Patents

Literature

62results about How to "No detonation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

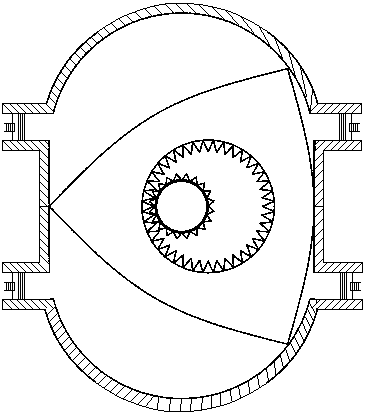

Rotor high-low pressure power device and work doing method of rotor high-low pressure power device

InactiveCN103912324AOvercoming the need for an expanderOvercome costsEngine componentsSteam engine plantsEnvironmental resistanceLiquid storage tank

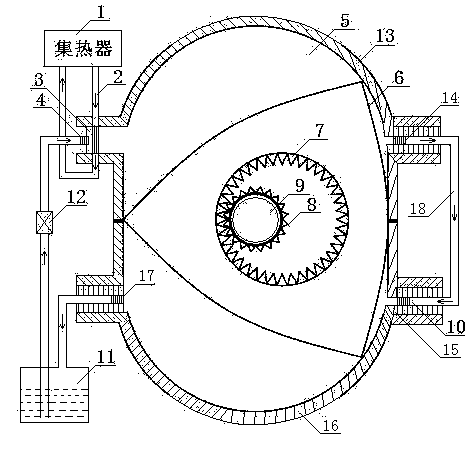

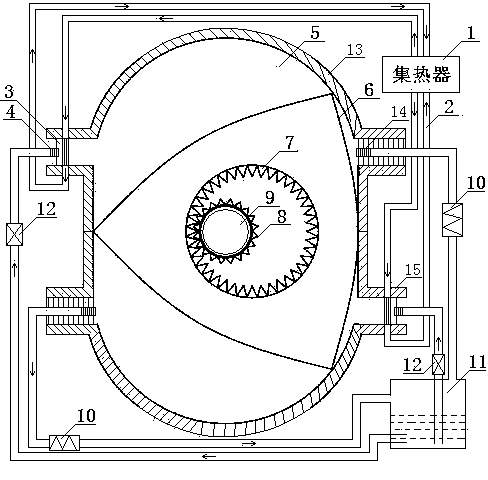

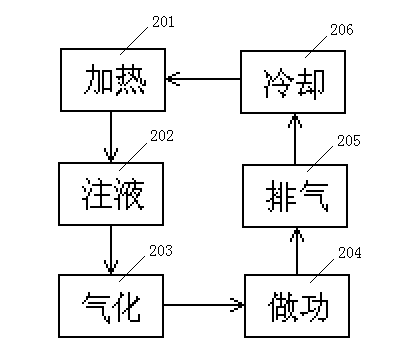

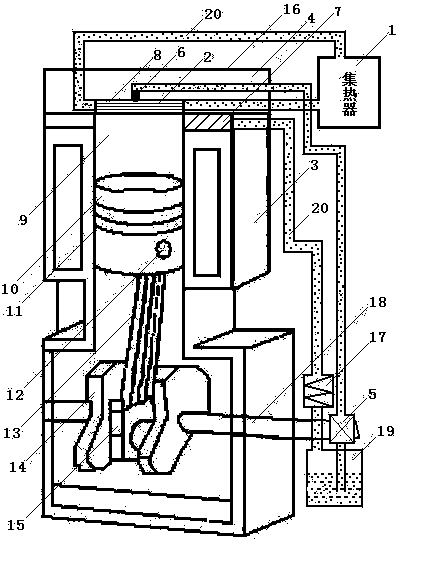

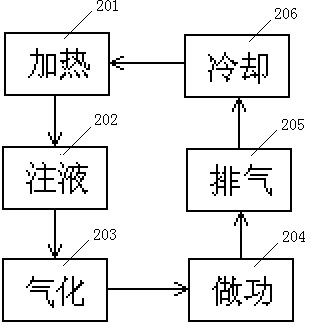

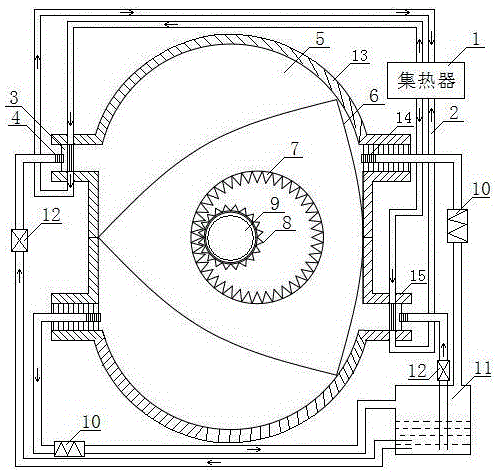

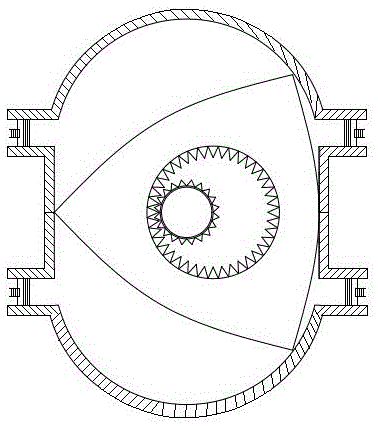

The invention relates to a rotor high-low pressure power device. The rotor high-low pressure power device comprises a heat collector, a heat preservation pipe, a gasification reactor, an atomizer, an air cylinder, a triangular rotor, an inner gear ring, a gear, an output shaft, a one-way air inlet valve, a liquid storage tank, a pressure valve, a heat preservation layer, an automatic air discharging valve, a device shell, a heat dissipation device and an air discharging control valve. The triangular rotor is arranged in the device shell, the inner gear ring and the gear matched with the inner gear ring are arranged in the center of the triangular rotor, the gear is fixed to the output shaft, the air cylinder is divided by the triangular rotor into three even independent spaces, and the ratio of the tooth number of the inner gear ring to the tooth number of the gear is 3:2. The rotor high-low pressure power device has the advantages that work is done three times when a rotor with a rotor engine rotates by a circle, and the horsepower volume ratio is high; the rotor high-low pressure power device is high in operation rotating speed, small in size, light in weight, low in gravity center and small in vibration; media are recycled, and pollution is avoided; the heat energy conversion efficiency ranges from 65% to 98%; conventional energy sources can be substituted, the economic benefits are high, energy is saved, and the rotor high-low pressure power device is environmentally friendly and low in noise.

Owner:郭远军

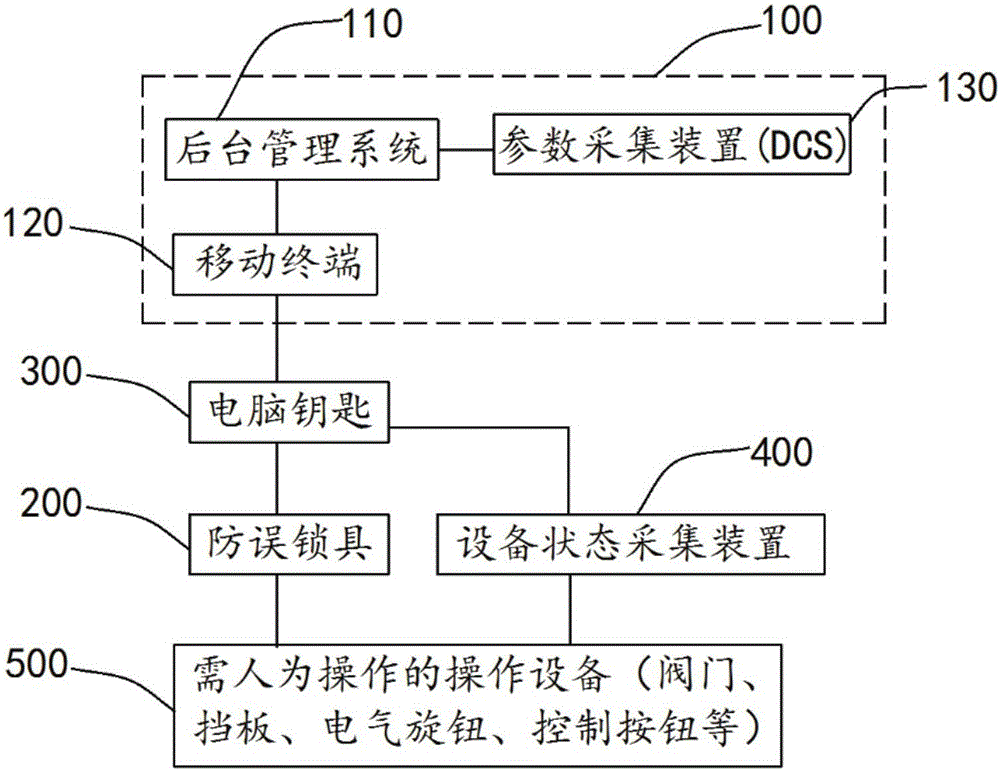

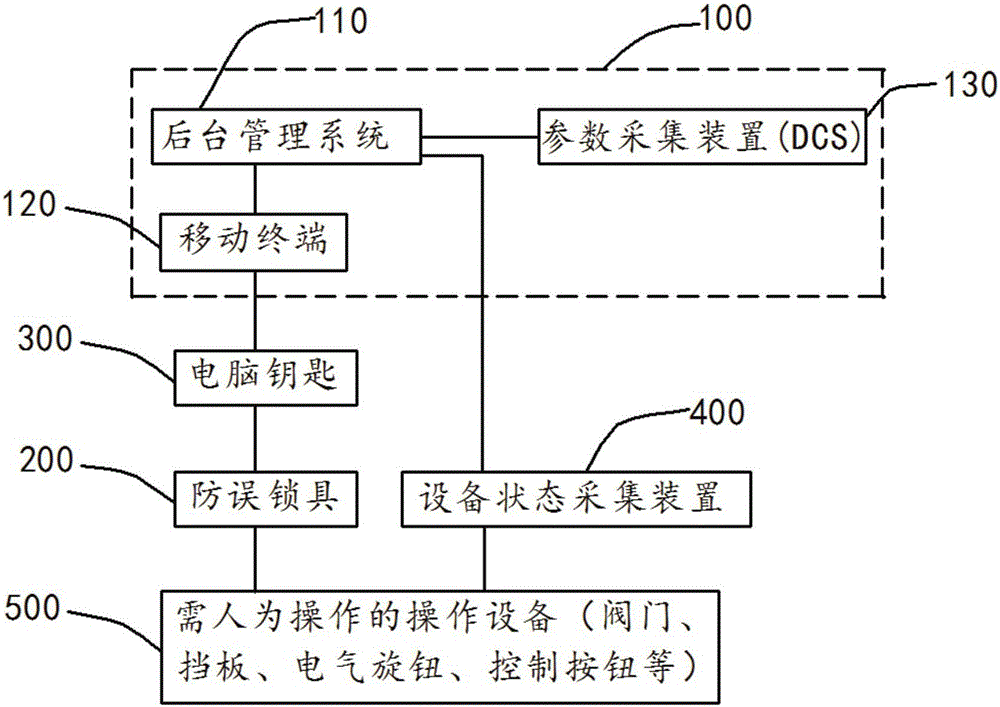

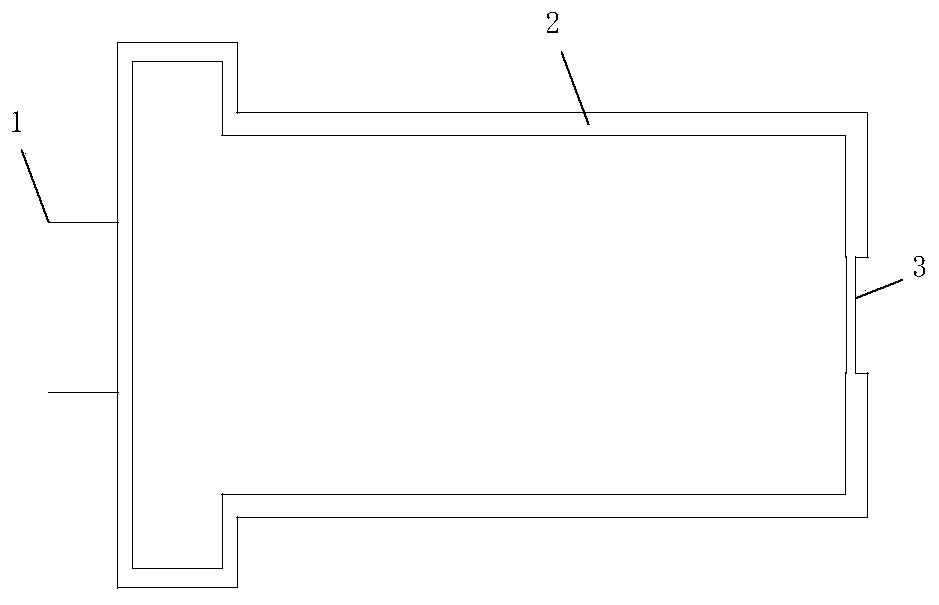

Industrial flow anti-misoperation system and industrial flow anti-misoperation method

PendingCN107436567AEnsure safetyAvoid misuseProgramme control in sequence/logic controllersControl systemControl engineering

The invention provides an industrial flow anti-misoperation system and an industrial flow anti-misoperation method. The anti-misoperation system comprises a control system, an anti-misoperation lock, a computer key, and a parameter acquisition device. The control system is communicated and connected with the computer key. The anti-misoperation lock is disposed on operation equipment, which has a requirement on prevention of manual misoperation during a technological flow process, and is used to lock the operation state of the operation equipment. The parameter acquisition device is communicated and connected with the control system, and is used to acquire real-time parameters during the technological flow process in a real-time manner, and is used to transmit the acquired parameters to the control system synchronously. The control system is used to determine whether an operation condition or an operation requirement is satisfied according to the current real-time parameters. The computer key is provided with a code reading device and an unlocking device used to unlock the anti-misoperation lock. The anti-misoperation system and the corresponding anti-misoperation method are advantageous in that correct operation of operators on the operation equipment requiring the manual operation during the technological flow process is guaranteed, and the industrial flow anti-misoperation system is capable of preventing the misoperation effectively.

Owner:CYG CONTRON

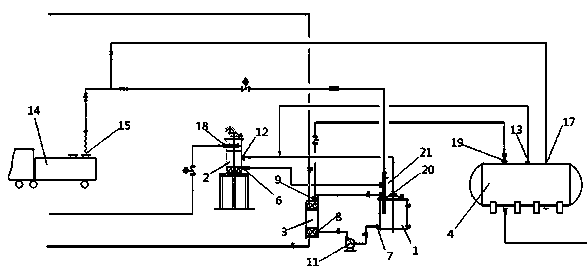

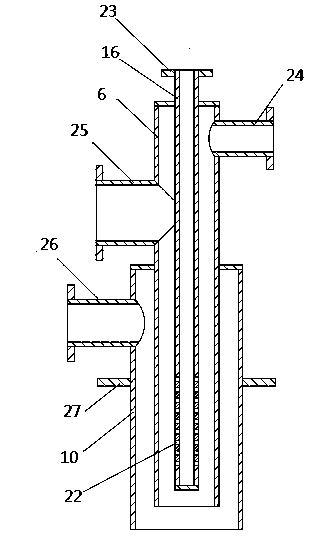

System and method for rapid preparation of ammonia water

ActiveCN103833048AEasy maintenanceLow costAmmonia preparation/separationWater storage tankEnvironmental engineering

The invention discloses a system for rapid preparation of ammonia water, which comprises an ammonia water preparation tank, an ammonia absorption tower, a cooling heat exchanger and an ammonia water storage tank, wherein a new water outlet formed in the bottom of the ammonia absorption tower is communicated with a new water pipe; an ammonia water outlet A formed in the bottom of the ammonia water preparation tank is communicated with an ammonia water inlet A formed in the bottom of the cooling heat exchanger; a circulating pump is arranged on a pipeline between the ammonia water outlet A and the ammonia water inlet A; an ammonia water outlet B formed in the top of the cooling heat exchanger is communicated with a circulating ammonia water pipe; the ammonia water outlet B formed in the top of the cooling heat exchanger is also communicated with an ammonia water inlet B of the ammonia water storage tank; an ammonia gas outlet formed in the top of the ammonia gas preparation tank is communicated with a gas inlet formed in the middle part of the ammonia absorption tower; the gas inlet is also communicated with a gas outlet of the ammonia water storage tank; and the distance from the bottom of the ammonia absorption tower to the top of the ammonia water preparation tank is larger than or equal to 1m. The system can be used for rapid preparation of the ammonia water in a manner of integrating the advantages of an ammonia water preparation process utilizing gaseous ammonia and the ammonia water preparation process utilizing liquid ammonia.

