Discharge system and process of refuse incinerator flue gas

A waste incinerator and flue gas technology, which is applied in the exhaust system and process field of waste incinerator flue gas, can solve the problems of limited deacidification efficiency, difficulty in completely realizing ultra-low emission treatment, and difficulty in emission control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

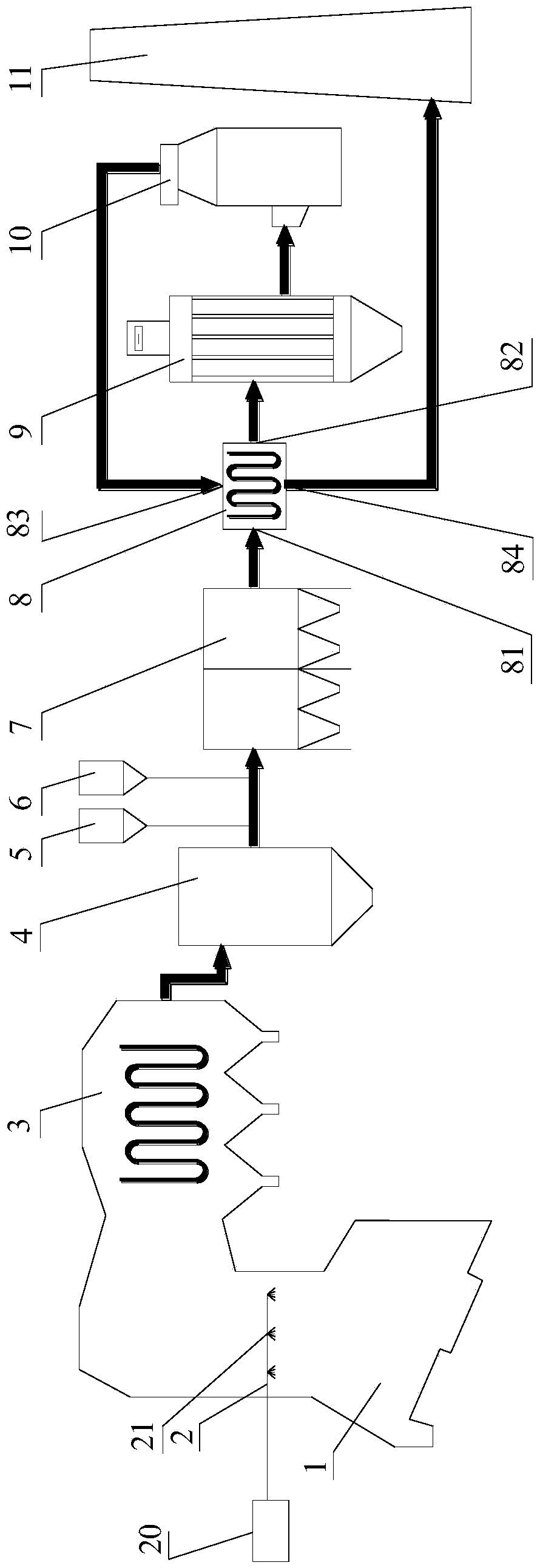

[0043] Please refer to figure 1 As shown, the present invention provides a waste incinerator flue gas discharge system, comprising: an incinerator 1 connected in sequence, a waste heat boiler device 3, a semi-dry rotary spray device 4, a bag dust removal device 7, and a gas-gas heat exchanger (GGH) 8, low temperature plasma reactor 9 and wet deacidification tower 10.

[0044] The incinerator 1 is provided with an SNCR denitrification device 2 for primary denitrification of the flue gas generated by the incinerator 1 . The semi-dry rotary spraying device 4 and the bag dust removal device 7 are connected through a flue, and the flue is provided with an activated carbon flue mixing injection device 5 and a dry powder flue mixing injection device 6 .

[0045] The gas-gas heat exchanger 8 has a hot gas inlet 81, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com