Frameless natural gas filter element structure and mounting and fixing method

A natural gas, skeletonless technology, applied in the field of machinery, can solve the problems of reducing the weight of filter elements, waste of resources, and high processing costs, and achieve the effects of reducing leakage risks, reducing workload, and reducing hazardous waste processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

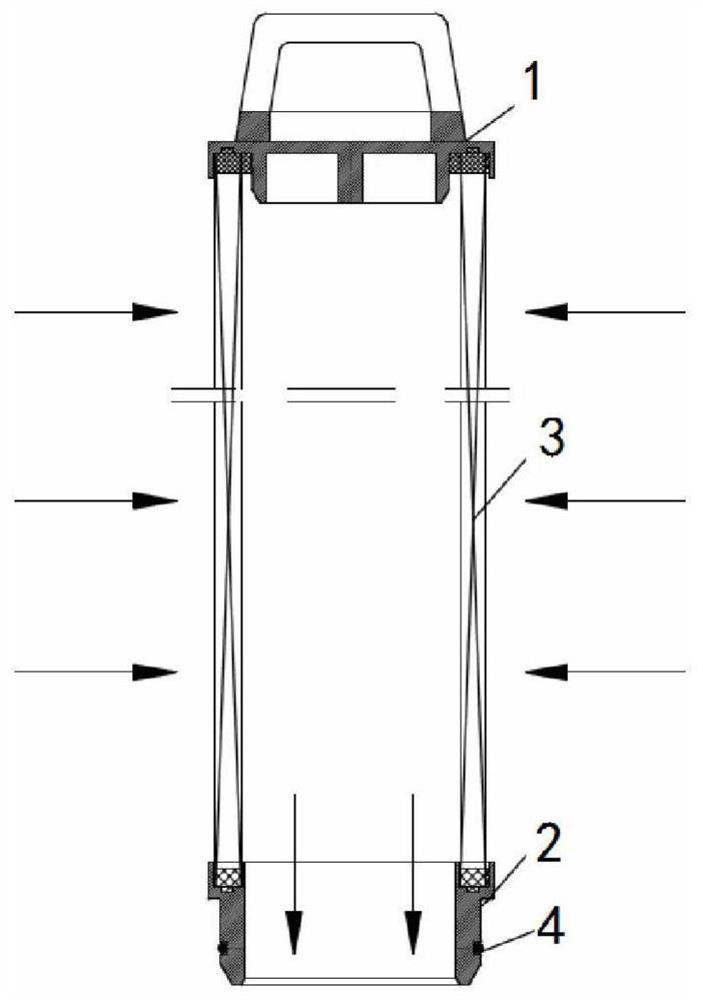

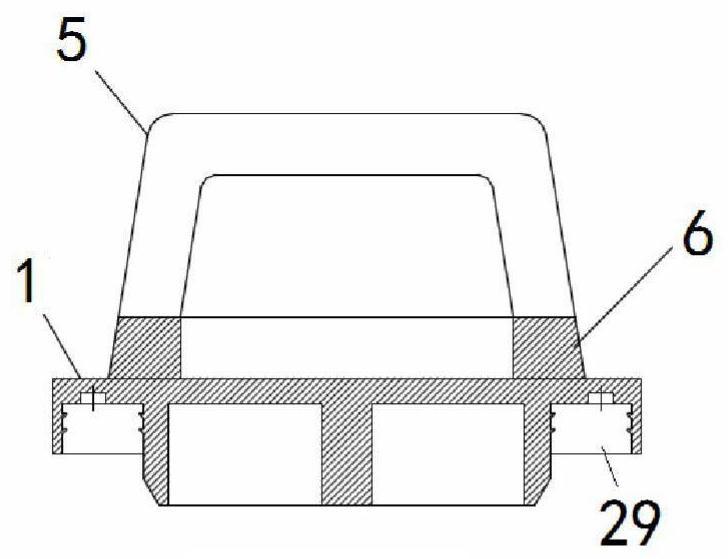

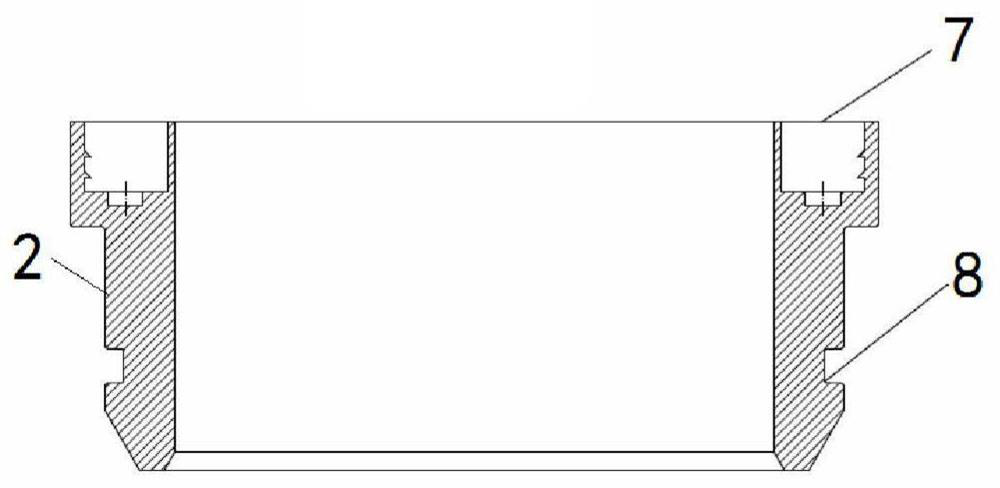

[0038] Embodiment 1: a kind of frameless natural gas filter element structure, such as figure 1 As shown, the filter element is mainly composed of an upper end cover 1, a lower end cover 2 and a filter layer 3. The upper end cover 1 of the filter element is in the form of a blind cover, and the upper part of the upper end cover 1 has a handle 5; the lower end cover 2 of the filter element is in the form of a circular opening, and the lower end cover 2 has a sealing ring groove 8, which is connected to an O-shaped seal Circle 4.

[0039] The sealing form of the filter element is O-ring 4 radial seal.

[0040] The materials of the upper end cover 1 and the lower end cover 2 are polymer plastics, which are processed by injection molding, and this material can be directly incinerated.

[0041] The filter element filter layer 3 is a tubular structure of polyester fiber tube formed by hot-melt bonding of multi-layer polyester fiber non-woven fabrics. While ensuring the filtration ...

Embodiment 2

[0052] Embodiment 2: a kind of frameless natural gas filter core structure, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, the structure of the natural gas filter element and its installation and fixing methods mainly include the structural form of the natural gas filter element, the installation and fixing form of the core seat and frame, and the structural form of the bracket fixing:

