Straight-through proportional valve

A quantitative valve, straight-through technology, used in quantitative devices, sliding valves, valve details, etc., can solve the problems of complex structure of quantitative valves, and achieve the effect of simple structure, convenient maintenance and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

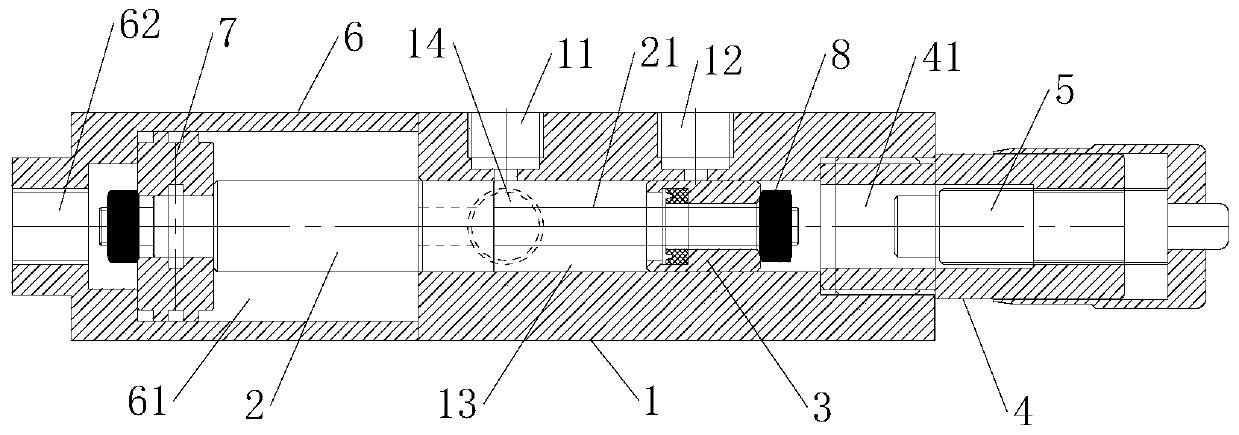

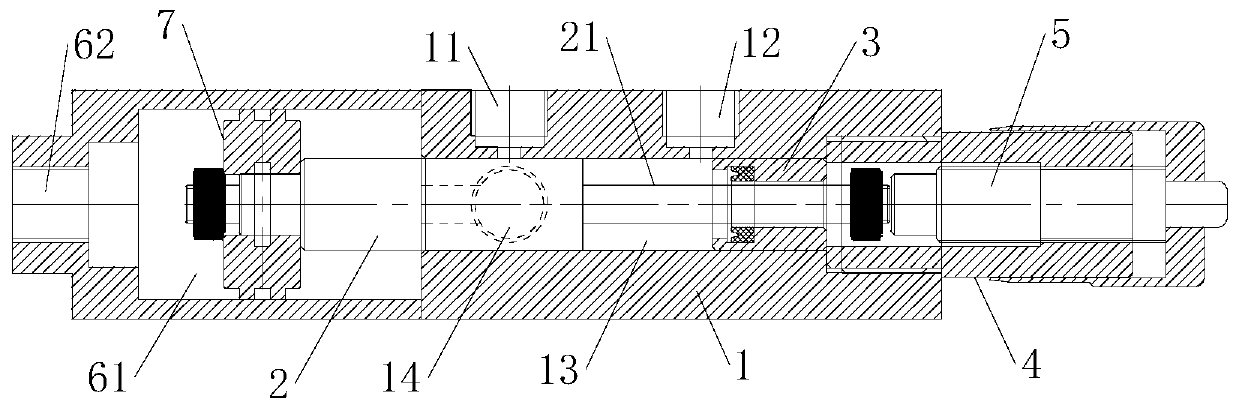

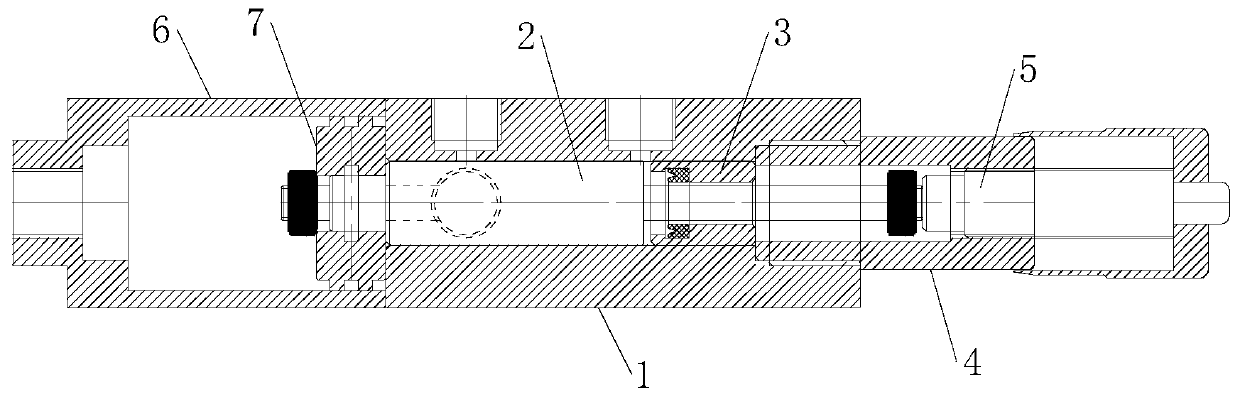

[0030] like Figure 1 to Figure 8 As shown, the straight-through quantitative valve includes a quantitative valve body 1. The quantitative valve body 1 is provided with a quantitative hole 13, an oil inlet hole 11, and an oil outlet hole 12. Both the oil inlet hole 11 and the oil outlet hole 12 communicate with the quantitative hole 13. Quantitative spool 2, one end of quantitative spool 2 is provided with quantitative valve stem 21, the diameter of quantitative spool 21 is less than the diameter of quantitative spool 2, quantitative spool 2 slides and inserts in quantitative hole 13, quantitative spool 2 and The quantitative hole 13 matches; the quantitative piston 3, the center of the quantitative piston 3 is provided with a hole, the quantitative piston 3 slides and is inserted on the quantitative valve stem 21, the quantitative piston 3 is also slid and inserted in the quantitative hole 13, the quantitative piston 3 and the quantitative hole 13 Matching, the quantitative p...

Embodiment 2

[0038] On the basis of above-mentioned example one, also comprise quantitative adjustment device, quantitative adjustment device comprises quantitative adjustment rod 5, quantitative adjustment rod 5 is screwed in the stem hole 41 of quantitative seat 4 by screw thread, quantitative adjustment rod 5 is used for adjusting quantitative valve position of rod 21.

[0039] The quantitative adjustment rod 5 can limit the moving position of the quantitative valve rod 21, that is, control the distance between the quantitative valve core 2 and the quantitative piston 3 when extruding grease, thereby controlling the size of the oil storage chamber when the oil is discharged, and realizing the oil output. Adjustment, expanding the adjustment range of the oil output, so that the straight-through quantitative valve has a wide range of applications.

Embodiment 3

[0041] The difference between this embodiment and the second embodiment lies in the quantitative valve rod 5, and the quantitative adjustment rod 5 is a differential head in this embodiment. The differential head can accurately adjust the oil output to achieve high-precision adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com