Oil-gas recycling device based on glassy-state membrane separation-absorption process

A recovery device and glass-like technology, which is applied in the recovery of liquid hydrocarbon mixtures, separation methods, and dispersed particle separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

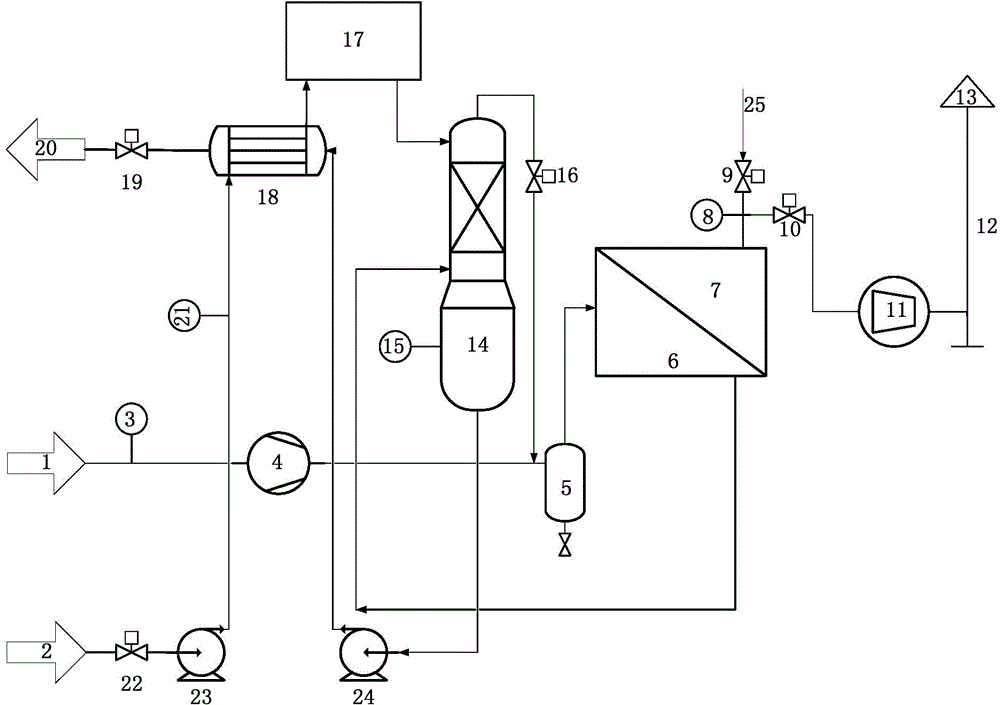

[0026] figure 1 In the oil and gas recovery process shown, the oil and gas inlet is connected to the oil and gas closed collection system of the tank farm, the oil and gas closed collection system of the oil generating station or other oil and gas closed collection systems. The oil and gas inlet pipeline is connected to the inlet of the induced fan, the outlet of the induced fan is connected to the inlet pipeline of the condensate tank, the gas phase outlet of the condensate tank is connected to the inlet of the glassy membrane module, the permeate side of the glassy membrane module is connected to the inlet of the vacuum pump, and the glassy membrane The retentate side outlet of the module is connected to the absorption tower, the top outlet of the absorption tower is connected to the inlet pipeline of the condensate tank, the bottom outlet pipeline of the absorption tower is connected to the tube side inlet of the heat exchanger, and the shell side inlet of the heat exchanger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com