Motorcar tail lamp and rear steering lamp mounting assembly and motorcar thereof

A technology for rear turn signals and motorcycles, applied in bicycle accessories, transportation and packaging, optical signals, etc., can solve the problems of monotonous shape of metal rear fenders, incomplete illumination of rear license plate lights, and inability to form a whole tail light cover, etc. Achieve the effect of facilitating circuit connection, increasing overall stability and strength, and regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

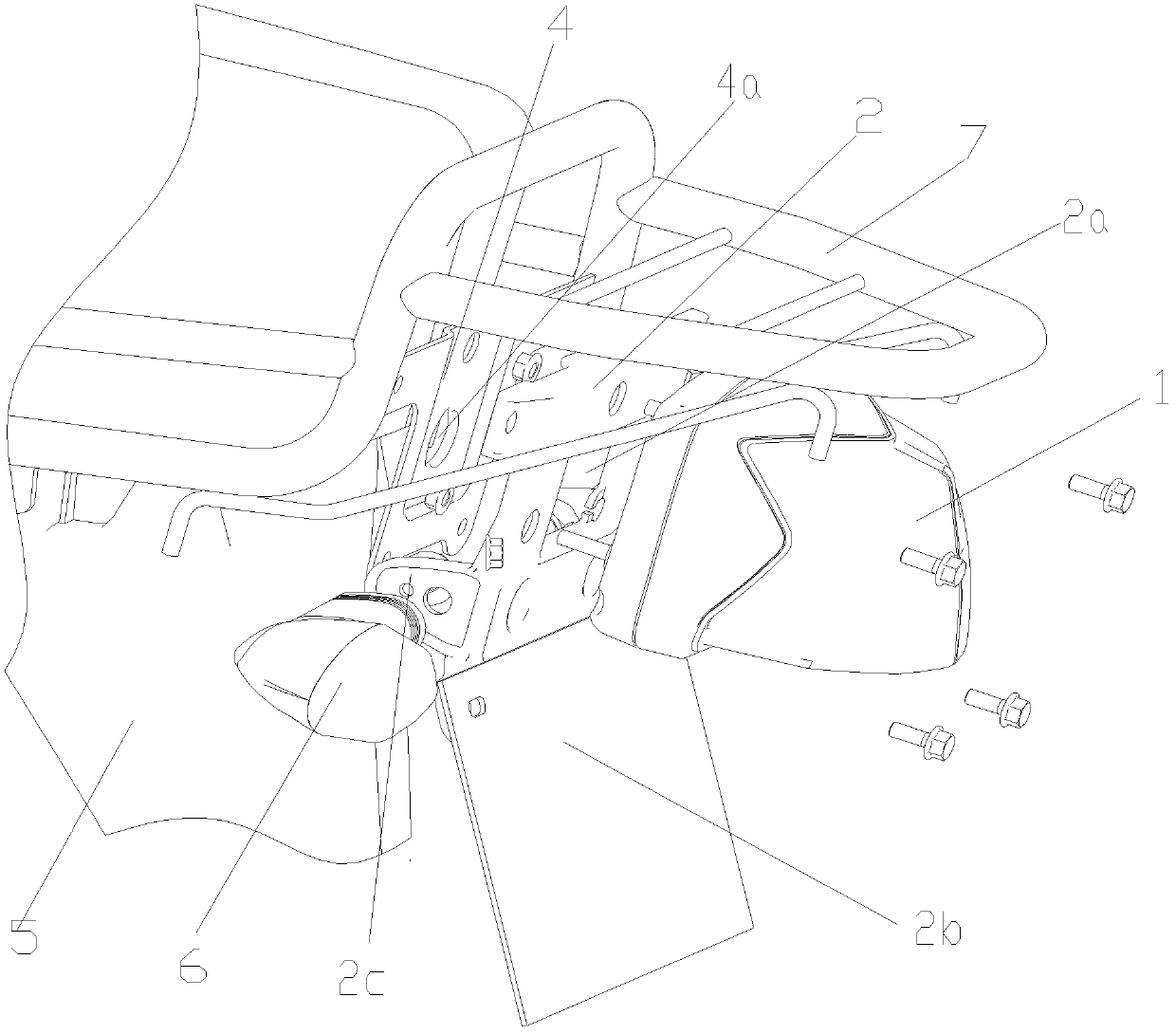

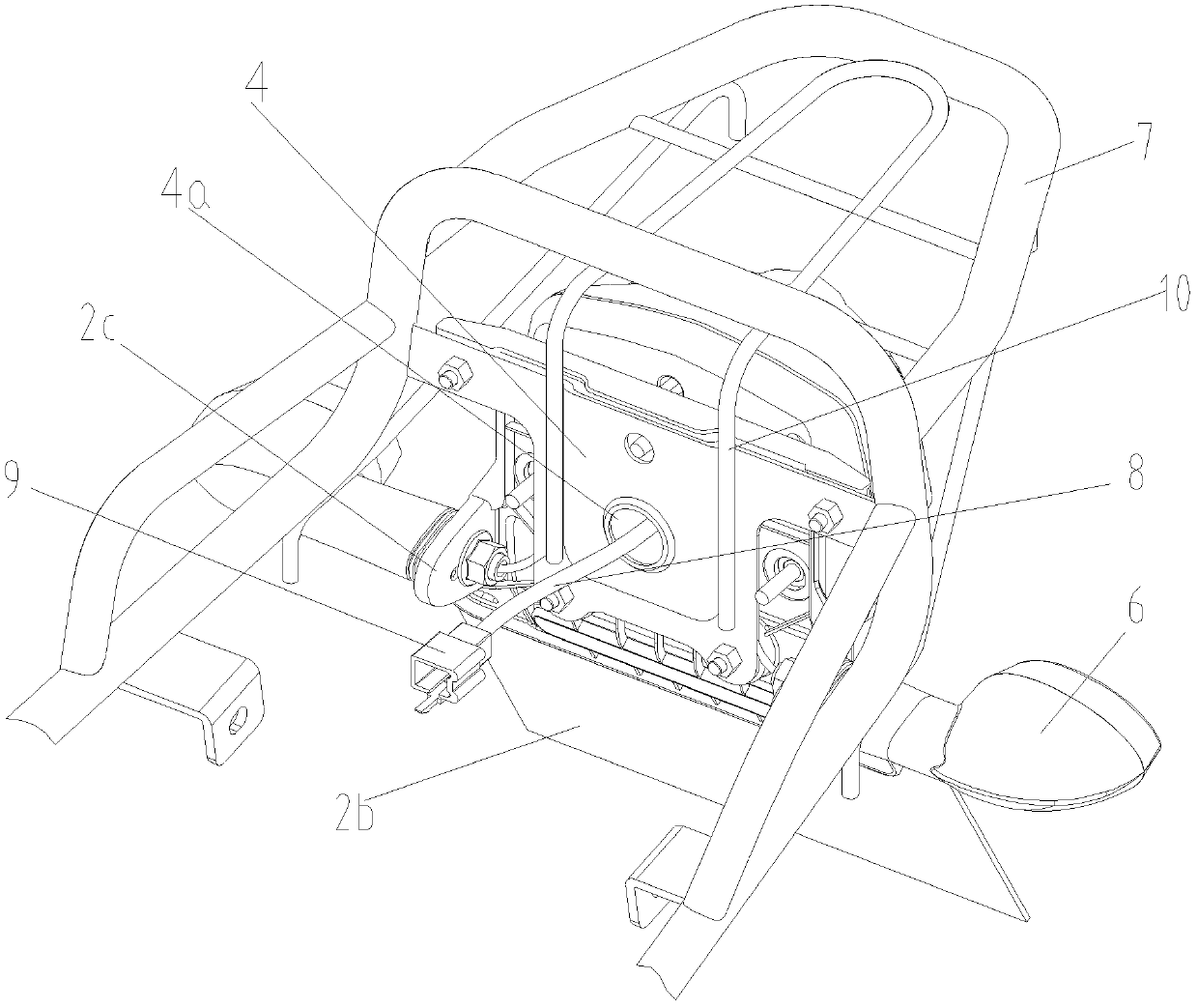

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view of place A, as shown in the figure: the motorcycle tail light and rear turn signal installation assembly of the present embodiment includes tail light assembly 1, turn signal assembly 6 and the tail for being fixedly connected on the motorcycle rear carrier 7 Bracket 2, the tail light assembly 1 and the turn signal assembly 6 are all fixedly connected to the tail bracket 2, the tail bracket 2 extends downwards and forms a license plate installation part 2b for installing the motorcycle license plate frame; the tail light assembly 1 and the turn signal Components 6 all include a lamp holder, a bulb and a lampshade, which are the same as those of the prior art, and will not be repeated here. The difference from the prior art is that the taillight lampshade is an integral structure, or it is firmly bonded as one, so there is no need to replace the bulb. And disman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com