A low-friction variable-diameter hydraulic thruster

A low-friction, thruster technology, applied in the direction of drill pipe, casing, borehole/well components, etc., can solve the problems of difficult pressurization of the drill bit, reduce the friction of the drill string, etc., and achieve the reduction of pipe sticking accidents and friction reduction. Resistance, improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

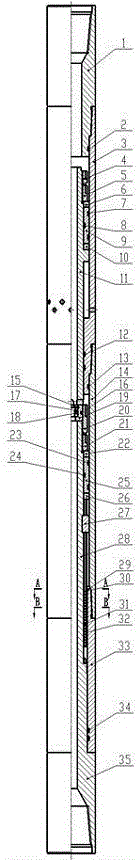

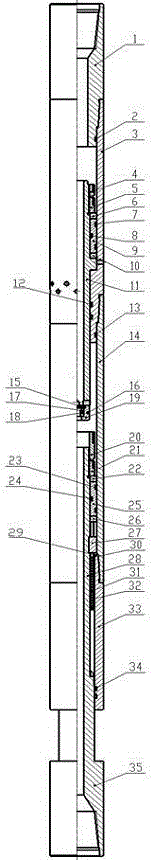

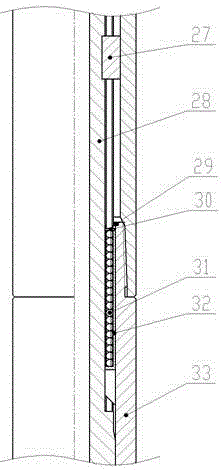

[0016] according to figure 1 After assembling the parts, the whole tool is connected to the drill pipe through the threaded buckle of the upper joint 1, and the lower part of the tool is connected to the drill bit through the mandrel joint 35, and then goes down to the designated drilling position; figure 2 As shown, at this time, the hydraulic thruster is in the initial state, that is, the non-working state, the piston 11 is located at the bottom of the auxiliary cylinder 3, the mandrel 28 is located at the bottom of the main cylinder 14, and the variable diameter structure (nozzle 17 and circle) at the lower end of the piston 11 hole) and the top of the mandrel 28 still have a certain distance; when the drill bit contacts the bottom of the well and encounters resistance, the drill string continues to be lowered, and the mandrel 28 retracts under the action of the drill bit resistance, and contacts with the nozzle seat 19, so that the piston 11 The variable diameter structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com