A hydraulic power compensation balance valve

A compensation balance and hydraulic power technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of many sealing points of balance valves, difficult processing, and increased leakage points, etc., to achieve load-flow Compensation, improvement of fretting performance, and less sealing points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

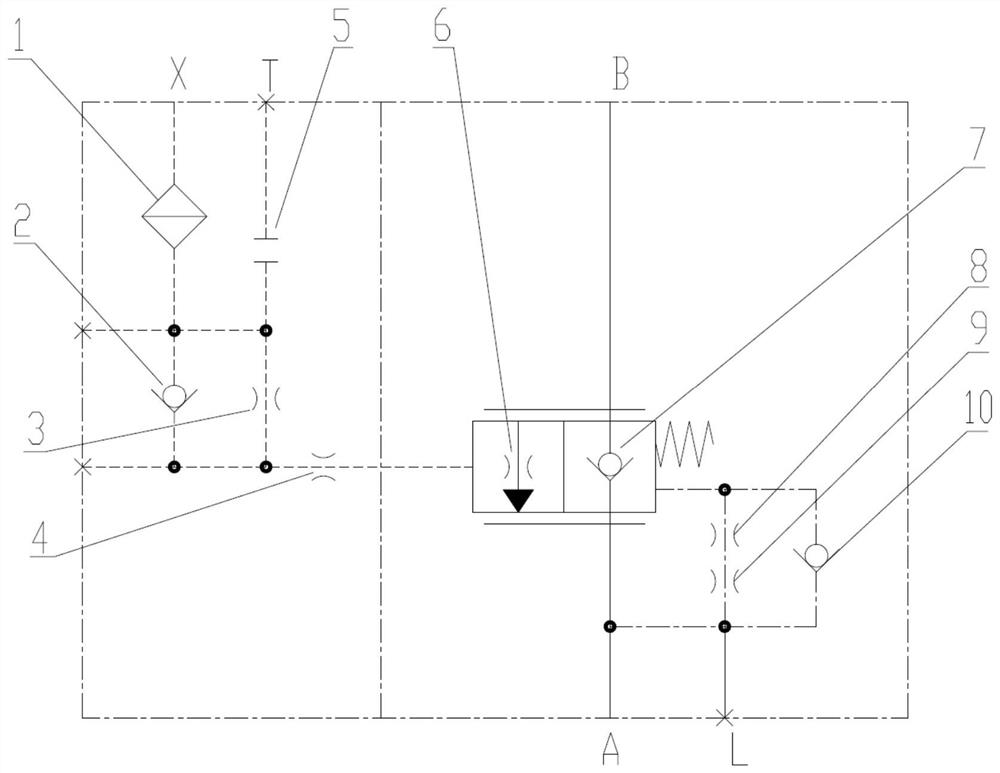

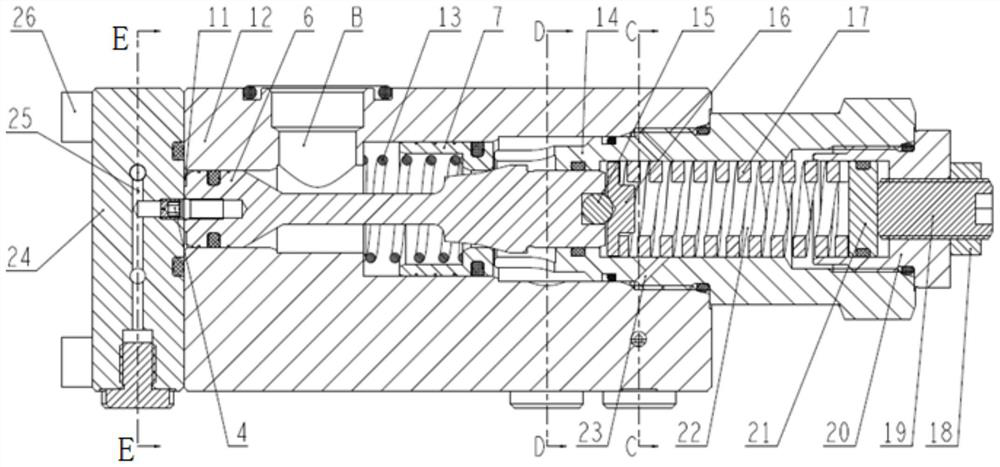

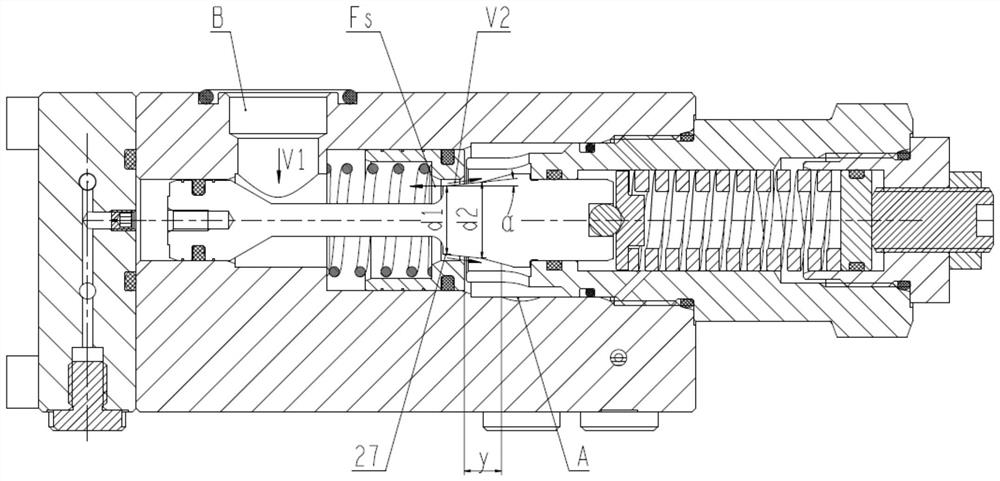

[0043] Such as figure 1 , figure 2 , image 3 As shown, a hydraulic power compensation balance valve includes: pilot control end cover assembly, balance valve body assembly, valve core assembly, one-way valve seat assembly;

[0044] The pilot control end cover assembly includes a control end cover valve body 24, which is provided with a pilot oil port X and a pilot oil passage 25; the spool assembly includes a throttle spool 6, a main spring 17, and a regulating valve seat 20 The one-way valve seat assembly includes a one-way valve 7 and one-way valve spring 13; the balance valve body assembly includes a balance valve body 12 and a valve seat 14, and the balance valve body 12 is provided with oil port B and oil port A, It is also provided with a valve core hole for installing the throttle valve core 6 and the check valve assembly;

[0045] The valve body 24 of the control end cover is fixed and sealed with the left end of the balance valve body 12, the valve seat 14 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com