Owner:CINF ENG CO LTD

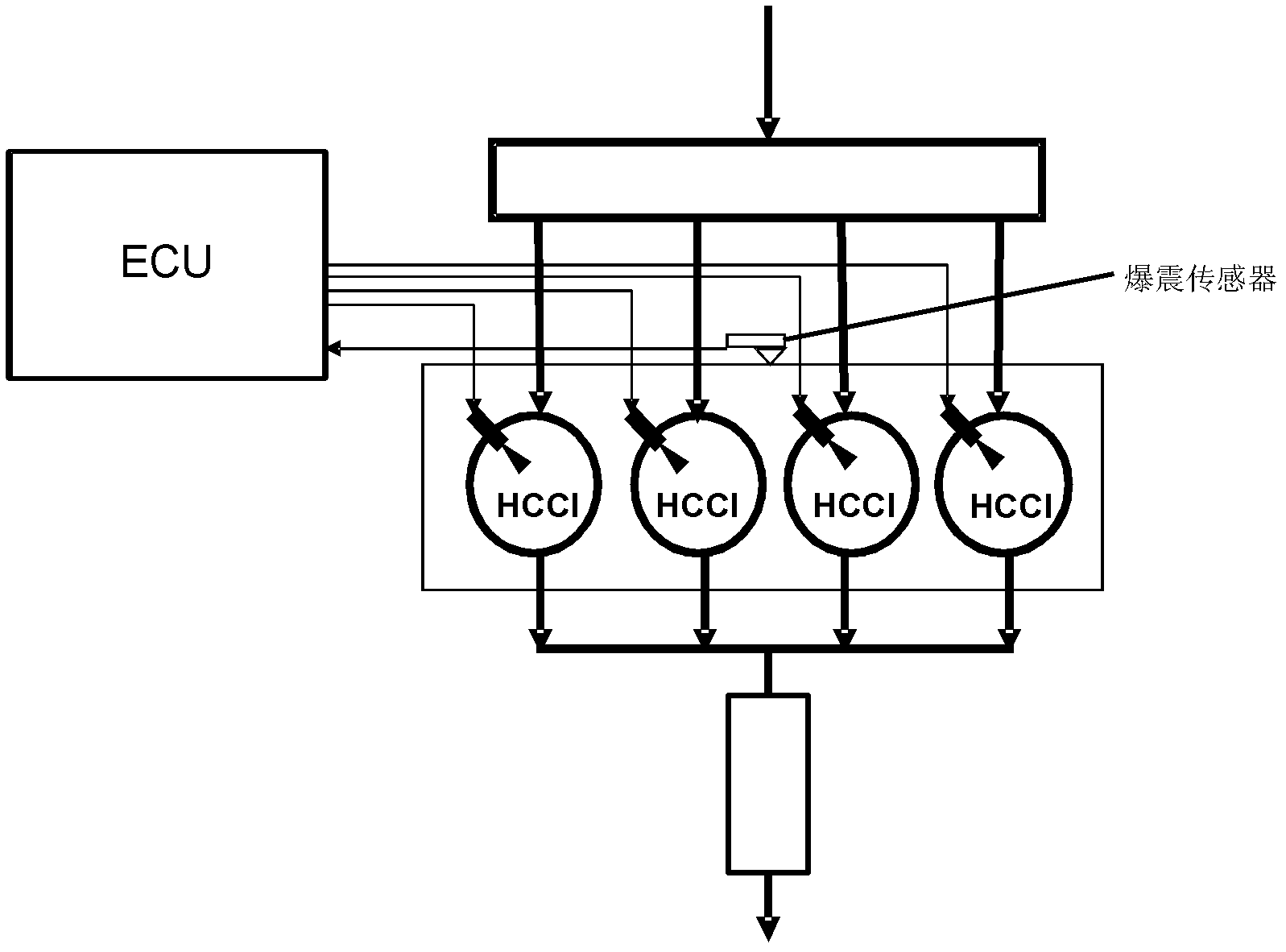

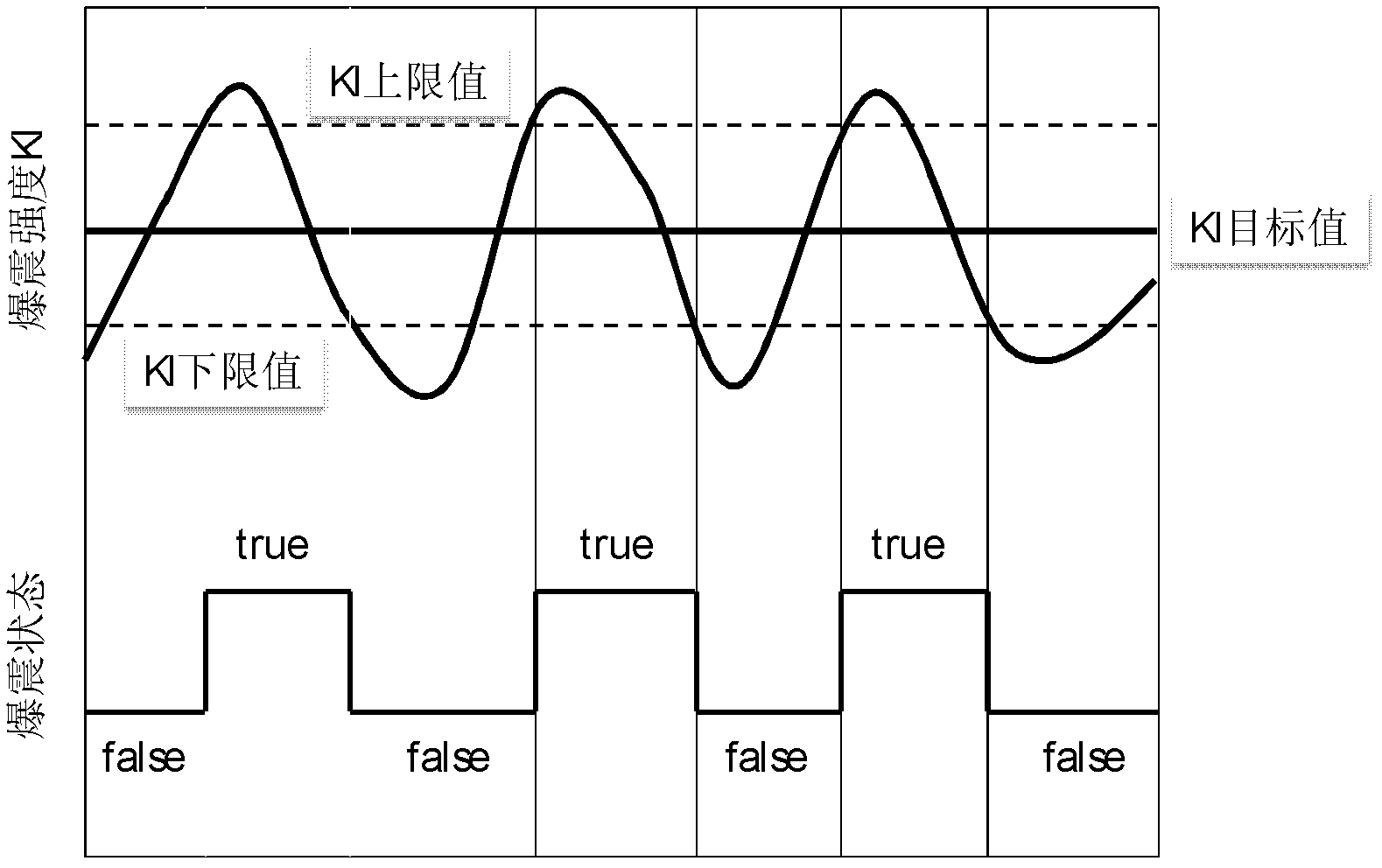

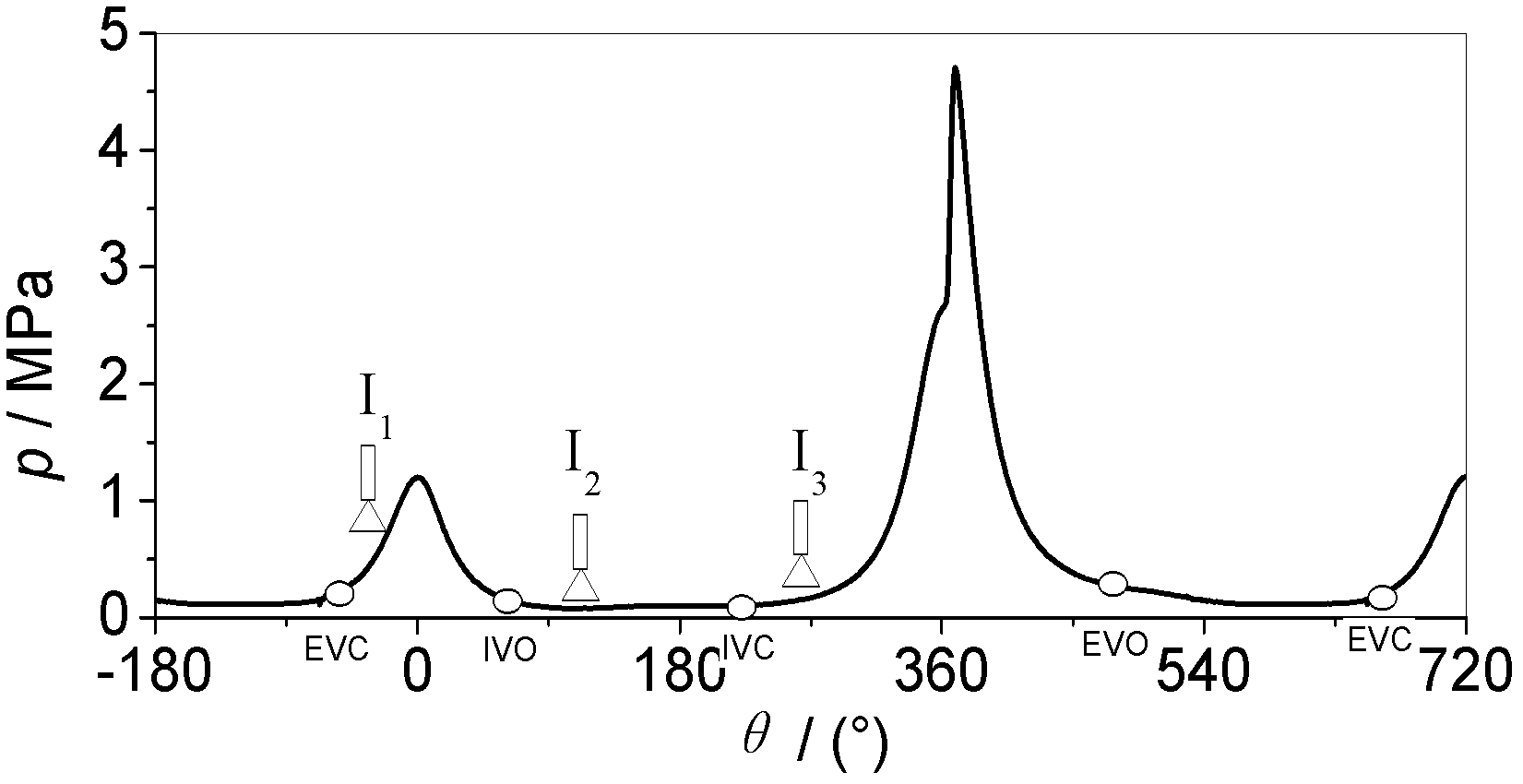

Split cylinder independent closed loop control method for homogeneous charge compression ignition (HCCI) combustion on basis of knock sensor

InactiveCN102518522AStable HCCI combustionLow costElectrical controlInternal combustion piston enginesElectronic control unitHcci combustion

The invention discloses a split cylinder independent closed loop control method for homogeneous charge compression ignition (HCCI) combustion on the basis of a knock sensor, which belongs to the technical field of internal combustion engines and comprises the following steps of utilizing the knock sensor to detect a vibration signal during combustion of the engine; utilizing an electronic control unit (ECU) to perform integral evaluation to obtain a knock strength value according to a vibration signal of the knock sensor; and setting a target value, an upper limit value and a lower limit value of knock input (KI)_i in an ECU procedure. When the knock strength of some cylinder is higher than KI_max, the oil jetting ratio for secondary jetting in the cylinder is increased to enable combustion phase to be delayed; and when the knock strength value of the cylinder is lower than KI_min, the oil jetting ratio for the secondary jetting in the cylinder is decreased to enable the combustion phase to be advanced. Therefore, based on the signal of the knock sensor, the KI_i value is controlled in a closed loop mode, and the HCCI combustion is stabilized in a state close to knock but not enabling knock to happen. Simultaneously, HCCI combustion can not cause fire so that the problem of large difficulty in controlling fire of a petrol HCCI engine is solved. The combustion control method is based on the knock sensor; and compared with a cylinder pressure sensor, cost is low, and reliability is high.

