Constant-pressure gas collecting device and method for recycling casing pipe associated gas inside oil field wellbore

A technology for recovering sleeves and gas-collecting devices, which is applied to valve devices, pipe components, pipes/pipe joints/fittings, etc., and can solve problems such as hidden dangers of freezing of pipelines and deflation valves, leakage, and difficulties in the construction of gas-gathering pipelines. Achieve the effect of high technical superiority, reliable sealing process and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

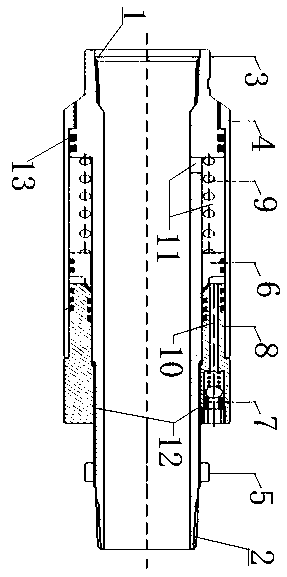

[0022] In order to overcome the leakage risk of conventional surface air release valves and gas gathering pipeline connections, hidden dangers of freezing and blocking of pipelines and air release valves in winter, and difficulties in the construction of repeated disassembly and assembly of gas gathering pipelines during workover operations, the purpose of the present invention is to provide a method such as figure 1 The shown casing associated gas recovery device and method are used in oil field wellbore. The present invention simplifies the process flow of ground associated gas collection and recovery, does not change the existing wellhead facilities and technical specifications and management habits of ground gathering and transportation process, and adds an oil well casing associated gas collection and recovery device under the wellhead tubing, and replaces the conventional wellhead ground The gas collection and recovery mode is changed to the downhole wellbore gas collecti...

Embodiment 2

[0028] Based on Embodiment 1, in this embodiment, the exhaust valve 6 is a concentric sliding sleeve exhaust valve, including an exhaust valve body with a sliding cavity and a through-hole that is slidably connected to the exhaust valve body. The concentric sliding sleeve in the sliding cavity, wherein the concentric sliding sleeve is located at the upper end of the exhaust passage 11 and is fixedly connected with one end of the pressure regulating spring 9, and the other end of the pressure regulating spring 9 is fixedly connected with the body 3, and the exhaust valve body is adjusted by position The mechanism is connected with the body 3 .

[0029] Preferably, the position adjustment mechanism includes a pressure regulating valve 8 and a pressure regulating threaded slide rail 12. The pressure regulating threaded slide rail 12 is arranged on the outer surface of the body 3 and is located at the rear of the body 3. The pressure regulating valve 8 The front end of the valve i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com