Patents

Literature

43results about How to "Improve torque transmission efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

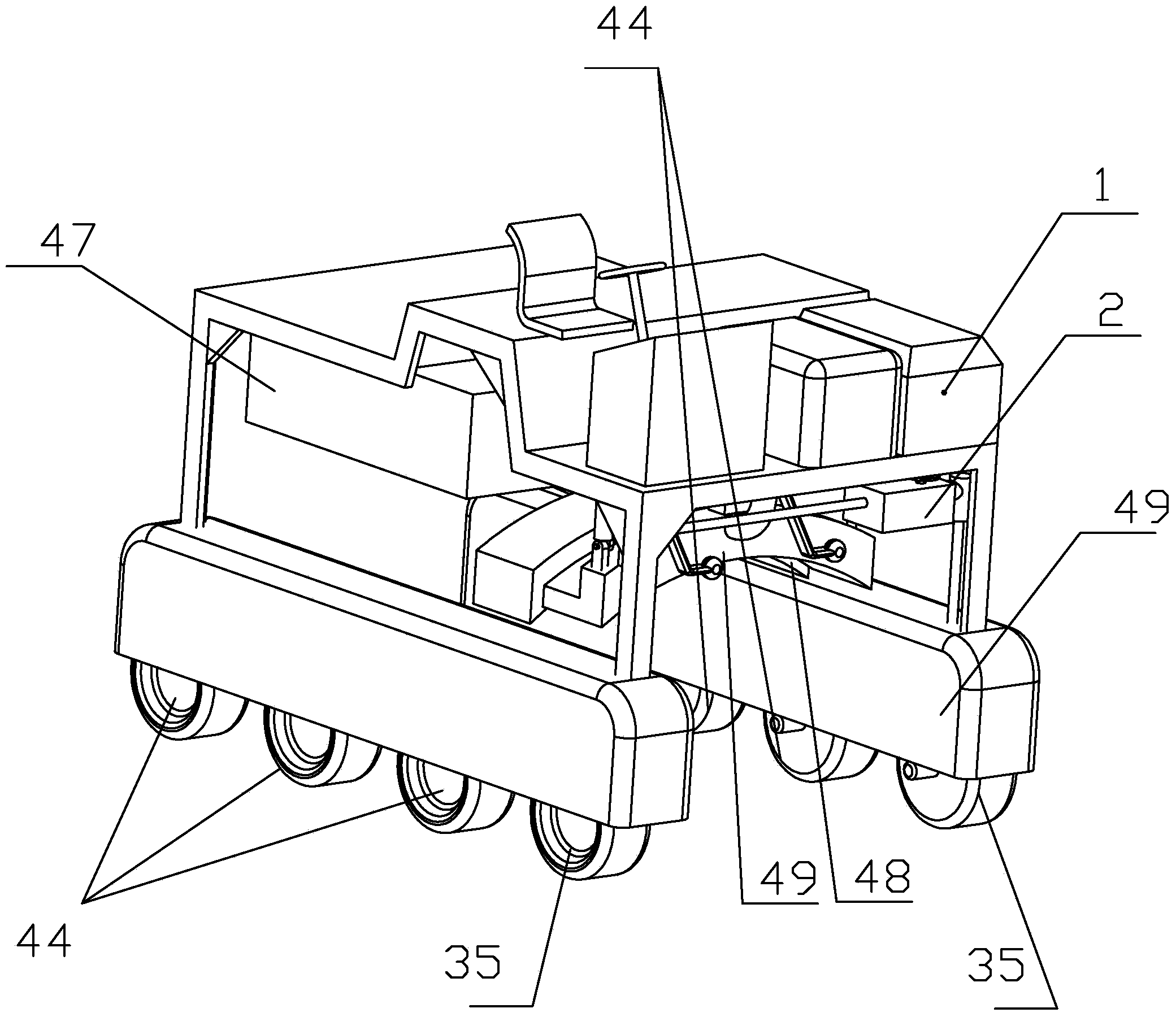

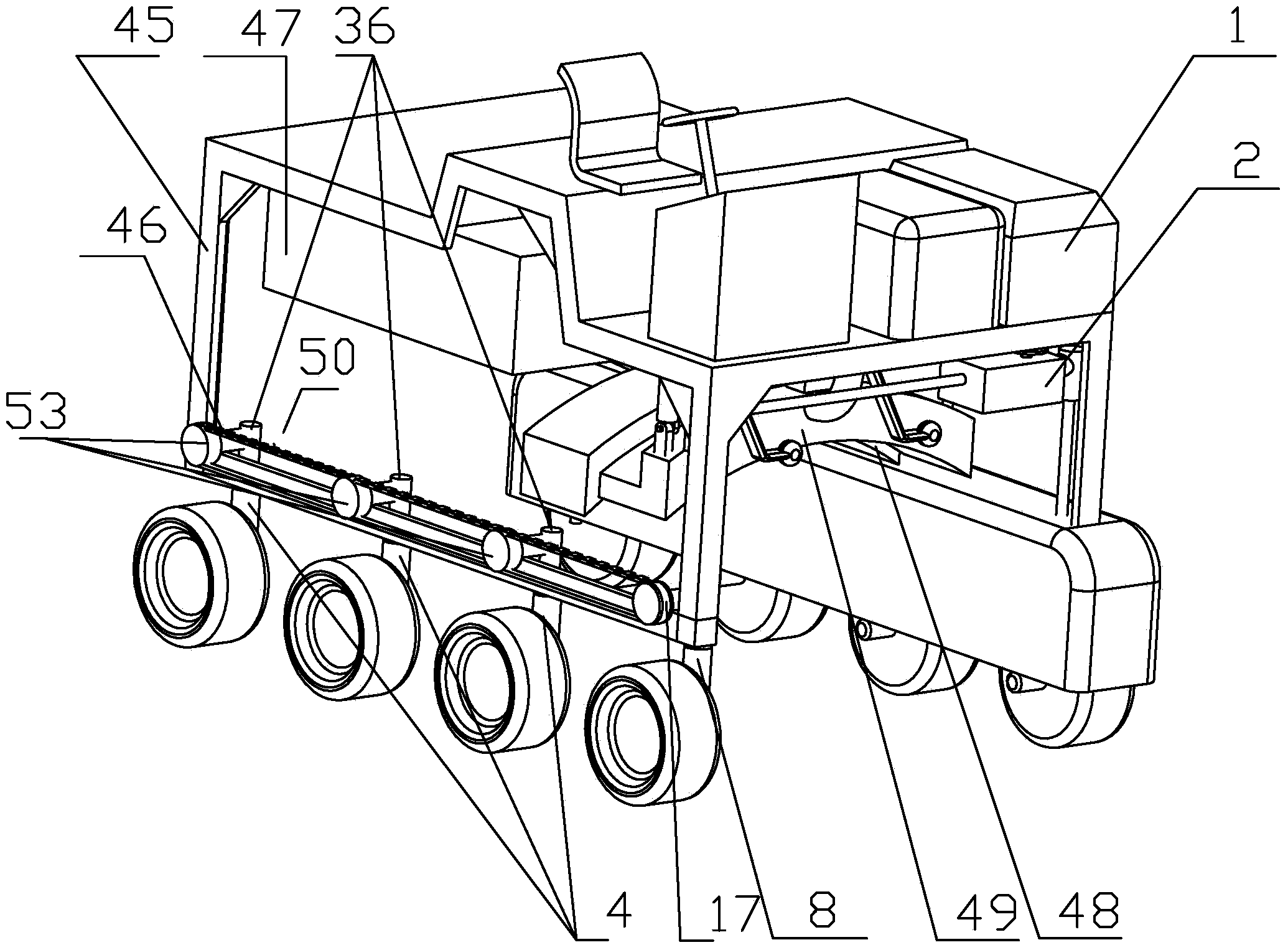

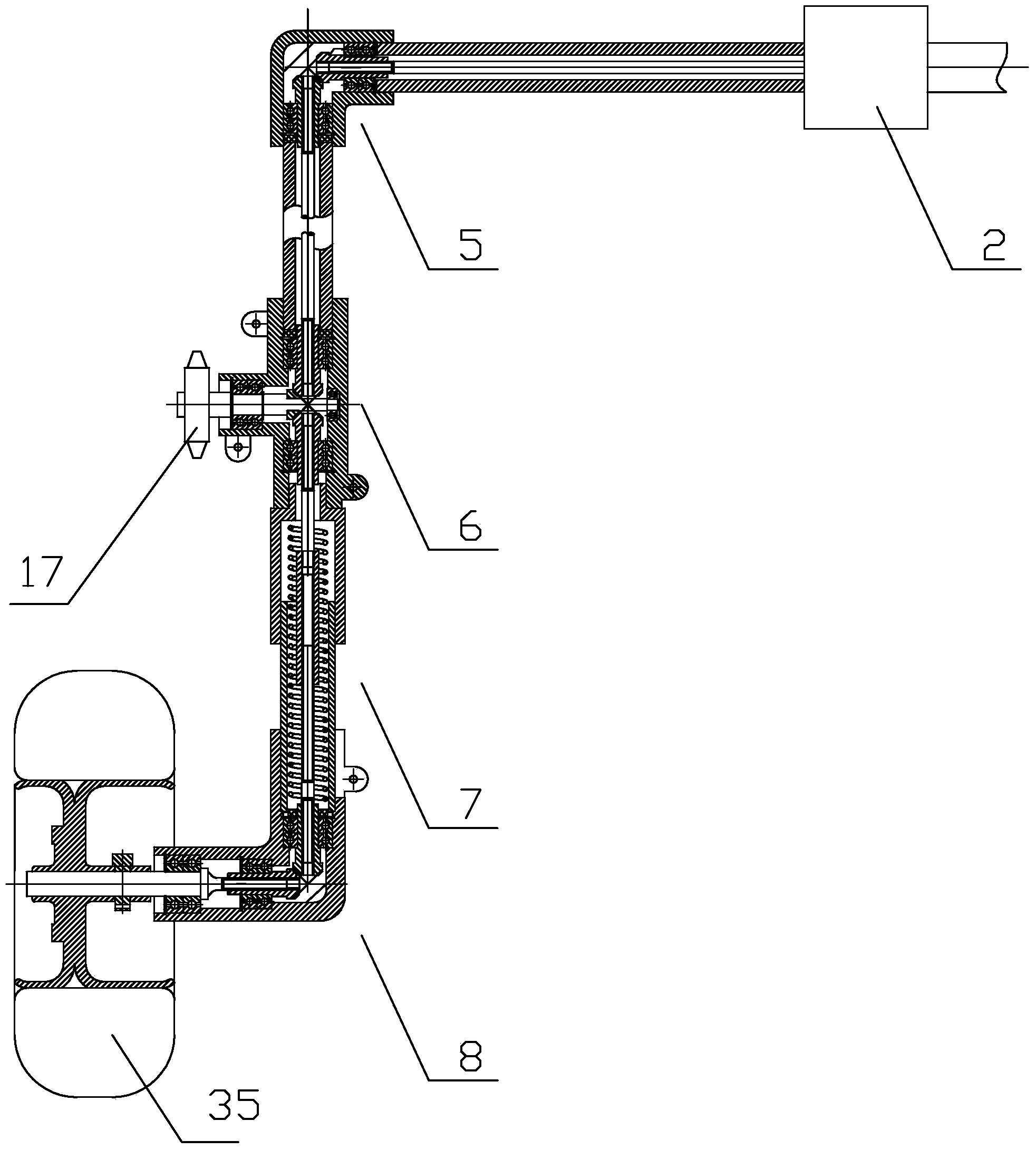

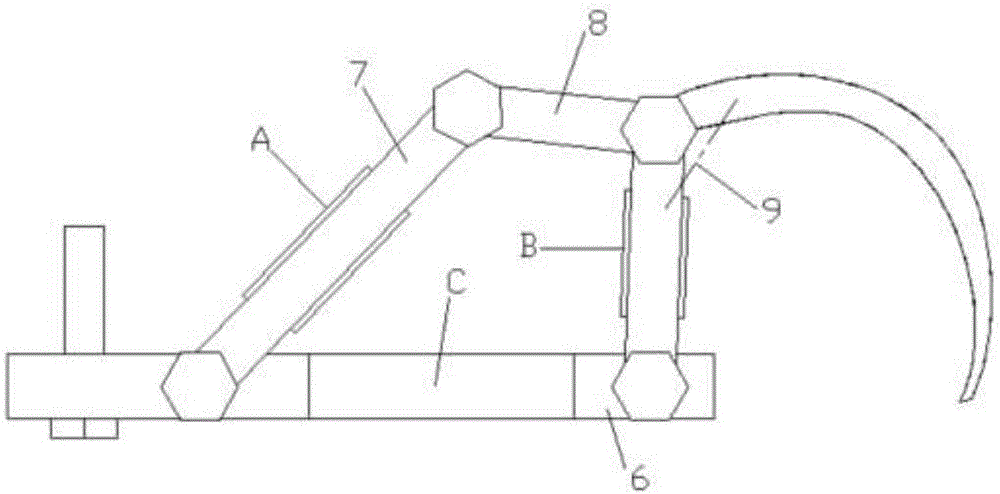

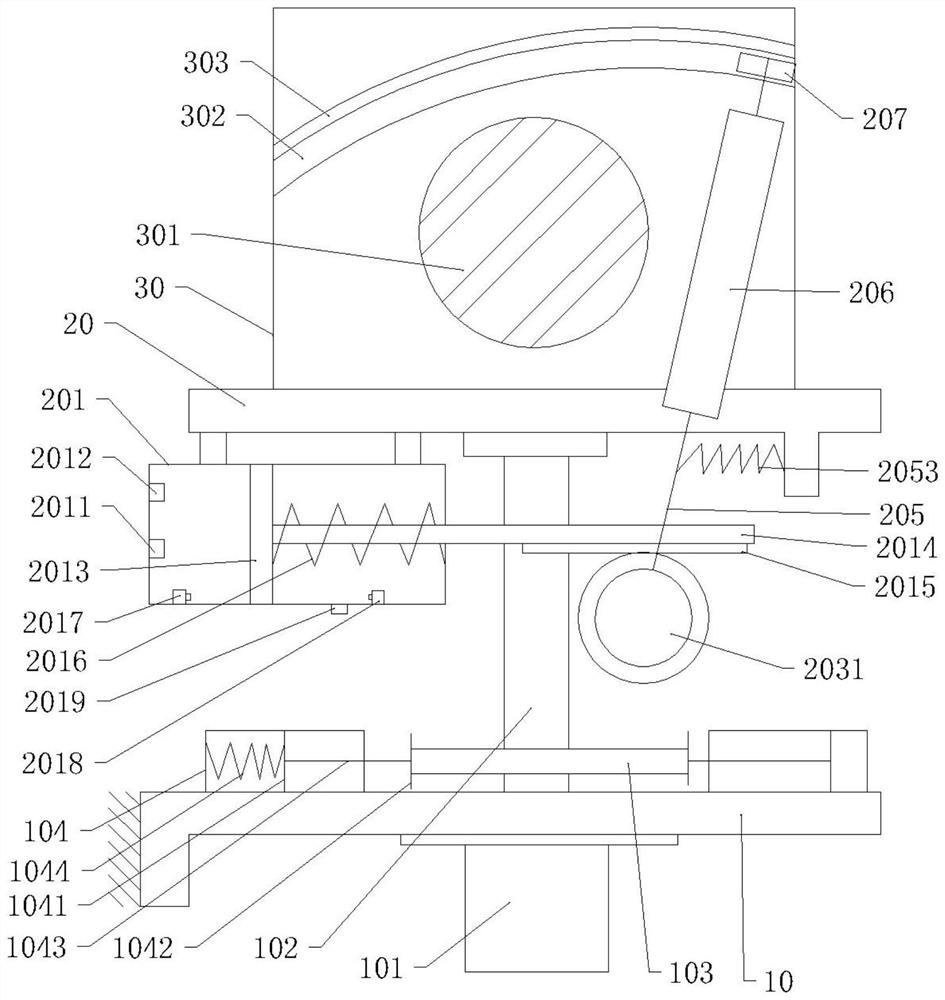

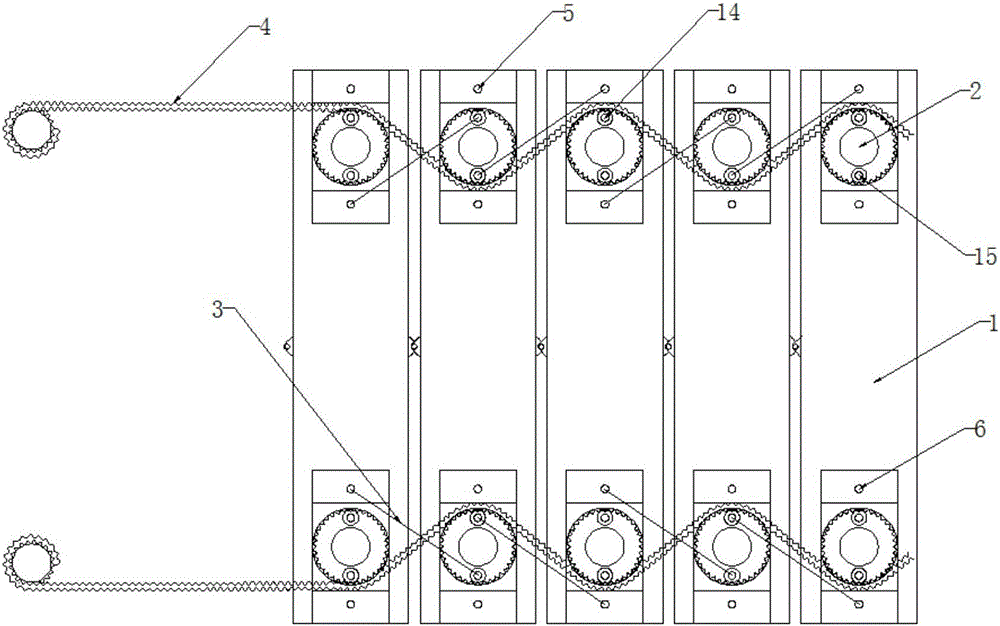

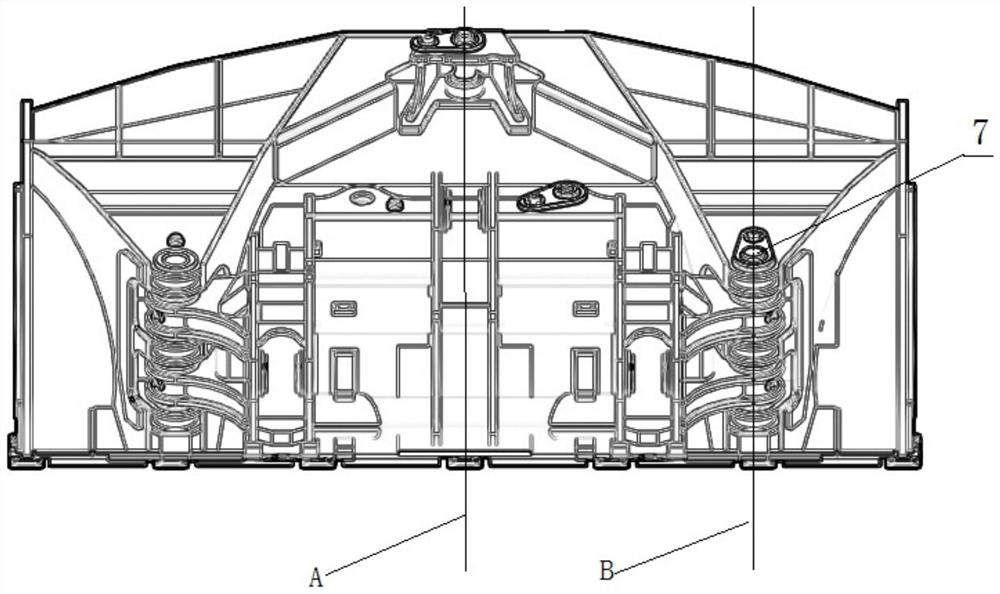

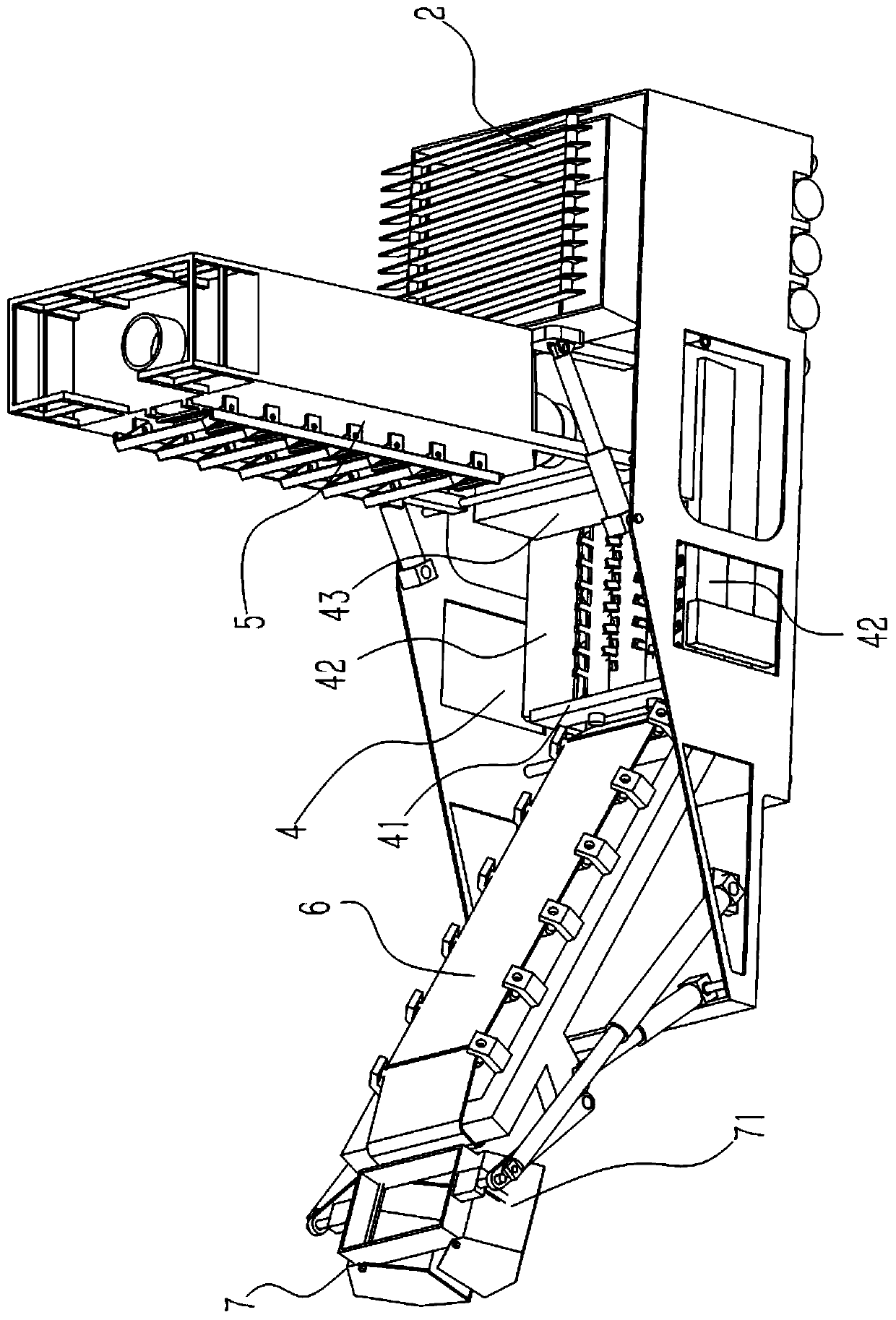

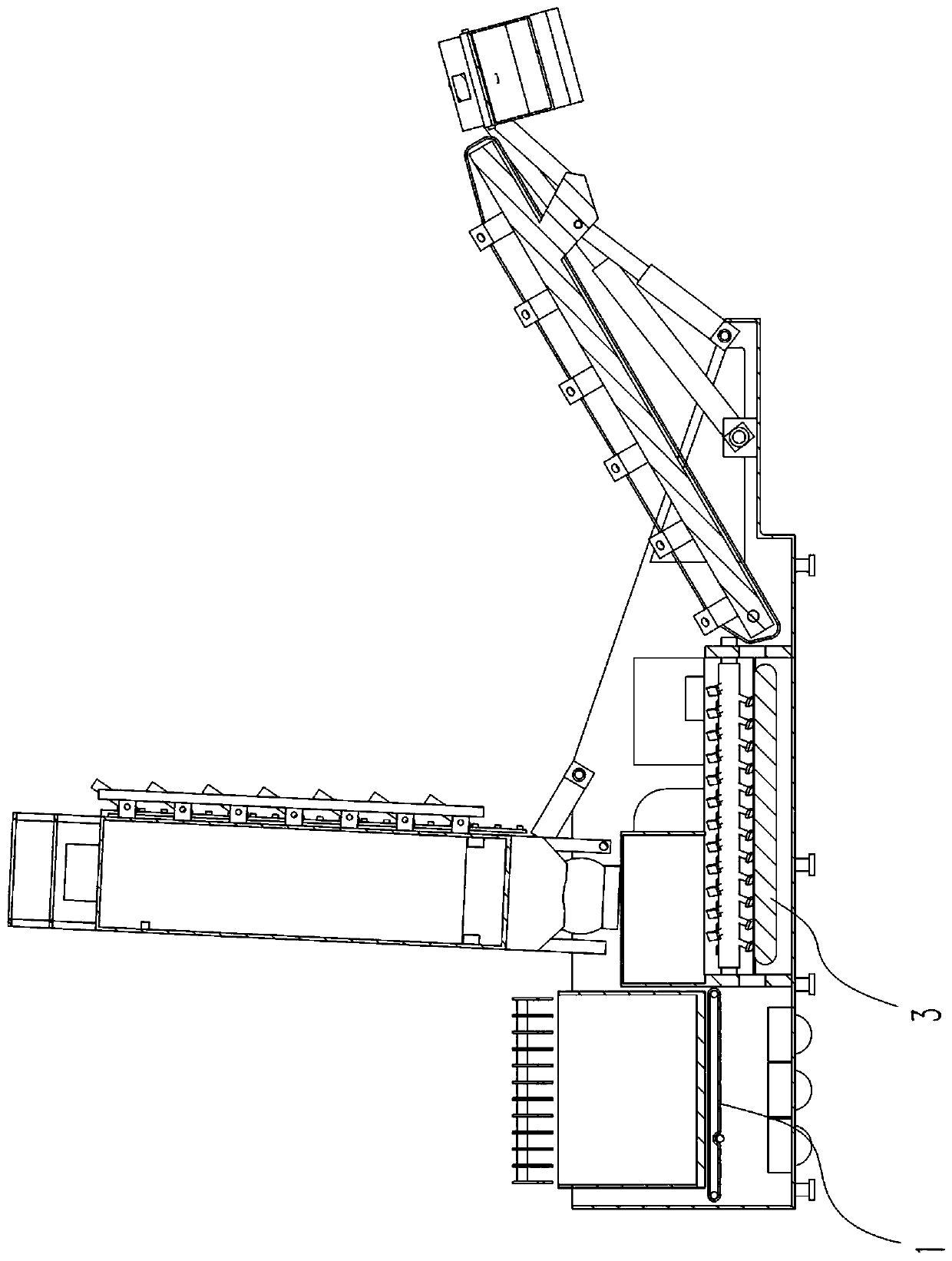

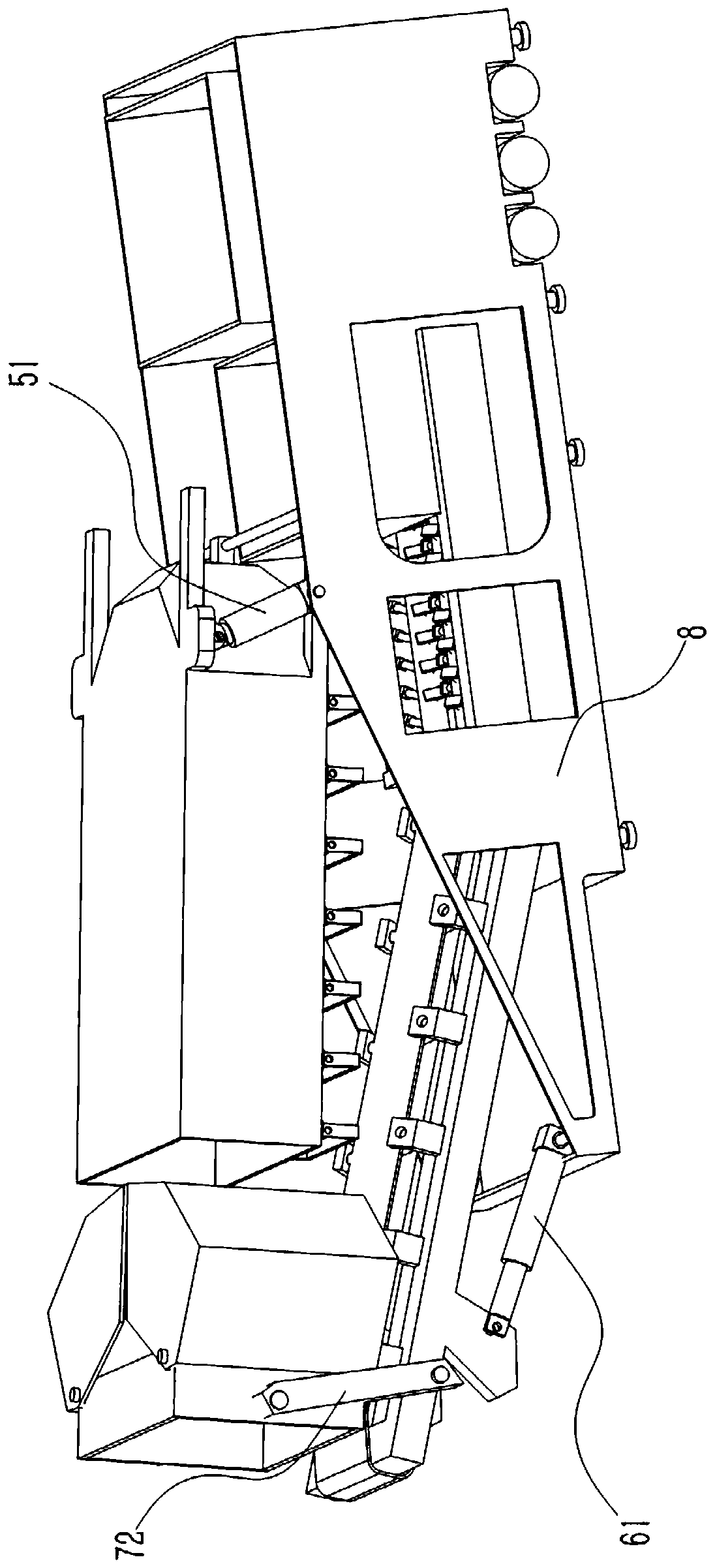

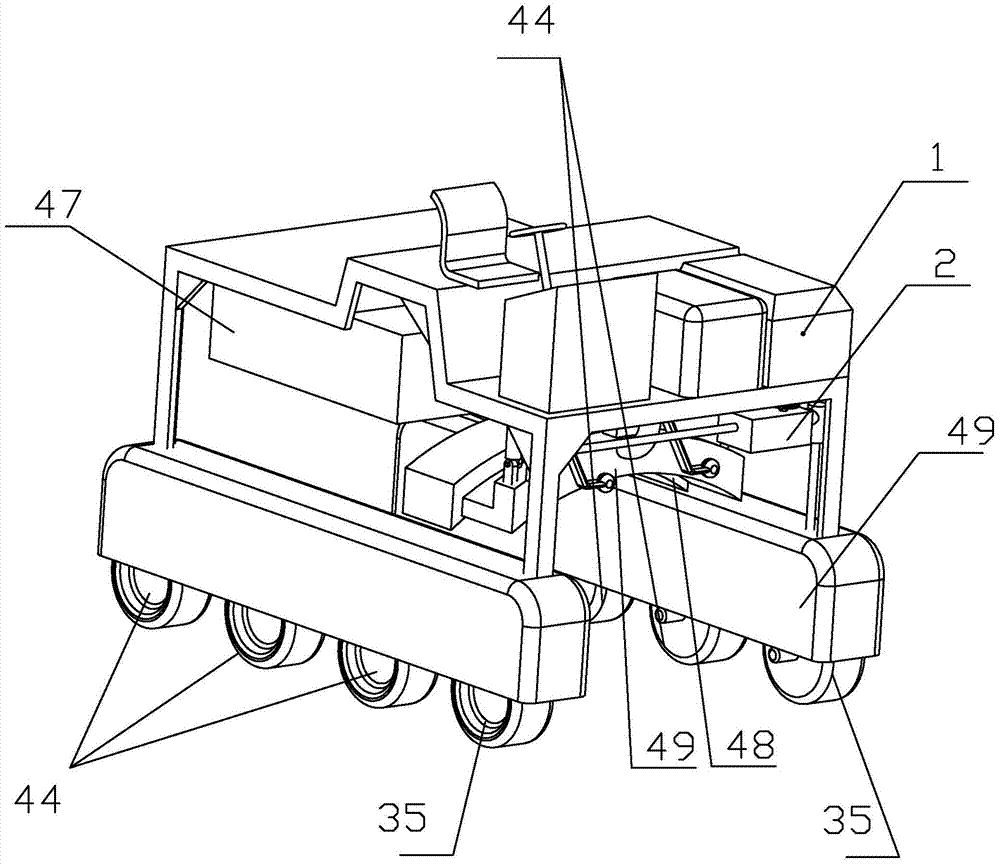

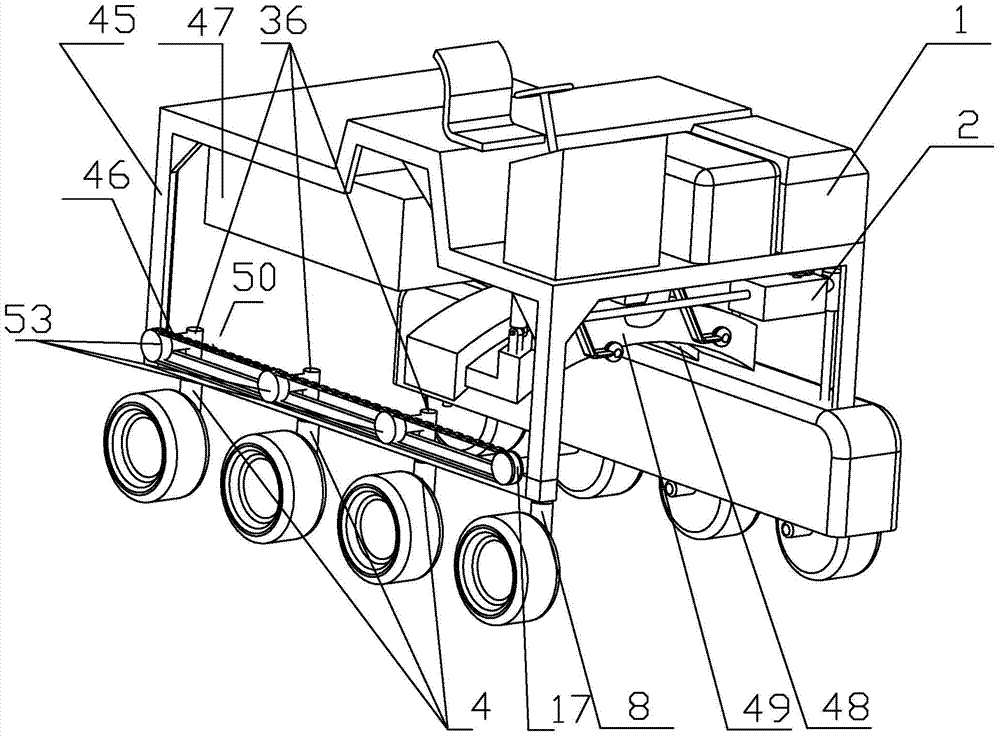

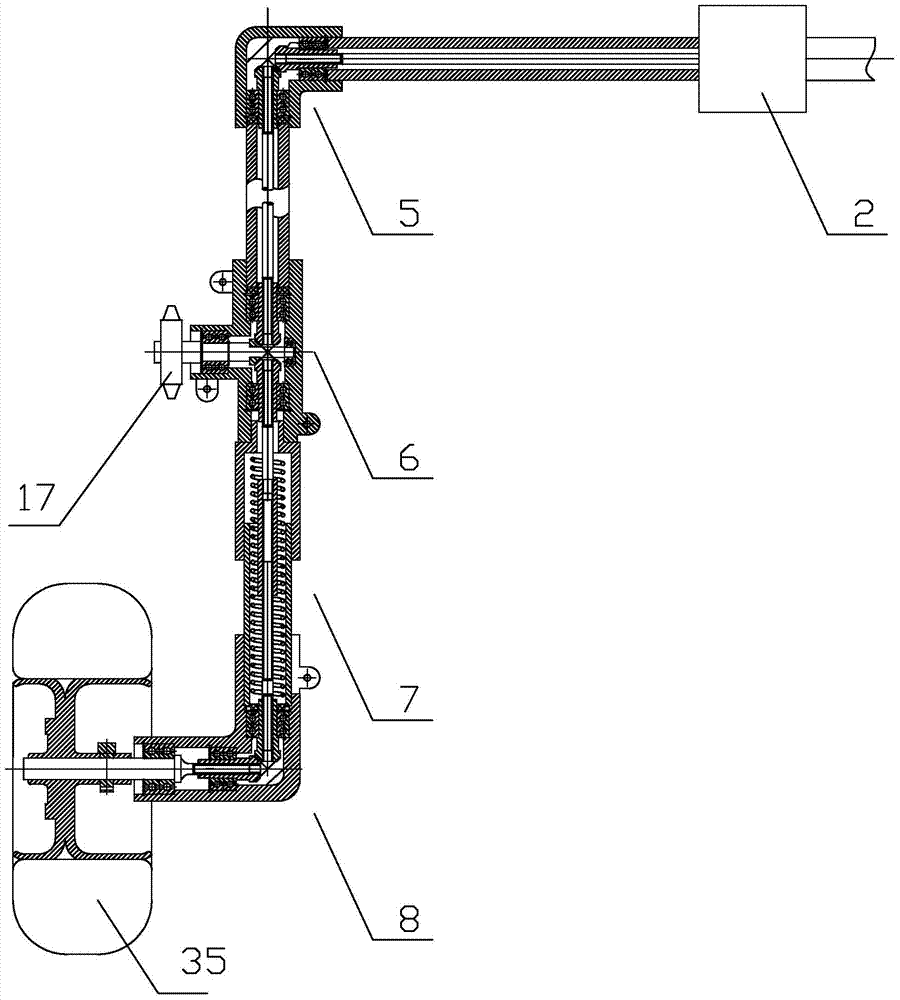

Tea picking machine with multi-wheel bump-proof walking mechanism

ActiveCN103766076APicking tea with high quality and quantityHigh torque transmission efficiencyPicking devicesControl devicesControl theoryFront-wheel drive

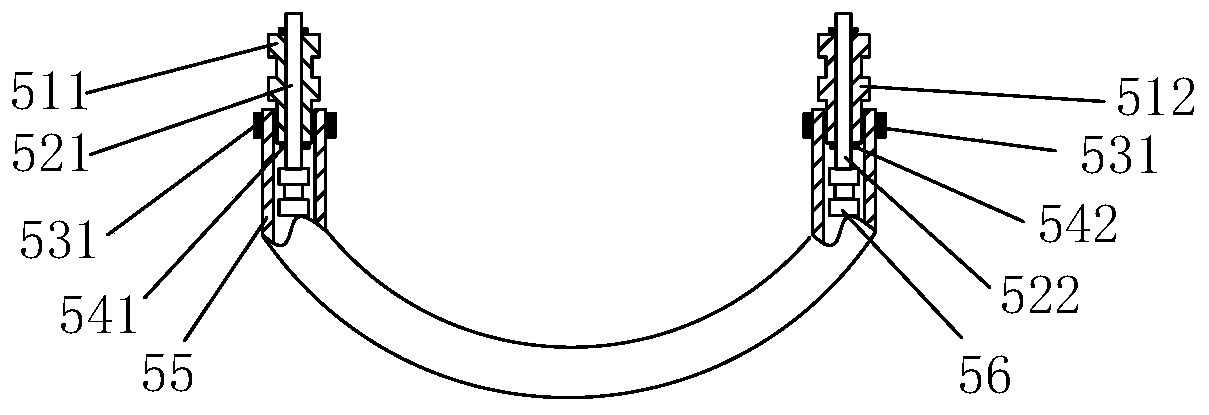

The invention belongs to the technical field of a tea picking machine,and particularly relates to a tea picking machine with a multi-wheel bump-proof walking mechanism.It comprises a door type structure machine frame, an engine on the machine frame, a gearbox, a tea picking mechanism, one front wheel is respectively arranged at the left and the right side of the machine frame, and more than one back wheel is respectively arranged at the left and the right side of the machine frame.The tea picking machine is characterized by also comprising two output shaft motive power driving transmission mechanisms, the front and back wheel motive power driving branched transmission mechanisms are connected with each output shaft motive power driving transmission mechanism, the front wheel motive power driving dump-proof vibration reduction transmission mechanism and the back wheel motive power driving transmission mechanism are connected with the front and back wheel motive power driving branched transmission mechanism,the front wheel driving transmission mechanism is connected with the front wheel motive power driving damp-proof vibration reduction transmission mechanism, and the back wheel dump-proof walking mechanisms are connected with the back wheel motive power driving damp-proof vibration reduction transmission mechanism.It has the advantages that the stable, efficient, quality-guaranteeing and quantity-guaranteeing tea picking on uneven hill ground can be realized.

Owner:睢宁下邳农业有限公司

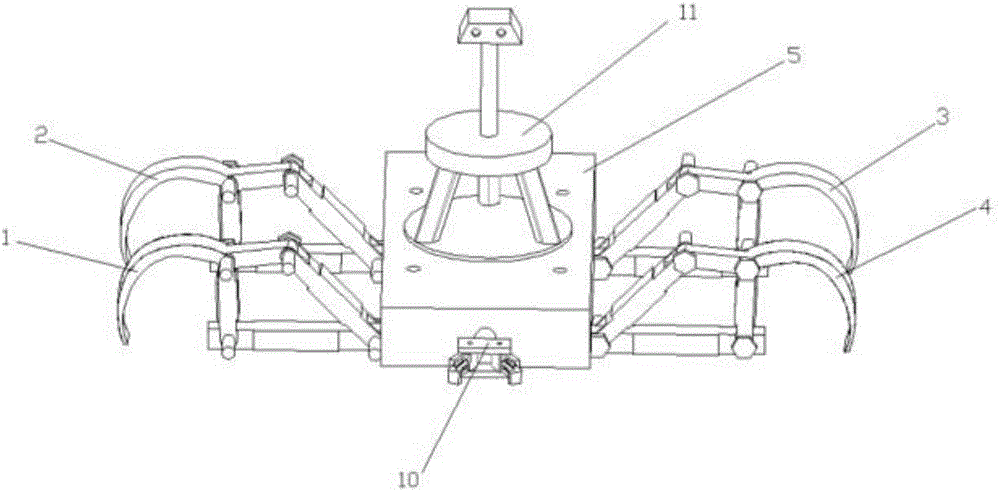

Bionic quadruped spider robot

ActiveCN106542017AWide field of visionFlexible movementVehicle componentsVehiclesEngineeringAdhesion force

A bionic quadruped spider robot comprises a body used as a trunk; two pairs of symmetrically-arranged leg crawling mechanisms are arranged on two sides of the body; a mouth clamping device is arranged on the front side of the body; a camera module is arranged in the middle of the body; the leg crawling mechanisms and the mouth clamping device are driven by corresponding piezoelectric patches to move; and piezoelectric patch groups of the leg crawling mechanisms, a vertical piezoelectric patch and a horizontal piezoelectric patch of the mouth clamping device and the camera module are connected with a control module. The leg crawling mechanisms of the robot have the higher adhesion force and the higher obstacle climbing ability with the ground, so that the robot can be used for carrying an object; the object can be grabbed by the mouth clamping device and can be carried to a destination along a set path, the clamping device has four degrees of freedom, the tightness for clamping the object can be controlled, the acting point for clamping the object can be adjusted through vertical rotation, and the robot has the higher flexibility and sensitivity; and the camera module at the top can rotate, and thus the bionic spider robot can capture a wider field of vision.