Owner:TSINGHUA UNIV

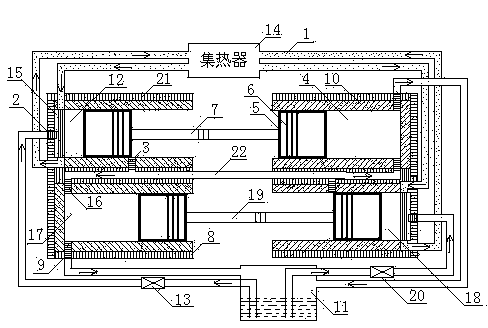

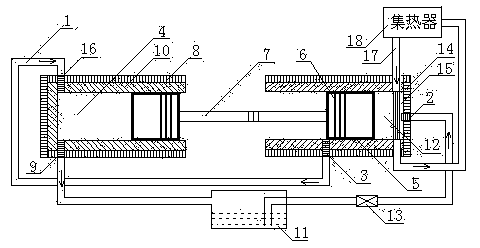

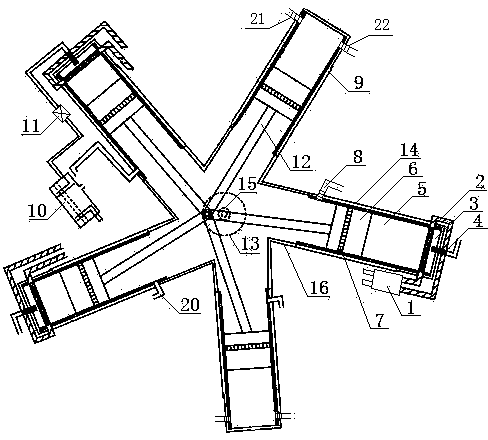

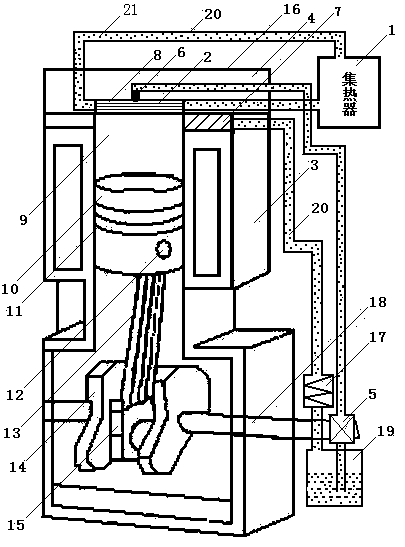

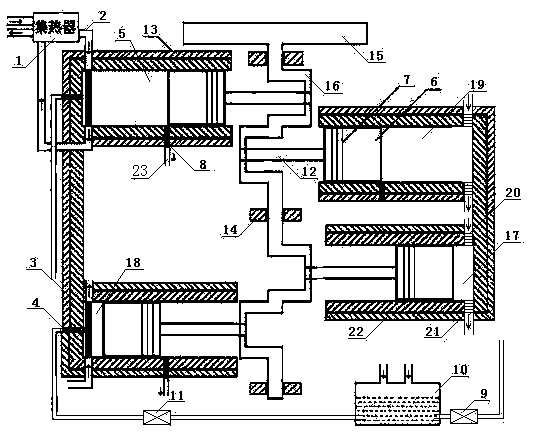

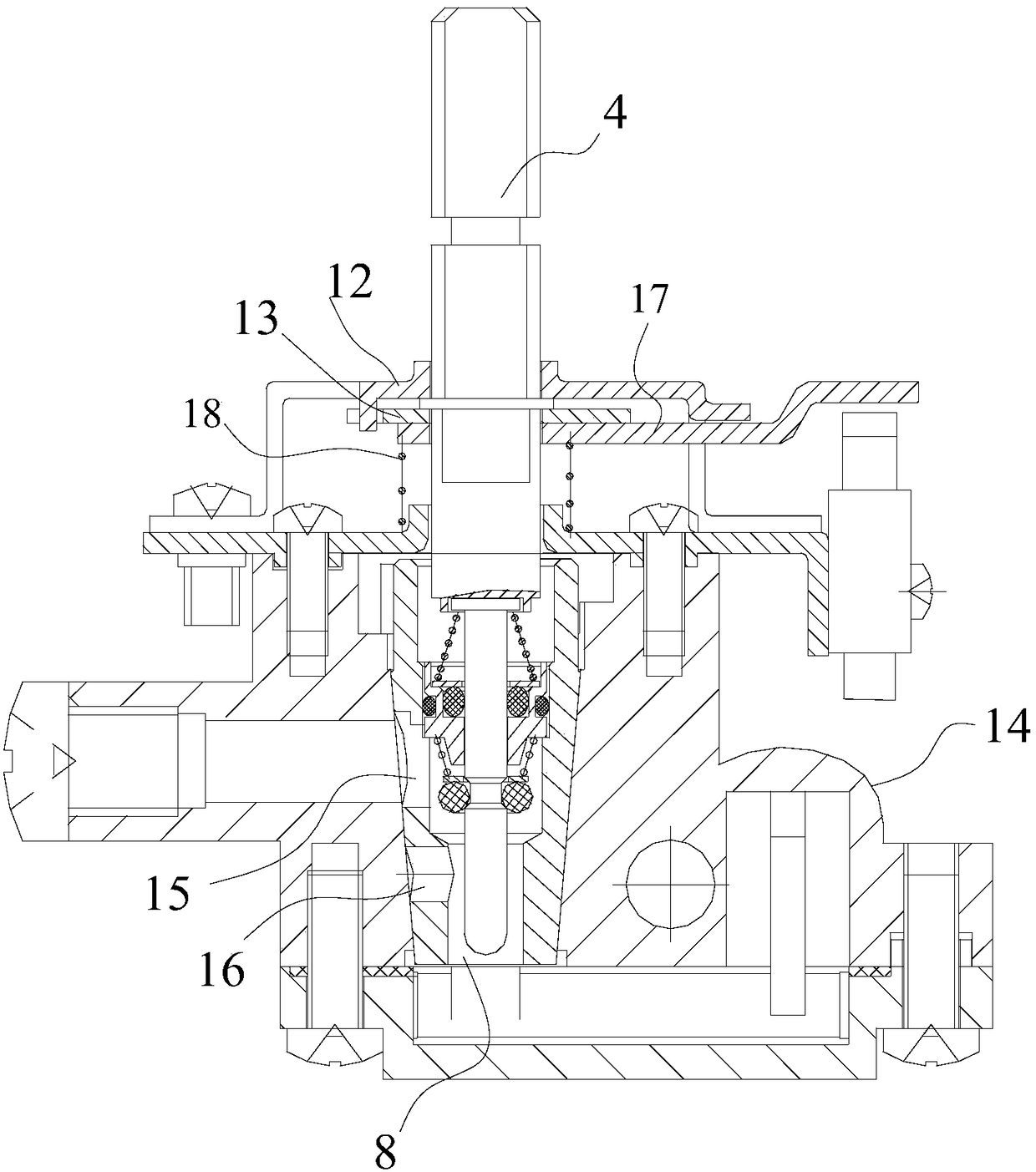

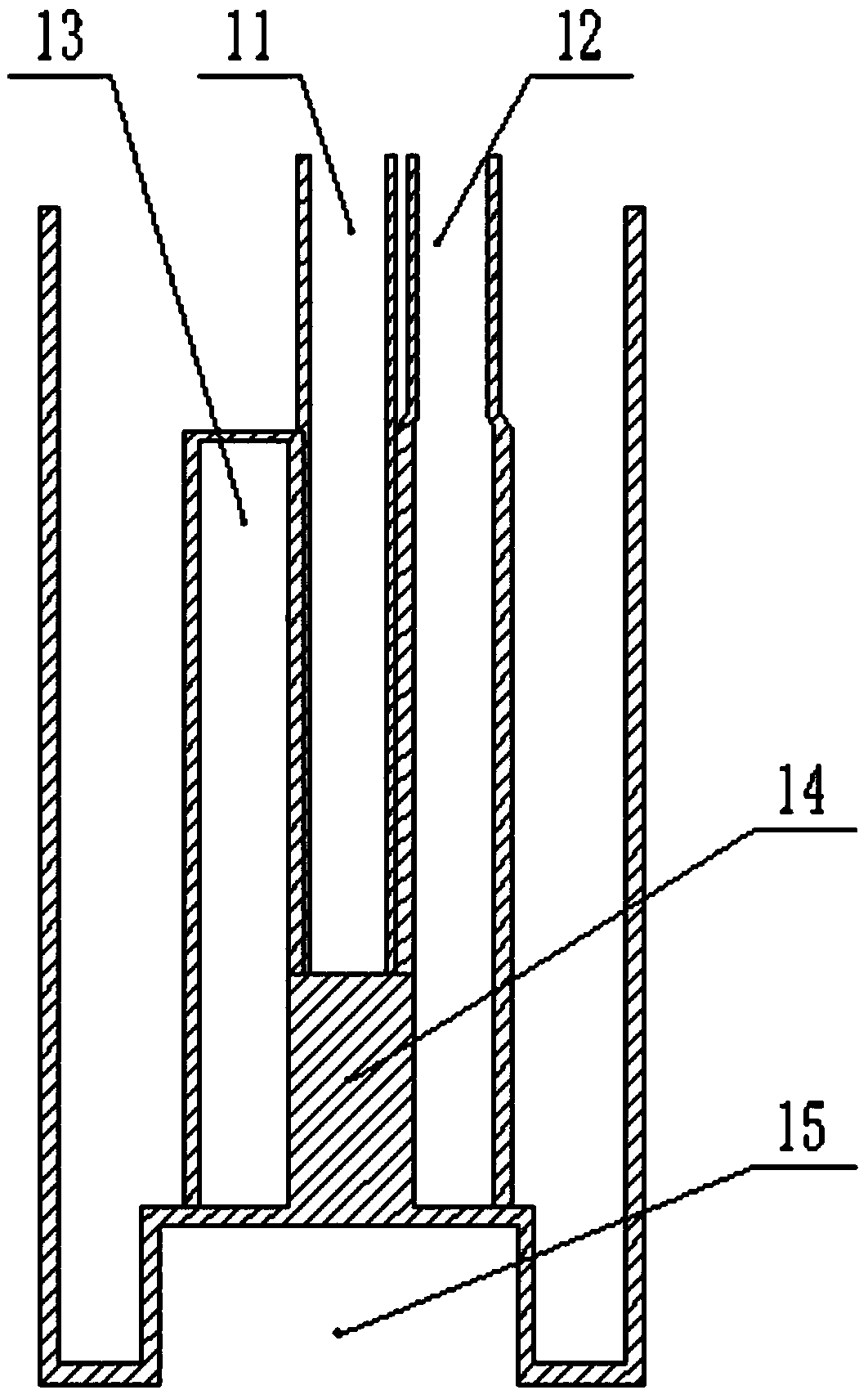

Parallel motion high-low-pressure power machine and application thereof

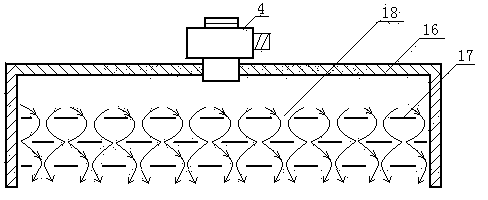

ActiveCN103925111AOvercoming the need for an expanderOvercome costsHot gas positive displacement engine plantsInsulation layerExhaust valve

The invention relates to a parallel motion high-low-pressure power machine and the application of the parallel motion high-low-pressure power machine. The machine comprises a heat insulation pipe, atomizers, exhaust valves, a low-pressure cylinder I, pistons, piston rings, a push-pull rod I, coolers, exhaust one-way valves, racks, a liquid storage tank, a high-pressure cylinder I, a pressure valve I, a heat collector, gasification reactors, intake one-way valves, a low-pressure cylinder II, a high-pressure cylinder II, a push-pull rod II, a pressure valve II and heat insulation layers. The machine has the advantages that recycling of working media is achieved, and no pollution is produced; the heat energy conversion efficiency ranges from 65% to 98%; the capacity of the air cylinders of the machine can be adjusted according to needed power to adjust output power; liquid filling can be adjusted in the largest power range to adjust the output power; the machine is used for carrying out gasification action on the working media, and knocking does not occur in the whole process; the machine is simple in structure and low in manufacturing cost; the acting power of the machine is two times that of a single cylinder; the machine can avoid the consumption of conventional energy resources, and is high in economic benefit, environmentally friendly and low in noise.

Owner:郭远军

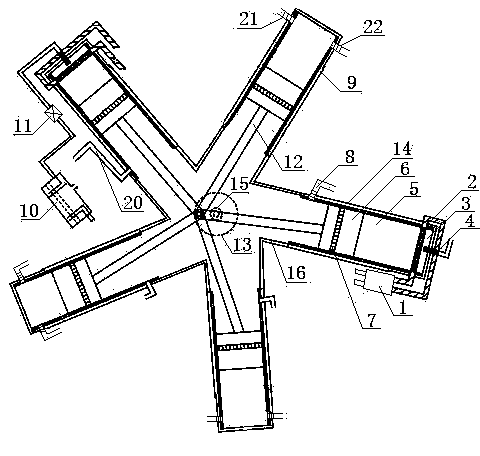

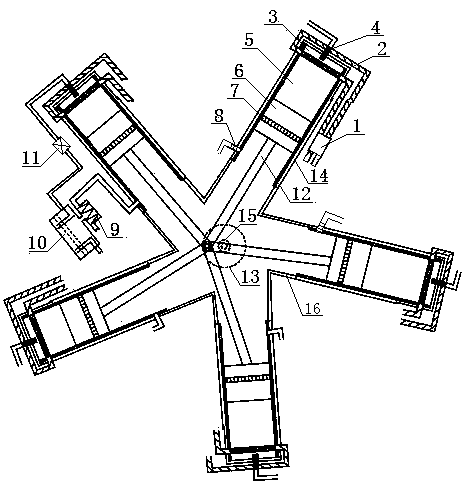

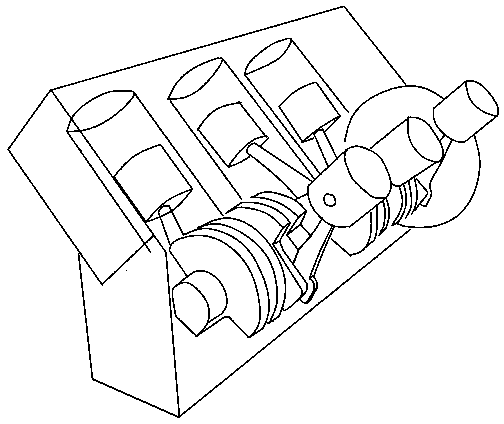

Star-type high-low pressure power machine and work-doing method of star-type high-low pressure power machine

ActiveCN103912403AOvercoming the need for an expanderOvercome costsHot gas positive displacement engine plantsExhaust valveSurvivability

The invention relates to a star-type high-low pressure power machine which comprises a heat collector, a heat preservation pipe, a gasification reactor, an atomizer, air cylinders, a piston, a piston ring, an automatic air exhaust valve, a radiator, a liquid storage tank, a pressure valve, a connecting rod, a crank shaft, a heat preservation layer, a rotating shaft and a machine shell. The five air cylinders are arranged on the machine shell and surround the crank shaft in a star-type mode, the piston is connected to the crank shaft through the connecting rod, the air cylinders include the three low-pressure air cylinders and the two high-pressure air cylinders, two low-pressure air cylinders are arranged in parallel, and the third low-pressure air cylinder is arranged between the two high-pressure air cylinders. The star-type structure of the star-type high-low pressure power machine is large in rigidity, light in weight, good in reliability, maintainability and survivability, large in power growth potential and high in rotating speed, displacement and power can be improved by increasing the diameters of the air cylinders, working media are recycled, pollution is avoided, the heat energy conversion efficiency is 65%-98%, conventional energy consumption can be replaced, the economic benefit is high, energy conservation and environmental protection are achieved, and noise is low.

Owner:郭远军

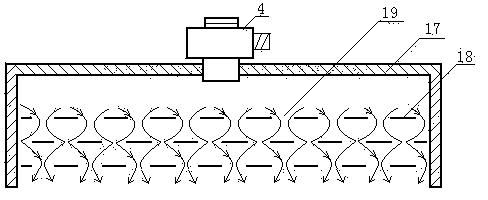

Parallel motion high-low pressure power device and application thereof

ActiveCN103912404AOvercoming the technical difficulties of high manufacturing costsOvercoming the need for an expanderHot gas positive displacement engine plantsExhaust valvePush pull

The invention relates to a parallel motion high-low pressure power device and application thereof. The parallel motion high-low pressure power device comprises a connection tube, an atomizer, an exhaust valve, a low-pressure cylinder, pistons, piston rings, a push-pull rod, a heat sink, an exhaust control valve, a machine frame, a liquid storage tank, a high-pressure cylinder, a pressure valve, a heater, a gasification reactor, a heat collector, a heat preservation tube and an air inlet one-way valve; the pistons are arranged at the two ends of the push-pull rod and arranged in the high-pressure cylinder and the low-pressure cylinder respectively, and the piston rings are arranged on the pistons; the exhaust valve is arranged on the bottom dead center of the high-pressure cylinder, the gasification reactor is arranged on the top dead center of the high-pressure cylinder, and the atomizer is arranged at the air inlet end of the gasification reactor; the top dead center and the bottom dead center of the low-pressure cylinder are provided with the air inlet one-way valve and the exhaust control valve respectively, and the pressure valve is connected with the atomizer on the high-pressure cylinder; the air inlet one-way valve on the low-pressure cylinder is connected with the exhaust valve. The parallel motion high-low pressure power device and the application thereof have the advantages that heat energy conversion efficiency ranges from 65% to 98%; output power can be adjusted; the machine is simple in structure and low in manufacturing cost, energy conservation and environmental protection are achieved, and noise is low.

