Gasoline and diesel general purpose internal-combustion engine

A technology for internal combustion engines and combustion chambers, which is applied in the field of general-purpose internal combustion engines combining gasoline and diesel, and can solve problems such as unrealizable structures, failure to meet expected indicators, and inability to separate from spark plugs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

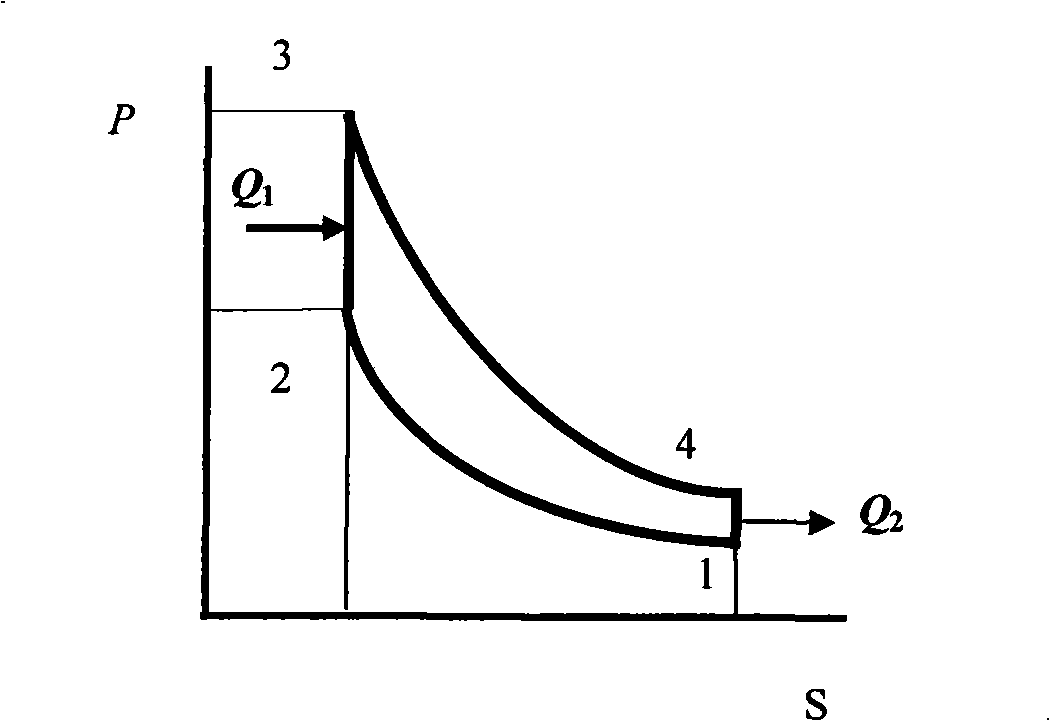

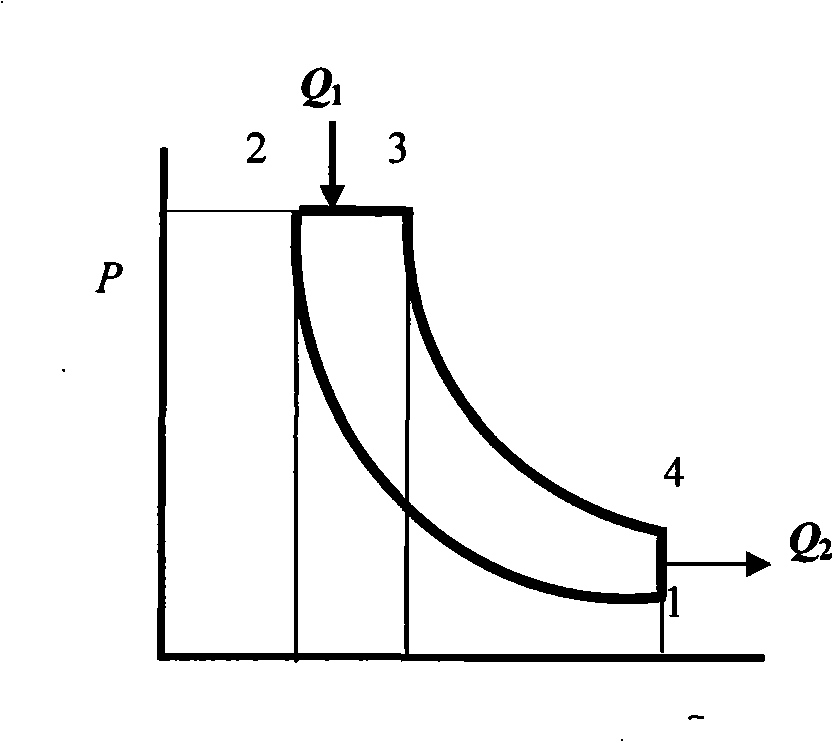

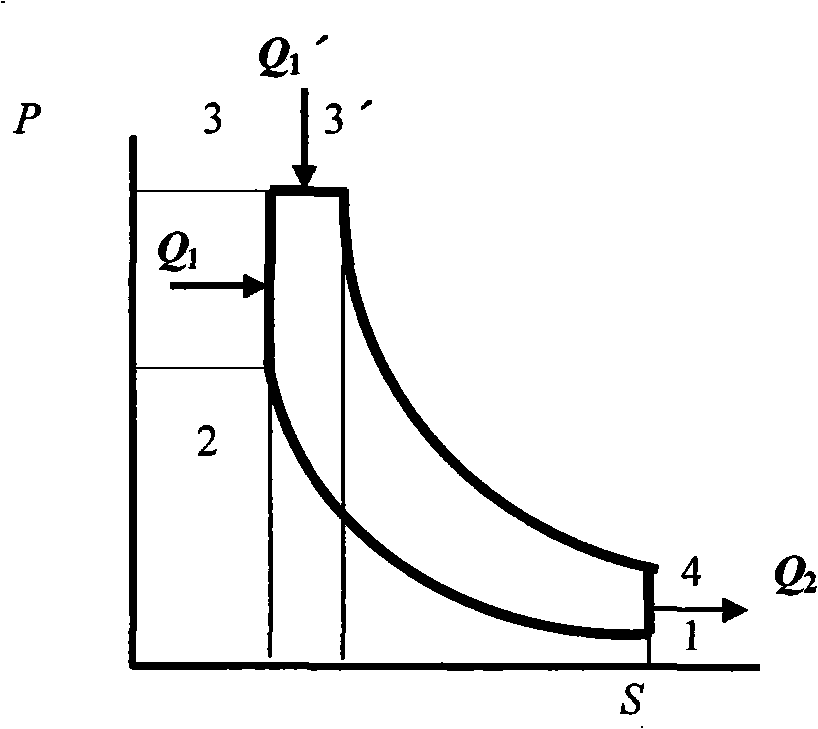

[0025] see Image 6 with Figure 7 , the combustion chamber 16 composed of the cylinder head 17 and the piston 14, the combustion chamber 16 is a high compression ratio combustion chamber, the upper end of the buffer pressure storage valve body 1 is provided with a communication pipe 13 connected with the buffer pressure storage valve body 1, and the communication pipe 13 is installed On the cylinder head 17, the other end is provided with a compression nut 2 with a first through hole 4 and an adjusting gasket 3 with a second through hole 6, and a bushing 15 and a cone are provided in the buffer pressure storage valve body 1. The sealing piston 9 and its spring 8 and sealing ring 10 are provided with an adjusting bolt 5 corresponding to the tapered sealing piston 9 on the compression nut 2, and a pressure storage chamber 11 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com