Owner:NINGBO UNIV

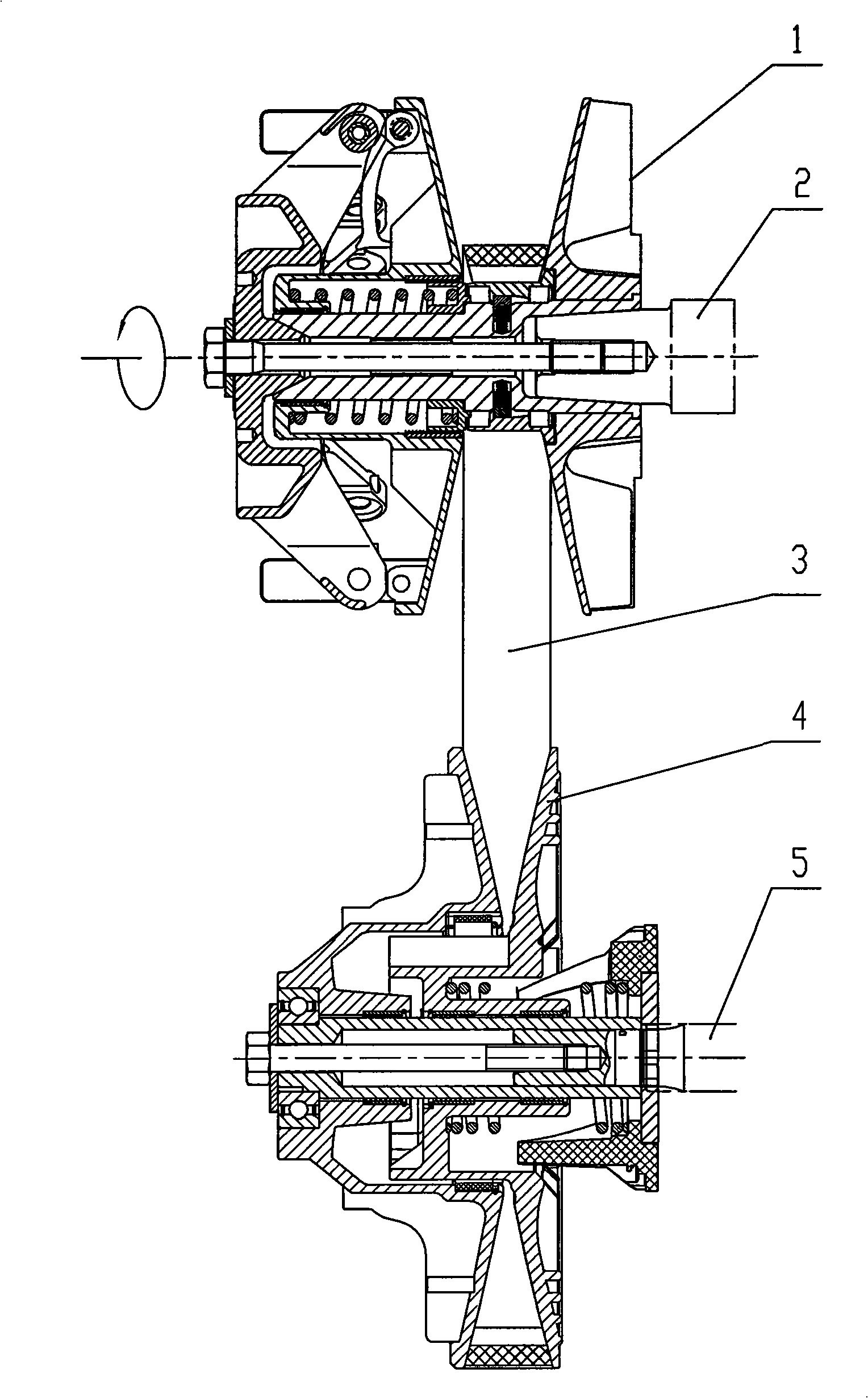

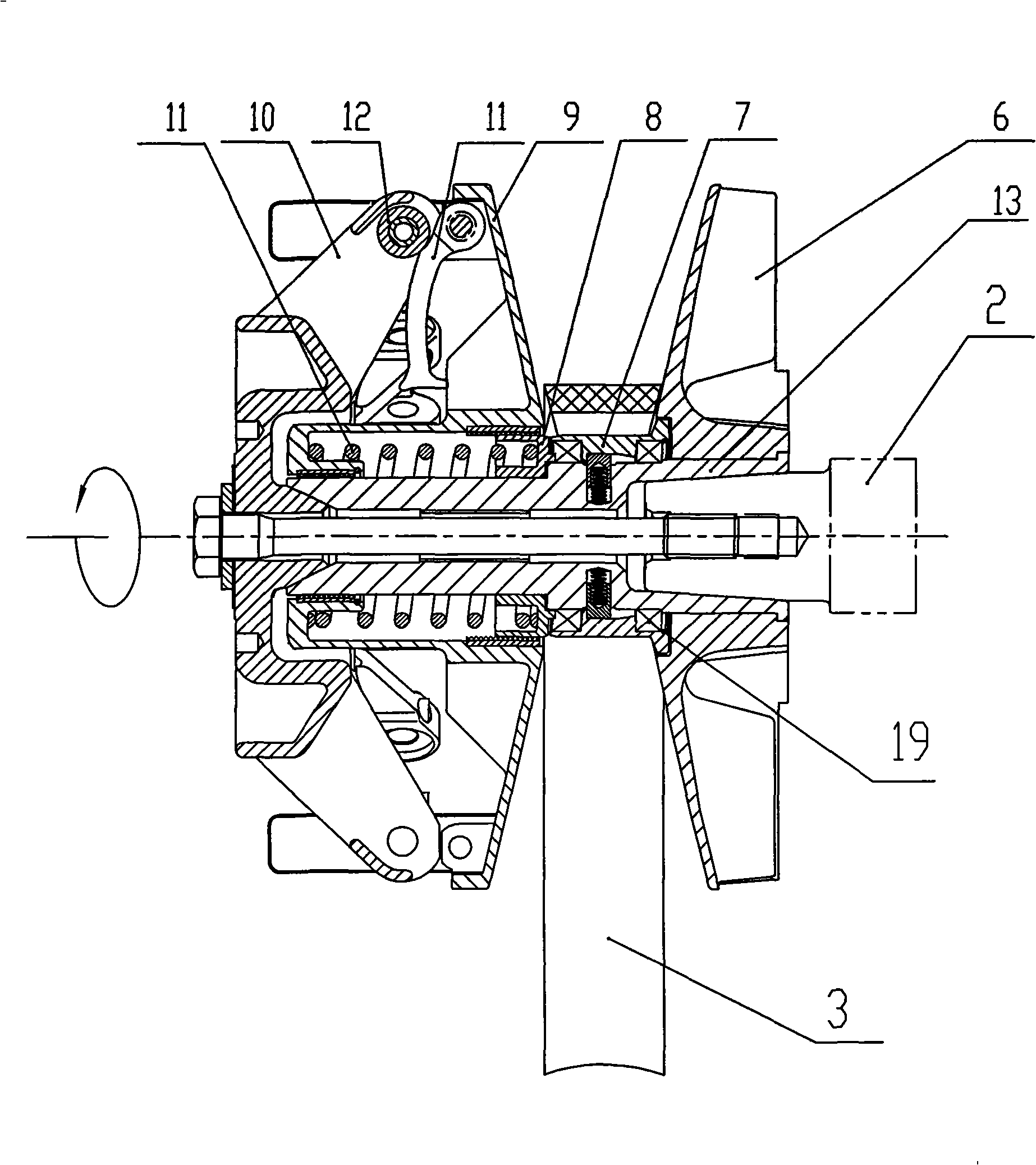

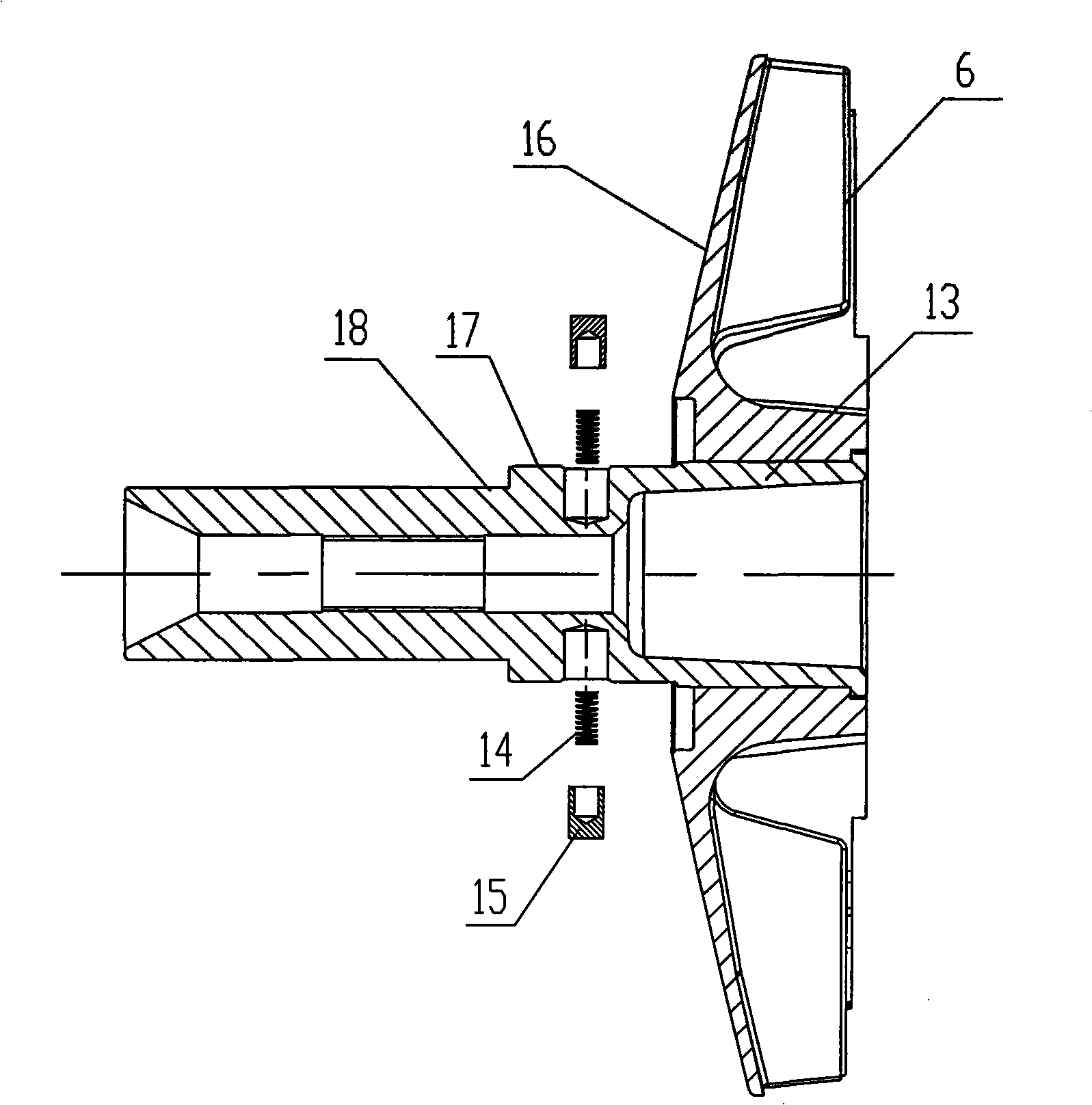

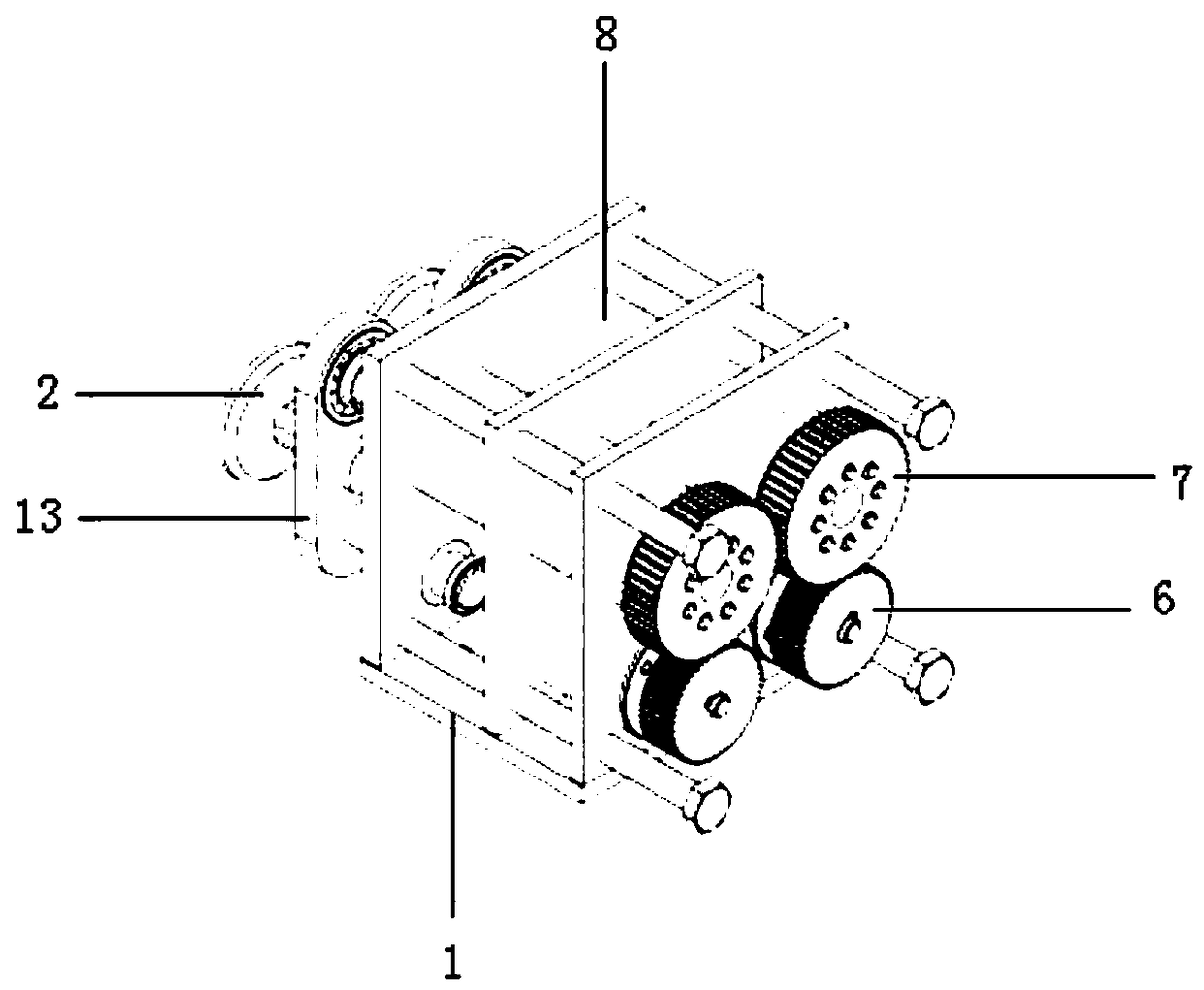

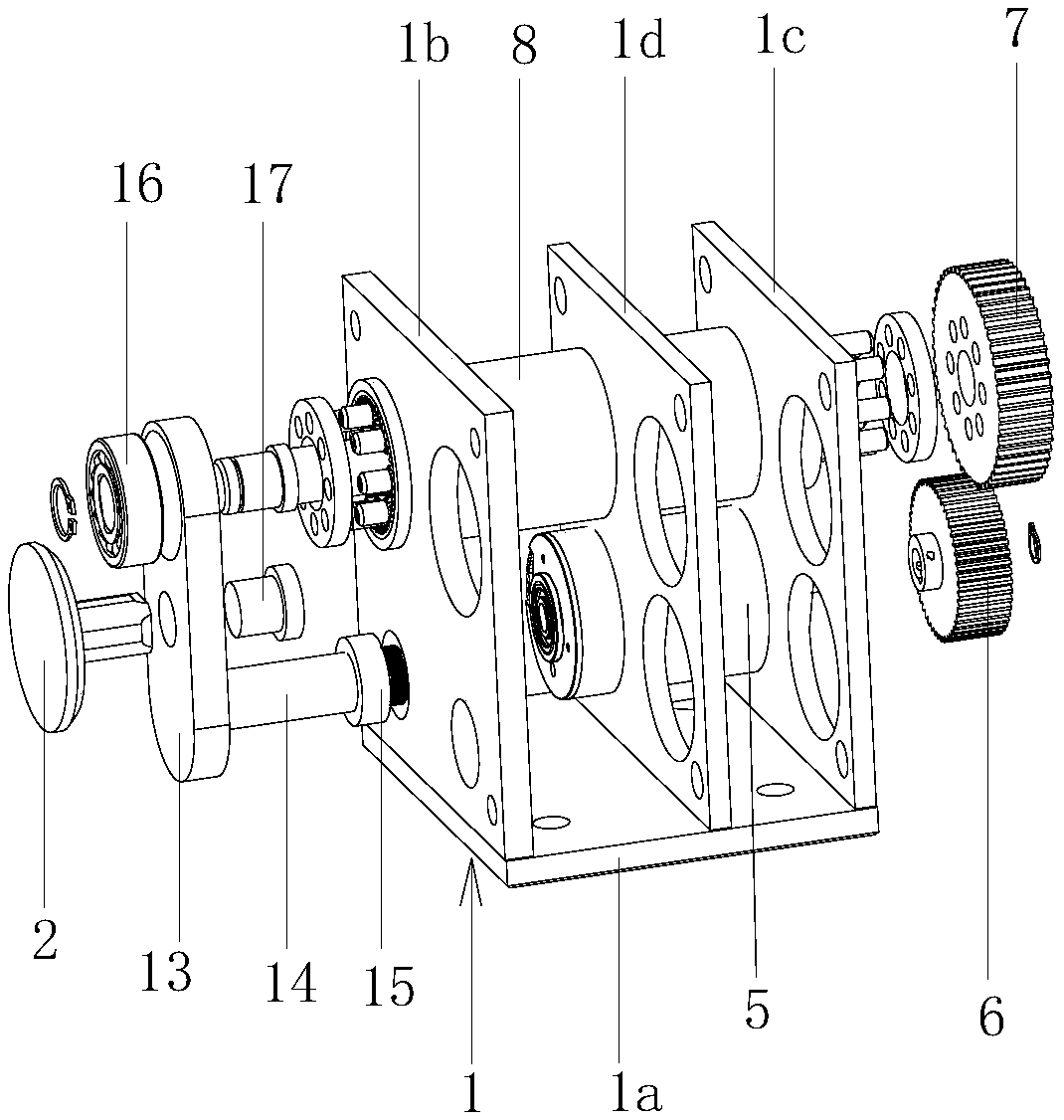

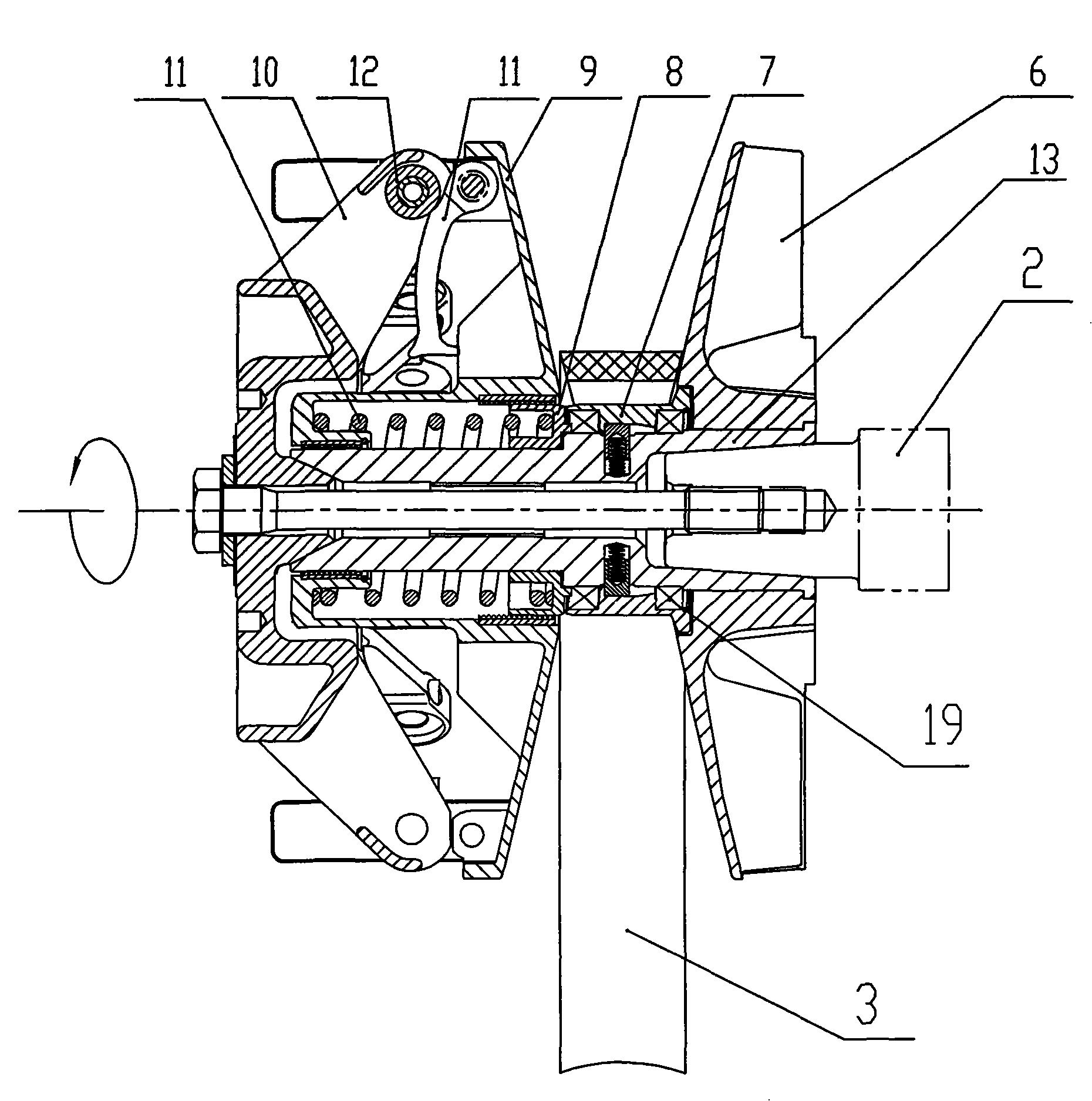

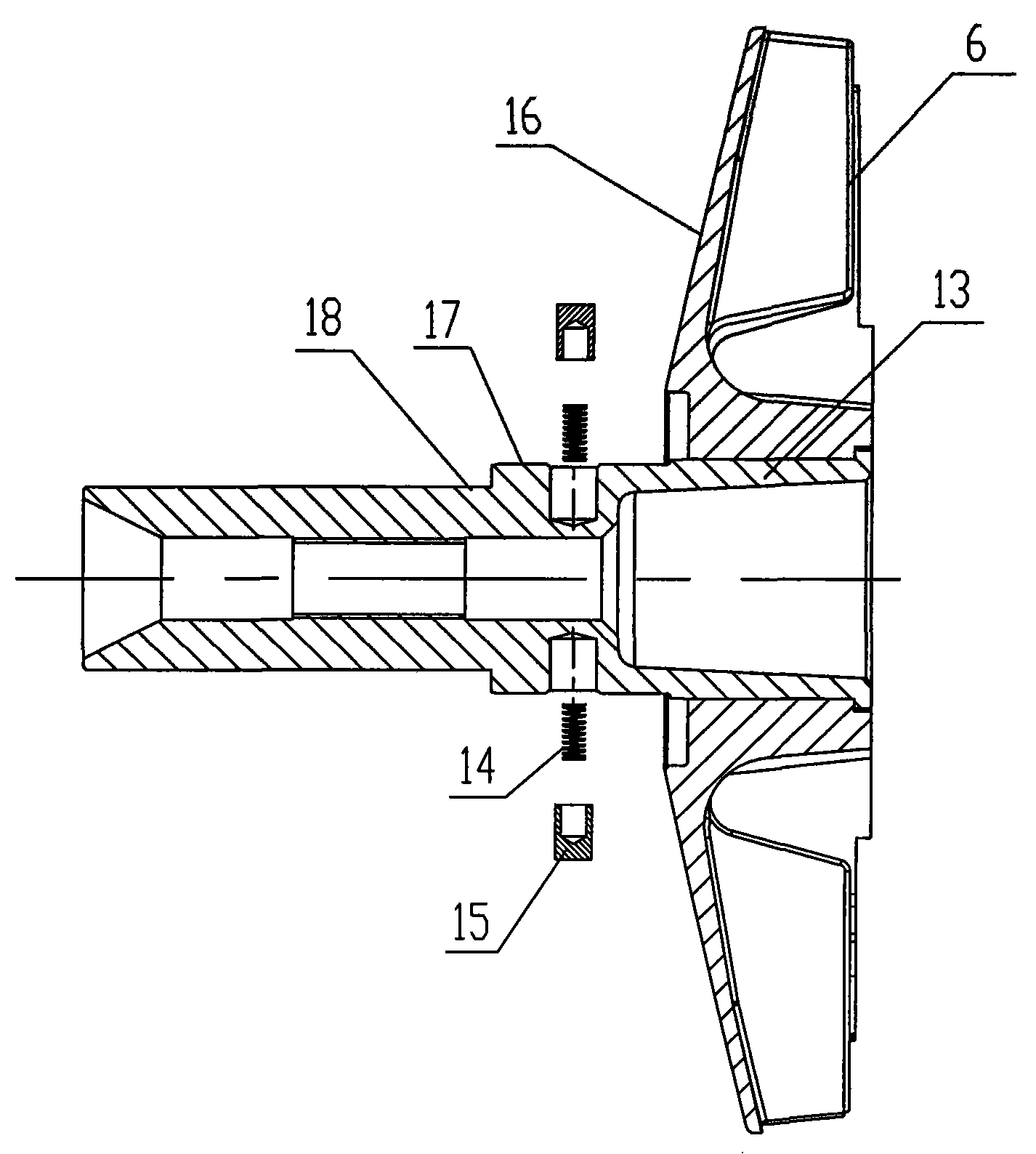

Unidirectional clutch type stepless speed change device for off-road motor vehicles

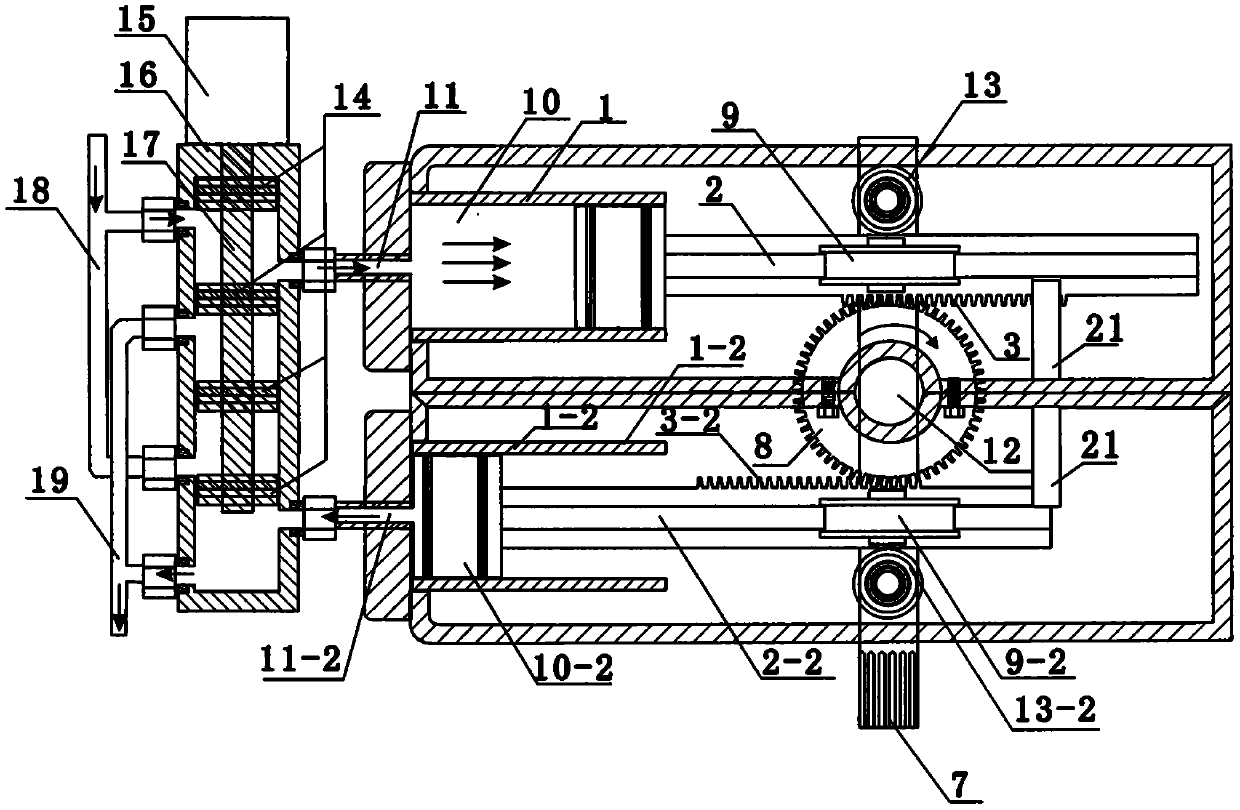

The invention discloses a unidirectional clutch type stepless speed change device for off-road motor vehicles, comprising a driving wheel component (1), a driven wheel component (4), a belt (3); the driving wheel component (1) comprises a pulley (6), an axle (13), a sliding sleeve (7), a spring seat (8), a pressure roller (9), a driving wheel spring (11), a supporting wheel (10); wherein, the sliding sleeve (7), the spring seat (8) and the pressure roller (9) are sheathed on the axle (13) and are positioned by the supporting wheel (10), the driving wheel spring (11) is arranged between the spring seat (8) and the pressure roller (9); the inner surface of the sliding sleeve (7) is provided with spiral grooves (22), spiral guide surfaces (21) facilitate the transition between two spiral grooves, the axle (13) is provided with pin springs (14) and pins (15), the pins (15) are contacted with the spiral grooves (22) of the sliding sleeve (7). With the structure adopted, the unidirectional clutch type stepless speed change device has the characteristics of simple and reasonable structure, reliable performance and small volume, high integrity and convenient operation and maintenance.

