Novel light fuel internal combustion engine

An internal combustion engine and light fuel technology, applied in the direction of combustion engines, machines/engines, mechanical equipment, etc., can solve problems such as low efficiency, difficult to achieve higher engine efficiency, and complex force components, so as to improve power output efficiency and increase torque The effect of transmission efficiency, energy saving and emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

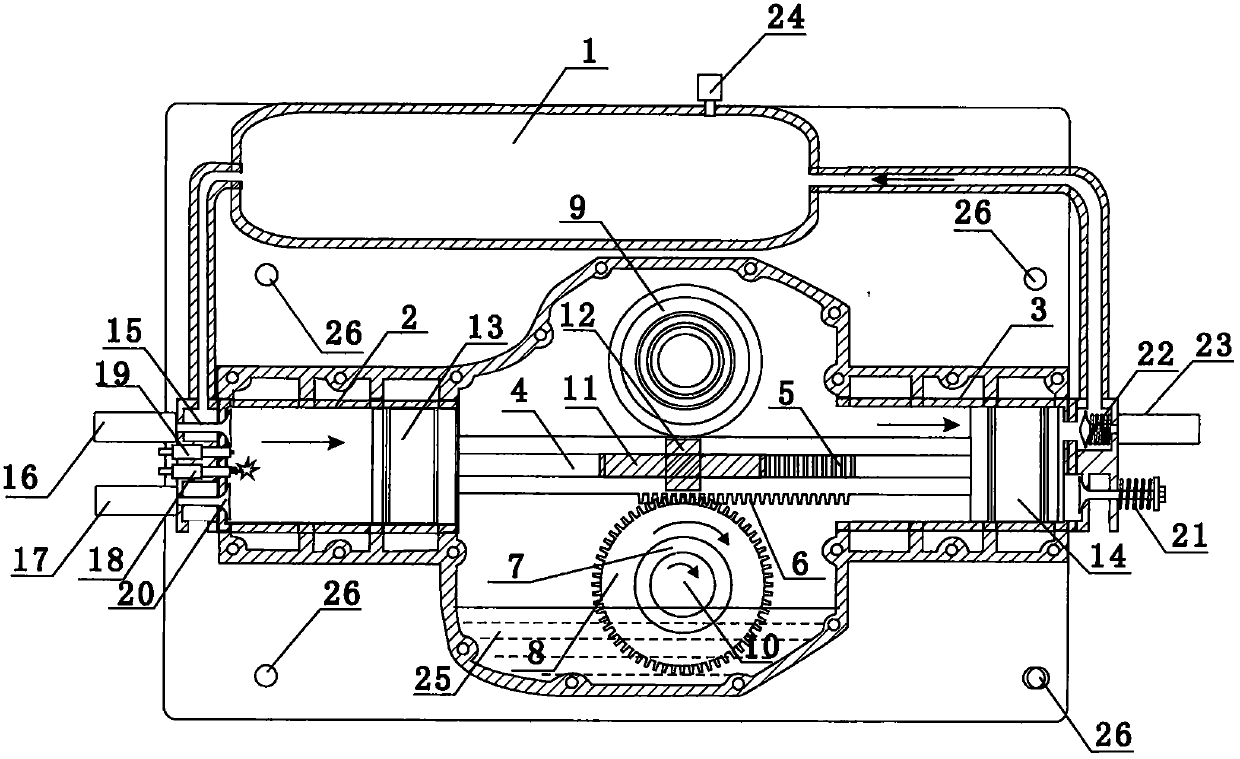

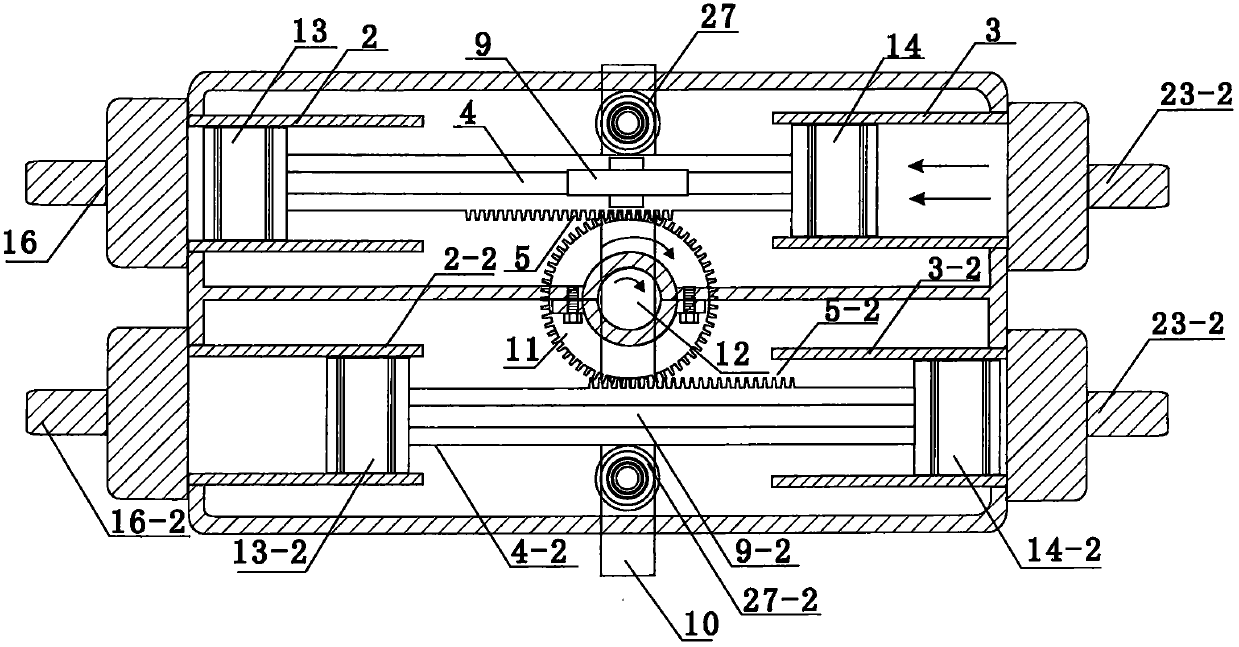

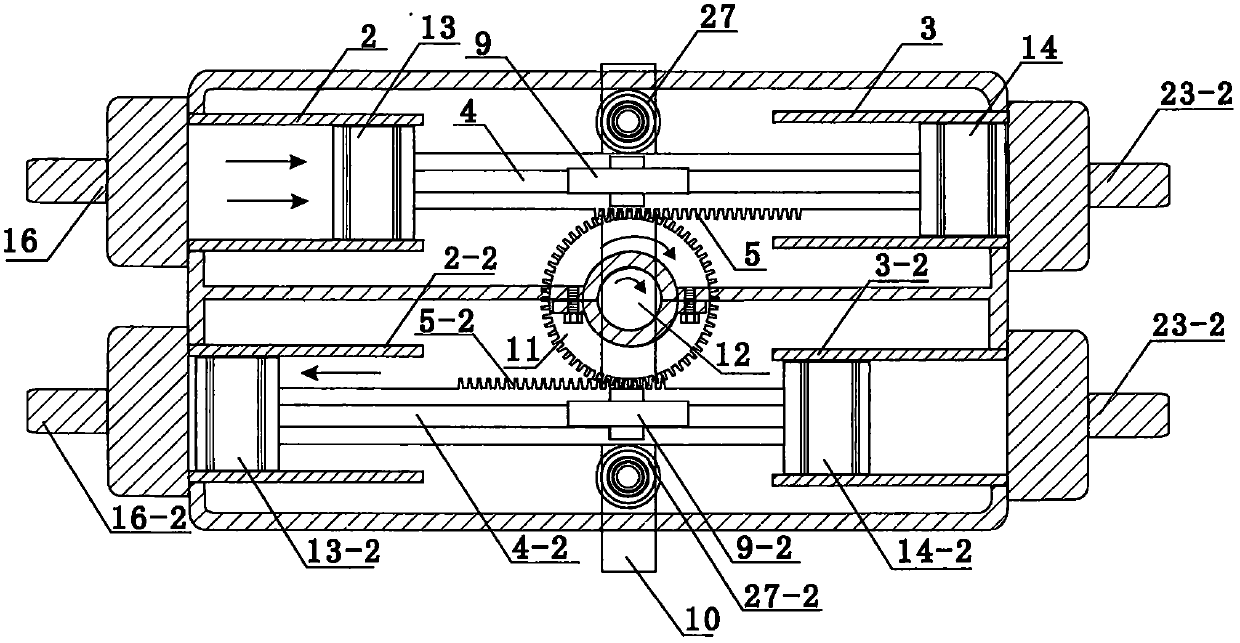

[0012] Such as figure 1 , 2 , 3 design and manufacture a kind of novel light-fuel internal combustion engine, this engine working cylinder 2, 2-2 is coaxially opposite with compression cylinder 3, 3-2, two groups of working and compression cylinders are horizontally arranged side by side to form a four-cylinder unit (such as figure 2 ), the working piston 13 and the compressor piston 14 are directly connected by the multi-faceted rack piston connecting rod 4 to form a piston connecting rod group. Acting and compressing are one stroke respectively, and exhausting and sucking are one stroke, and each working cycle has two strokes altogether, and the diameter of compressed gas 3, 3-2 is suitably greater than the diameter of working cylinder 2, 2-2, to reach the increase The working piston 13, 13-2 directly pushes the pressure piston 14, 14-2 through the multi-faceted rack piston connecting rod 4 to pressurize the gas and store the high-pressure air in the high-pressure air stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com