Cooled housing

A shell and cooling channel technology, applied in the field of electric motor shells, can solve the problem of high assembly costs and achieve the effect of ensuring a clear extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

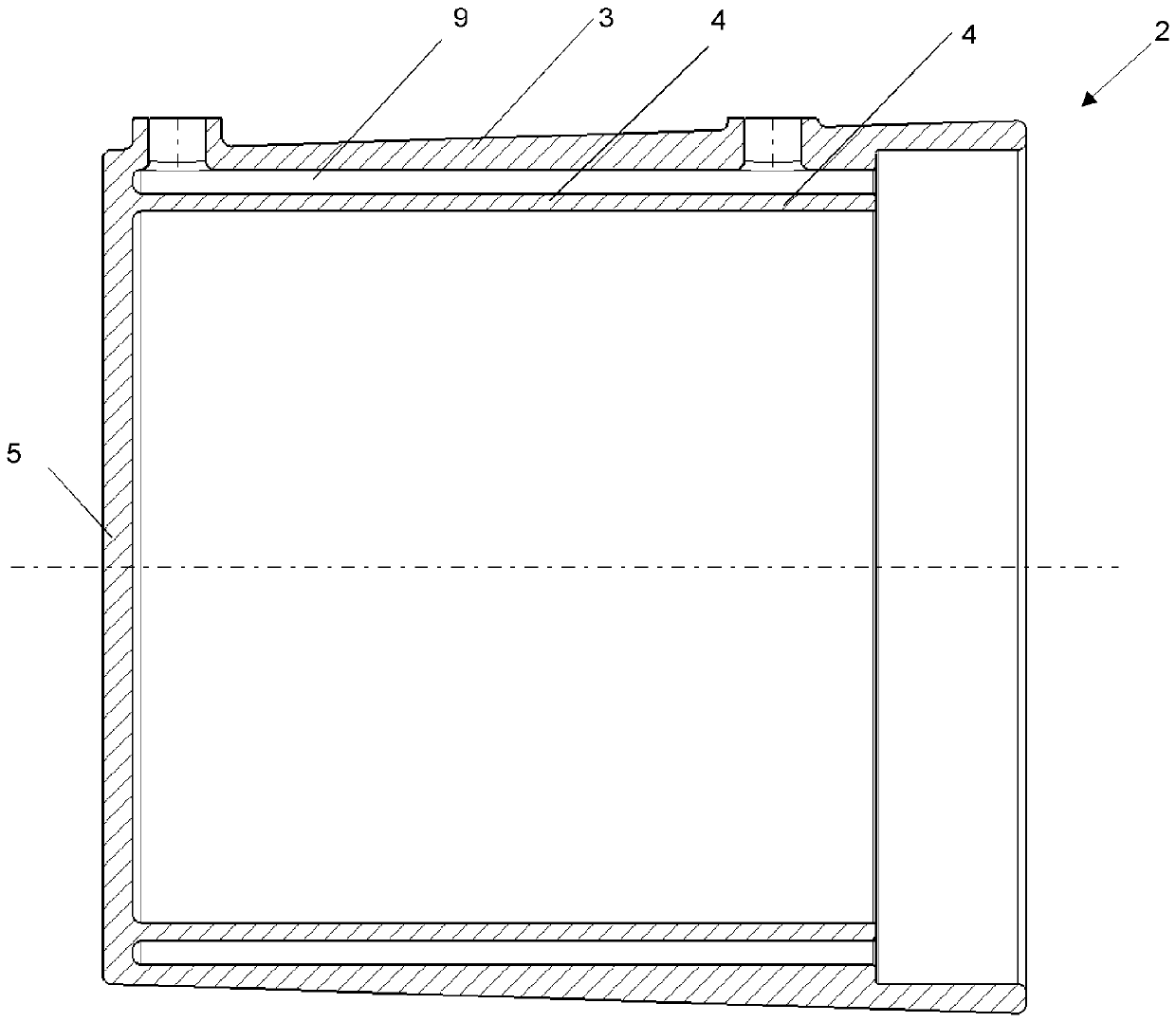

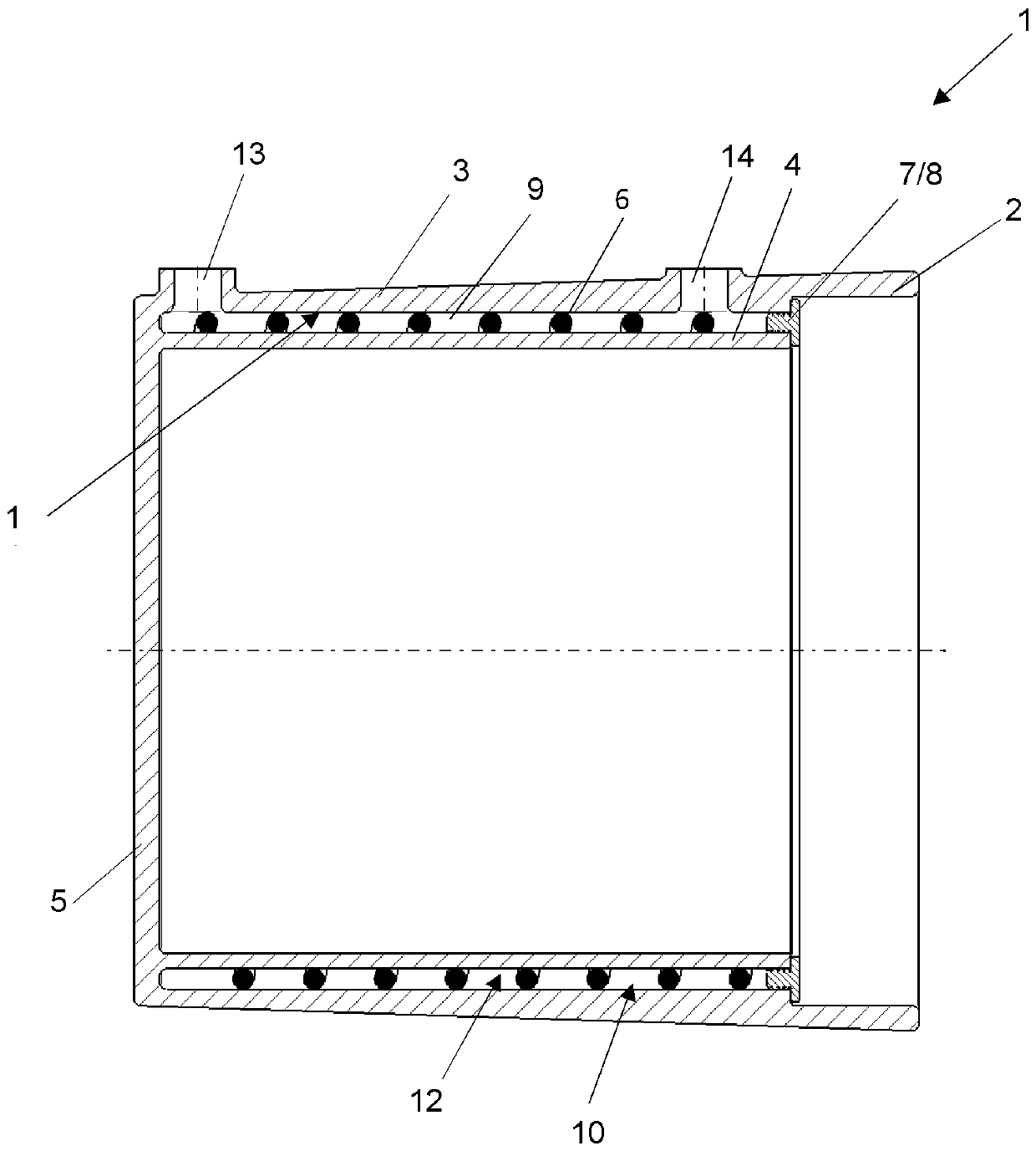

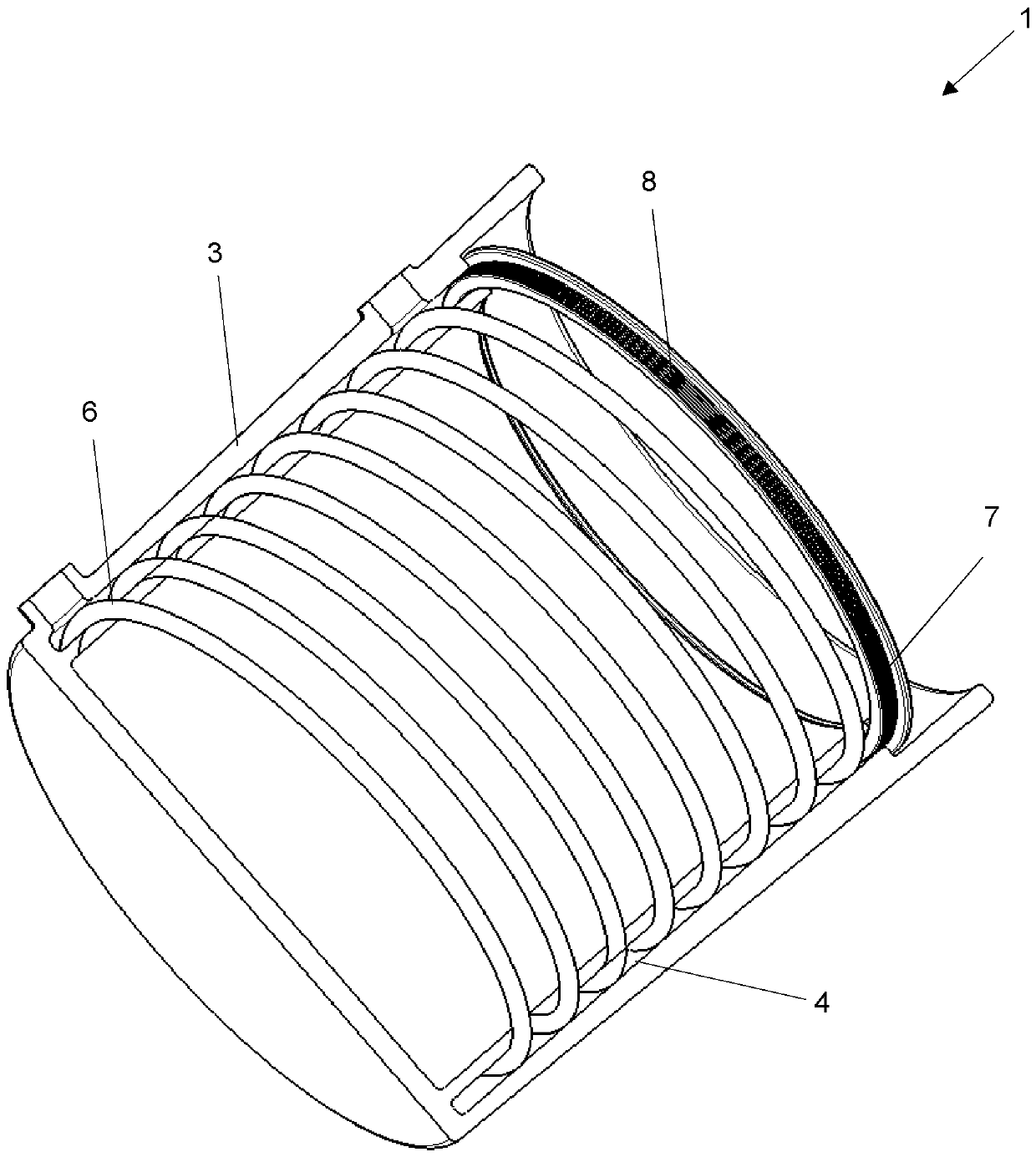

[0026] figure 1 The drawing represented in shows a longitudinal section through an electric motor housing 1 according to the invention. It is clearly evident that the housing 2 is formed in one piece, or in one piece, which in image 3 It is also evident in , where the housing 2 is shown separately. The housing 2 has an outer shell 3 , an inner shell 4 and a termination wall 5 . The outer shell 3 and the inner shell 4 are arranged concentrically to each other and have a circular cross section so as to thus resemble the housing 2 . The inner shell 4 is arranged spaced apart from the outer shell 3 such that a cooling gap 9 is formed between the interior 11 of the shell 3 and the exterior 12 of the inner shell. A helical element 6 is positioned in the cooling gap 9 , said helical element 6 forming a cooling channel 10 extending helically. The helical element 6 is tangential to the interior 11 of the outer shell 3 and the exterior 12 of the inner shell 4, thus forming a closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com