Owner:胡济荣

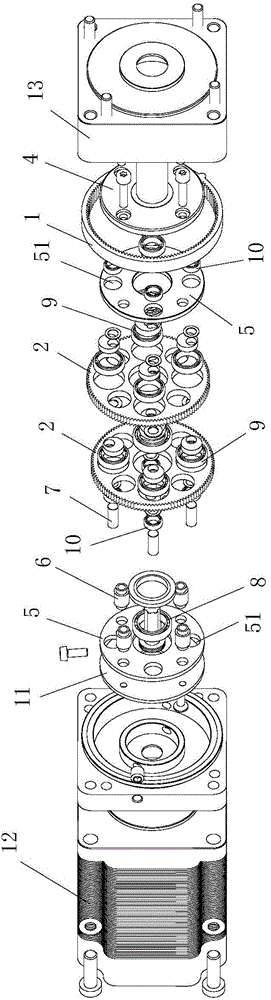

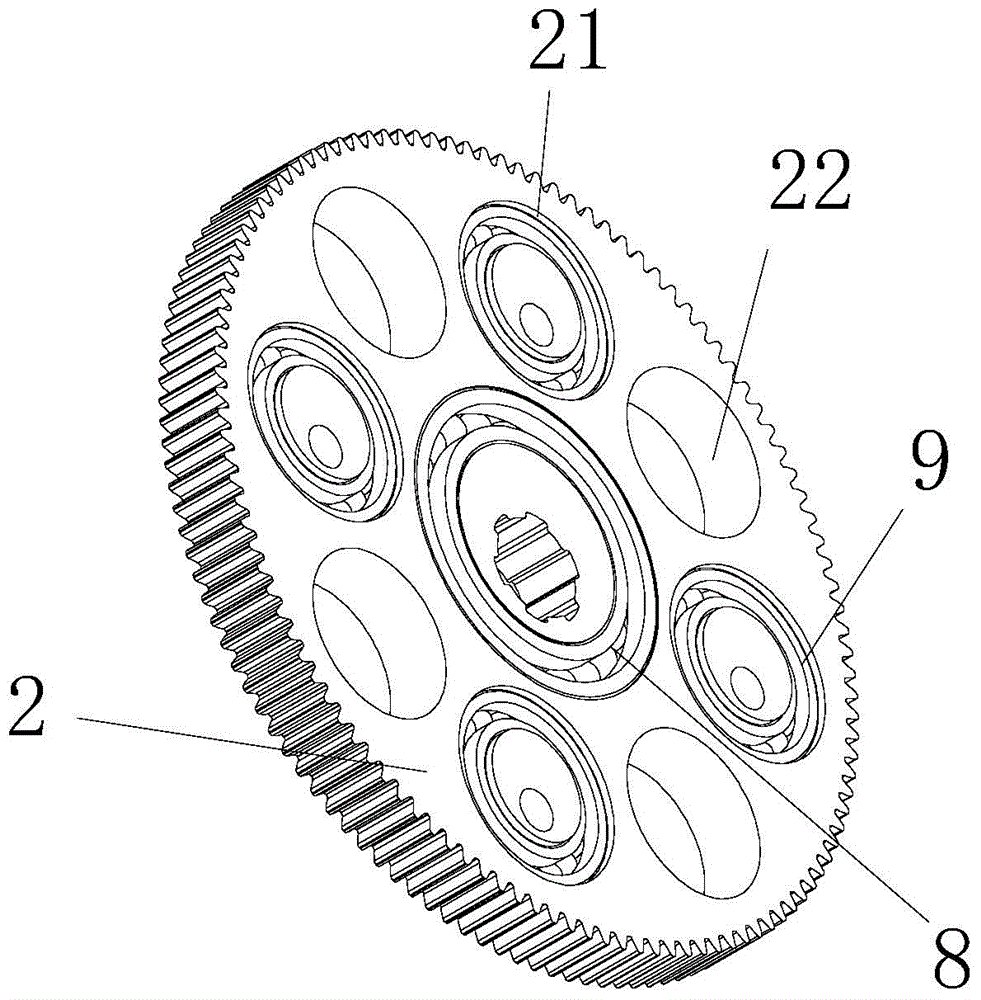

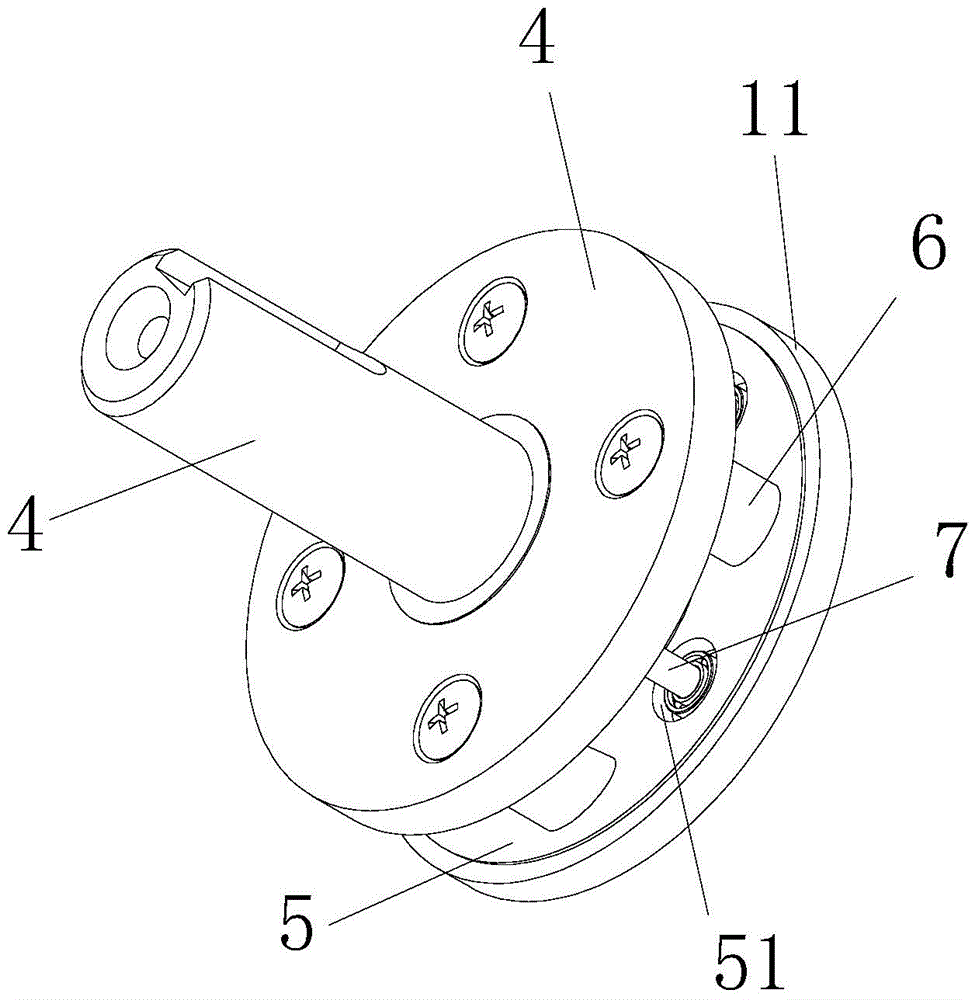

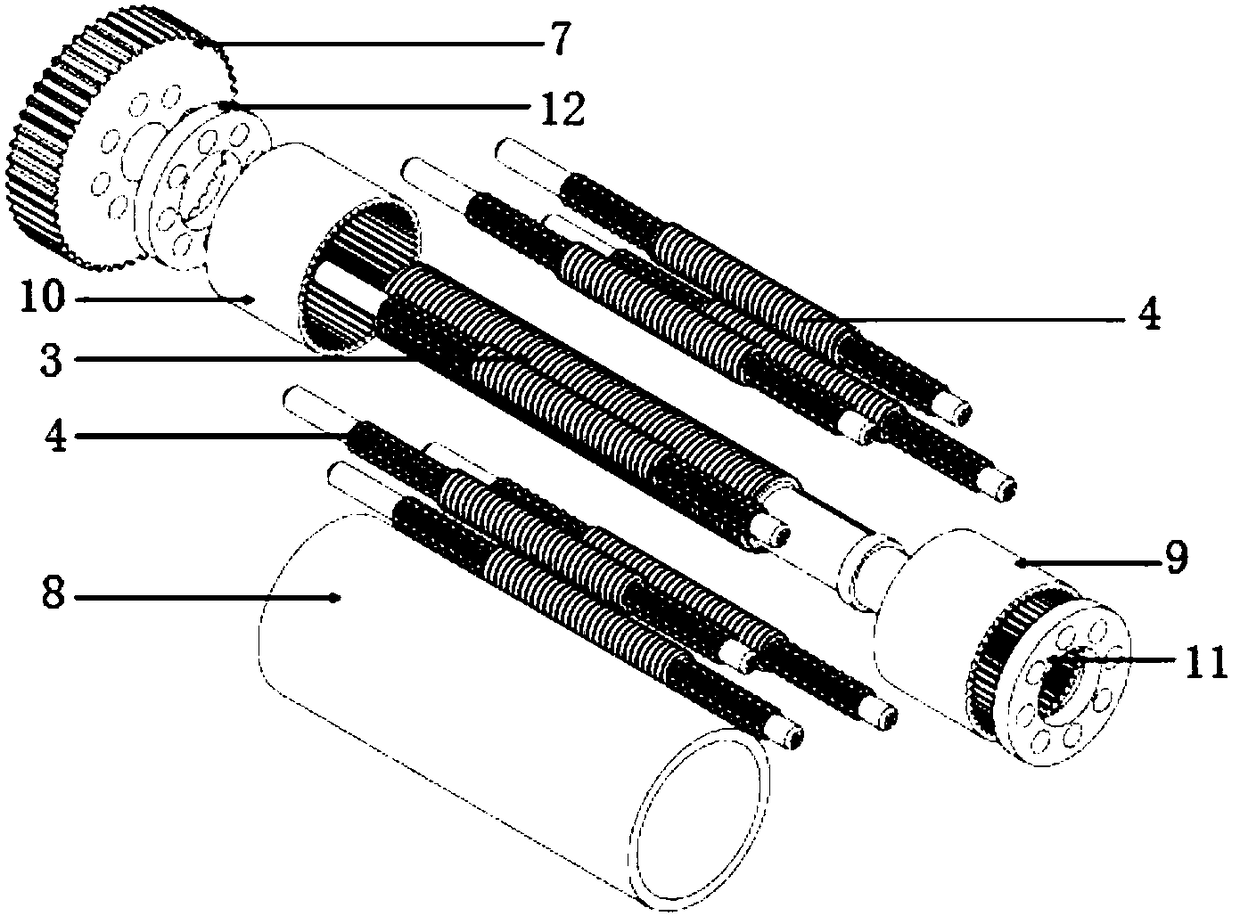

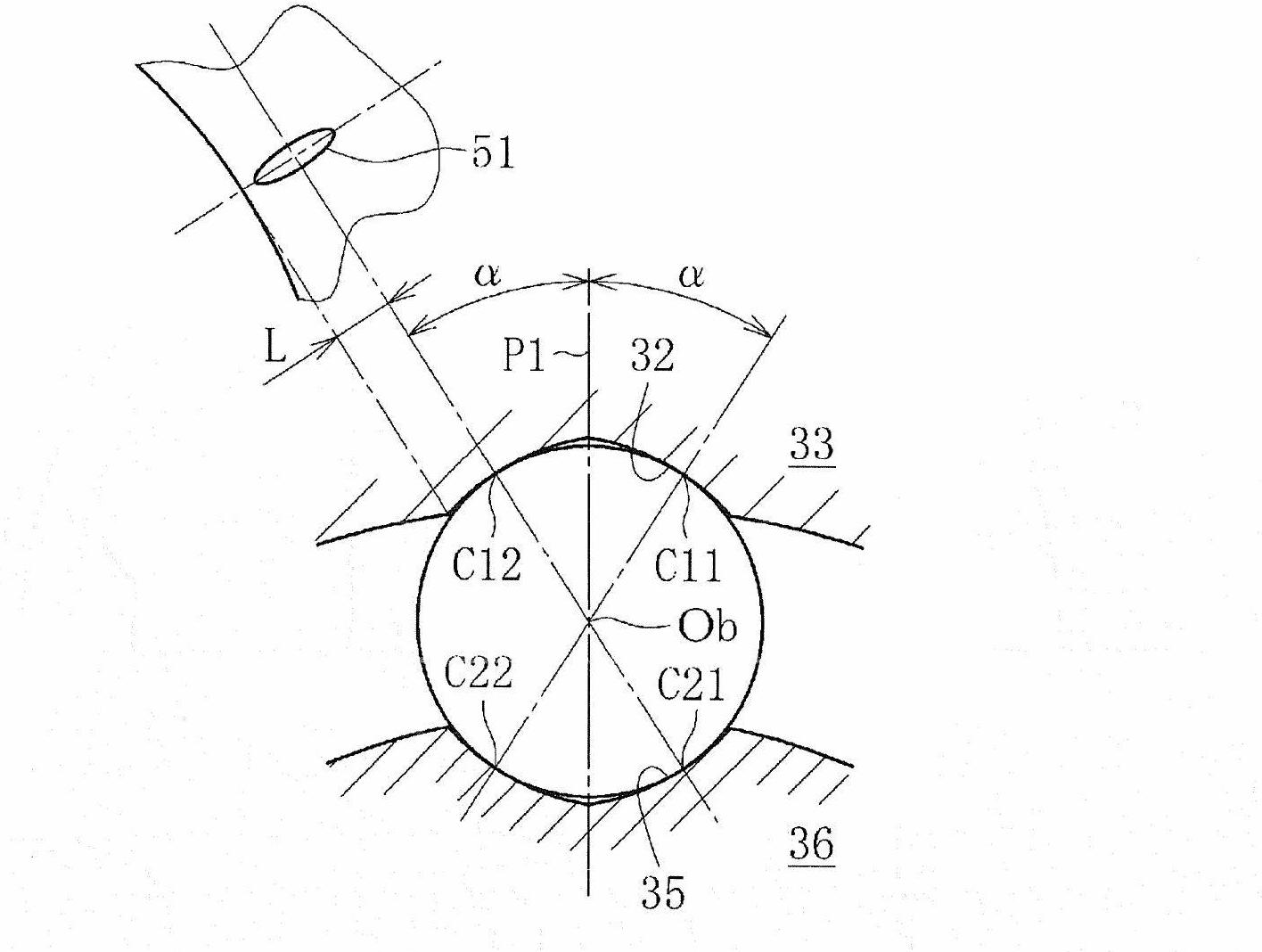

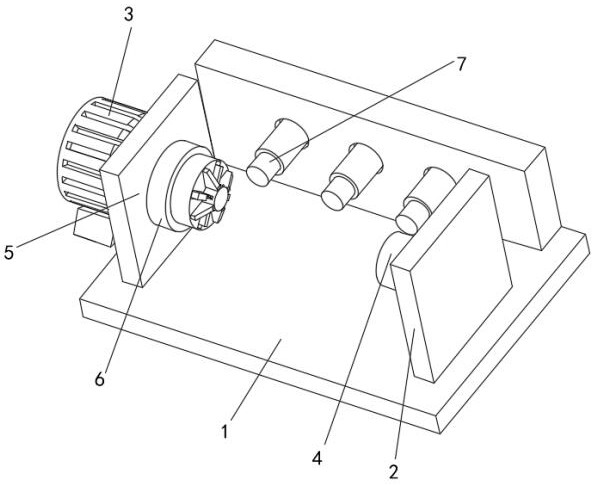

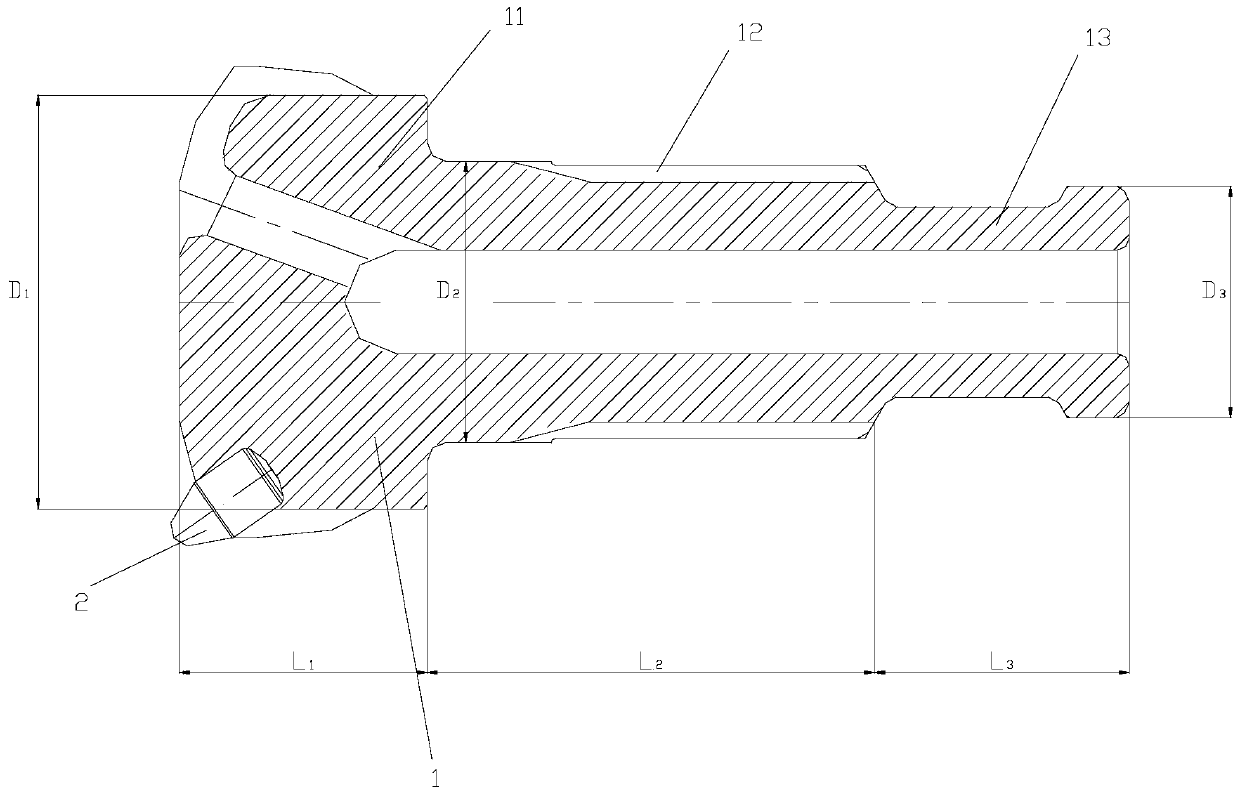

Small-tooth-difference high-precision cycloid gear speed reducer

The invention relates to a small-tooth-difference high-precision cycloid gear speed reducer which comprises an input shaft, a speed reduction mechanism and an output shaft. The speed reduction mechanism comprises a tooth ring, cycloid tooth pieces, a holder and eccentric shafts. The cycloid tooth pieces are eccentrically arranged on the input shaft through a first eccentric assembly. The holder comprises two holding end covers and connecting columns. The connecting columns are connected with and located on the holding end covers. The eccentric shafts penetrate through tooth penetrating shaft holes. A second eccentric assembly is arranged between the eccentric shafts and the tooth penetrating shaft holes of the cycloid tooth pieces. The two holding end covers are provided with cover penetrating shaft holes respectively. A third eccentric assembly is arranged between the two ends of the eccentric shafts and the cover penetrating shaft holes of the holding end covers. The cycloid gear speed reducer is small in size, all speed reduction parts can achieve close fitting, the precision of the whole speed reducer is improved, and the high transmission ratio can be achieved.

Owner:CHANGZHOU XINWEI ELECTRONICS CO LTD

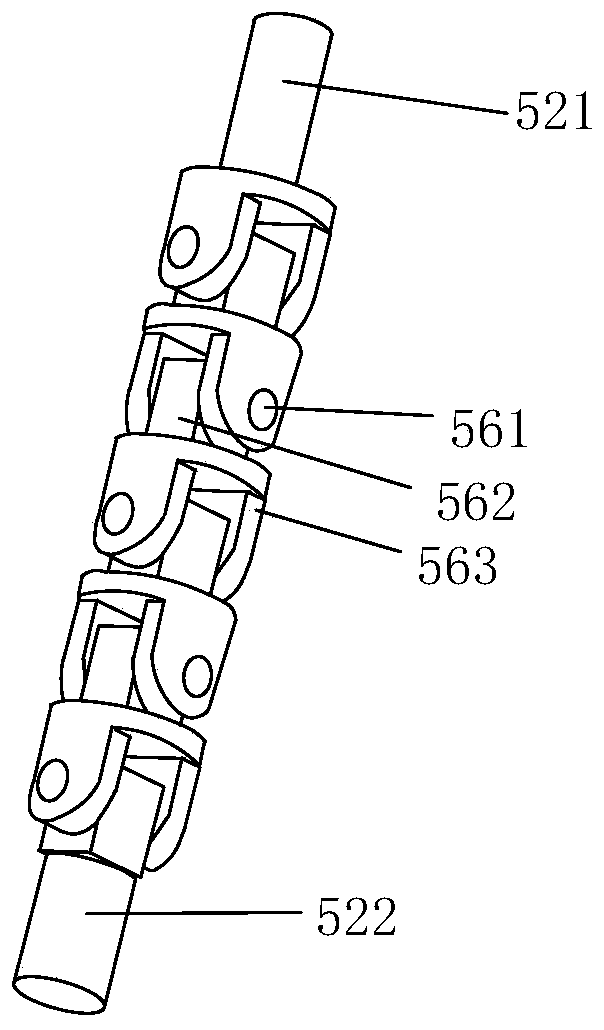

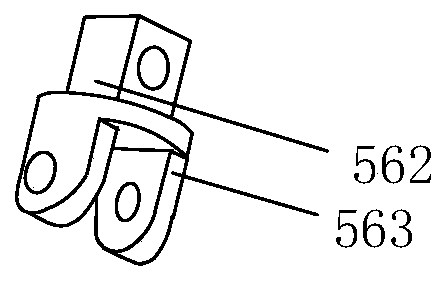

Universal soft cable

The invention discloses a universal soft cable. The universal soft cable comprises a first rotation shaft, multiple joints, a second rotation shaft, a first connector and a second connector; the firstrotation shaft, the multiple joints and the second rotation shaft are sequentially connected through pin shafts in series in a hinged mode, and the axes of the two pin shafts on the same joint are not located in a same plane; the first connector is arranged outside the first rotation shaft in a sleeving mode, and the first rotation shaft can rotate; the second connector is arranged outside the second rotation shaft in a sleeving mode, and the second rotation shaft can rotate; and when the first rotation shaft rotates, the second rotation shaft can be driven to rotate through linkage of the multiple joints. The universal soft cable further comprises a soft casing pipe, the two ends of the soft casing pipe are fixed to the first connector and the second connector separately, the multiple joints penetrate into the soft casing pipe, therefore, the soft casing pipe can provide safety protection for the multiple joints, and meanwhile the multiple joints can orderly and evenly distribute therotation angles. The universal soft cable further comprises hoops which can enable the soft casing pipe to be compressed outside the first connector or the second connector in a sleeving mode. A 90-degree included angle is formed between the axes of the two pin shaft on the same joint. The universal soft cable has the beneficial effects that the structure is simple, the cost is low, universal torque transmission is achieved, and the torque transmission efficiency is high.

Owner:王锰墩

Smooth polishing system

PendingCN108161680AReduce contact gapHigh transmission precisionGrinding machine componentsBurnishing machinesEngineeringScrew thread

The invention provides a smooth polishing system, and belongs to the technical field of polishing equipment. The technical problem that an existing polishing system is poor in response transmission precision is solved. The smooth polishing system comprises a rack, a polishing head, a center screw rod and a plurality of rolling screw rods, and the polishing head is rotationally connected to the outer end of the center screw rod and is axially positioned on the center screw rod; the center screw rod is rotationally connected to the rack around the self-axis, and all the rolling screw rods rotatearound the self-axis and are axially positioned on the rack; the rolling screw rods are distributed in the circumferential direction of the center screw rod and are in threaded transmission connection with the center screw rod. The polishing system further comprises a driving mechanism for driving all the rolling screw rods to rotate at the same time. The rolling screw rods of the polishing system are in thread line contact with the center screw rod, the contact clearance of the structure is smaller, the transmission precision is higher, the rigidity is higher, the torque which can be transmitted is larger, and movement is more stable.