Owner:郭远军

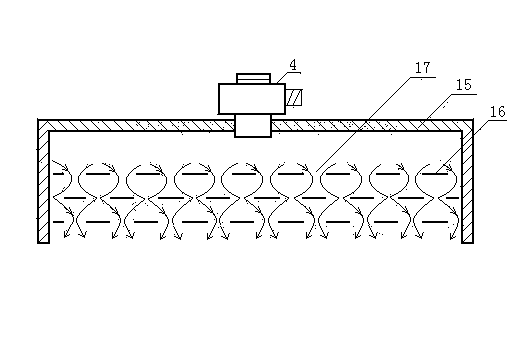

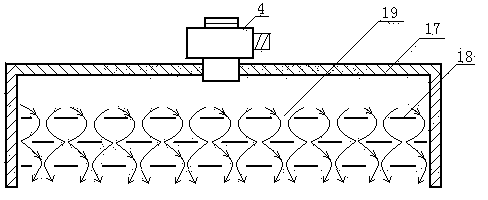

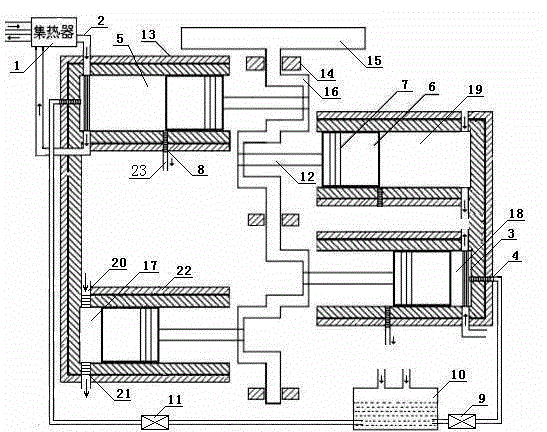

Star-shaped heat energy power device and working method thereof

InactiveCN103925108AOvercoming the need for an expanderOvercome costsHot gas positive displacement engine plantsSurvivabilityExhaust valve

The invention relates to a star-shaped heat energy power device and a working method thereof. The star-shaped heat energy power device comprises heat collectors, heat preservation tubes, gasification reactors, atomizers, air cylinders, pistons, piston rings, automatic exhaust valves, coolers, liquid storage tanks, pressure valves, connection rods, a crank shaft, heat preservation layers, a rotating shaft and a casing; the air cylinders are arranged on the casing and distributed around the crank shaft in a star shape, and the pistons are connected with the crank shaft through the connection rods. The star-shaped heat energy power device of the star-shaped structure is high in rigidity, low in weight, good in reliability, maintainability and survivability, high in power growth potential, and high in rotating speed; the diameters of the air cylinders can be enlarged so as to improve the discharge capacity and power; working media are used circularly, and no pollution is caused; conversion efficiency of heat energy ranges from 65% to 98%; conventional energy consumption can be replaced, economic benefits are high, energy is saved, the environment is protected, and noise is low.

Owner:郭远军

Star-type high-low pressure power device and work-doing method of star-type high-low pressure power device

ActiveCN103912326AImprove rigidityReduce weightSteam engine plantsReciprocating piston enginesSurvivabilityExhaust valve

The invention relates to a star-type high-low pressure power device and an acting method of the star-type high-low pressure power device. The star-type high-low pressure power device comprises a heat collector, a heat preservation pipe, a gasification reactor, an atomizer, air cylinders, a piston, a piston ring, an automatic air exhaust valve, a radiator, a liquid storage tank, a pressure valve, a connecting rod, a crank shaft, a heat preservation layer, a rotating shaft and a machine shell. The five air cylinders are arranged on the machine shell and surround the crank shaft in a star-type mode, the piston is connected to the crank shaft through the connecting rod, the air cylinders include the three high-pressure air cylinders and the two low-pressure air cylinders, two high-pressure air cylinders are arranged in parallel, and the third high-pressure air cylinder is arranged between the two low-pressure air cylinders. The star-type structure of the star-type high-low pressure power device is large in rigidity, light in weight, good in reliability, maintainability and survivability, large in power growth potential and high in rotating speed, displacement and power can be improved by increasing the diameters of the air cylinders, working media are recycled, pollution is avoided, the heat energy conversion efficiency is 65%-98%, conventional energy consumption can be replaced, the economic benefit is high, energy conservation and environmental protection are achieved, and noise is low.

Owner:郭远军

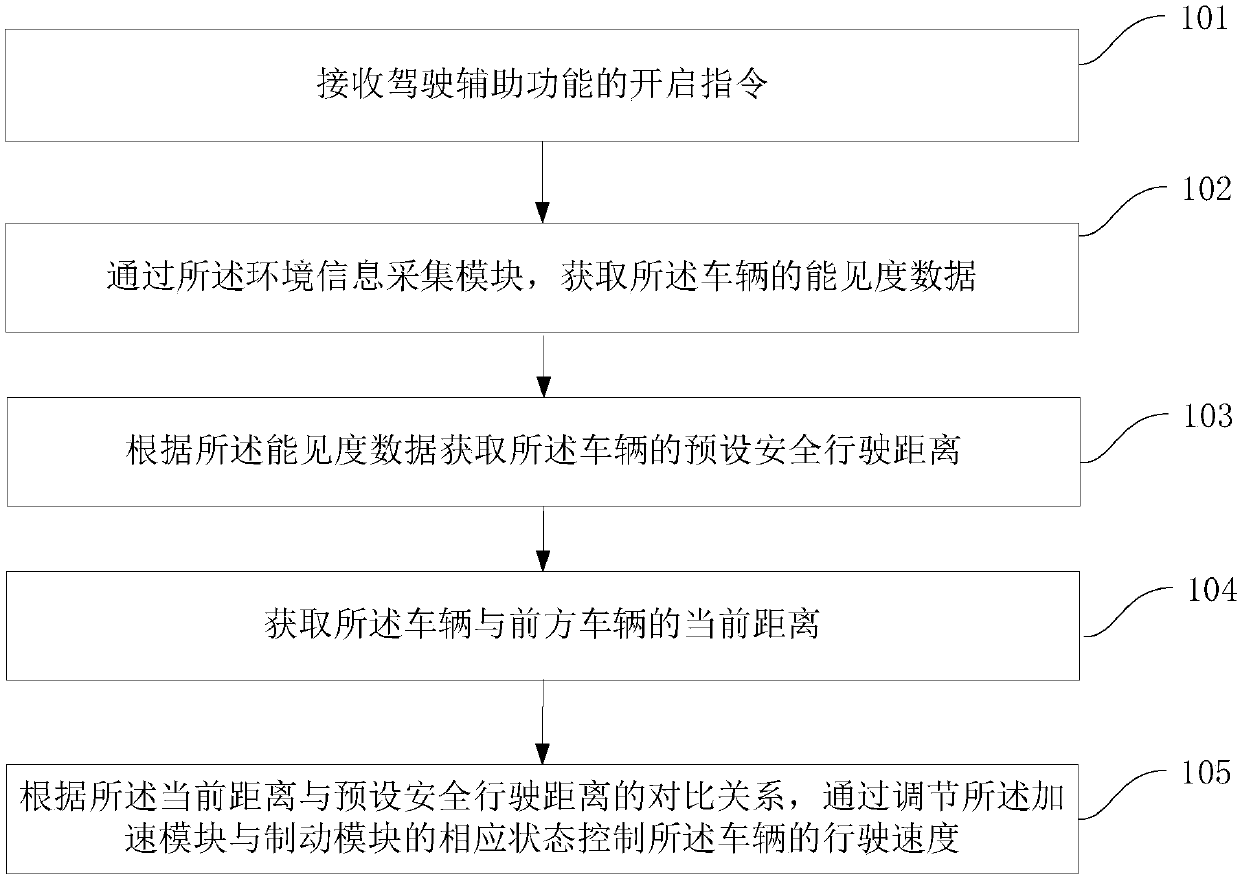

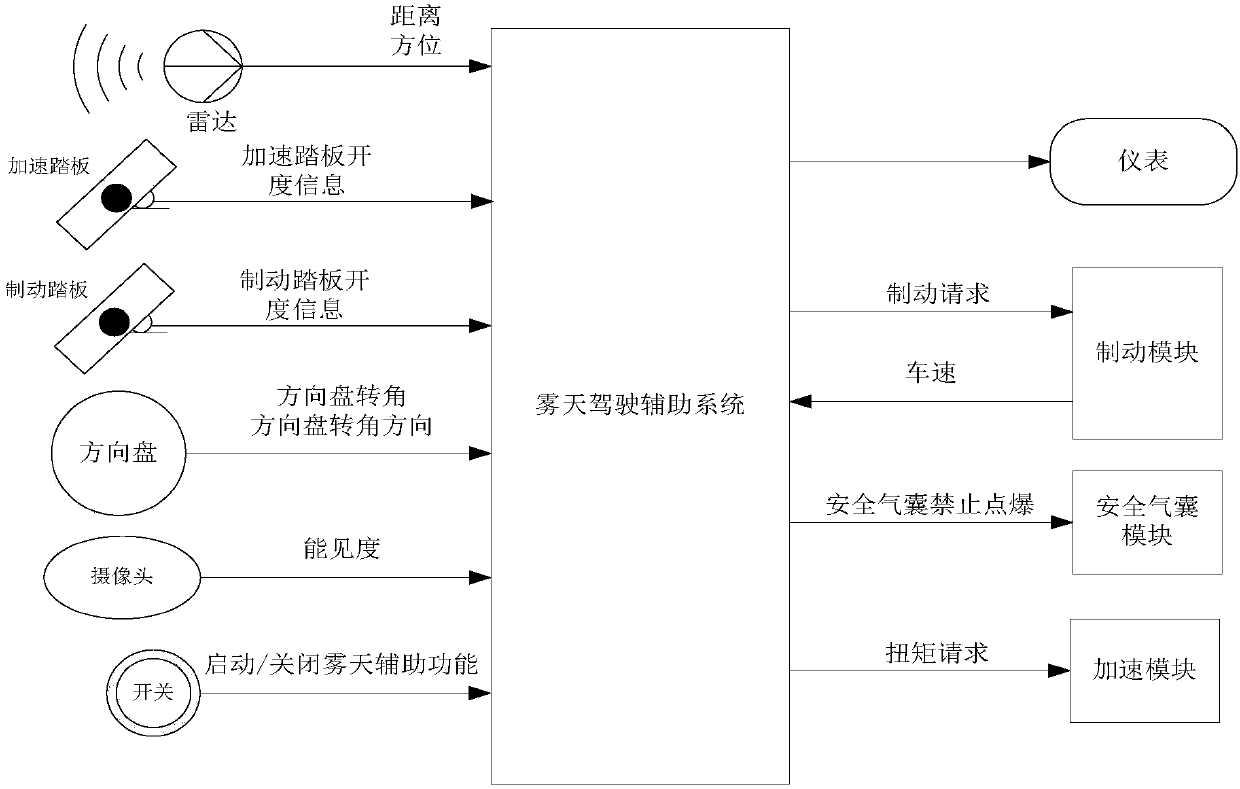

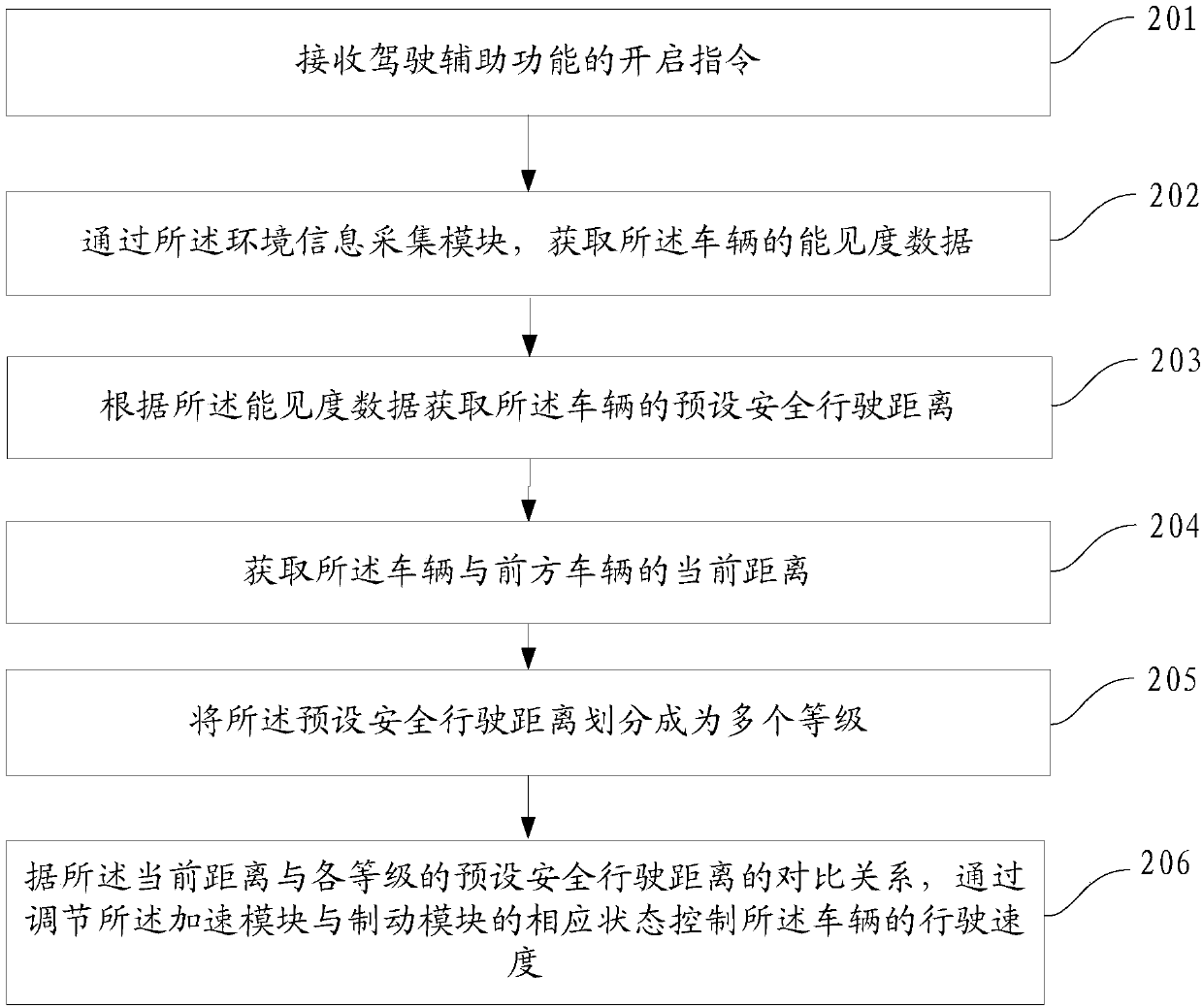

Vehicle control method and apparatus

The invention provides a vehicle control method and apparatus. The vehicle control method includes the steps: receiving a starting instruction of a driving assistance function; acquiring visibility data of the vehicle by using an environmental information collecting module; acquiring a preset safe driving distance of the vehicle according to the visibility data; acquiring the current distance between the vehicle and a front vehicle; and controlling the traveling speed of the vehicle by adjusting the corresponding state of an acceleration module and a braking module according to the comparisonrelationship between the current distance and the preset safe driving distance. The vehicle control method solves the problem that in the prior art, the user misjudges the environment in the foggy day, thus causing the vehicle speed to be too high and being prone to traffic accidents.

