Multifunctional clutch and gearbox

A clutch and multi-functional technology, applied in the field of gearboxes, can solve the problems of complex clutch structure, high cost and short service life of clutch plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments are mainly aimed at the gearbox of the present invention. Since the gearbox of the present invention adopts the clutch of the present invention, the embodiment of the clutch has been described in the description of the gearbox embodiment.

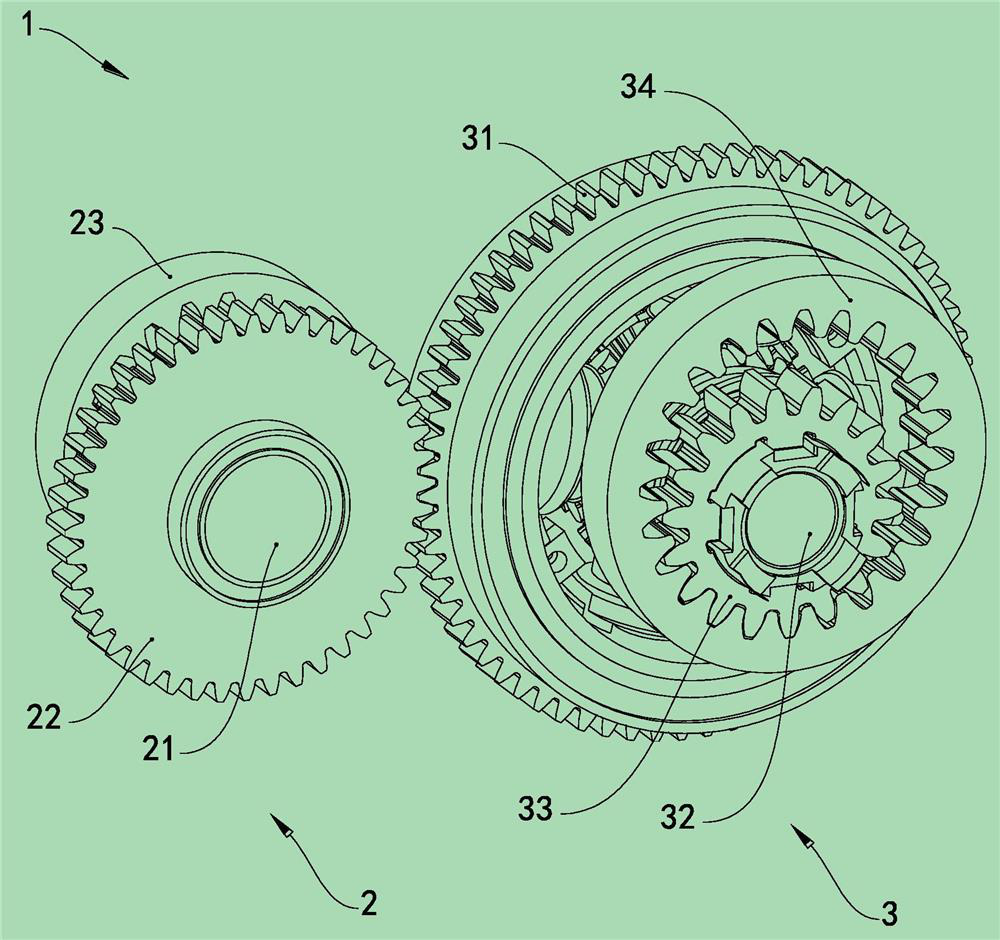

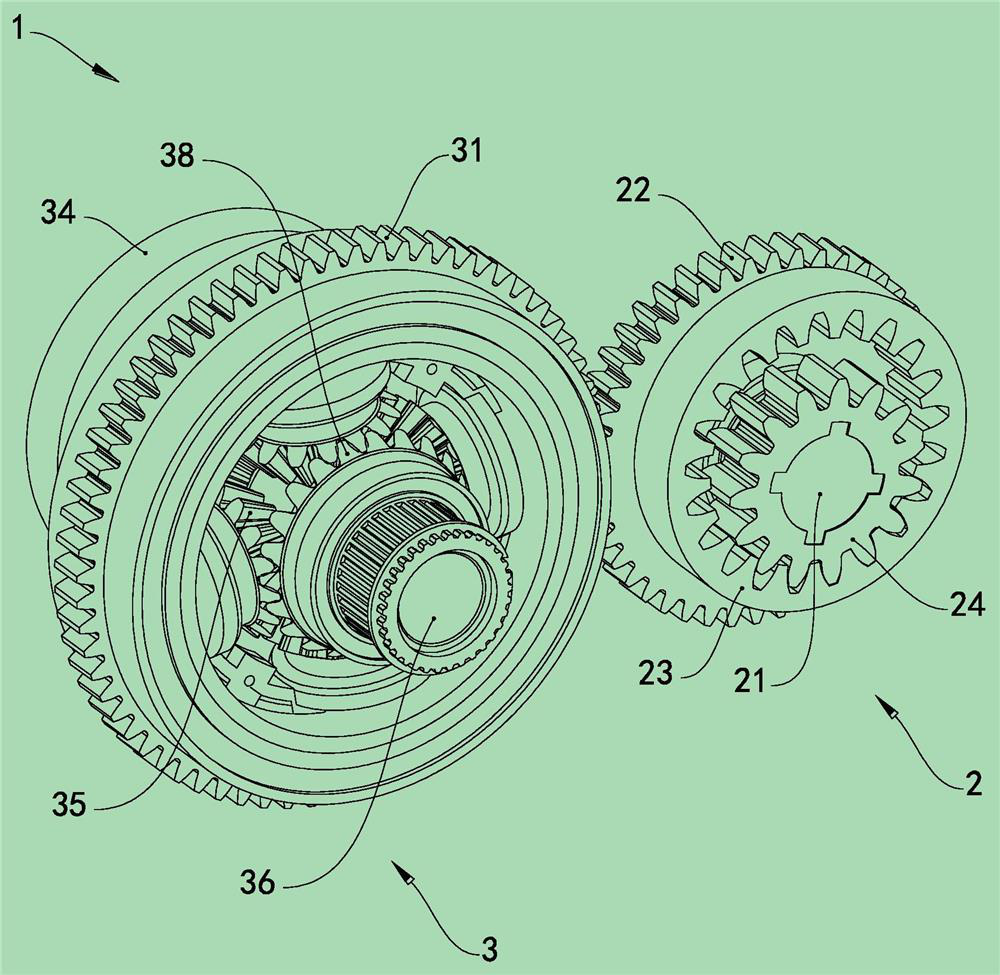

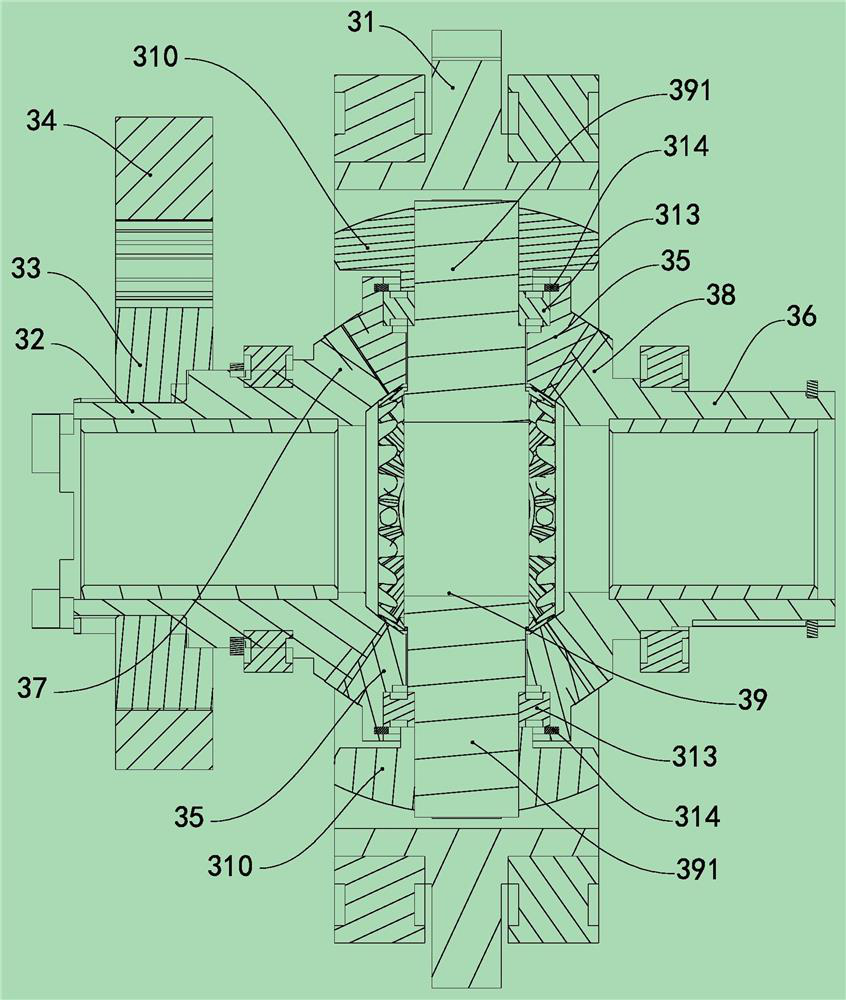

[0028] see Figure 1 to Figure 4 , this embodiment discloses a gearbox 1, including a driving oil pump, a transmission mechanism 3 and a clutch 2, and the transmission mechanism 3 includes an input shaft 32, a braking outer ring gear 31, a cross shaft 39, four planetary gears 35 and an output shaft 36 , the first end of the input shaft 32 is coaxially provided with an input bevel gear 37 , and one end of the output shaft 36 is coaxially provided with an output bevel gear 38 . The driving internal rotation gear 33 of the driving oil pump is coaxially sleeved on the second end of the input shaft 32, and the driving external rotation ring gear 34 of the driving oil pump can rotate around its own axis and is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com