Owner:GUANGDONG INST OF INTELLIGENT MFG

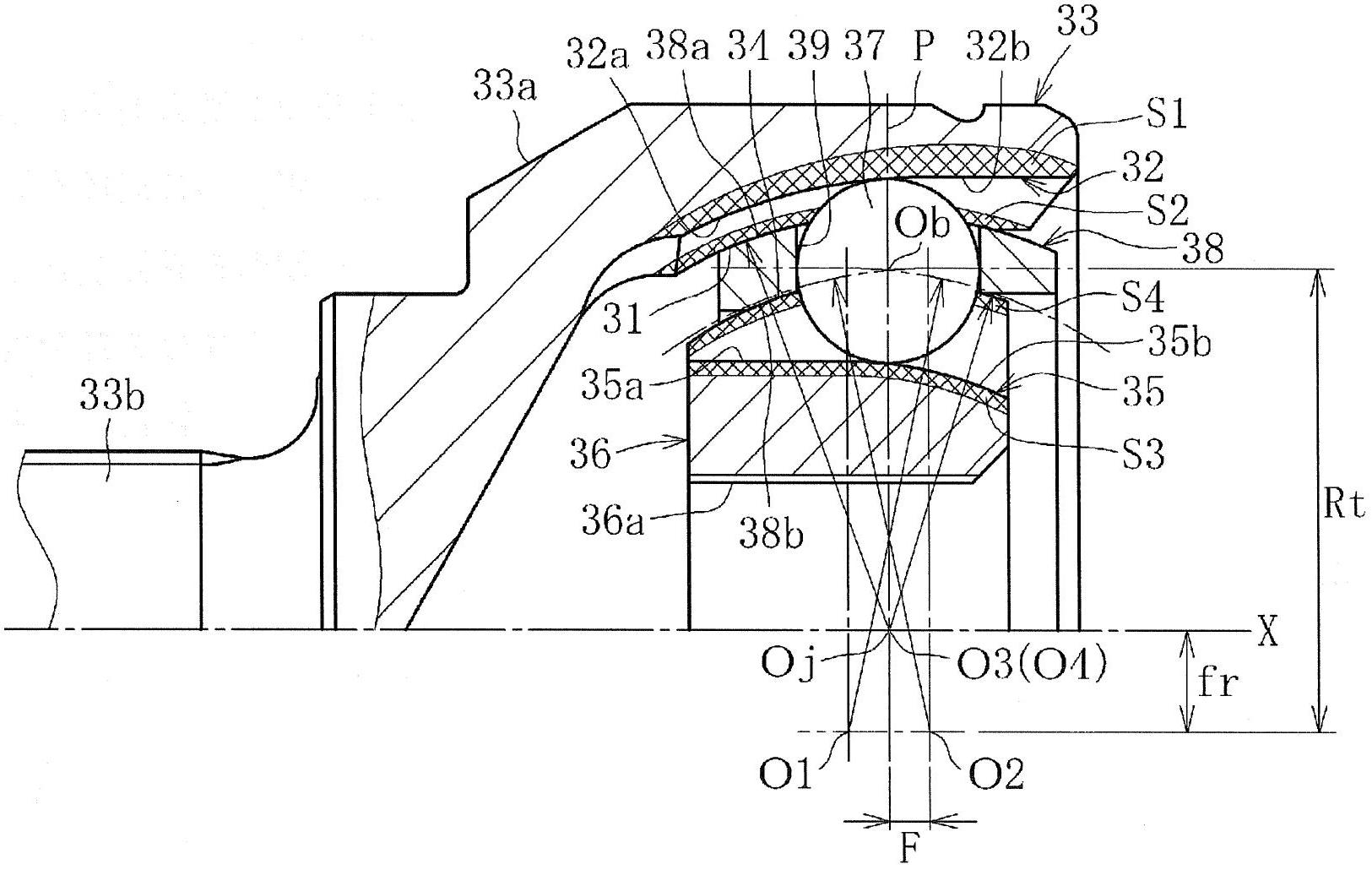

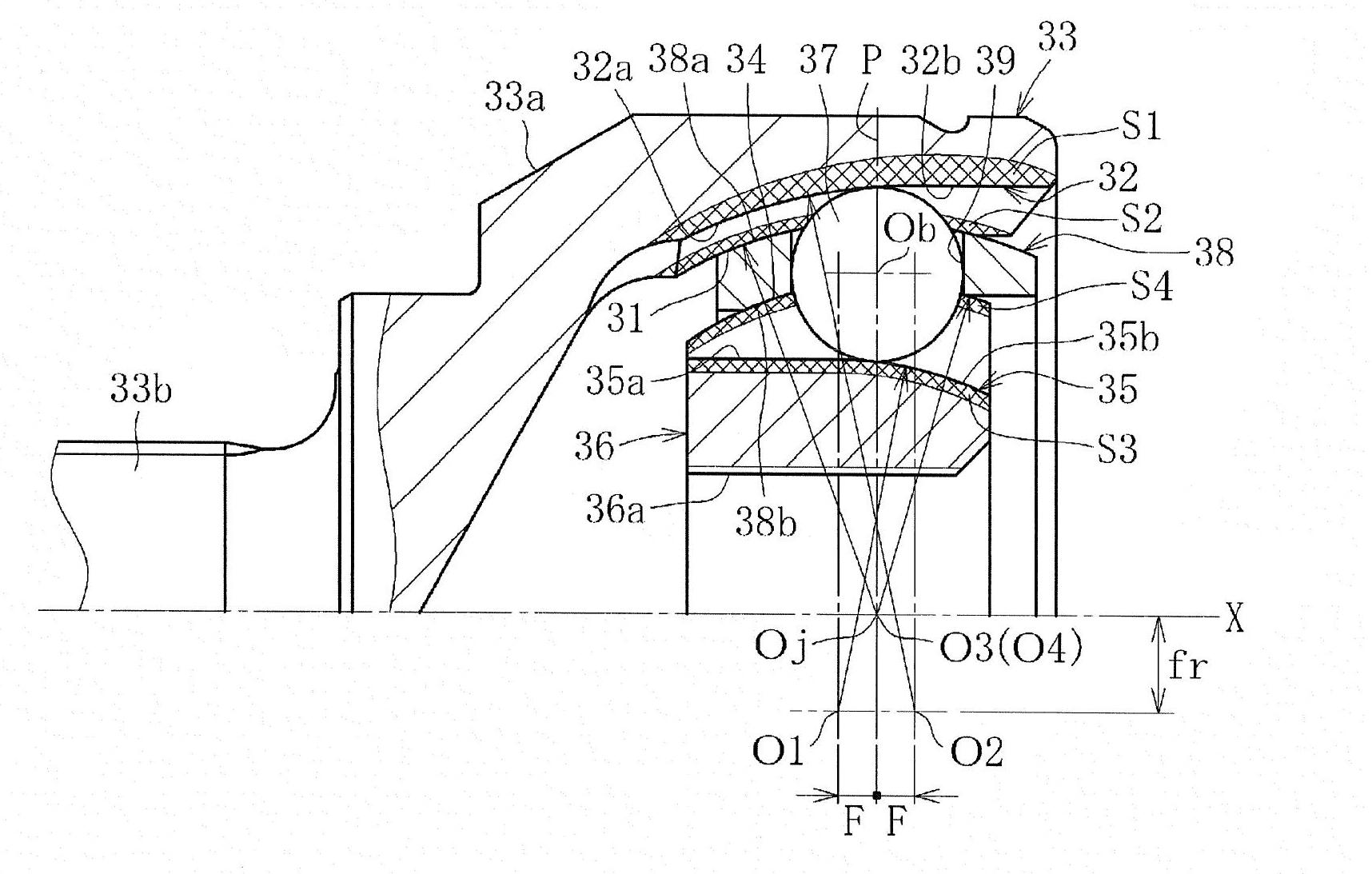

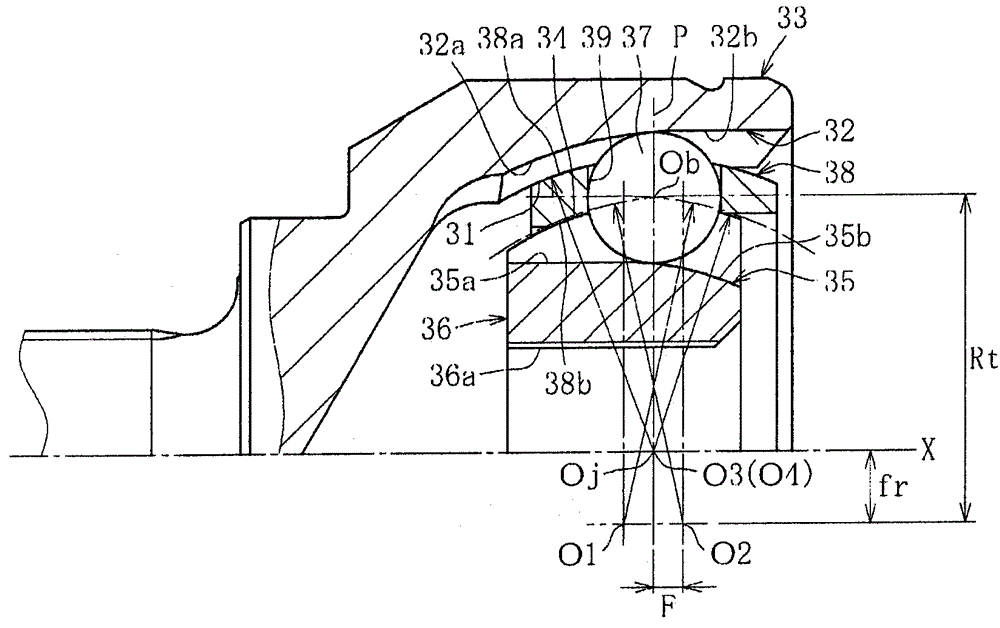

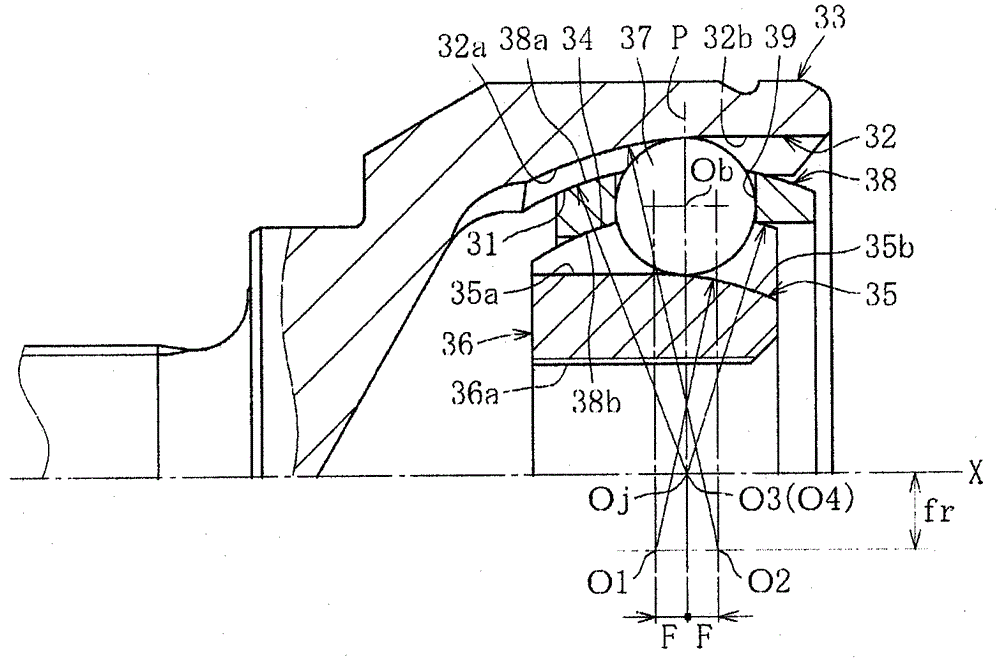

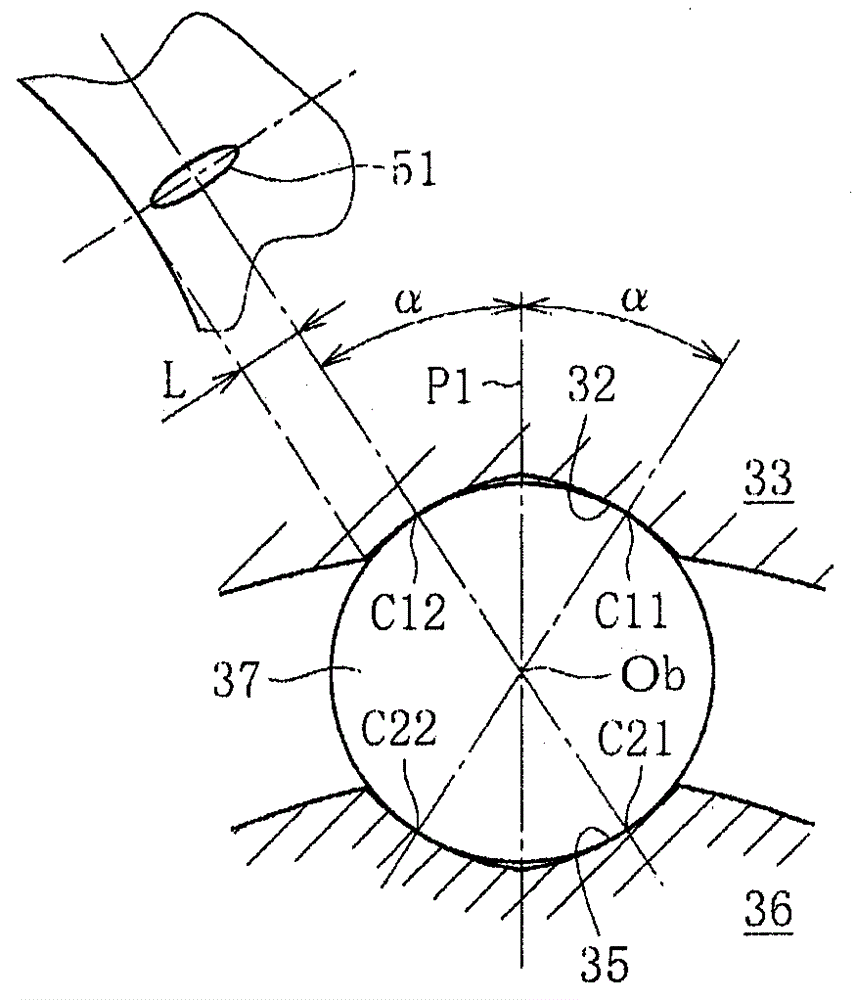

Stationary constant-velocity universal joint

InactiveCN102667202AIncreased durabilityImprove rigidityYielding couplingActuatorsUniversal jointEngineering