Owner:GREAT WALL MOTOR CO LTD

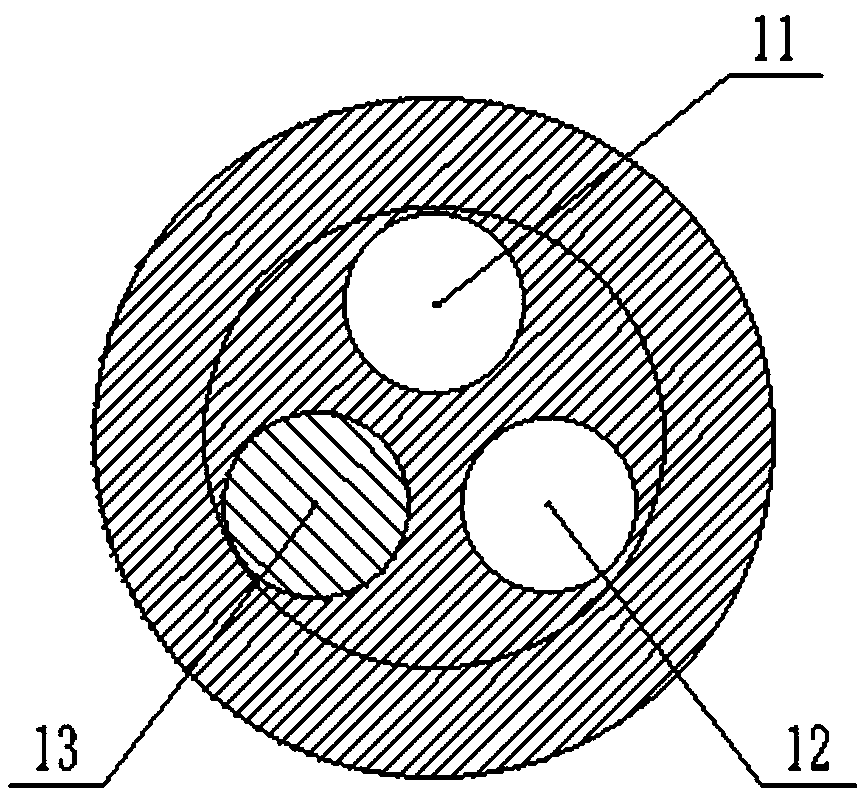

Thermal rotor power equipment and work method thereof

ActiveCN103953455AOvercoming complexityOvercome costsHot gas positive displacement engine plantsThermal energyExhaust valve

The invention relates to thermal rotor power equipment and a work method thereof. The equipment comprises a heat collector, an insulating pipe, a gasification reactor, an atomizer, an air cylinder, a triangle rotor, an annular gear, a gear, an output shaft, a cooler, a liquid storage tank, a pressure valve, an insulating layer, an automatic exhaust valve and a casing, wherein the triangle rotor is arranged in the casing; the annular gear and the gear matched with the annular gear are arranged in the center of the triangle rotor; the gear is fixed on the output shaft; the triangle rotor divides the air cylinder into three uniform and independent space; the rate of tooth numbers of the annular gear to the gear is 3:2; the gasification reactor and the automatic exhaust valve are respectively arranged on two sides of the air cylinder. The equipment has the advantages that work is done for three times when a rotor of a rotor engine rotates for one circle, the horsepower to volume ratio is high, the operation speed is high, the volume is small, the weight is low, the gravity center is low, vibration is small, working medium can be recycled, pollution is not caused, the thermal energy conversion efficiency is 65 to 95 percent, conventional energy consumption can be replaced, the economic benefit is high, the equipment is energy-saving and environmentally friendly, and the noise is low.

Owner:郭远军

Eco-friendly energy-saving gasoline for haze treatment

InactiveCN106978222ANo pollutionReduce consumptionLiquid carbonaceous fuelsFuel additivesAromatic hydrocarbonMethyl tert-butyl ether

The invention discloses eco-friendly energy-saving super-gasoline (78#) for haze treatment. The eco-friendly energy-saving super-gasoline comprises 30 to 40% of alkylated gasoline, 15 to 20% of straight-run gasoline, 20 to 25% of an aromatic hydrocarbon, 20 to 25% of carbon olefin, 2 to 5% of a metal purification agent and 0.04% of a MG2000 gasoline accelerator. Gasoline prepared from methyl tert-butyl ether (MTBE) and methylcyclopentadienyl manganese tricarbonyl (MMT) as additives produces a large amount of PM2.5 after burning so that environment is polluted. The eco-friendly energy-saving super-gasoline solves the above problem and is suitable for ordinary vehicles.

Owner:QINGDAO YONGQUAN PETROLEUM CO LTD

Improved composite lead-free gasoline and its producing method

InactiveCN1587355AEasy to startImprove evaporation effectLiquid carbonaceous fuelsEvaporationN-Butanol

The improved composite lead-free gasoline consists of methanol, 90# gasoline, n-butanol, iospropanol, xylene, acetone and kernel additive. The kernel additive consists of zinc oxide, antioxidant, metal purifying agent, coloring agent and smoke-eliminating combustion promoter. The improved composite lead-free gasoline of the present invention has excellent evaporation property, anti-explosion property, good stability and anticorrosive property, and may be used through togecher with gasoline and ethanol gasoline in any ratio. The present invention also relates to the compounding process of the improved composite lead-free gasoline.

Owner:鲁希诺

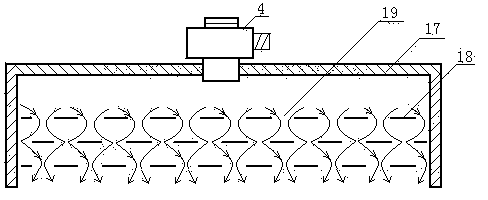

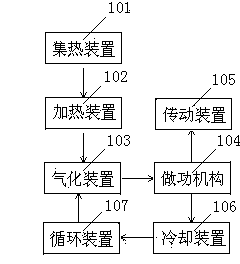

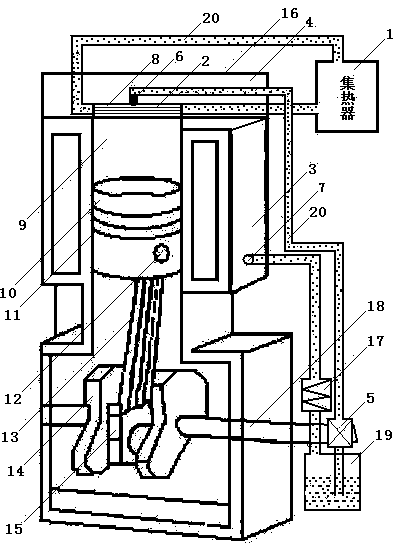

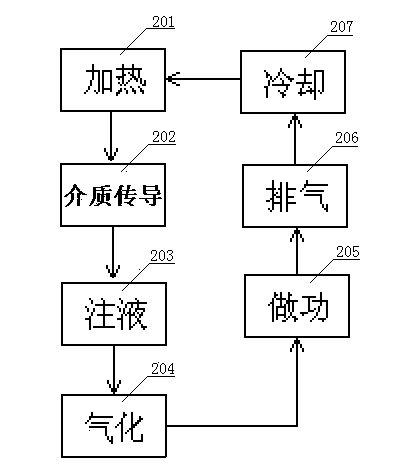

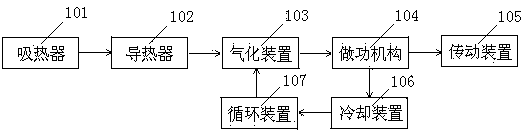

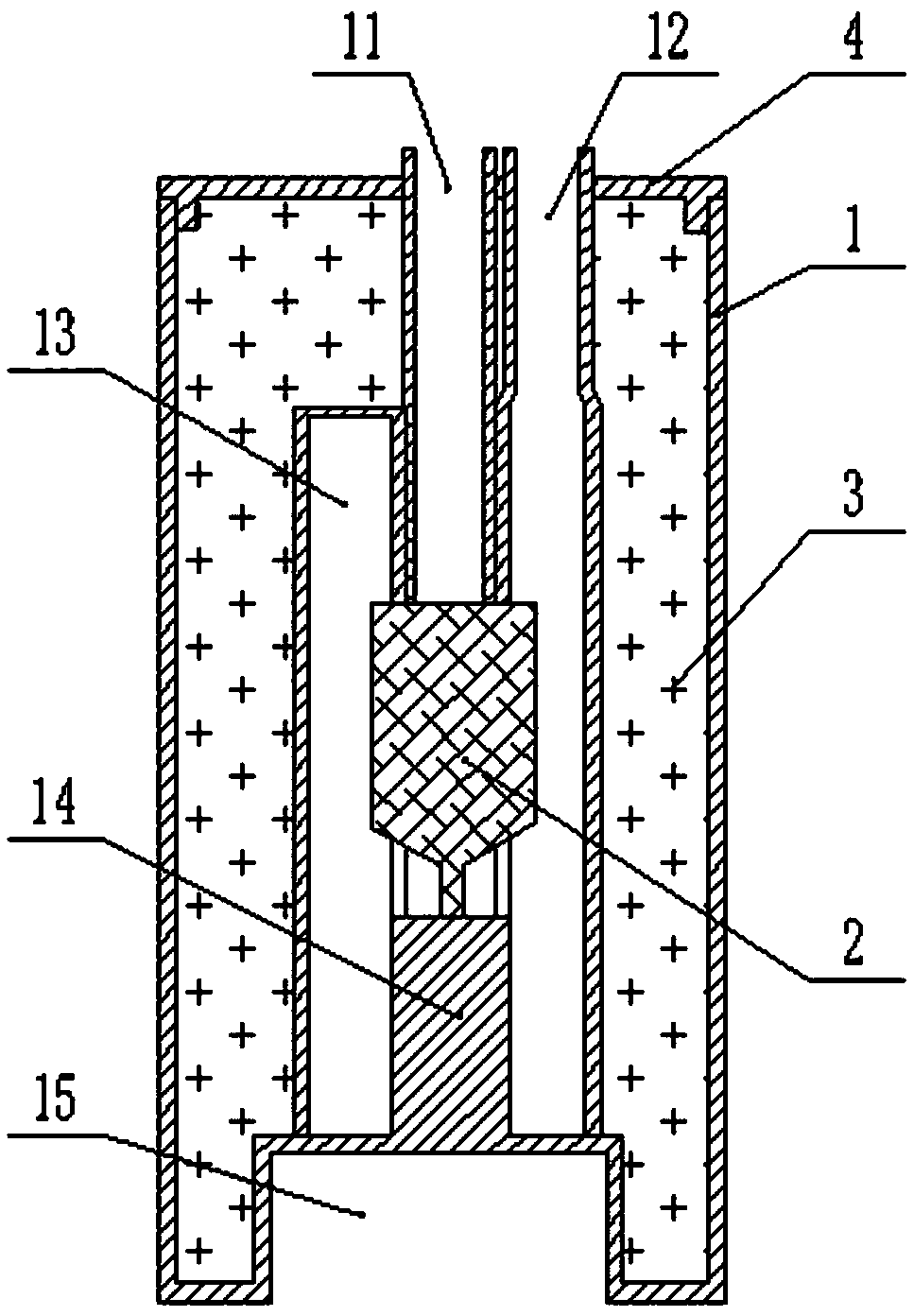

Heat energy power equipment and work doing method thereof

ActiveCN103925107ASimple structureReduce lossHot gas positive displacement engine plantsThermal energyEconomic benefits

The invention relates to heat energy power equipment and a work doing method of the heat energy power equipment. The heat energy power equipment comprises a heat collection device, a heating device, a gasifying device, a work doing mechanism, a cooling device, a transmission device and a circulation device. The heat collection device is connected with the heating device through a pipeline, the heating device is arranged on the gasifying device, the gasifying device is arranged on the front portion of the work doing mechanism, the work doing mechanism is connected with the cooing device and the transmission device, the cooling device is connected with the circulation device, and the circulation device is connected with the gasifying device. The equipment has the advantages that working media can be recycled, and pollution does not exist; the heat energy conversion efficiency ranges from 65% to 98%; output power can be adjusted by adjusting the capacities and number of machine air cylinders according to required power; liquid injection can be adjusted to adjust output power within the maximum power value; gasifying working doing is carried out on the working media, and therefore knocking will not be generated in the whole process; the equipment is simple in structure, and energy consumption is reduced through the automatic exhaust function; ordinary energy resource consumption can be replaced, the economic benefit is high, energy is saved, the environment is protected, and noise is small.

Owner:郭远军

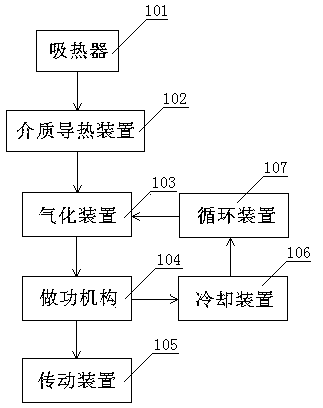

Power machine with two media conducting heat energy and work doing method thereof

The invention relates to a power machine with two media conducting heat energy and a work doing method of the power machine. The power machine comprises a heat absorber, a medium heat conducting device, a gasifying device, a work doing mechanism, a cooling device, a transmission device and a circulation device, wherein the heat absorber is connected with the medium heat conducting device through a medium heat conducting heat preservation pipe, the medium heat conducting device is arranged on the gasifying device, the gasifying device is connected with the work doing mechanism, the work doing mechanism is connected with the cooling device and the transmission device, the cooling device is connected with the circulation device, the circulation device is connected with the gasifying device, and the transmission device is connected with the circulation device. Every time a cycle is completed, the circulation device is opened and closed once. Because working media are recycled, pollution does not exist; the heat energy conversion efficiency ranges from 65% to 98%; output power can be adjusted; gasifying working doing is carried out on the working media, and therefore knocking will not be generated in the whole process; the machine is simple in structure; ordinary energy resource consumption can be replaced, the economic benefit is high, energy is saved, the environment is protected, and noise is small.

Owner:郭远军

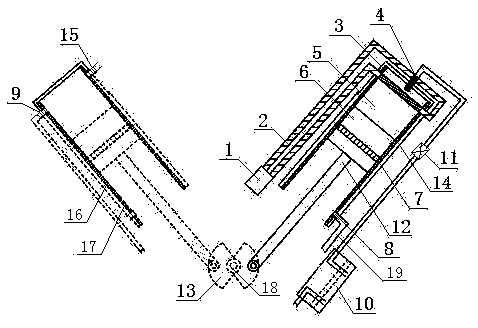

V type high and low pressure power machine and acting method thereof

ActiveCN103925020AShorten the lengthReduce the overall heightSteam engine plantsReciprocating piston enginesExhaust valveInlet valve

The invention relates to a V type high and low pressure power machine and an acting method thereof. The V type high and low pressure power machine comprises a heat collector, a heat preservation pipe, a gasification reactor, an atomizer, air cylinders, a piston, a piston ring, an automatic exhaust valve, an exhaust control valve, a liquid storage tank, a pressure valve, a connection rod, a crankshaft, a heat preservation layer, a one-way air inlet valve, a machine shell, a radiator and a rotating shaft. The air cylinders on the machine shell are divided into a left set and a right set. The two sets of air cylinders are of a V type structure. The two outermost air cylinders on the left side and the middlemost air cylinder on the right side form a set of high-pressure cylinders, and the two outermost air cylinders on the right side and the middlemost air cylinder on the left side form a set of low-pressure cylinders. Due to the V type structure, the length and the height of a machine body are shortened, the air cylinders are arranged in a staggered mode, large space is obtained, and the diameters of the large air cylinders can be enlarged to improve the discharge capacity and power; working media are used cyclically, and pollution is avoided; the heat energy conversion efficiency is 65 percent to 98 percent, conventional energy consumption can be replaced, economic benefits are high, energy is saved, environmental friendliness is achieved, and noise is low.

