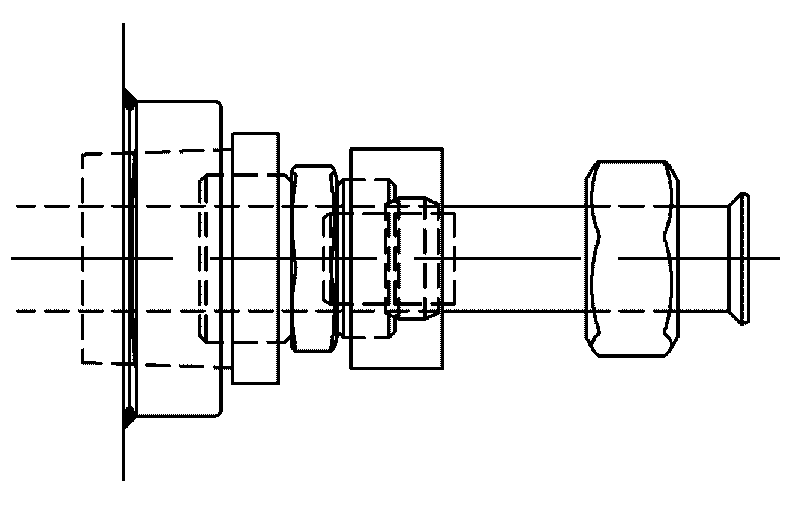

Sealing method for mounting coil pipe of solar water tank

A technology for solar water tanks and coils, applied in the field of sealing, which can solve the problems of high thread processing requirements, many sealing points, and unreliability, and achieve the effect of low installation requirements, no possibility of leakage, and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

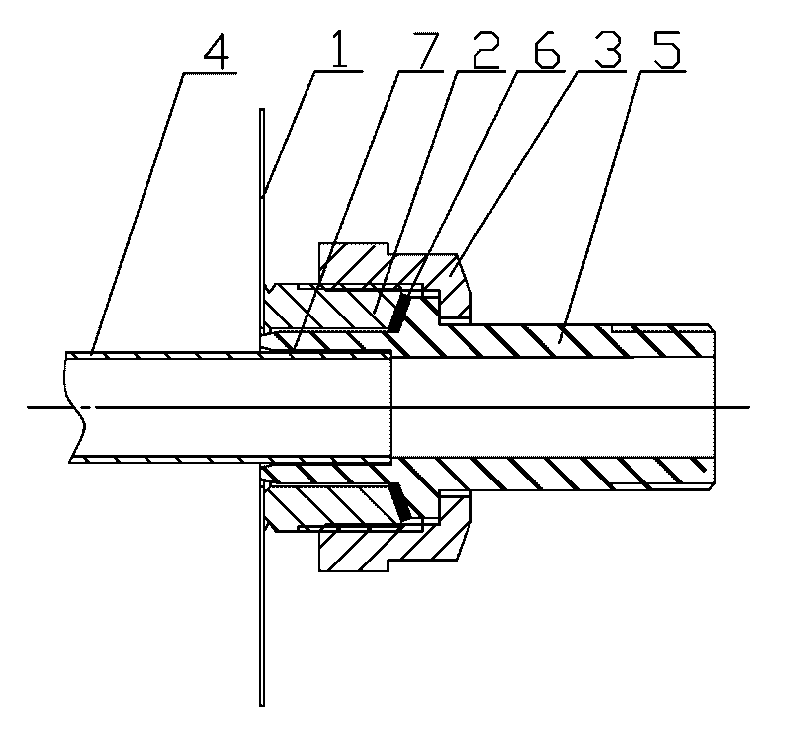

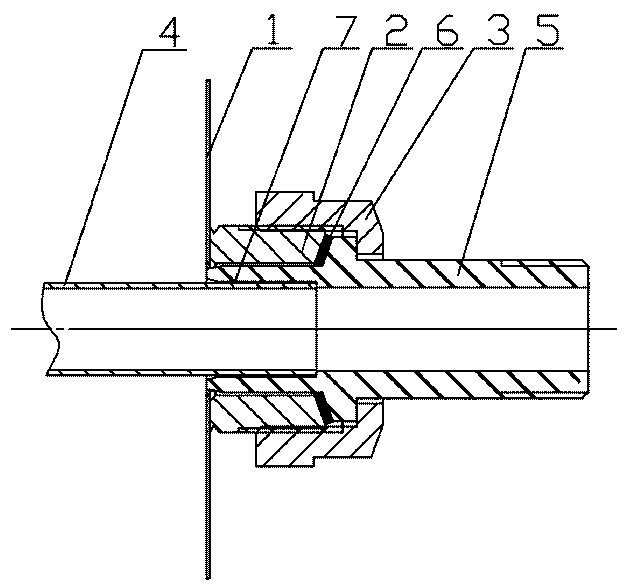

[0010] As can be seen from the accompanying drawings, the sealing method for installation of solar water tank coils includes welding the tube base 2 on the water tank liner cylinder 1, and is characterized in that it includes the following steps: 1) connecting the copper coil 4 from the water tank liner cylinder 1 protrude from the installation hole position, and the sealing joint 5 with butterfly sealing surface is set on the end of the copper coil tube 4, and the sealing joint 5 and the copper coil tube 4 are welded together by silver soldering brazing process; 7 in the figure 2) On the butterfly sealing surface of the sealing joint 5, a sealing gasket 6 processed by a thin copper sheet is used, and the sealing joint 5 welded with the pipe end of the copper coil tube 4 is inserted into the inner hole of the pipe seat 2 for installation 3) Put the nut 3 on the sealing joint 5, and fasten it with the thread connection on the pipe seat 2, and the sealing gasket 6 is tightly comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com