Owner:NTN CORP

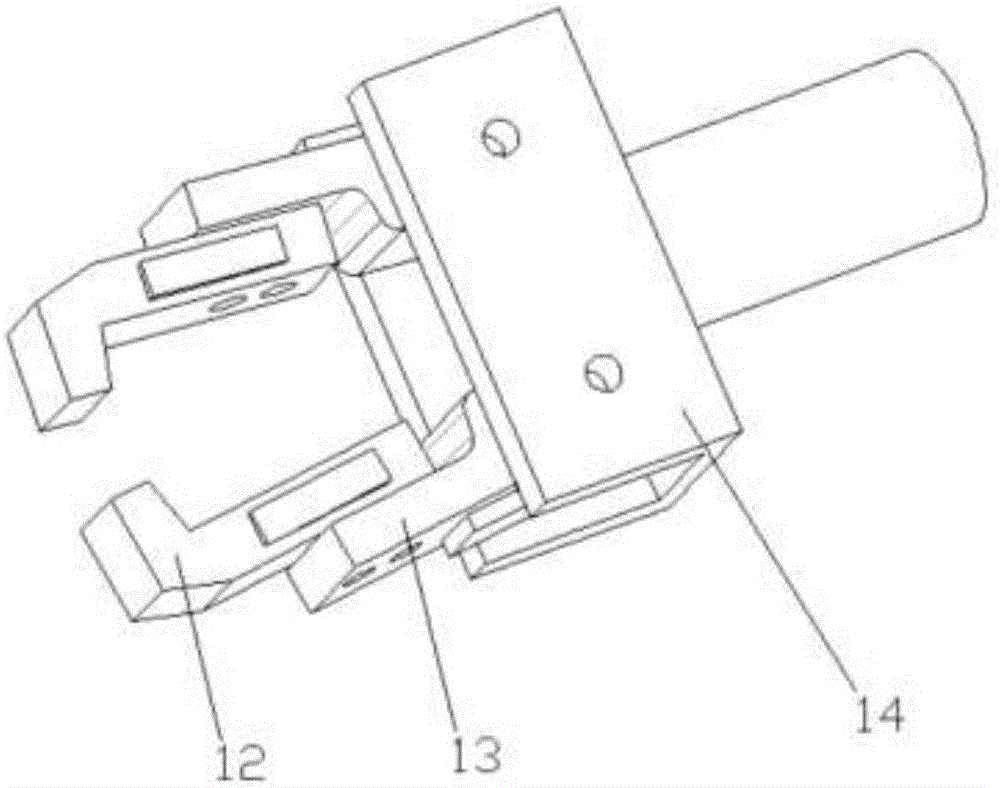

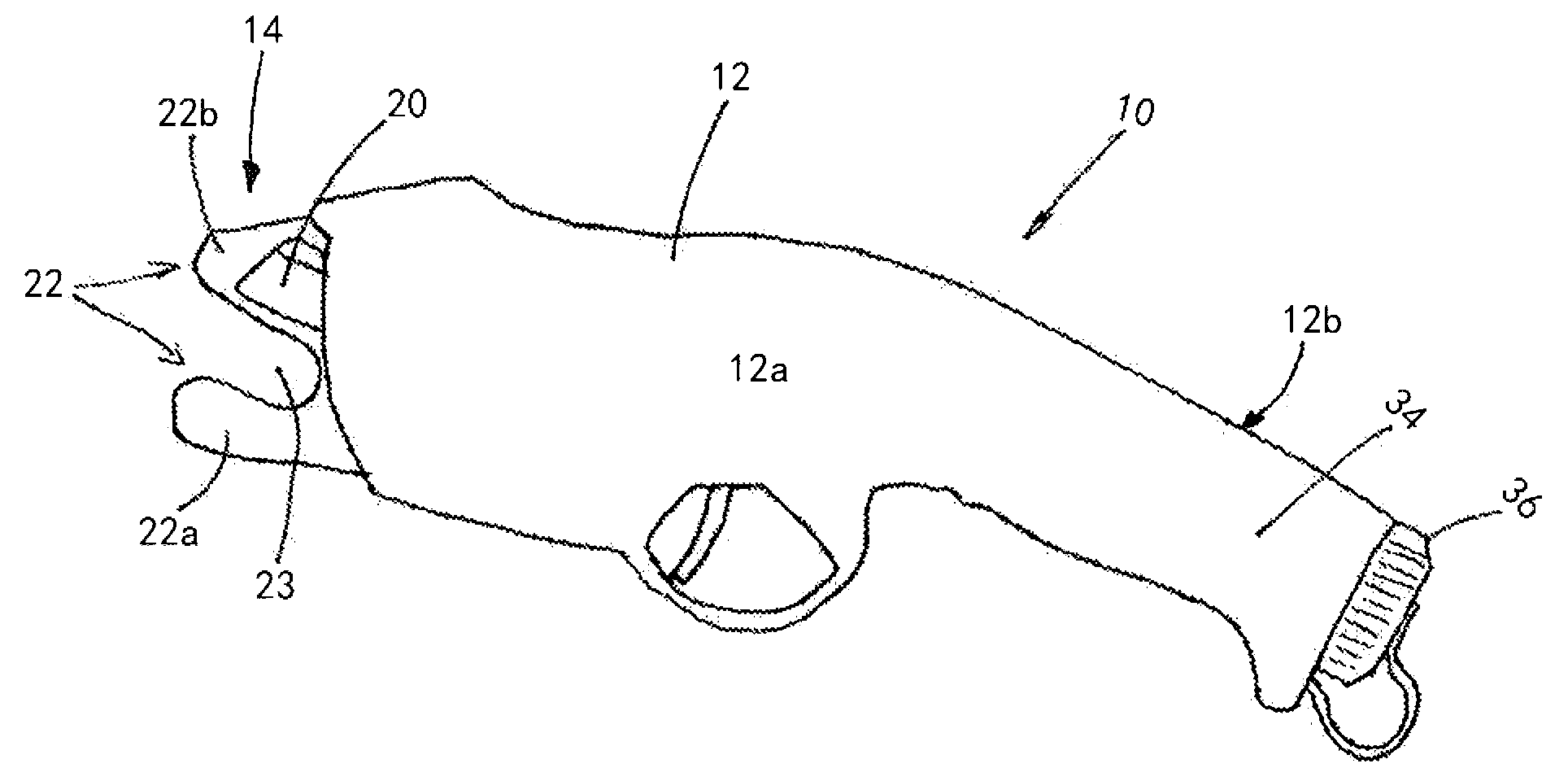

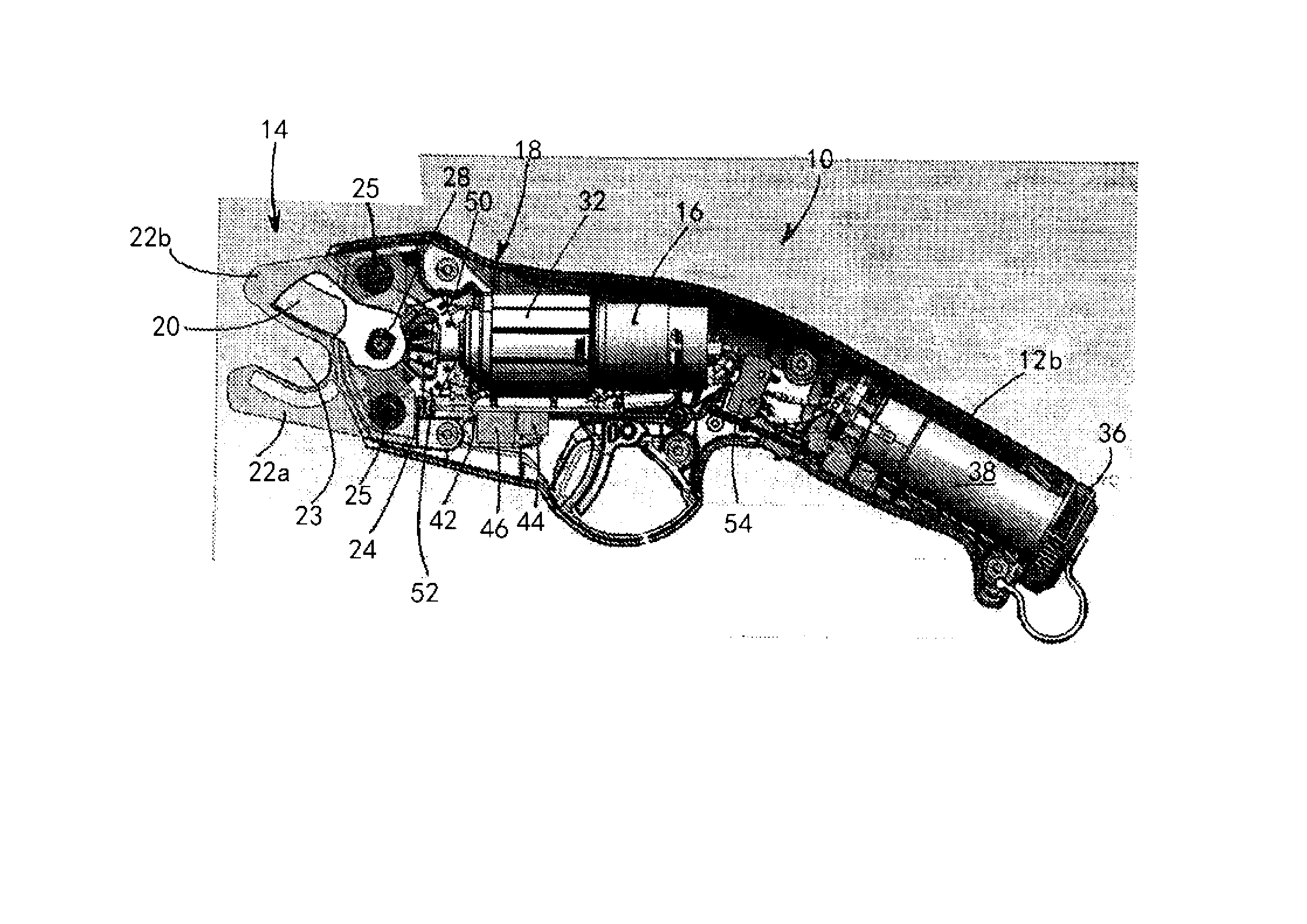

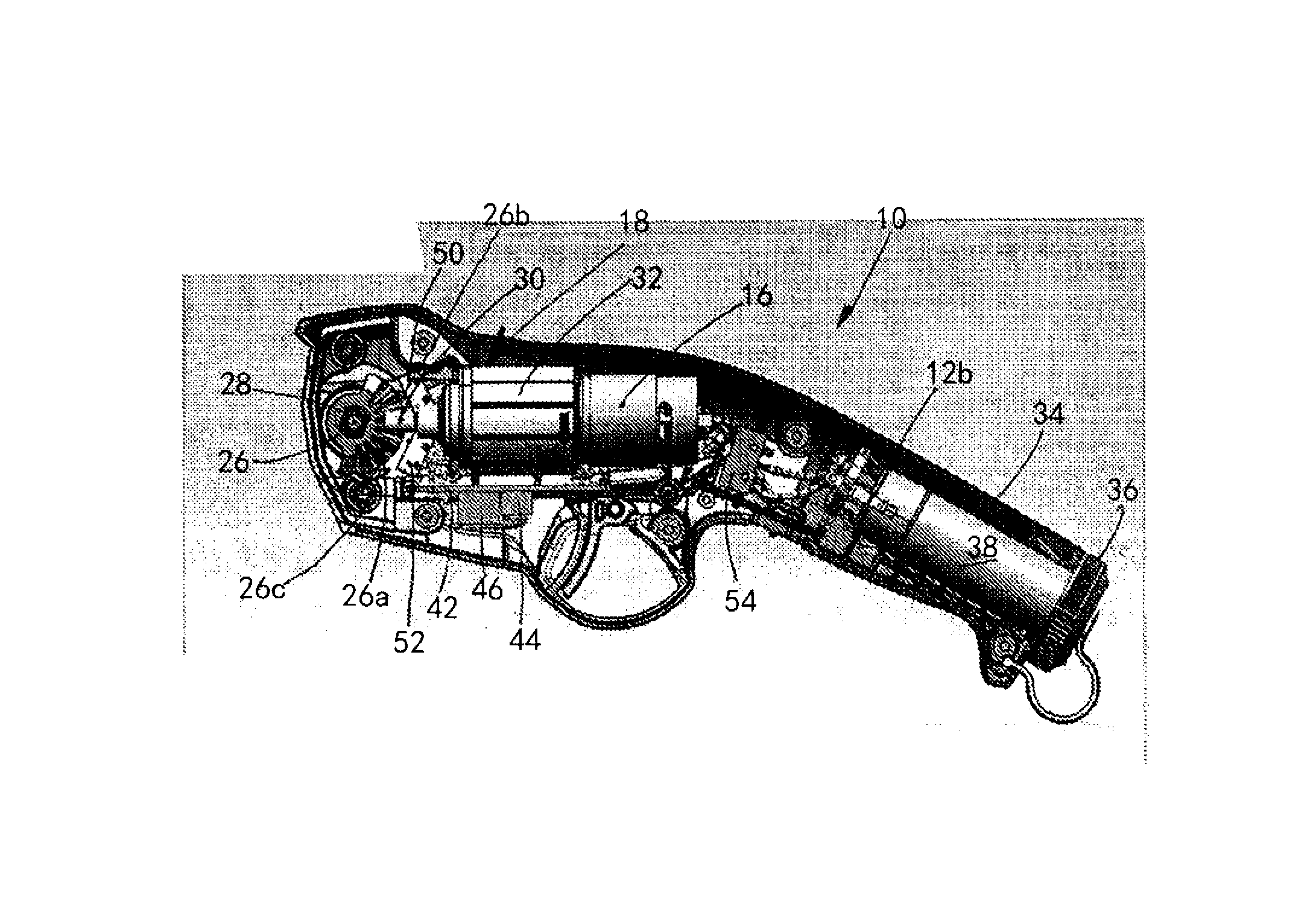

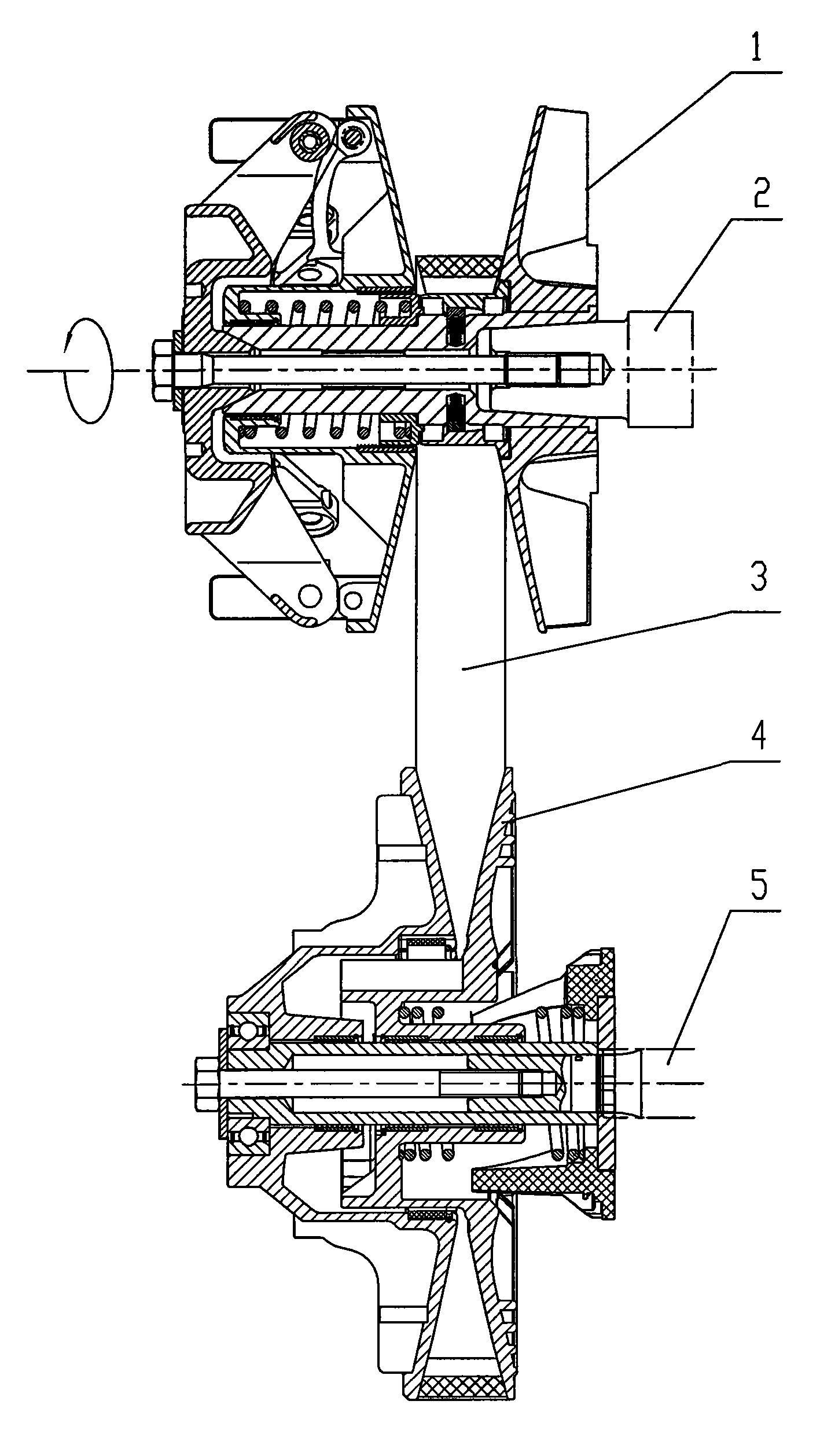

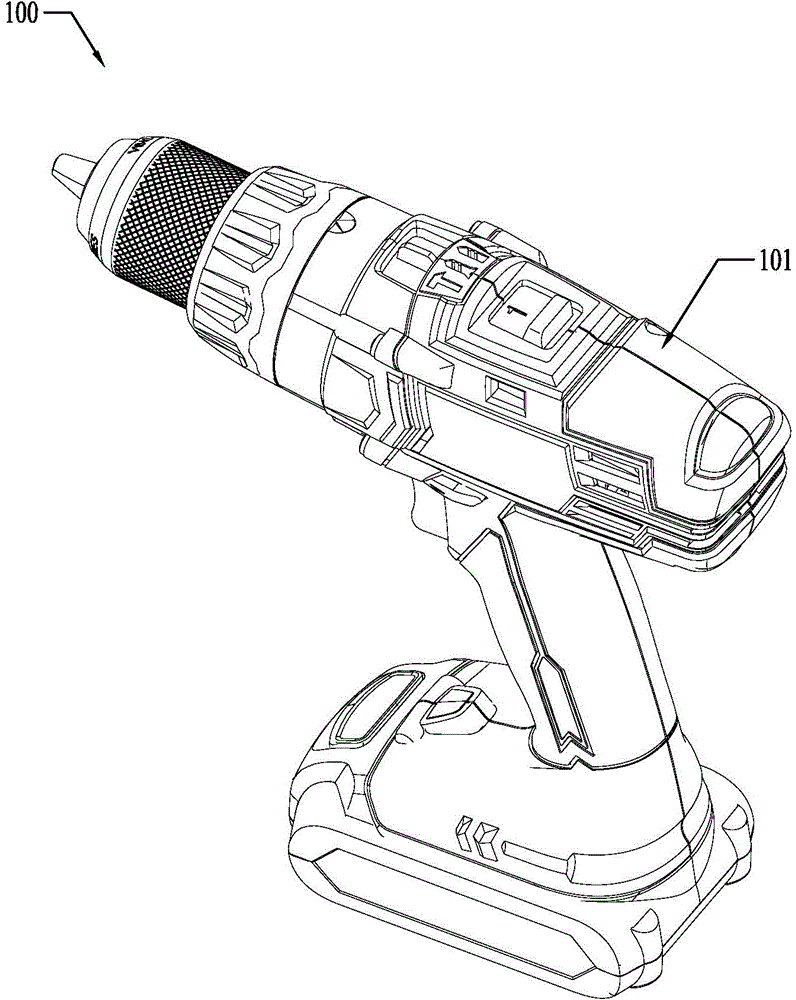

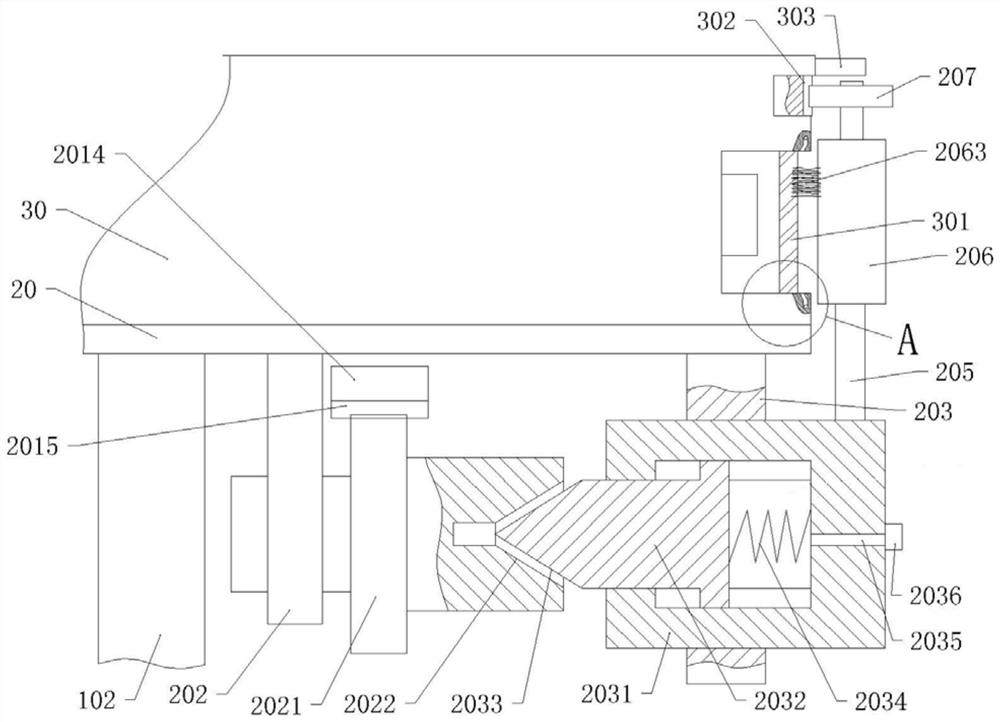

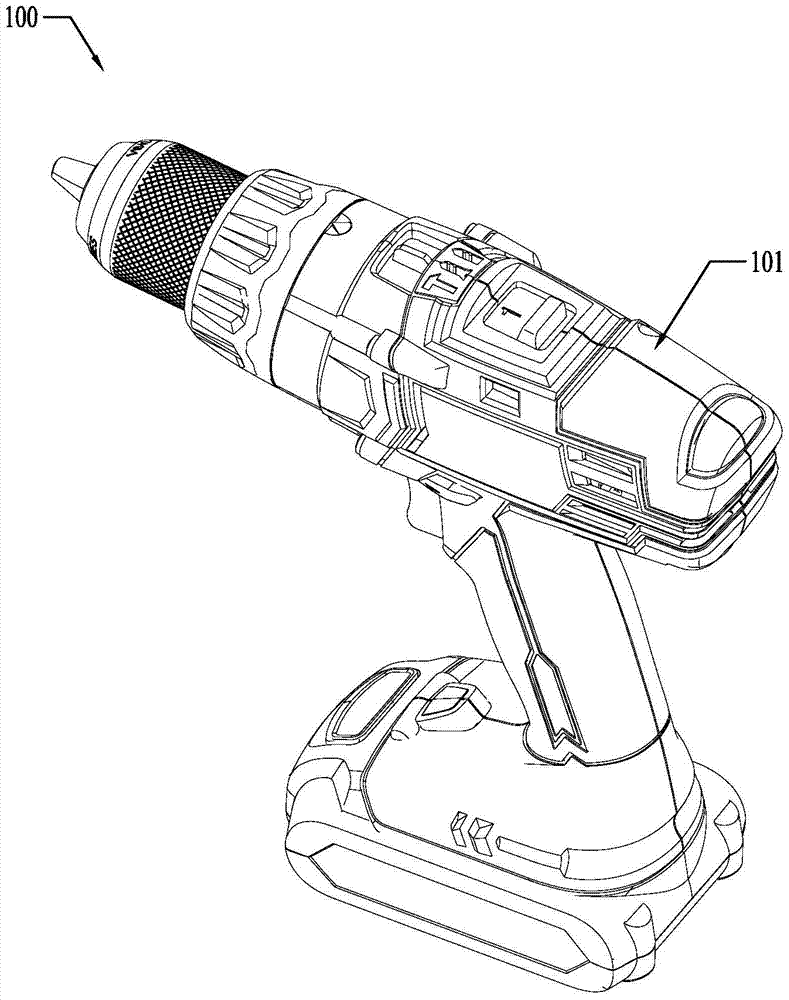

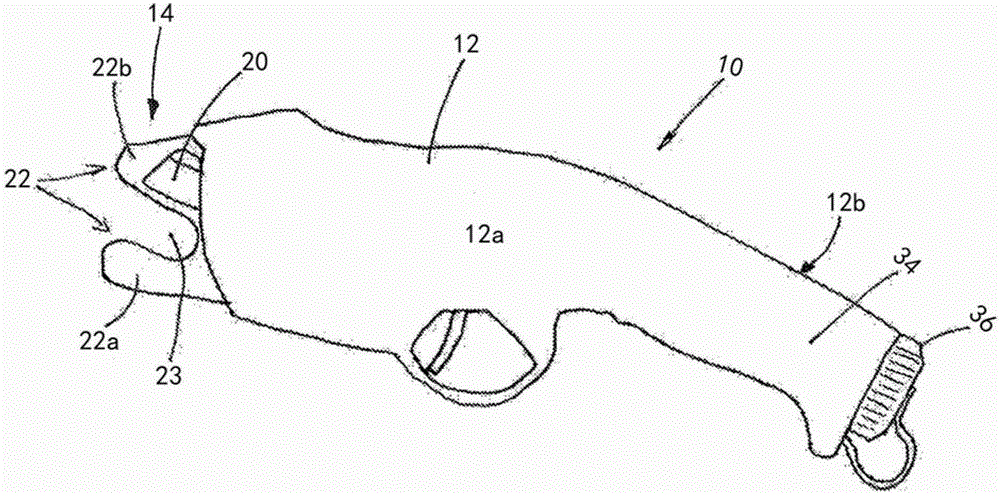

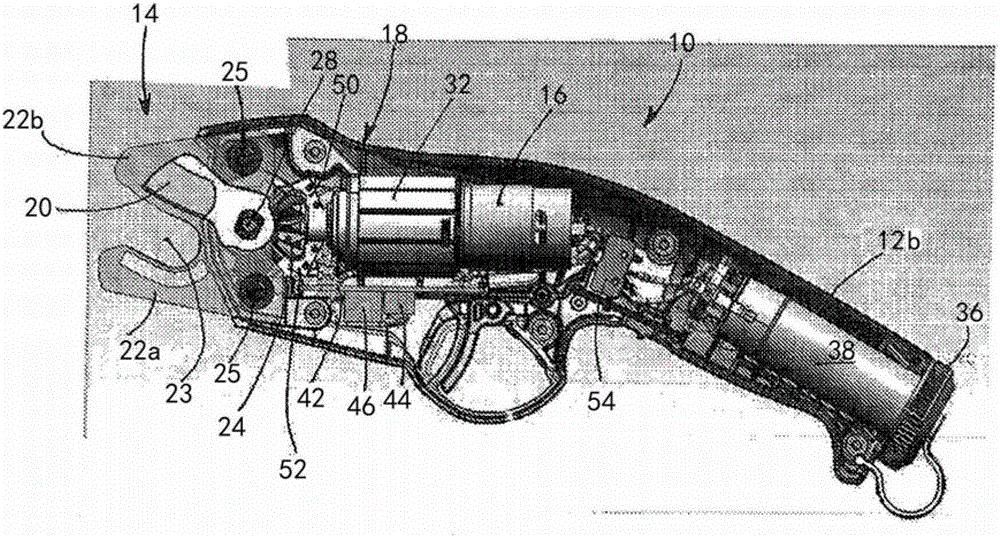

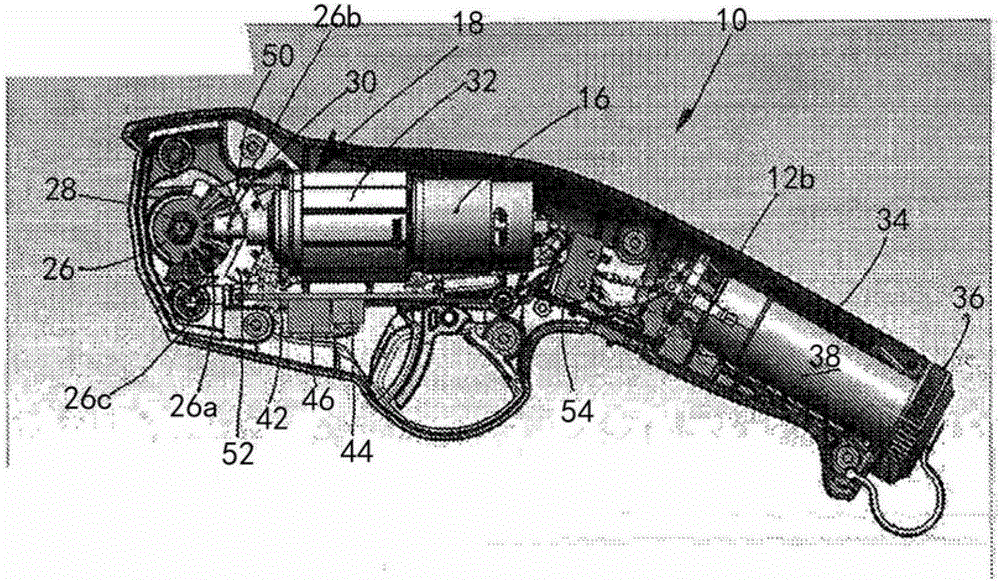

A powered cutting tool

ActiveCN103327806AImprove torque transmission efficiencySimple structureCuttersCutting implementsAutomatic controlLimit switch

A cutting tool has a cutting head, a motor and a transmission means drivable by the motor. The cutting head comprises first and second cutting members, wherein the first cutting member is pivotably moveable with respect to the second cutting member. At least the first cutting member is drivable by the transmission means between a first angular position with respect to the second cutting member and a second angular position with respect to the second cutting member, in which a space between the respective cutting blades is closed. The transmission means is a bevel gear on the output shaft of a gearbox which conveys drive power from the motor to the drive gear. The bevel gear directly engages a bevel wheel member connected to the first cutting member and which swivels with the first cutting member about the same swivel point. A controller comprises main, first and second switches which control the motor to move the first cutting member (movable blade). The main switch acts as a main power switch whereas the first and second switches act as limit switches detecting movement of said movable blade at the limits of its intended motion. The controller exerts automatic control over movement of the first cutting member in response to inputs from the first and second limit switches.

Owner:TECHTRONIC OUTDOOR PRODS TECH

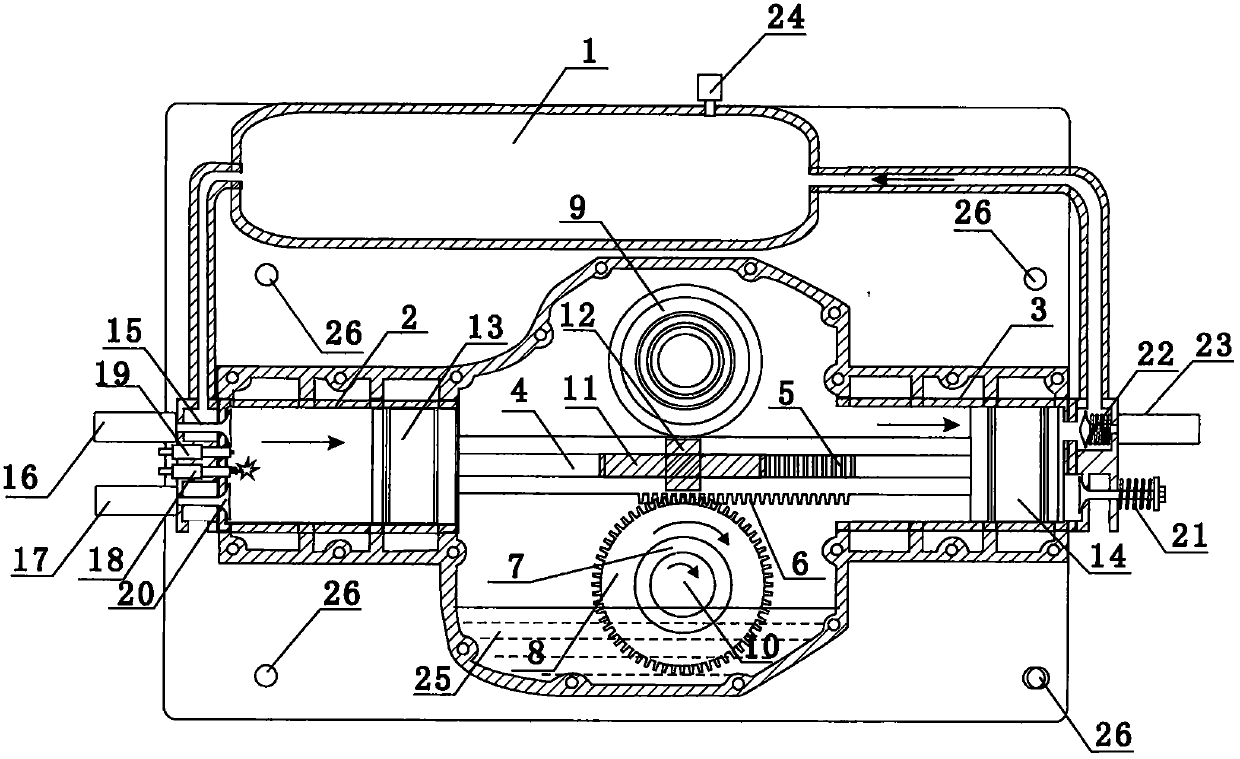

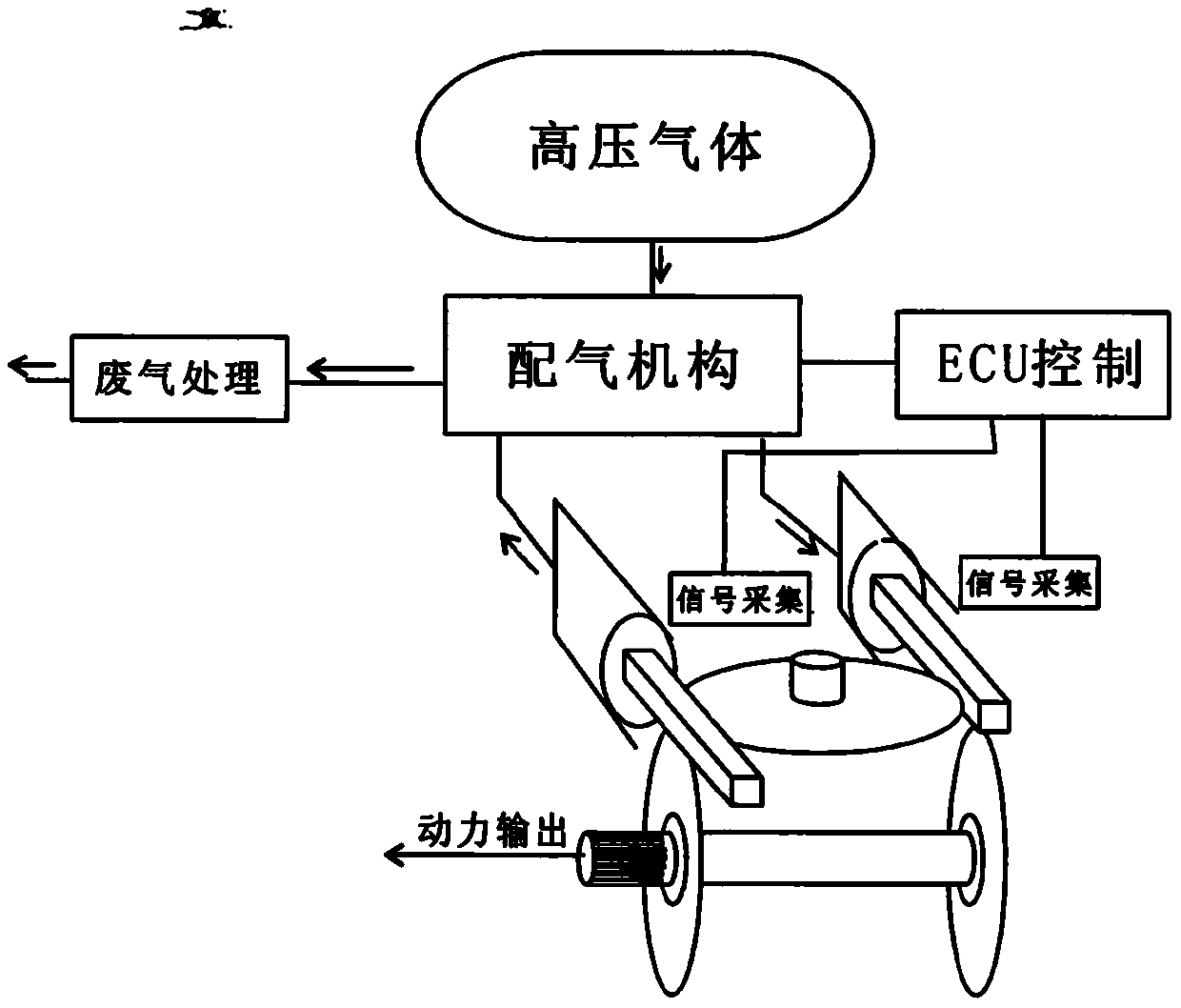

