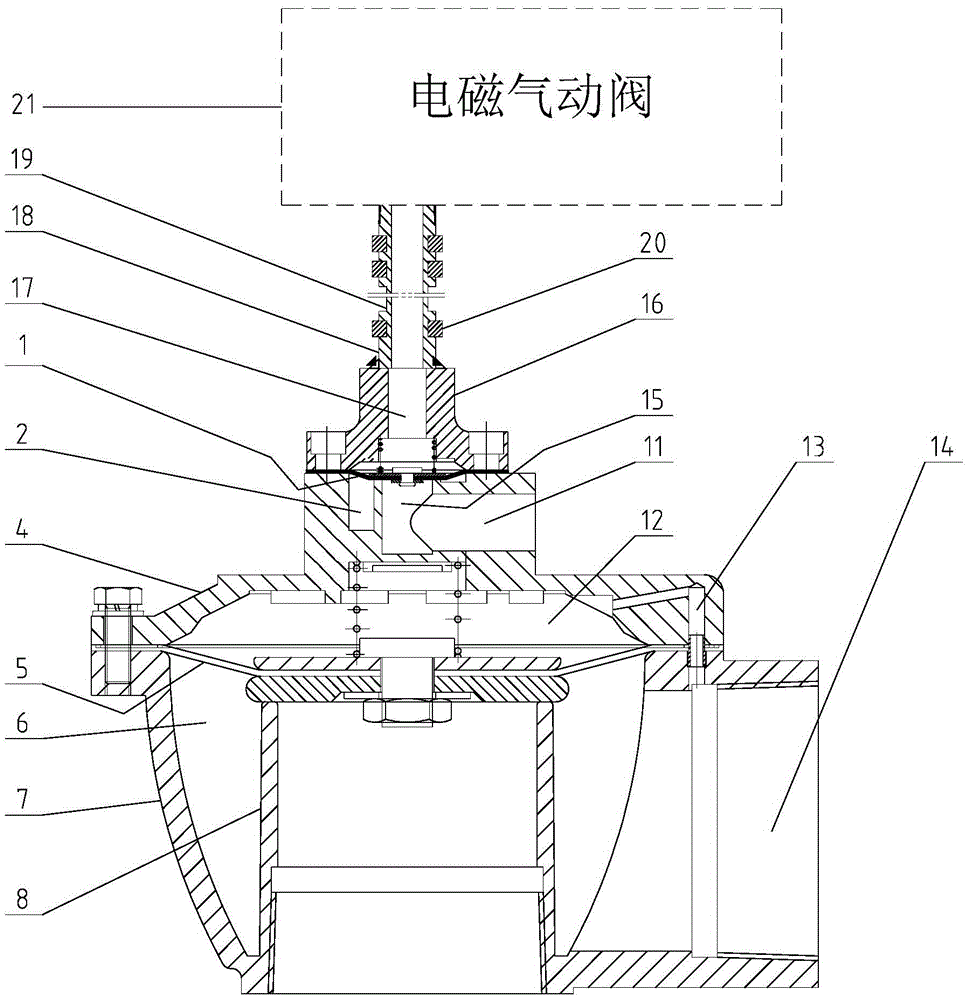

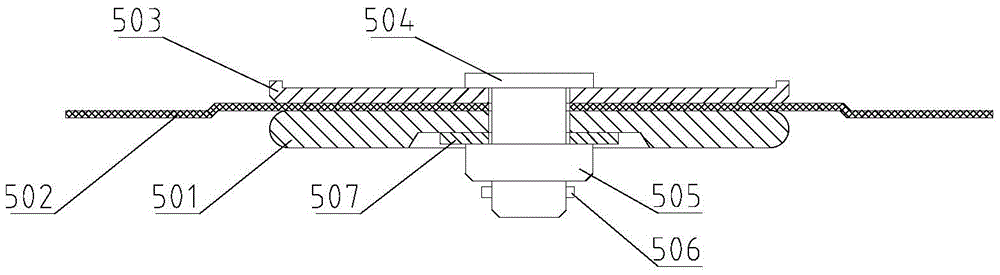

[0012] Such as figure 2 As shown, the pulse valve includes a valve body composed of a valve body 7 and a valve cover 4. A moving diaphragm 5 that can move forward and backward is installed between the valve body 7 and the valve cover 4. There is a valve inside the valve body 7 that can be moved forward. The valve port 8 closed by the moving diaphragm 5 on the top is held by the spring between the moving diaphragm 5 and the valve cover 4 and forms a front air chamber 6 with the valve body 7. The moving diaphragm 5 and the A rear air chamber 12 is formed between the valve covers 4, and the front air chamber 6 and the rear air chamber 12 are communicated through an air guide hole 13 provided in the valve body. Diaphragm 1, the valve cover 4 is located below the upper moving diaphragm 1 and is provided with an air intake chamber 2 and an exhaust chamber 15 that can be blocked by the upper moving diaphragm 1 in the forward position, and the air intake chamber 2 It communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com