An electronically controlled formation tester

A formation tester and formation testing technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of adjusting the test time, unable to guarantee the test success rate, affecting the switch performance, etc., to achieve the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

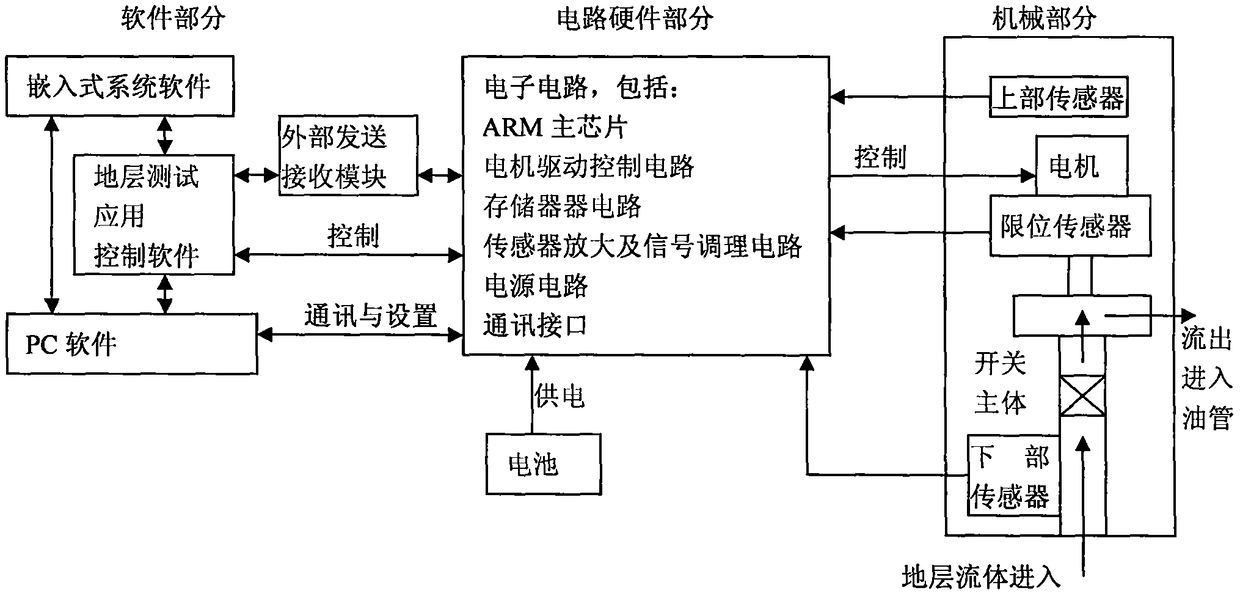

[0064] An electronically controlled formation tester: including a software part, a circuit hardware part and a mechanical part, the software part is a program written into the ARM chip after the program code is compiled, and it sends instructions to the circuit hardware part, and the circuit hardware part is based on The software command controls the work of the mechanical part; wherein, the software includes: embedded system software, formation test application control software and PC software; the circuit part includes: electronic circuit and power supply; the mechanical part includes: motor, more than one sensor It is composed of a formation tester; wherein: the more than one sensor is installed on the formation tester, and the formation tester is provided with a main body switch controlled by a motor ( figure 1 shown).