Novel light fuel internal combustion engine

InactiveCN109695502AImprove torque transmission efficiencyImprove power output efficiencyCombustion enginesDetonationLighter fuel

The invention relates to a novel light fuel internal combustion engine. Acting air cylinders are arranged coaxial with air pressing air cylinders, a high-pressure air storage tank is arranged betweenthe acting air cylinders and the air pressing air cylinders, acting pistons are directly connected with air pressing pistons through a multi-surface rack piston connecting rod, the lower rack of the multi-surface rack piston connecting rod is meshed with an output gear, the output gear is installed on an output shaft through an overrun clutch, piston connecting rod sets are used for converting thereciprocating motion of the piston connecting rod sets into circular motion of the output shaft through the overrun clutch to do work, side racks of the two sets of piston connecting rods are meshedwith reverse pushing gears, two groups of acting air cylinders and the air pressing cylinders are arranged in parallel to form a four-cylinder unit, and the two sets of piston connecting rods move repeatedly to form a working cycle; due to the fact that the acting air cylinders adopt indirect high-pressure air inflation, detonation cannot be generated; and light-weight fuel can be used, so that the energy-saving and emission-reducing effects are obvious.

Owner:闫传东

Unidirectional clutch type stepless speed change device for off-road motor vehicles

InactiveCN101526126BAchieve brakingImprove torque transmission efficiencyGearingOff-Road Motor VehicleDrive wheel

Owner:胡济荣

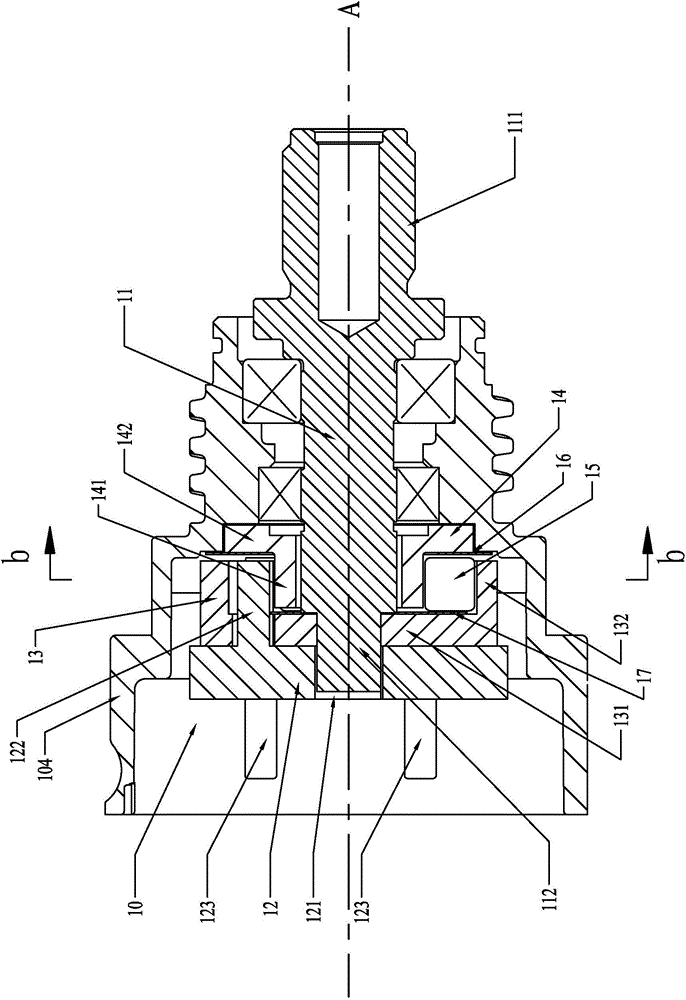

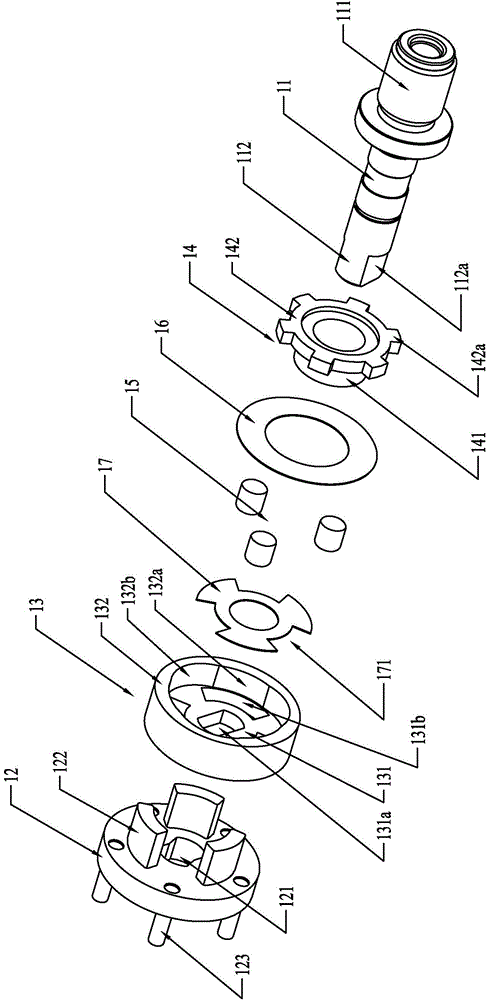

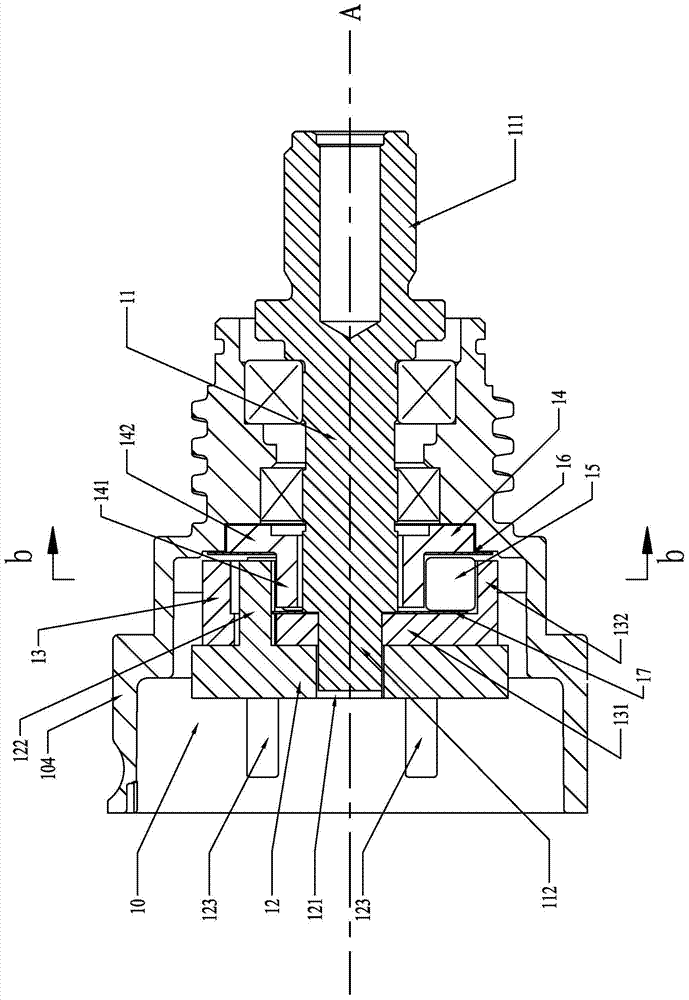

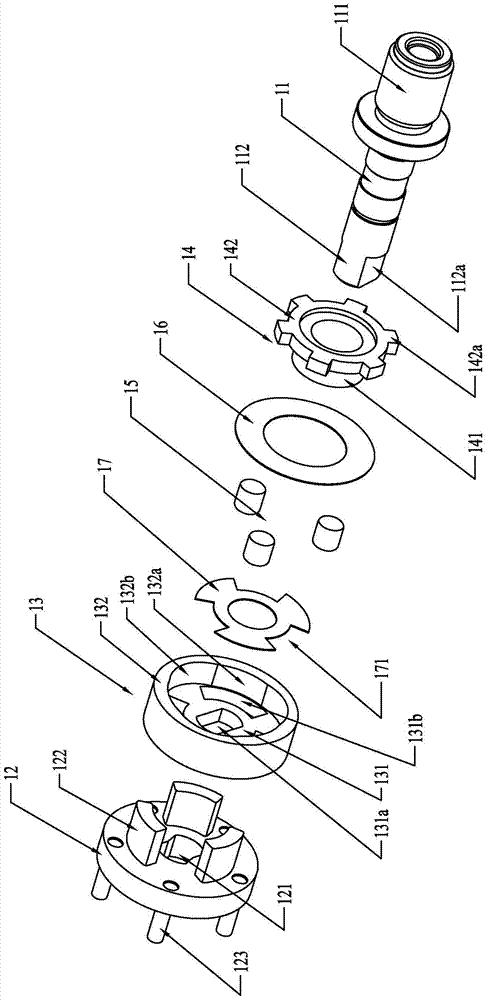

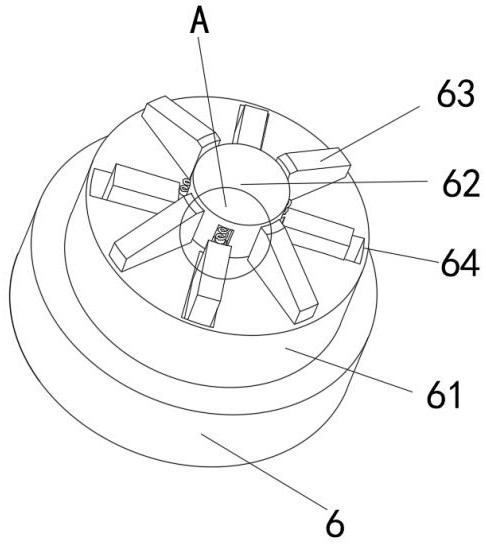

Torque output tool and one-way torque transmission mechanism thereof

ActiveCN105202064AImprove efficiencyReduce heatPower driven toolsFreewheel clutchesTorque transmissionCentrifugal force