Owner:郭远军

Heat energy power machine and working method thereof

ActiveCN103912406ASimple structureNo detonationHot gas positive displacement engine plantsDetonationHeat conducting

The invention relates to a heat energy power machine and a working method thereof. The heat energy power machine comprises a heat absorber, a heat conducting device, a gasification device, a working mechanism, a cooling device, a transmission device and a circulating device. The heat energy power machine is characterized in that the heat absorber is connected with the heat conducting device through a pipeline, the heat conducting device is arranged on the gasification device connected with the working mechanism, the working mechanism is connected with the cooling device and the transmission device, the cooling device is connected with the circulating device connected with the gasification device, the transmission device is related to the circulating device, and the circulating device is turned on and off by one time every time circulation is completed. The heat energy power machine and the working method thereof have the advantages that working media are used circularly, and no pollution is caused; heat energy conversion efficiency ranges from 65% to 98%; output power can be adjusted; the machine is used for conducting gasification working on the working media, and detonation is not produced in the whole process; the machine is simple in structure, conventional energy consumption can be replaced, economic benefits are high, energy conservation and environmental protection are achieved, and noise is low.

Owner:郭远军

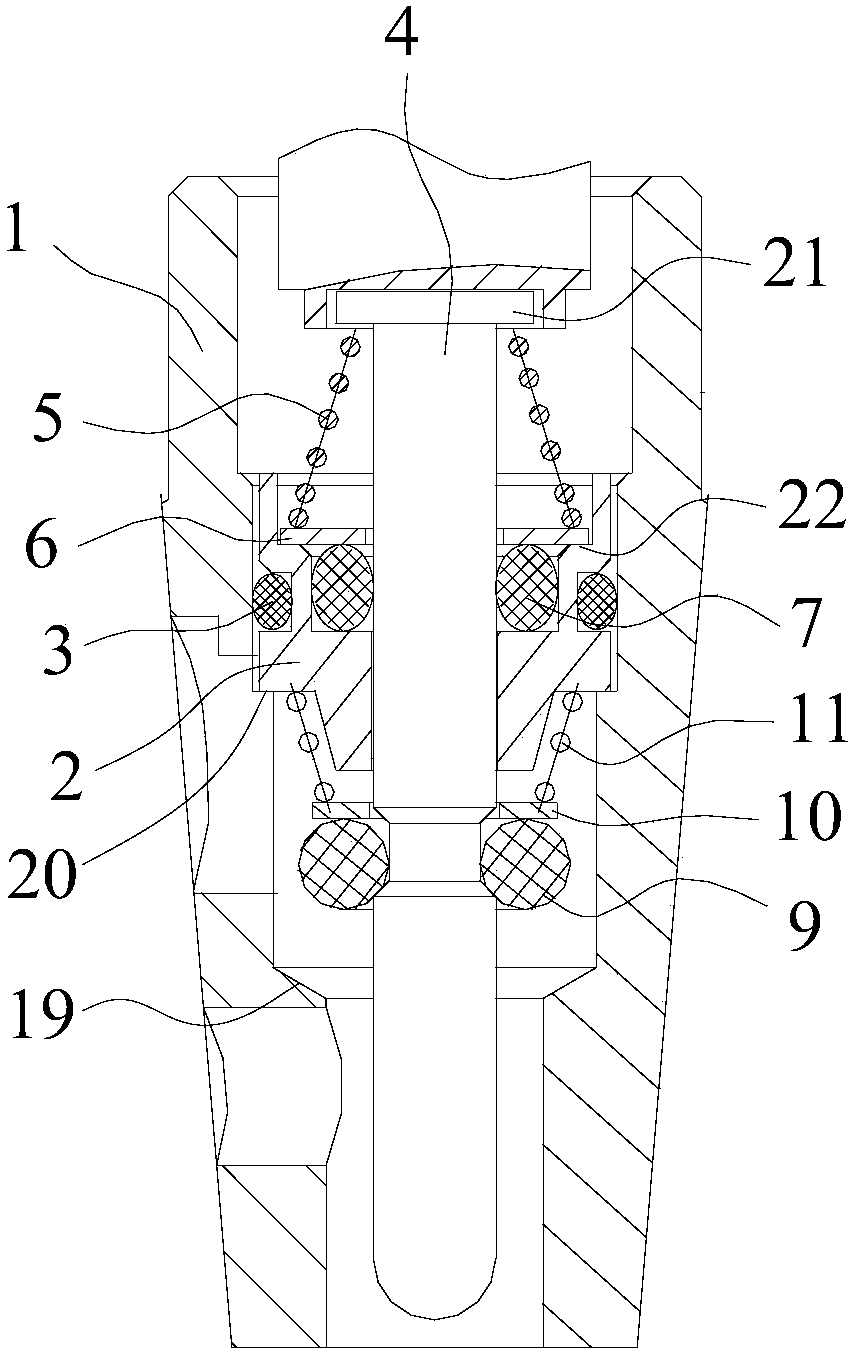

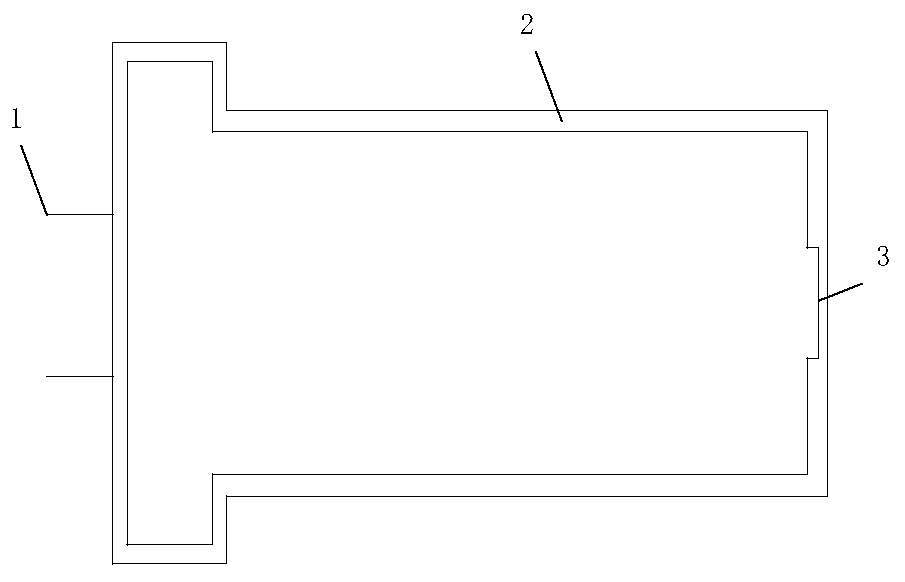

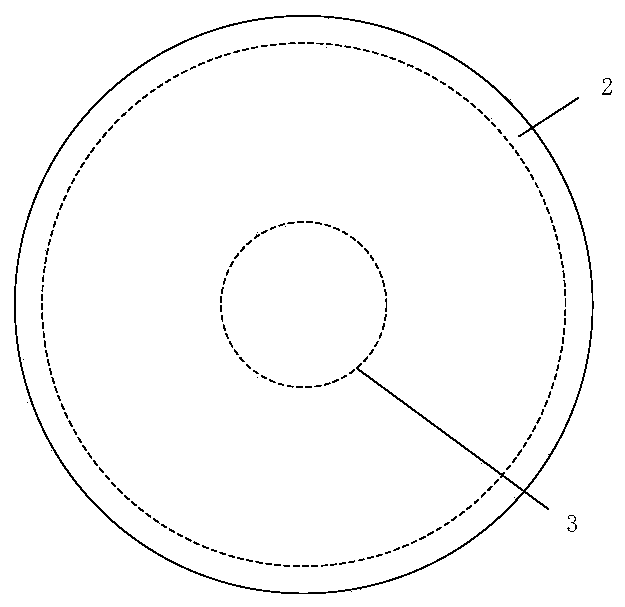

Horizontally opposed type high and low pressure power machine and working method thereof

ActiveCN103939209ASimple machine structureLow manufacturing costMachines/enginesLiquid storage tankInsulation layer

The invention relates to a horizontally opposed type high and low pressure power machine and a working method thereof. The horizontally opposed type high and low pressure power machine comprises a heat collector, an insulation pipe, a gasification reactor, an atomizer, a high pressure cylinder I, pistons, piston rings, automatic exhaust valves, a pressure valve I, a liquid storage tank, a pressure valve II, connection rods, insulation layers, a machine case, a flywheel, a crankshaft, a low pressure cylinder I, a high pressure cylinder II, a lower pressure cylinder II, air inlet check valves, exhaust control valves and a radiator, wherein the high pressure cylinder I, the lower pressure cylinder II, the low pressure cylinder I and the high pressure cylinder II are arranged on the machine case in a horizontally opposed mode at 180 degrees with the crankshaft as the center. The horizontally opposed type high and low pressure power machine has the advantages that a work medium is recycled without pollution, heat energy conversion efficiency ranges from 65% to 98%, the output power is adjusted by adjusting the volume and number of the cylinders of the machine as required, injected liquid and output power can be adjusted in the largest power range, the machine is simple in structure, low in manufacturing cost, high in economic efficiency, energy-saving, environment-friendly, low in noise, gravity and vibration and good in stability.

Owner:郭远军

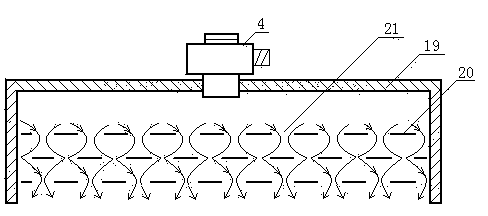

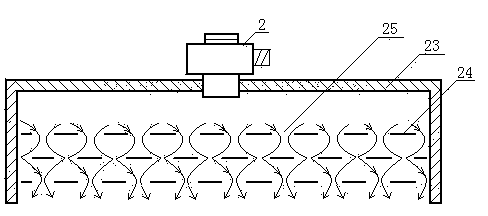

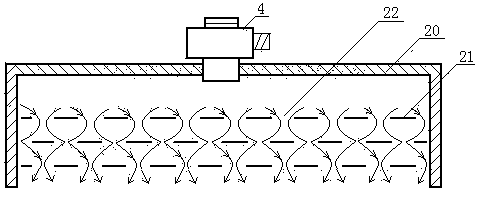

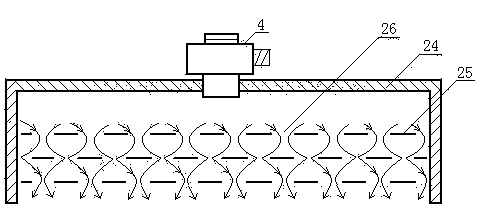

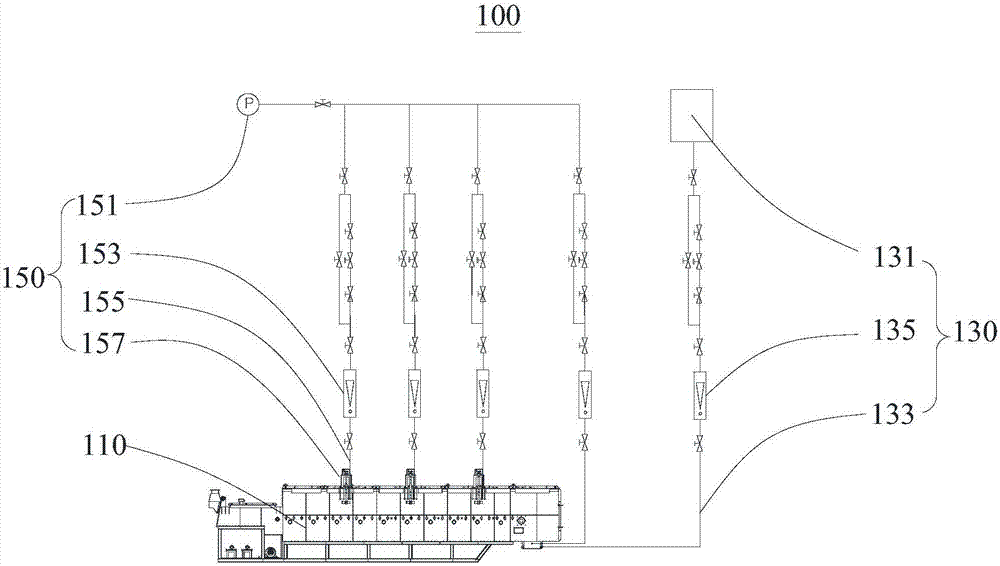

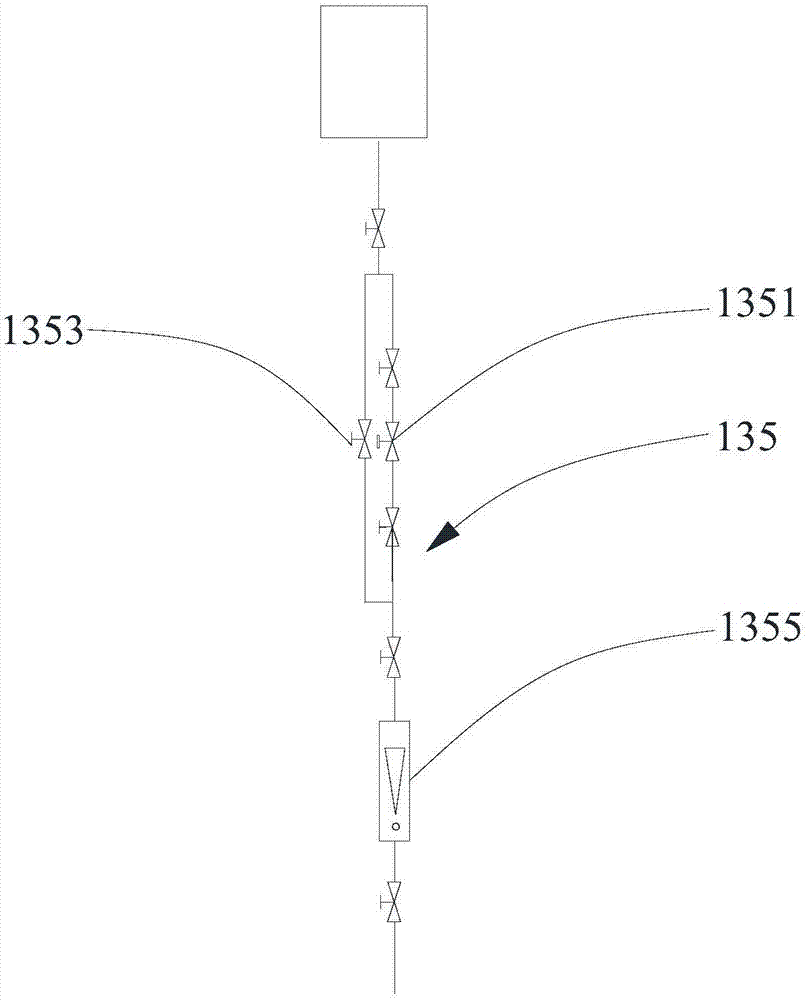

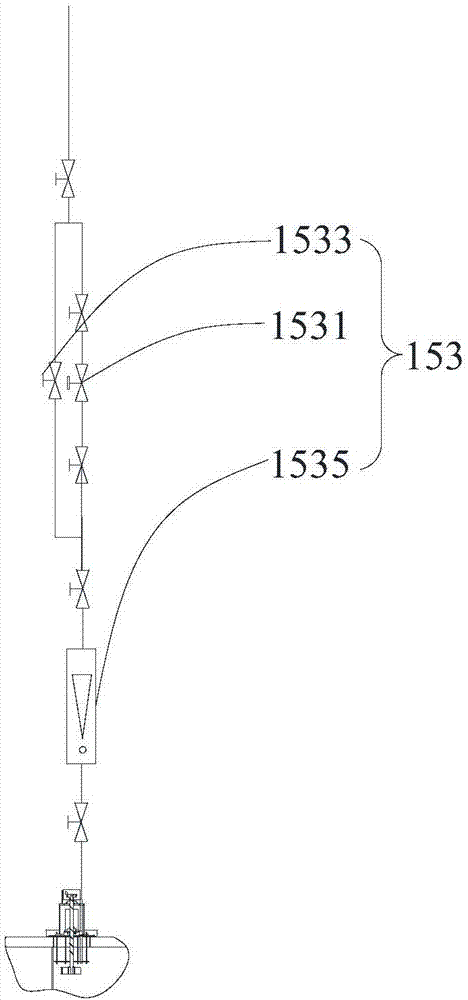

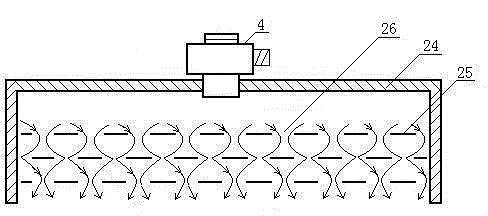

Mesh belt furnace rapid carbon burning system

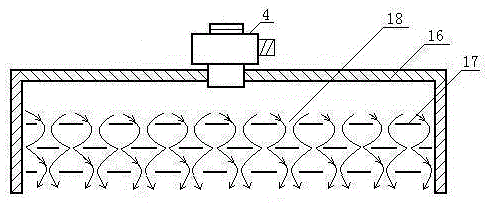

ActiveCN107151731AQuick clearEfficient removalFurnace typesHeat treatment furnacesEngineeringHeat treated