[0053] A natural gas filter element structure, the filter element is mainly composed of an upper end cover 1 , a lower end cover 2 and a filter layer 3 . The upper end cover 1 of the filter element is in the form of a blind cover, with a handle 5 on the upper part; the lower end cover 2 is in the form of a circular opening, and is provided with a sealing ring groove 8 for installing an O-ring 4 .

[0054] The sealing form of the filter element is O-ring 4 radial seal. The materials of the upper end cover 1 and...

Embodiment 3

[0070] Embodiment 3: A method for installing and fixing a frameless natural gas filter element. The overall structure of the natural gas frameless filter element and its installation and fixing mainly includes branch pipes, core seats, frames, filter elements, and brackets. Contains the following steps:

[0071] The materials of the upper end cover 1 and the lower end cover 2 are polymer plastics, which are processed by injection molding. The filter layer 3 of the filter element is a fiber tubular structure formed by hot-melt bonding of multi-layer polyester fiber non-woven fabrics. When purifying natural gas, the direction of natural gas flowing through the filter element is from outside to inside.

[0072]The natural gas filter element has no metal skeleton as the support layer. The entire filter element is made of polymer plastic material. The upper end cover 1 and the filter layer 3 are hot-melt bonded, which is in the form of a blind cover. The sealing ring groove 8 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com