The invention discloses a torque output tool and a one-way torque transmission mechanism thereof. The torque output tool comprises a shell, a motor and a transmission assembly, wherein the motor and the transmission assembly are arranged inside the shell. The transmission assembly comprises the one-way torque transmission mechanism, the one-way torque transmission mechanism comprises a main shaft, a driving part, a lock sleeve, a lock cylinder, locking parts and others, the lock sleeve comprises a lock ring, the lock cylinder comprises a cylinder, the inner wall of the lock ring at least comprises two limiting wall surfaces which are matched with the outer wall of the cylinder of the lock cylinder to lock or loosen the locking parts, the locking parts are arranged between the lock ring and the cylinder and only make contact with the lock sleeve stably when transmission is carried out to the main shaft from the driving part under the action of centrifugal force, no redundant impact and friction are generated, efficiency of torque transmission is improved, heat generated by the mechanism is reduced, and bad influences on reliability of the tool of temperature increase are reduced.

Owner:NANJING CHERVON IND

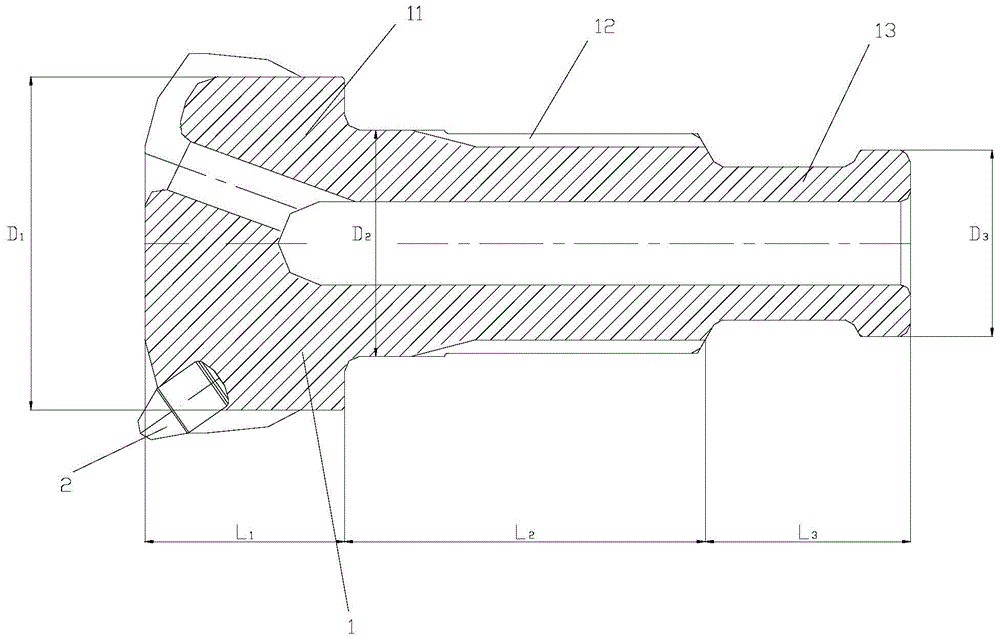

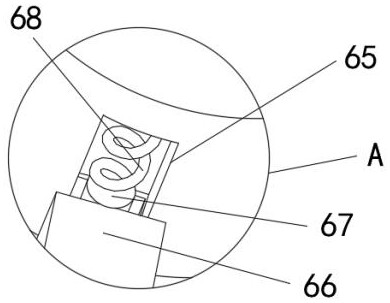

A high air pressure drill bit

The invention provides a high air pressure drill bit comprising a drill bit body and ally teeth. The drill bit body comprises a crushing head, a spline and a drill bit tail end. The alloy teeth are arranged on the crushing head with a length of L1. The length of the spline is L2. The length of the travel of the drill bit tail end is L3. The sum of L1, L2 and L3 is 230mm, L2 is greater than L1, and L2 is greater than L3. The loss of stress wave transmission of the drill bit body is reduced, so that the rotating torque transmission is more stable, the efficiency is higher and the service life is longer.

Owner:长沙天和钻具机械有限公司

Security monitoring device

ActiveCN112845202AImprove monitoring qualityGood light transmissionClosed circuit television systemsCleaning using toolsGear wheelDrive shaft

The invention relates to the technical field of monitoring, in particular to a security monitoring device which comprises a rack, a movable plate and a monitoring host, a motor is fixedly connected to the rack, the movable plate is fixedly connected with an output shaft of the motor, the monitoring host is located on the movable plate and fixedly connected with the movable plate, and a light transmitting mirror is arranged on a front panel of the monitoring host. A cam and an air barrel matched with the cam are fixedly connected to a transmission shaft, an air storage box is arranged on the movable plate, a piston is arranged in the air storage box, a push rod provided with a rack is fixedly connected to the piston, a gear meshed with the rack and a rotating sleeve capable of being in contact with or disconnected from the gear are arranged on the movable plate, and a cleaning mechanism for cleaning the light transmitting mirror is arranged on the rotating sleeve. According to the scheme, a series of devices which correlate and interact are arranged to convert the rotary motion of the monitoring host into rhythmic automatic cleaning of the light transmitting mirror, so that the light transmission of the light transmitting mirror is effectively improved to improve the monitoring quality of the monitoring host, and meanwhile, the danger and high labor cost generated during manual cleaning are avoided.

Owner:BEIJING TELLHOW INTELLIGENT ENG CO LTD

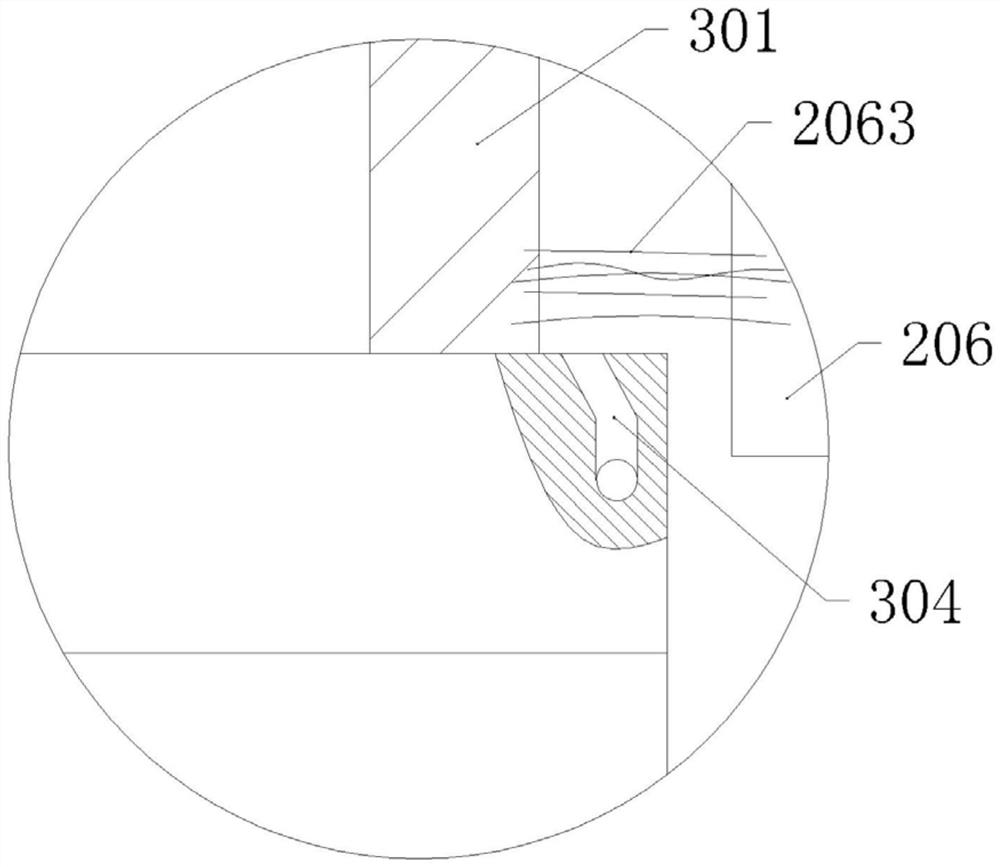

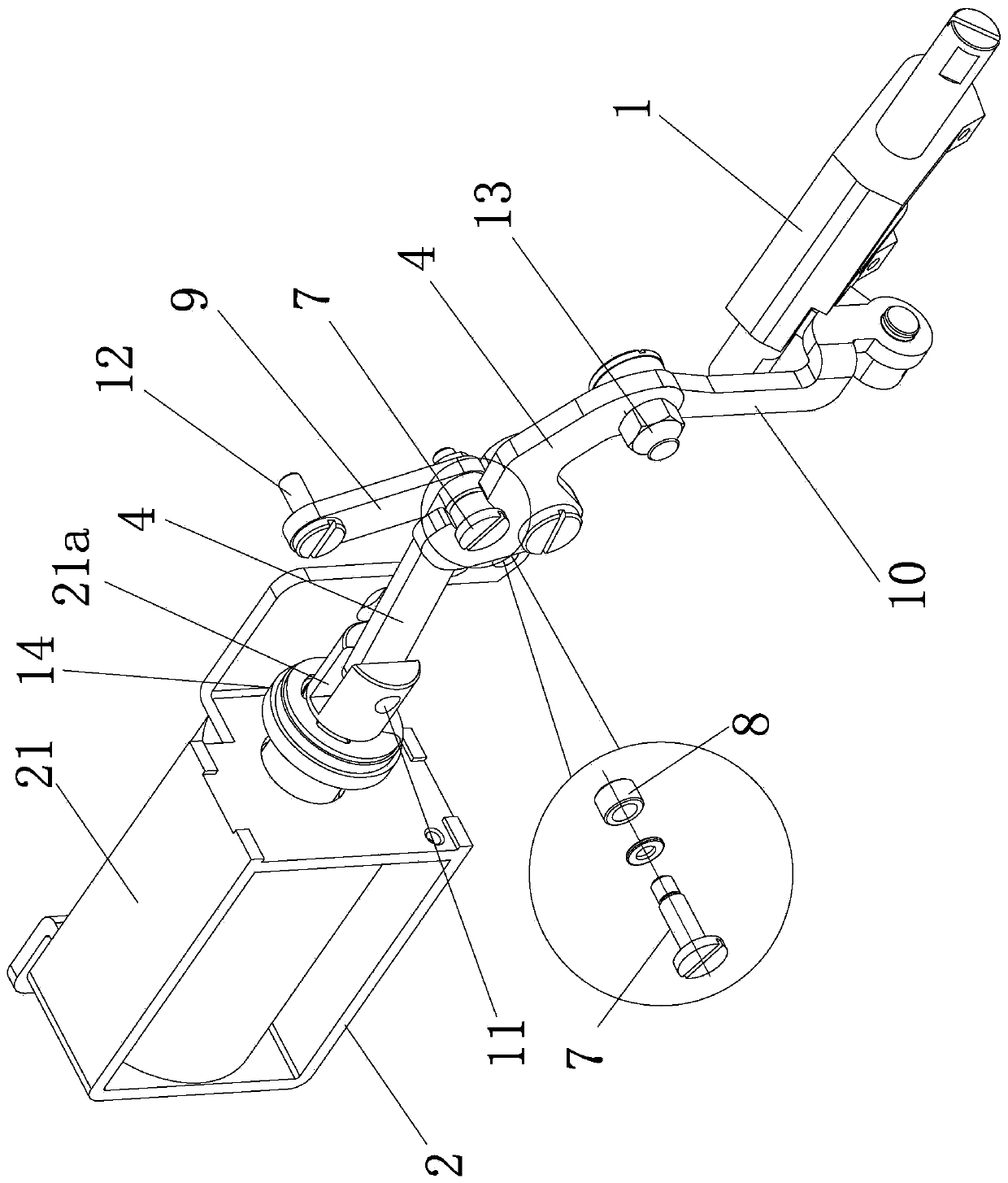

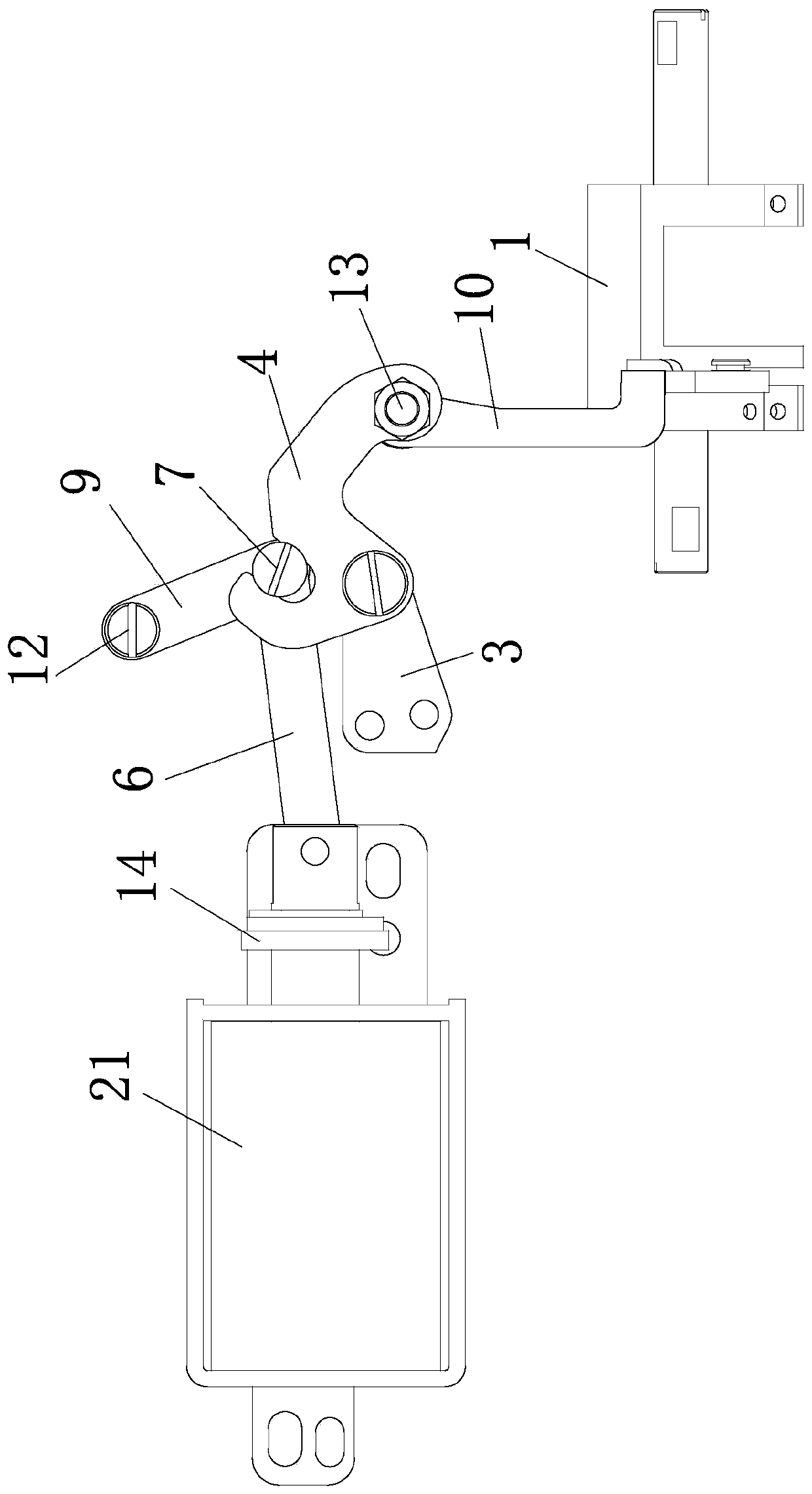

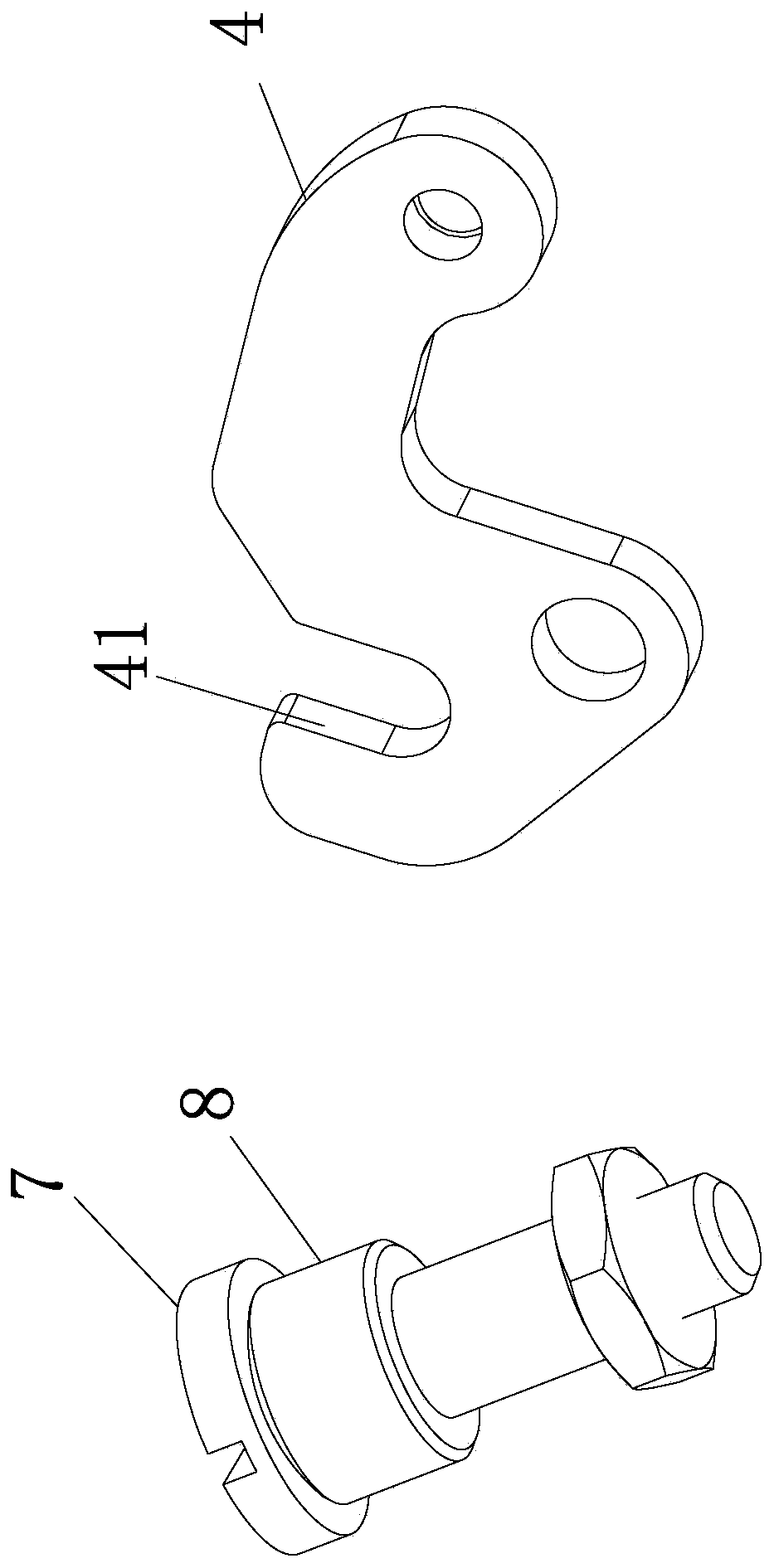

Backstitch structure of sewing machine

ActiveCN109868577AImprove torque transmission efficiencyReduce usage requirementsSewing-machine control devicesTorque transmissionEngineering

The invention provides a backstitch structure of a sewing machine, and belongs to the technical field of clothing manufacturing devices. The technical problem that a backstitch structure of an existing sewing machine cannot save labor enough is solved. The sewing machine comprises a bottom plate. The backstitch structure comprises a swing base, a driving piece fixedly arranged on the bottom plate,and a crank support. A backstitch crank is arranged on the crank support and rotationally connected to the crank support through a crank axial pin. An output shaft of the driving piece is connected with a crank pull rod. One end of the crank pull rod is connected with a rolling screw. The rolling screw is connected with an auxiliary rod. One end of the auxiliary rod is hinged to the bottom plate.A slide groove is formed in one end of the backstitch crank. One end of the rolling screw is movably clamped in the slide groove. A swing pull rod which can drive the swing base to swing is connectedto the swing base. One end of the swing pull rod is connected with the other end of the backstitch crank. According to the backstitch structure, by adding the auxiliary rod and reasonably arranging the connecting positions of all the parts, the torque transmission efficiency of a backstitch transmission structure is improved.