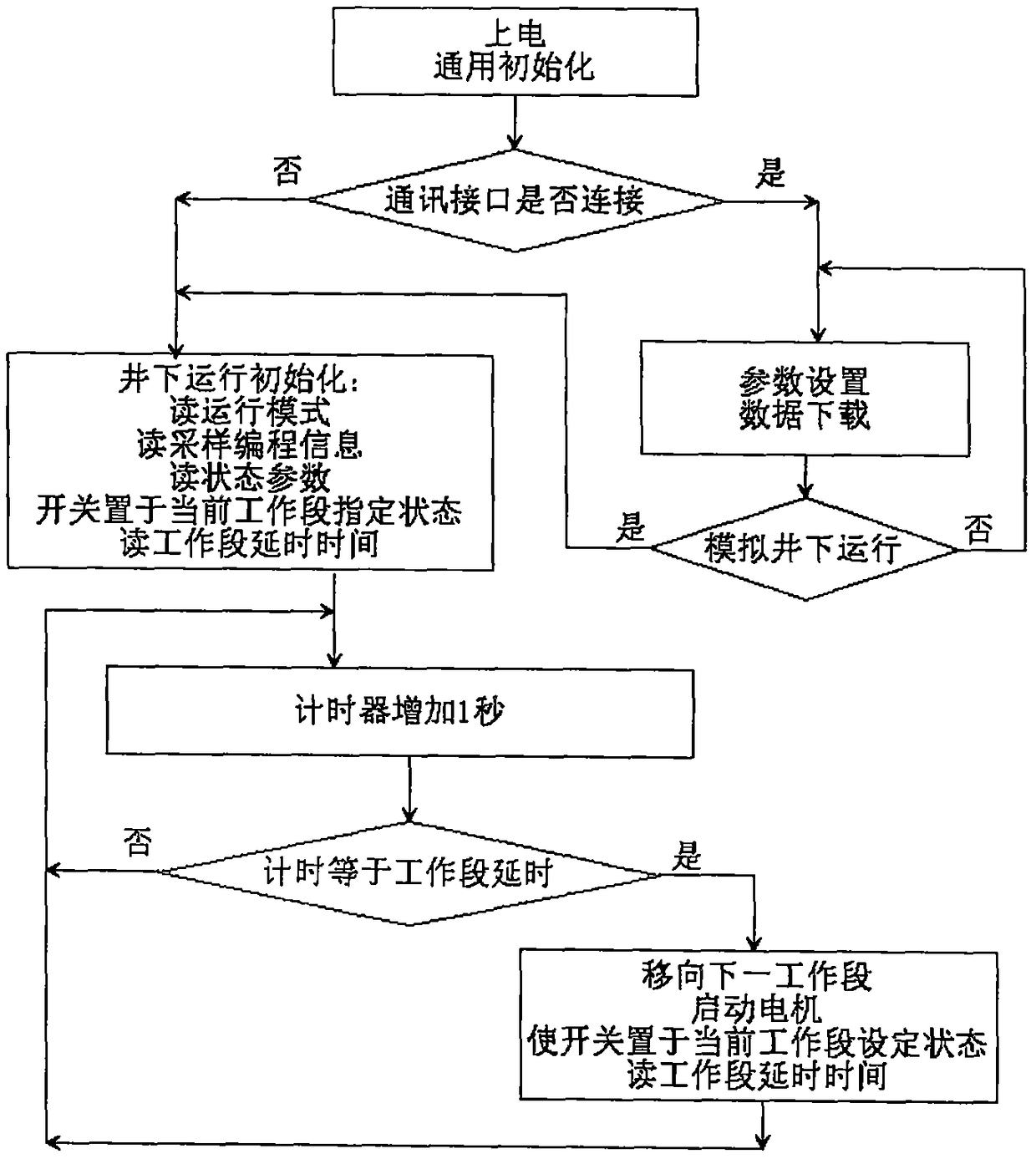

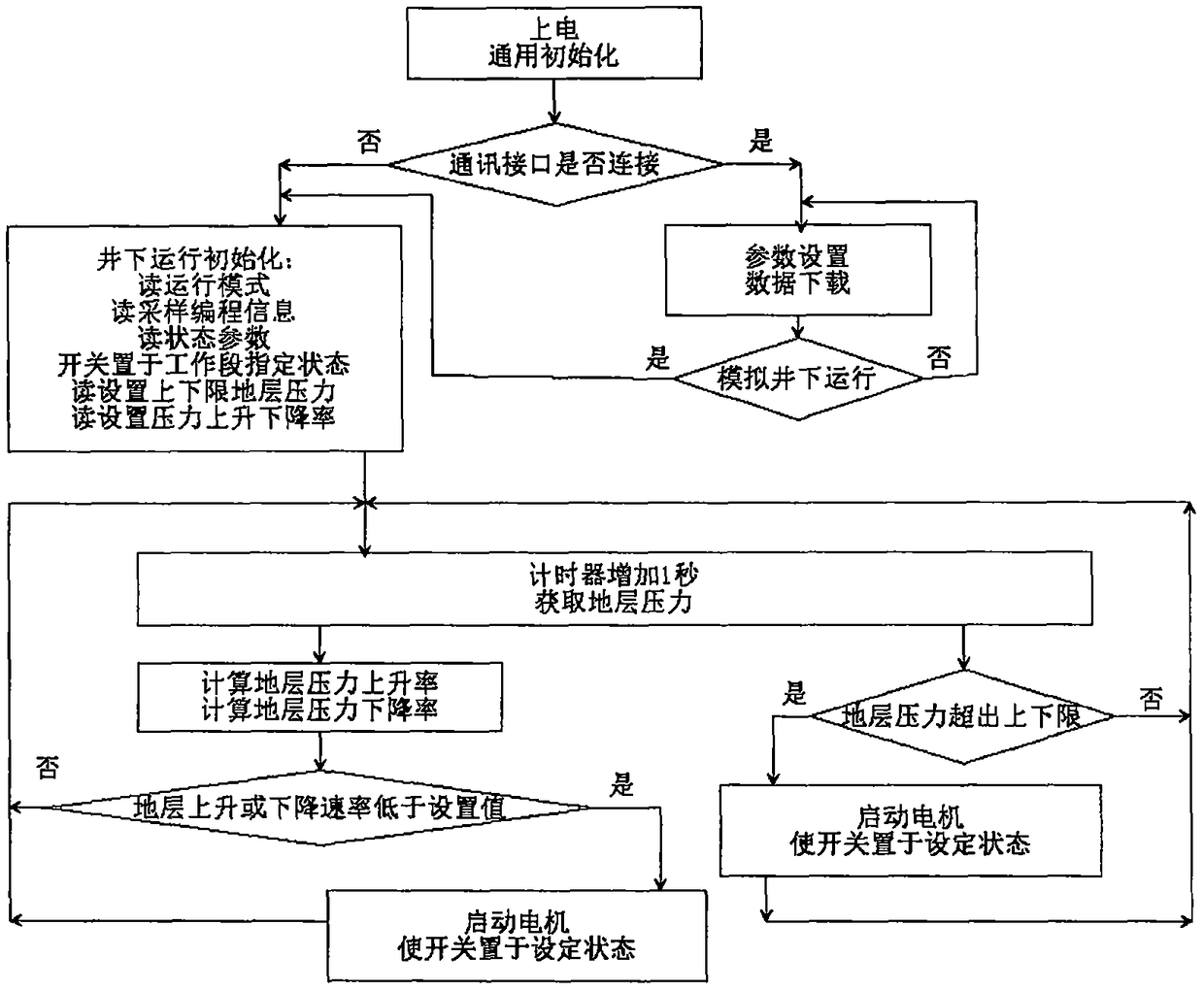

[0065] The formation tester is connected to the PC through the communication port before going into the well, and the parameters of the formation tester a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com