The invention provides a mesh belt furnace rapid carbon burning system and relates to the field of industrial heat treatment equipment. The mesh belt furnace rapid carbon burning system comprises a mesh belt furnace, a gas replacement device, a carbon burning device and a control device. The gas replacement device comprises an inert gas source, a spray pressing pump, a purging pipeline and a first flow adjusting assembly. The inert gas source is connected with the mesh belt furnace through the purging pipeline. The spray pressing pump is arranged in the position, between the inert gas source and the mesh belt furnace, of the purging pipeline. The first flow adjusting assembly is arranged in the position, between the spray pressing pump and the mesh belt furnace, of the purging pipeline. The carbon burning device is connected to the mesh belt furnace. The control device is electrically connected with the spray pressing pump, the first flow adjusting assembly and the carbon burning device. According to the mesh belt furnace rapid carbon burning system provided by the invention, compared with the prior art, inert gas is introduced before carbon burning, thus, an explosion whistle cannot occur when air is introduced through the carbon burning device, and meanwhile, deposited carbon in the mesh belt furnace can be effectively and rapidly removed by the carbon burning air introduced through the carbon burning device.

Owner:江苏丰东热技术有限公司

Improved type composite leadless gasoline and its compounding method

The improved compound lead-free gasoline is composed of methyl alcohol, 90# gasoline, normal butyl alcohol, isopropyl alcohol, modified ethyl alcohol, dimethylbenzene, acetone and core additive. The described core additive is formed from zinc oxide, chemical inhibitor, metal purifying agent, colouring agent and smoke-eliminating combustion-supporting agent. It has good vaporization property, antiknock quality, stability and corrosion-resisting property.

Owner:鲁希诺

A horizontally opposed high-voltage and low-voltage power equipment and its work method

ActiveCN103939232BSimple structureReduce manufacturing costHot gas positive displacement engine plantsInsulation layerExhaust valve

The invention relates to a horizontally opposed type high and low pressure power device and a working method thereof. The horizontally opposed type high and low pressure power device comprises a heat collector, an insulation pipe, a gasification reactor, an atomizer, a high pressure cylinder I, pistons, piston rings, automatic exhaust valves, a pressure valve I, a liquid storage tank, a pressure valve II, connection rods, insulation layers, a machine case, a flywheel, a crankshaft, a low pressure cylinder I, a high pressure cylinder II, a lower pressure cylinder II, air inlet check valves, exhaust control valves and a radiator, wherein the high pressure cylinder I, the lower pressure cylinder II, the low pressure cylinder I and the high pressure cylinder II are arranged on the machine case in a horizontally opposed mode at 180 degrees with the crankshaft as the center. The horizontally opposed type high and low pressure power device has the advantages that a work medium is recycled without pollution, heat energy conversion efficiency ranges from 65% to 98%, the output power is adjusted by adjusting the volume and number of the cylinders of the machine as required, injected liquid and output power can be adjusted in the largest power range, the machine is simple in structure, low in manufacturing cost, high in economic efficiency, energy-saving, environment-friendly, low in noise, gravity and vibration and good in stability.

Owner:郭远军

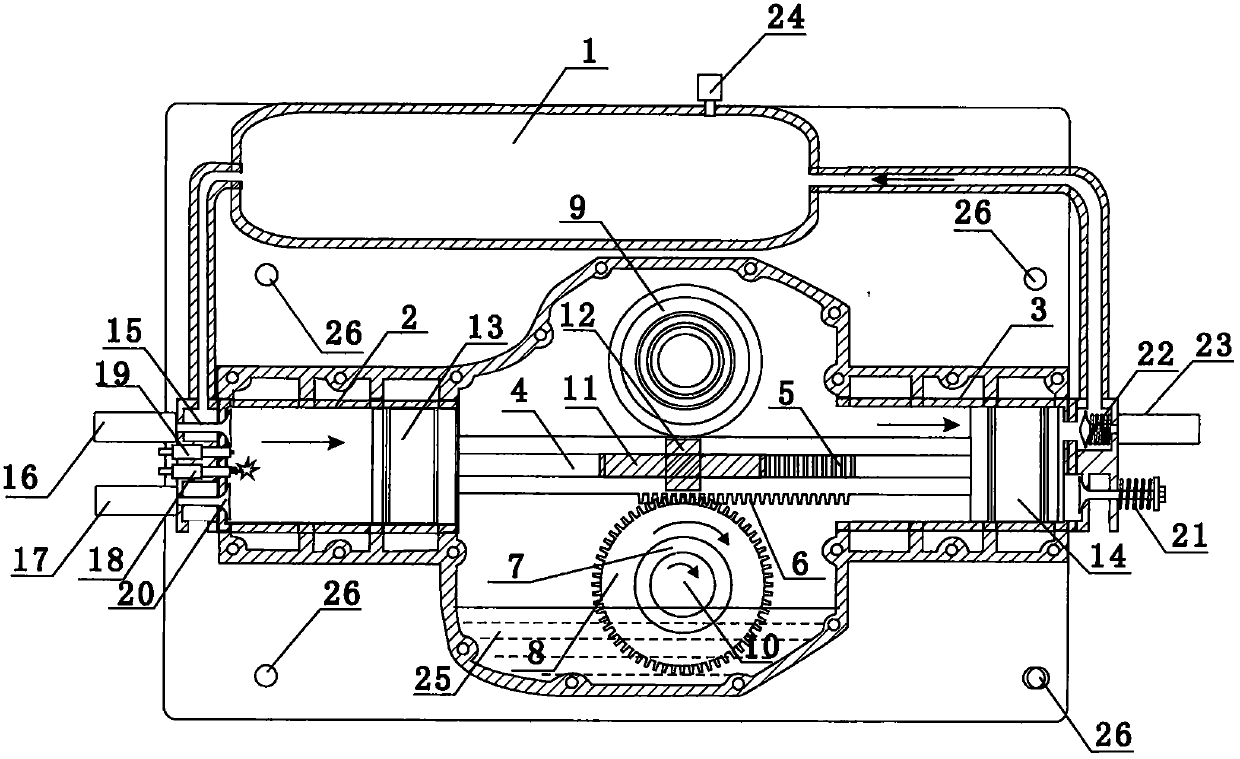

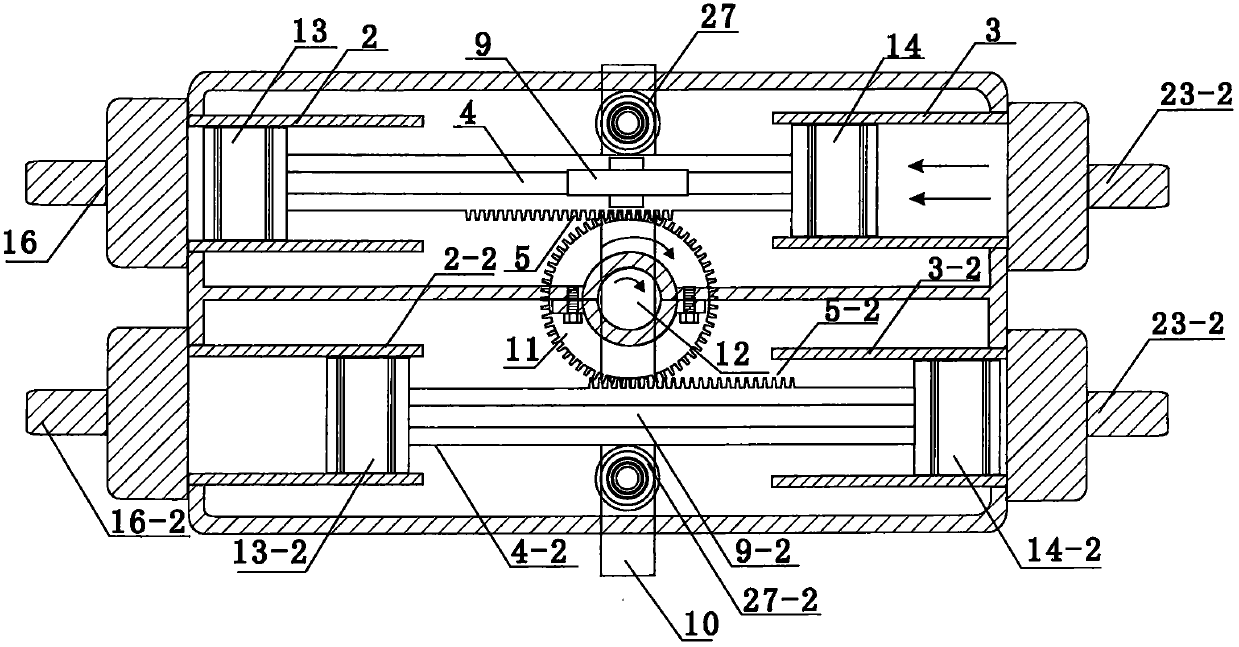

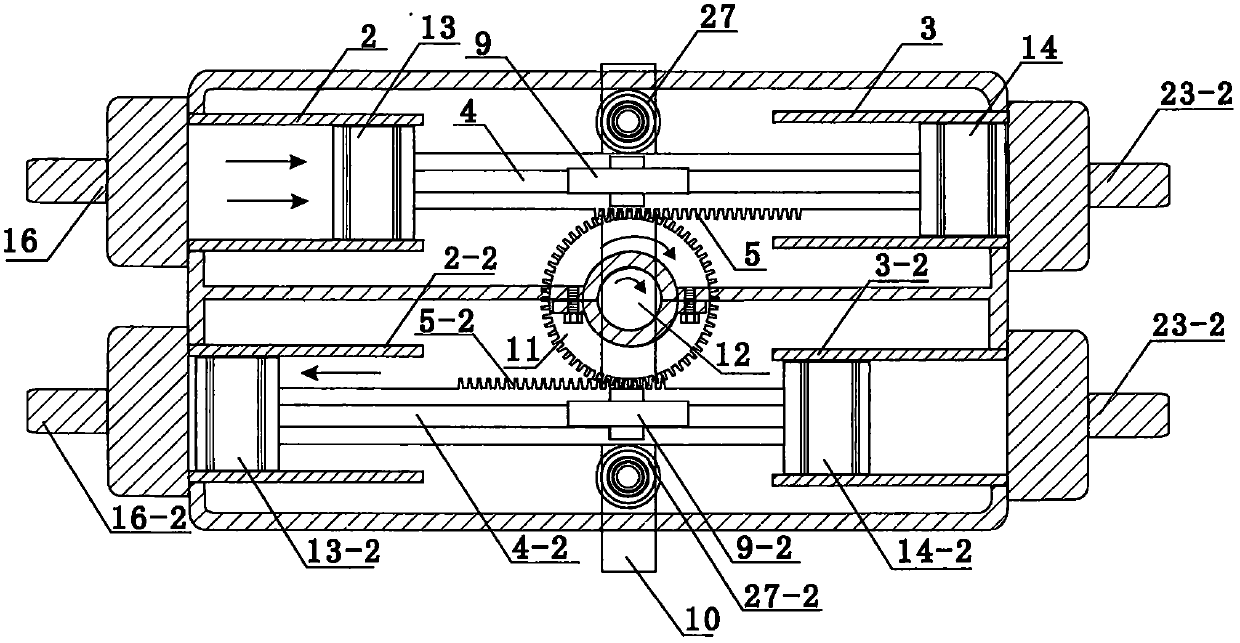

Novel light fuel internal combustion engine

InactiveCN109695502AImprove torque transmission efficiencyImprove power output efficiencyCombustion enginesDetonationLighter fuel

The invention relates to a novel light fuel internal combustion engine. Acting air cylinders are arranged coaxial with air pressing air cylinders, a high-pressure air storage tank is arranged betweenthe acting air cylinders and the air pressing air cylinders, acting pistons are directly connected with air pressing pistons through a multi-surface rack piston connecting rod, the lower rack of the multi-surface rack piston connecting rod is meshed with an output gear, the output gear is installed on an output shaft through an overrun clutch, piston connecting rod sets are used for converting thereciprocating motion of the piston connecting rod sets into circular motion of the output shaft through the overrun clutch to do work, side racks of the two sets of piston connecting rods are meshedwith reverse pushing gears, two groups of acting air cylinders and the air pressing cylinders are arranged in parallel to form a four-cylinder unit, and the two sets of piston connecting rods move repeatedly to form a working cycle; due to the fact that the acting air cylinders adopt indirect high-pressure air inflation, detonation cannot be generated; and light-weight fuel can be used, so that the energy-saving and emission-reducing effects are obvious.

Owner:闫传东

A gas cock valve

ActiveCN106051200BReasonable range of motionReduce gas outputSpindle sealingsPlug valvesDetonationGas supply

Owner:ZHEJIANG XINTAO ELECTRONICS MACHINERY

Primer with structure safety and assembling process thereof

PendingCN109405658AStable detonation abilityReduce security risksBlasting cartridgesBlastingDetonatorIntrinsic safety

The invention concretely relates to a primer with structure safety and an assembling process thereof, and belongs to the technical field of blasting equipment. The invention aims to solve the technical problem so as to provide the primer with high essential safety, and the excellent assembling process with safety, high efficiency and low cost. The invention adopts the technical scheme that the primer with structure safety comprises a shell, a priming drug box, a main charge and an upper cover, wherein the shell structurally comprises a wire through pipe, a detonating fuse through pipe, a detonator blind tract, a support positioning plate and an energy gathering hole; the shell is of a columnar structure which is opened in the upper end and sealed in the lower end; the wire through pipe, the detonating fuse through pipe, the detonator blind tract and the support positioning plate of the shell are integrally formed; the upper cover and the shell form a sealed cavity; the main charge is filled in the cavity; and the priming drug box is arranged above the support positioning plate. According to the primer with structure safety and the assembling process thereof provided by the invention, through the structure design of the shell, high essential safety, high water resistance and favorable processability of the primer product are realized.

