An anti-stick-slip torsional impact drilling tool

A technology of percussion drilling and torsion force, which is applied in earthwork drilling, wellbore/well components, vibration generating devices, etc., which can solve the problems of drilling tools and wellbore hazards, and achieve the effect of improving ROP and preventing stick-slip phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

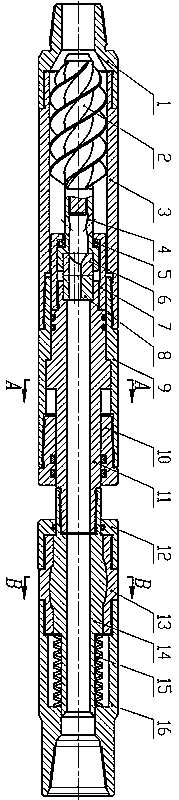

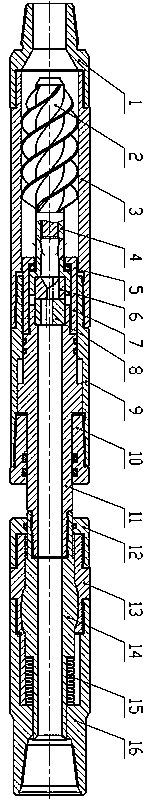

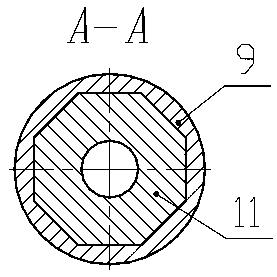

[0015] Such as figure 1 and figure 2 As shown, an anti-stick-slip torsion impact drilling tool of the present invention is composed of an upper joint 1, a helical rotor 2, an outer shell 3, a moving valve seat 4, a thrust bearing 5, a moving valve ring 6, a bearing pressure sleeve 7, a static valve Ring 8, transmission housing 9, upper anti-drop cap 10, transmission shaft 11, lower anti-drop cap 12, screw housing 13, screw shaft 14, disc spring 15 and output shaft 16; its structural features are: upper joint 1 It is connected with the thread on the upper drill string, and the lower end of the output shaft 16 is connected with the thread of the drill bit; the upper end of the outer shell 3 is connected with the lower end of the upper joint 1 with a thread, and the lower end of the outer shell 3 is connected with the upper end of the transmission shell 9; the lower end of the transmission shell 9 It is connected with the upper anti-drop cap 10 with a screw, the middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com