Owner:山西江阳兴安民爆器材有限公司

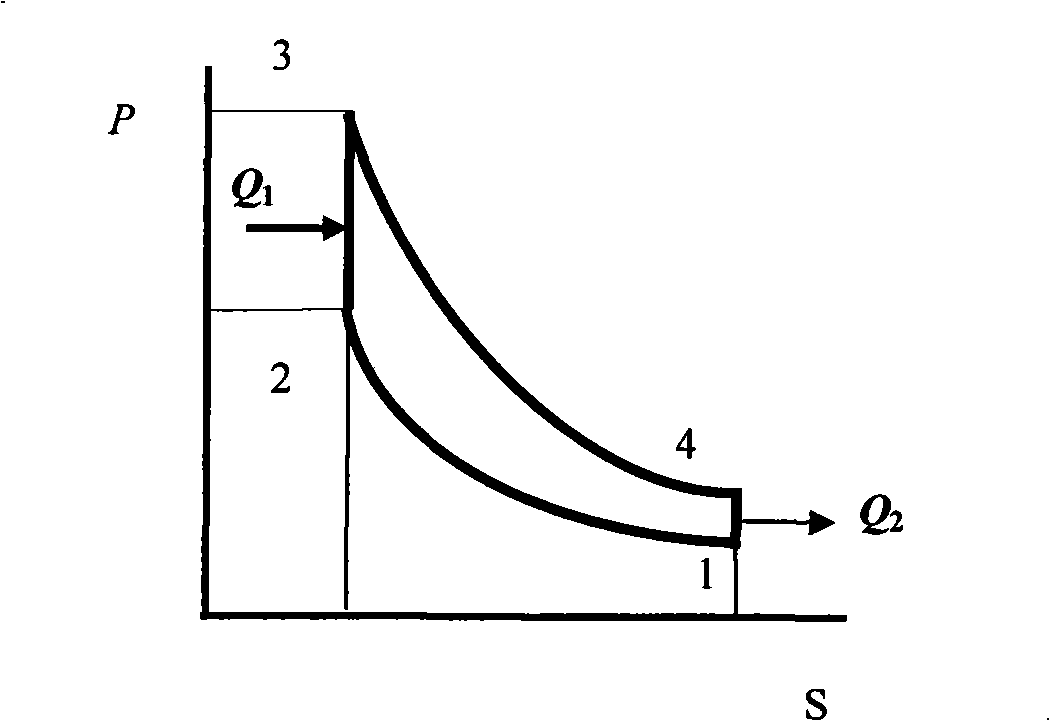

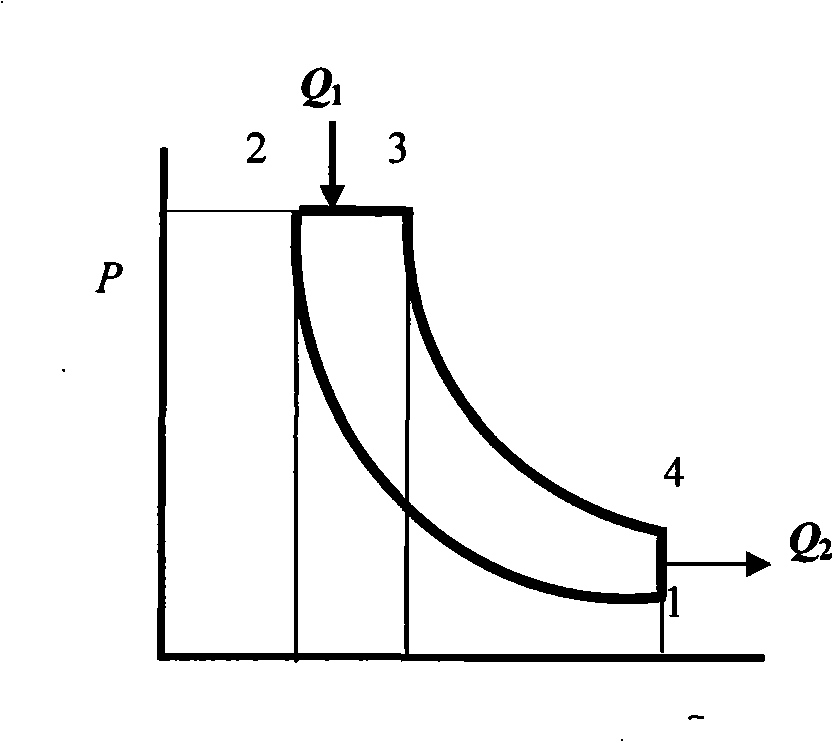

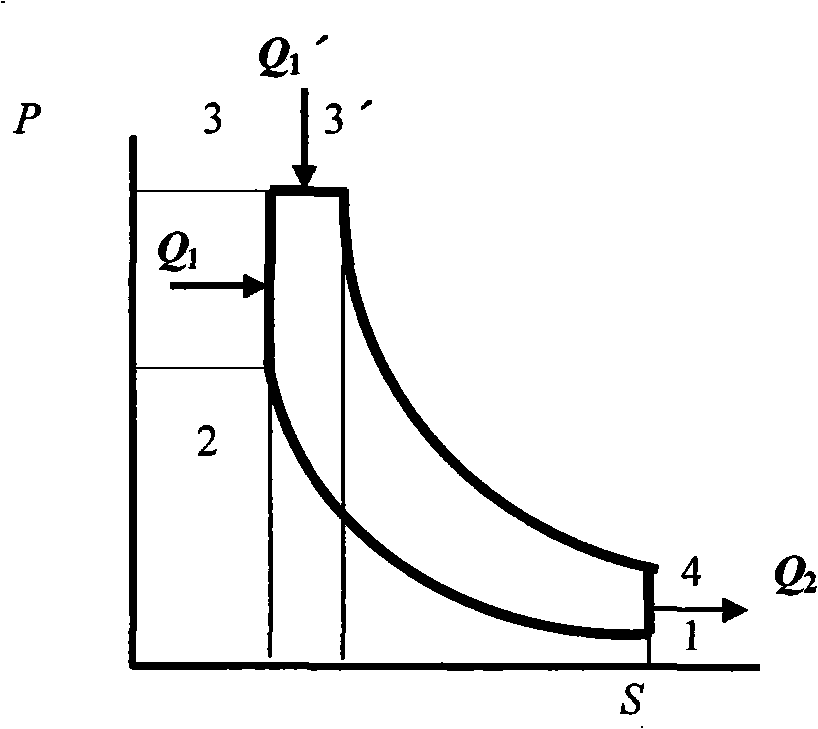

Gasoline and diesel general purpose internal-combustion engine

InactiveCN101338696AImprove powerImprove economyInternal combustion piston enginesGeneral purposeStored energy

The present invention discloses an universal gasoline-diesel internal combustion engine. A combustion chamber (16) is a high compression ratio combustion chamber. An explosion preventing and energy storing device which is communicated with the high compression ratio combustion chamber (16) is arranged on a cylinder cover (17). The energy q1of Pbz max larger than the allowed combustion pressure P1z during the combustion process is stored by the explosion preventing and energy storing device of the present invention to eliminate peak value and avoid detonation; when a piston descends, the stored energy q1 is transferred into q2 to be discharged under a controlled condition to form an isobaric combustion area between P1z and P2z, so as to obtain a full indicating diagram. The universal gasoline-diesel internal combustion engine is not provided with an electronic ignition system, processes for compression combustion ignition by high temperature produced by high compression ratio and has the advantages of good dynamic preoperty, economical efficiency and discharging performance, and the universal gasoline-diesel internal combustion engine is particularly advantaged under cold start, idle speed, warming up and low load and low temperature. When the universal gasoline-diesel internal combustion engine is applied to a diesel engine, the universal gasoline-diesel internal combustion engine also can improve the discharge and eliminate the influence caused by rough combustion, is good for the diesel engine to develop towards light weight and high speed and improves the performance of the diesel engine completely.

Owner:CHANGFENG GROUP

Combustion promoter for welding-cutting gas and welding-cutting liquid containing the same

InactiveCN101851538BRaise the combustion temperatureGood explosive performanceGaseous fuelsFuel additivesEnergy conservationPetroleum ether

The invention discloses a combustion promoter for welding-cutting gas and a welding-cutting liquid containing the same. The combustion promoter for welding-cutting gas comprises the following components by weight percent: 10%-30% of perchloric acid, 10%-30% of potassium dichromate, 10%-30% of petroleum ether and 20%-60% of methyl alcohol. The welding-cutting liquid comprises the following components by weight percent: 98%-99.3% of liquefied petroleum gas and 0.7%-2% of combustion promoter for welding-cutting gas. The welding-cutting liquid can be used for perforating, cutting, welding and thelike of metal products, and has the advantages of high efficiency, environment protection, safety, energy conservation and the like, the technical safety factor is 8 times that of acetylene, the harmful gas is not beyond the regulation of national standard TJ36-79, therefore, the welding-cutting liquid is an ideal product for replacing the acetylene.

Owner:RUODING SHENGLONG TECH

Thermal energy rotor power equipment and work-acting method thereof

ActiveCN103953455BIncrease the operating speedReduce volumeHot gas positive displacement engine plantsThermal energyExhaust valve

Owner:郭远军

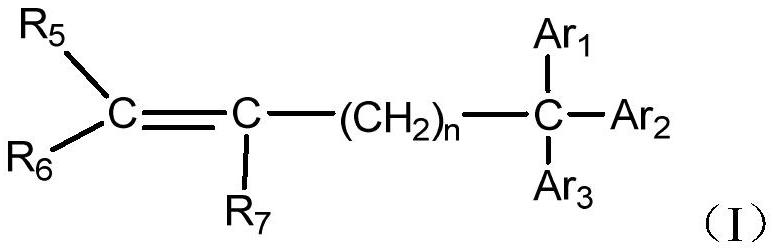

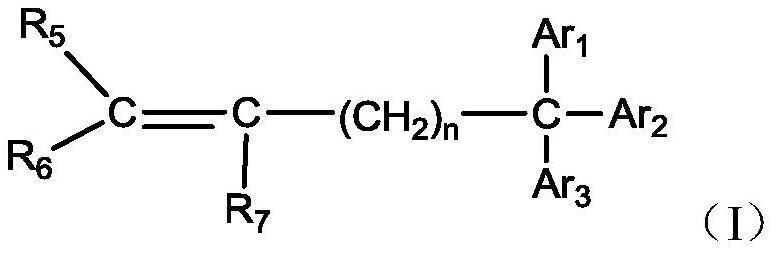

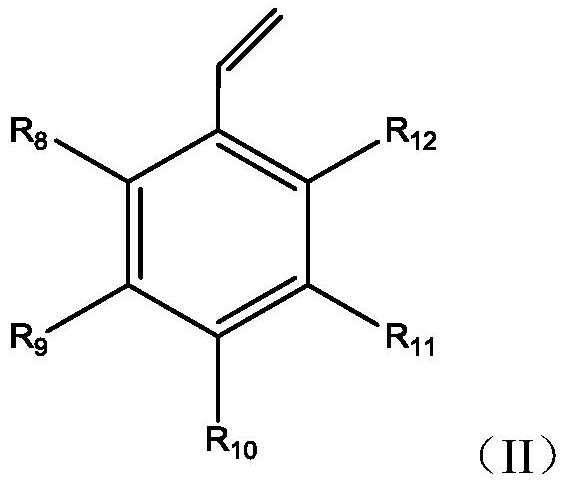

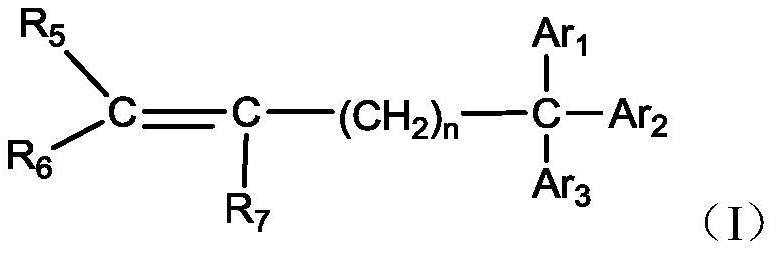

Polymethyl methacrylate polymer and preparation method thereof

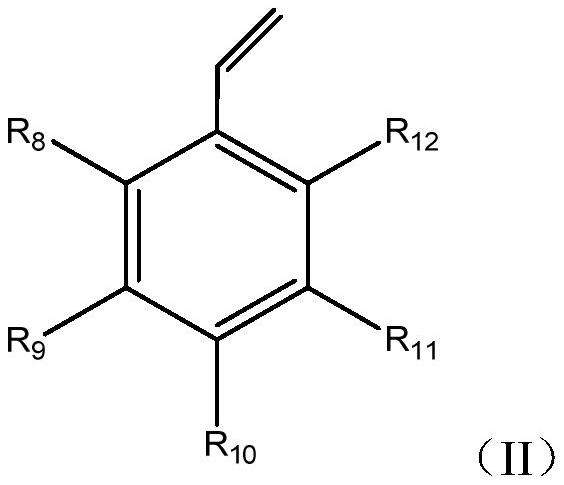

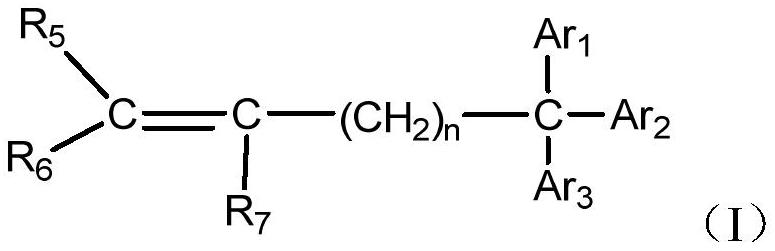

ActiveCN112625168BReduced exercise capacityImprove heat resistancePolymer sciencePolymethyl methacrylate

The invention provides a polymethyl methacrylate high molecular polymer, comprising the polymerization of a methyl methacrylate monomer, a vinyl monomer shown in formula (I) and a crosslinking agent shown in formula (II) reaction product. The polymethyl methacrylate macromolecular polymer of the invention can simultaneously improve the heat resistance and strength of the polymethyl methacrylate monomer resin, and the material has good comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fixed-point gas outlet method

ActiveCN110808537AImprove securitySo as not to damageSpark gap detailsThermodynamicsMechanical engineering

The invention discloses a fixed-point gas outlet method, and belongs to the technical field of power system lightning protection. A fixed-point gas outlet device is arranged. The fixed-point gas outlet device comprises a steel shell. A gas-producing fuel is placed in the steel shell. One end of the steel shell is provided with a trigger pin. The trigger pin penetrates through the steel shell to contact with the gas-producing material in the steel shell. The other end of the steel shell is provided with a gas outlet part. The shell at the gas outlet part is thinner than the shell at other partsof the steel shell. The wrapping strength of the steel shell is greater than the maximum atmospheric pressure of the gas-producing material. The lightning trigger signal contacts the gas-producing material after passing through the trigger pin. The gas-producing material in the steel shell instantly burns to generate arc-extinguishing gas. The arc-extinguishing gas breaks through the shell at thegas outlet part, and the arc-extinguishing gas ejects out from the gas outlet part to extinguish the arc. The method can improve the safety capability of the solid phase arc extinguishing lightning protection device without damaging the external structure under the condition that the external structure is not strengthened.

Owner:GUANGXI UNIV +1

Polymethyl methacrylate monomer high-molecular polymer and preparation method thereof

The invention provides a polymethyl methacrylate high-molecular polymer. The polymethyl methacrylate high-molecular polymer comprises a polymerization reaction product of a methyl methacrylate monomer, a vinyl monomer shown as a formula (I) and a cross-linking agent shown as a formula (II). The polymethyl methacrylate monomer high-molecular polymer provided by the invention can improve the heat resistance and strength of polymethyl methacrylate monomer resin at the same time, and the material has good comprehensive performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com