Owner:JACK SEWING MASCH CO LTD

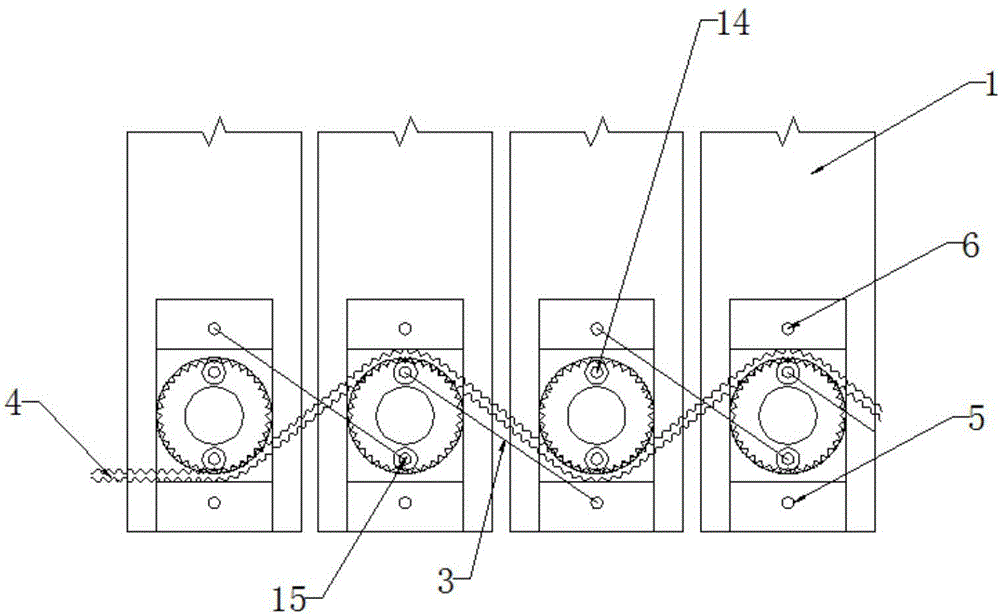

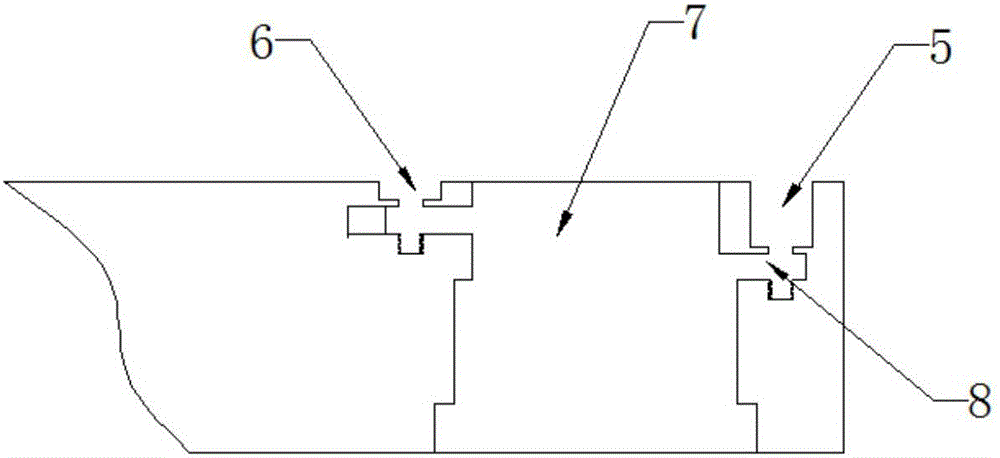

Conveyor belt type flexible connection rail torsion transmission device

The invention provides a conveyor belt type flexible connection rail torsion transmission device. The conveyor belt type flexible connection rail torsion transmission device comprises multiple steel light rails, torsion transmission rotors, steel wire flexible mooring ropes and transmission belts; the steel light rails are hinged, the torsion transmission rotors are arranged at the two ends of each steel light rail respectively and connected with the adjacent steel light rails through the steel wire flexible mooring ropes, and the transmission belts are wound around the torsion transmission rotors at the same ends of the steel light rails in a wave shape. According to the conveyor belt type flexible connection rail torsion transmission device, the damage to components by torsion transmission is reduced, and durability of the torsion transmission device is improved; secondly, the components are modularized and are convenient to install and easy to replace once the components are damaged; finally, torsion transmission efficiency is high, the synchronous belts are adopted to drive the torsion transmission rotors to rotate, and turning of the flexible connecting rails can be achieved fast. The conveyor belt type flexible connection rail torsion transmission device is particularly suitable for flexible rails of sea-railway combined transportation and can push implement of the roll-roll shipment flexible connection bridge technology.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

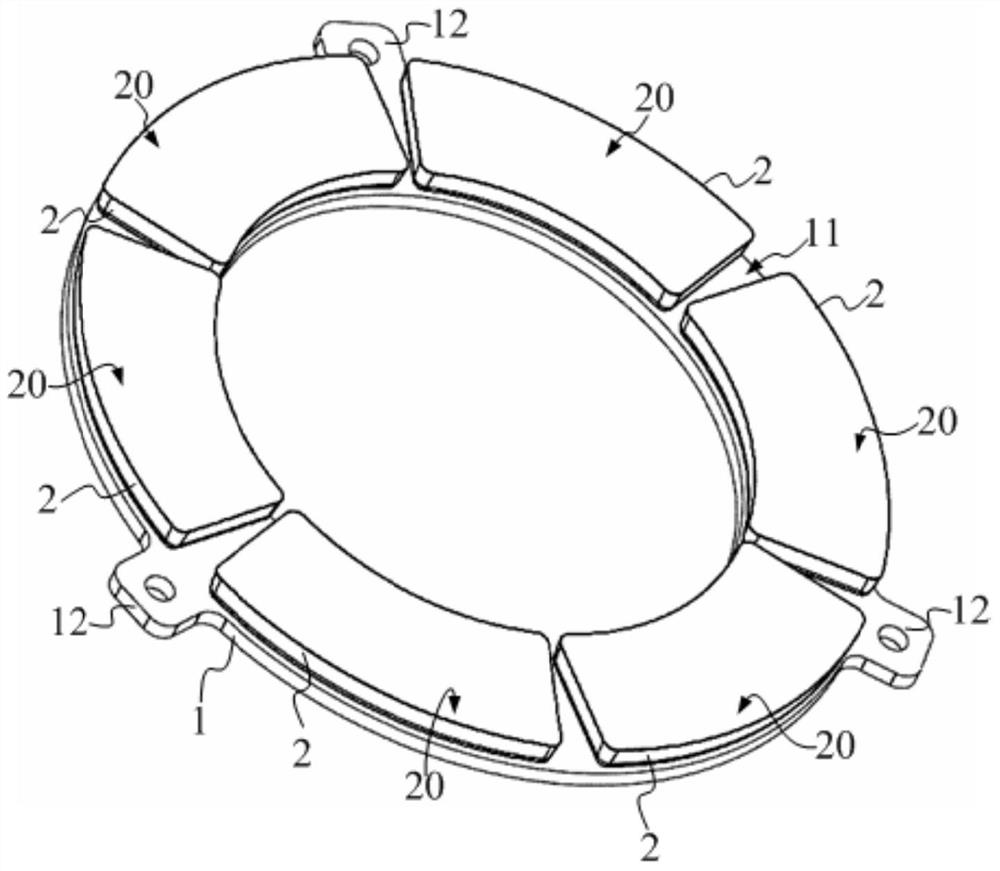

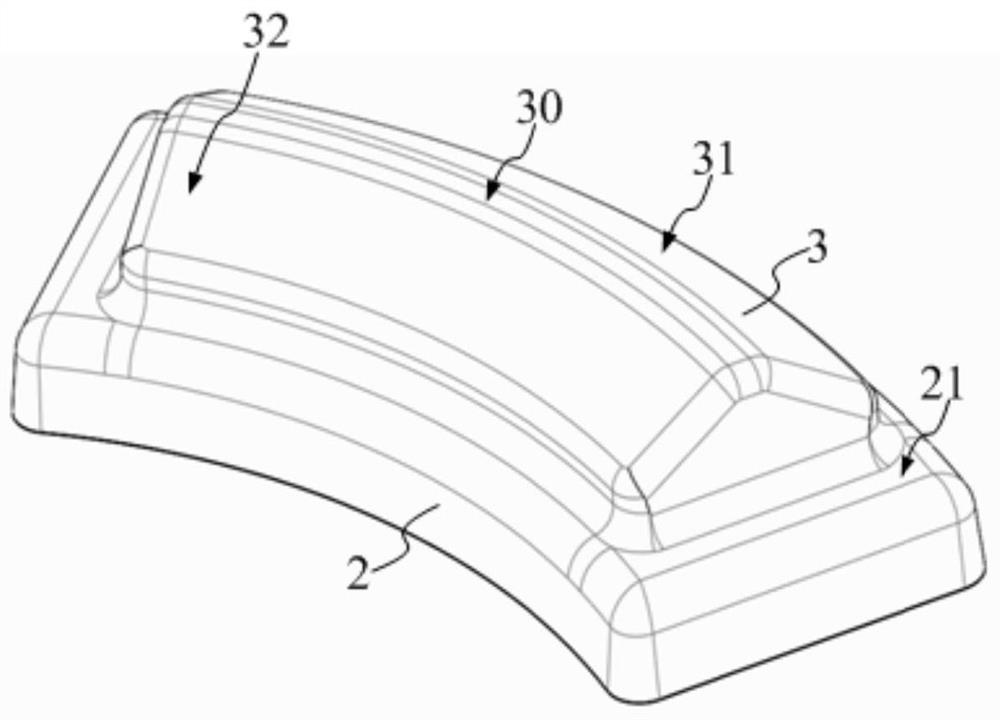

Clutches and Clutch Plates

A clutch and a clutch pressure plate, wherein the clutch pressure plate includes: a support plate, the material of which is steel; a friction member arranged on the support plate has a friction surface for frictionally combining with a clutch driven plate , the material of the friction member is cast iron. The support plate and the friction parts are composed of separate parts. The steel makes the support plate have high strength, and the cast iron makes the friction parts have high specific heat capacity. The clutch pressure plate of this technical solution integrates the advantages of high specific heat capacity friction parts and high-strength support plate, and has good performance. Torque transmission efficiency and a wider range of applications.

Owner:SCHAEFFLER TECH AG & CO KG

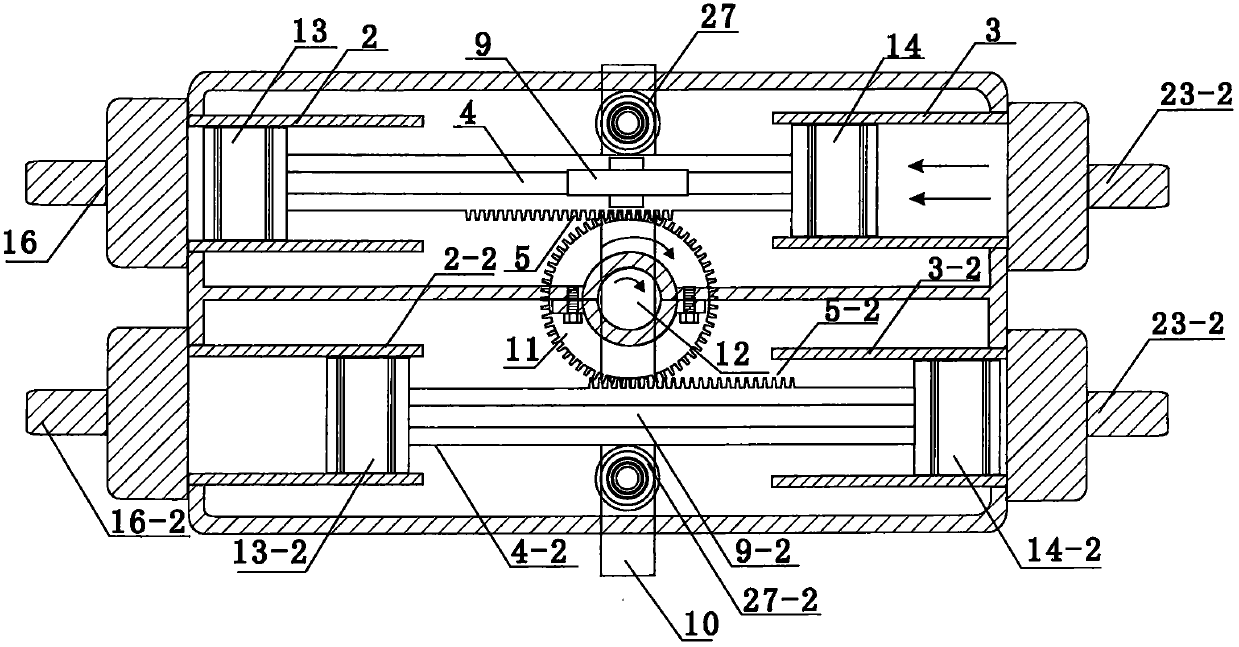

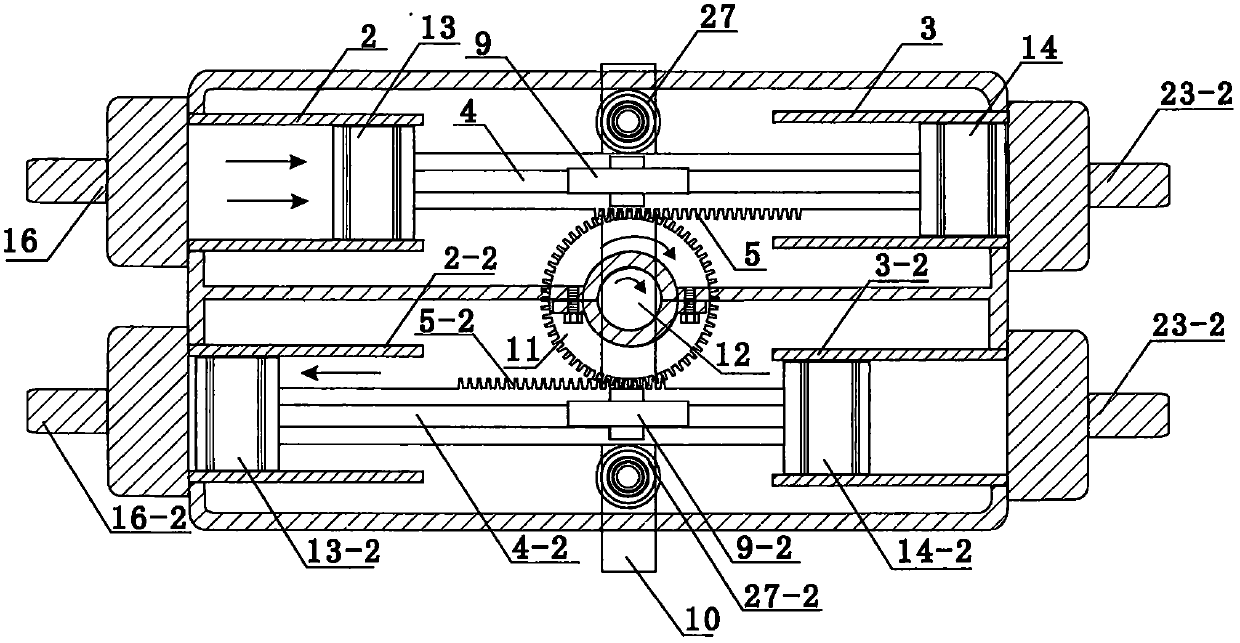

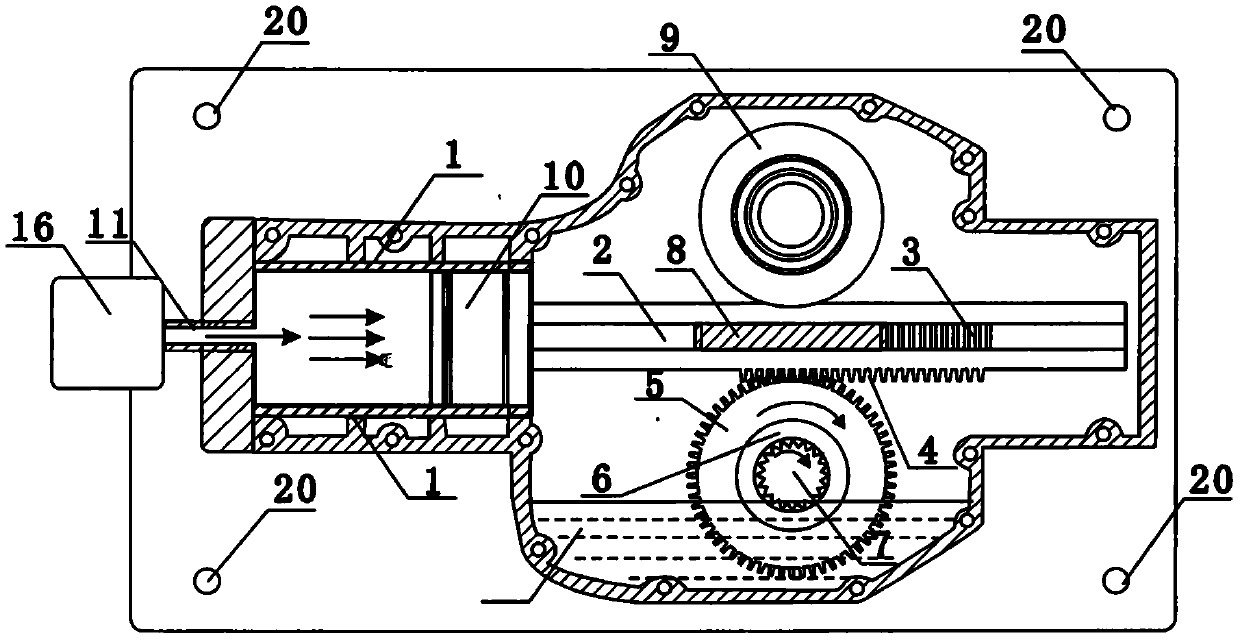

Novel ratchet wheel driving type pneumatic motor

PendingCN111022125AImprove torque transmission efficiencyImprove power output efficiencySafety/regulatory devicesReciprocating piston enginesRatchetGear wheel

The invention relates to a novel ratchet wheel driving type pneumatic motor. Two acting air cylinders are arranged in parallel by utilizing the characteristic that the piston of a cylindrical air cylinder has the best air impermeability; an acting piston is directly connected with multi-surface rack piston connecting rods; the side face backstepping racks of two groups of piston connecting rods are meshed with middle backstepping gears; the lower rack of the two multi-surface rack piston connecting rods is meshed with an output gear; the output gear is mounted on an output shaft through an overrunning clutch; and the piston connecting rod groups convert the reciprocating motion of the piston connecting rod groups into the circular motion of the output shaft to apply work externally throughthe overrunning clutch, so that the piston and crankshaft combination of the traditional air cylinder is improved, and the problems that the traditional crankshaft has a motion dead point and component force exists when a connecting rod acts on the air cylinder wall are eliminated to further optimize the torque output curve of the pneumatic motor and greatly improve the acting efficiency of the pneumatic motor.

Owner:闫传东

A torque output tool and its one-way torque transmission mechanism

ActiveCN105202064BImprove torque transmission efficiencyReduce heatPower driven toolsFreewheel clutchesTorque transmissionCentrifugal force

The invention discloses a torque output tool and its one-way torque transmission mechanism, which comprises: a casing, a motor and a transmission assembly, the motor and the transmission assembly are arranged in the casing, the transmission assembly includes a one-way torque transmission mechanism, and the one-way torque transmission mechanism Including: main shaft, driving part, lock sleeve, lock core, lock piece, etc., the lock sleeve includes a lock ring, the lock core includes a cylinder, and the inner wall of the lock ring includes at least two sections that can be locked or loosened with the outer wall of the lock cylinder cylinder The limiting wall surface of the locking part, the locking part is arranged between the locking ring and the cylinder, under the action of centrifugal force, when the driving part is driven to the main shaft, it only contacts the locking sleeve stably without unnecessary impact and friction , improve the efficiency of torque transmission, and reduce the heat generated by this mechanism, so as to reduce the adverse effects of temperature rise on tool reliability.

Owner:NANJING CHERVON IND

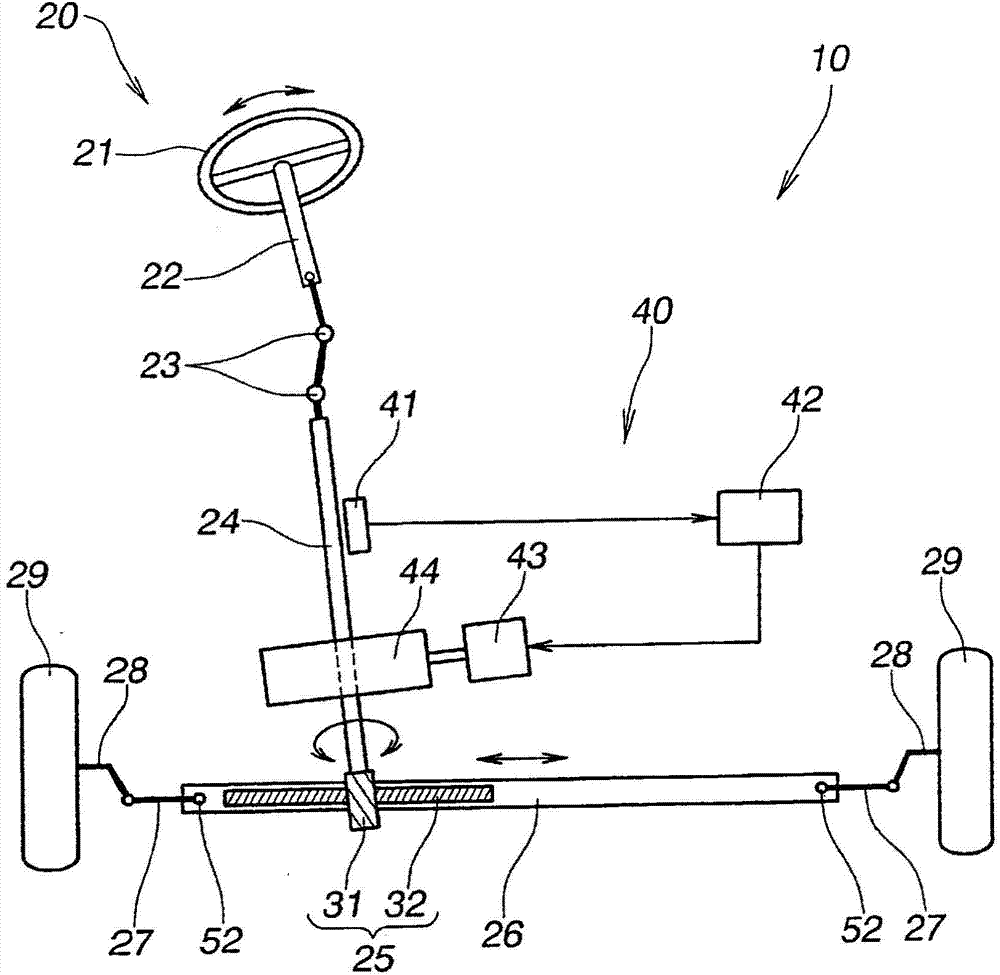

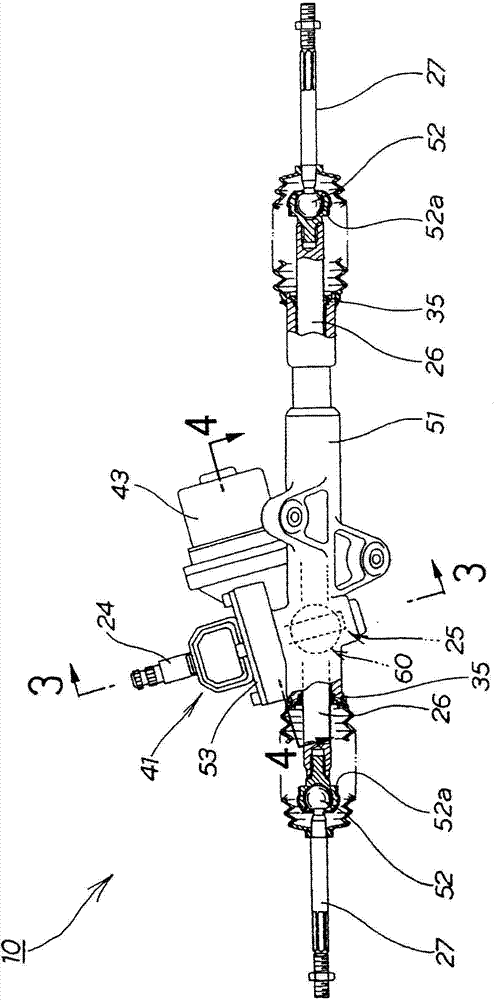

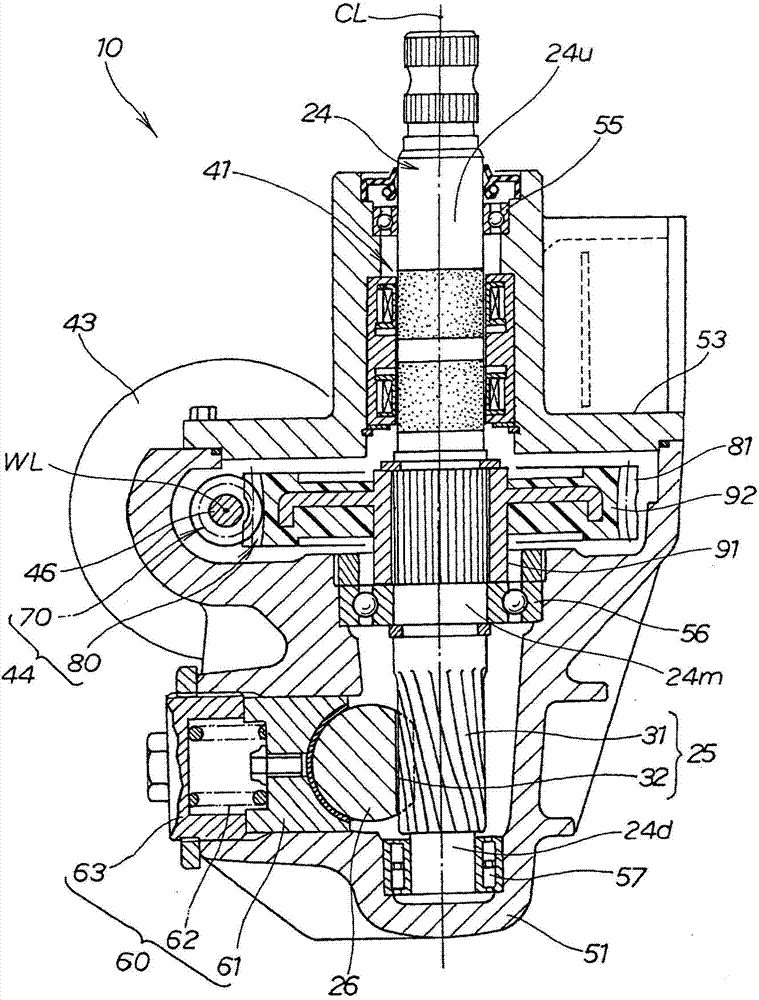

Worm gear mechanism

InactiveCN103930693AIncrease contact areaInhibit wearToothed gearingsPortable liftingEngineeringElectric motor

The invention provides a worm gear mechanism. The worm gear mechanism (44) is configured to comprise a worm (70) which is connected to an electric motor, and a worm wheel (80) engaged with the worm. In the worm wheel (80), at least a tooth flank (81a) is formed of a resin material. In the tooth flank (81a), an engagement recess (81dr), which is based on a the trajectory of a contact point being in contact with a tooth (71) of the worm (70) according to a rotation of the worm (70), is formed by injection molding only, together with the tooth flank, using a mold (100). The engagement recess (81dr) comprises a plurality of points (P1a-P9a) which are recessed the most in a the direction of a tooth of the tooth flank of the worm wheel correspondingly to the trajectory of the contact point with which the most convex portion of the tooth (71) of the worm (70) is in contact. A line (Loa) which connects the plurality of points intersects with respect to a tooth width center line (Ct) of the tooth flank (81a) of the worm wheel (80).

Owner:HONDA MOTOR CO LTD

A loader side unloading device

ActiveCN109056861BAvoid the disadvantages of easy deformation and fractureReduce pressureMechanical machines/dredgersHydraulic cylinderTorque transmission

The invention relates to the technical field of engineering machinery, in particular to a loader side unloading device, which includes a bucket and a bracket. The bottom end of the bucket is equipped with an arc-shaped sliding part. The sliding part cooperates with the arc-shaped guide rail, and the bucket slides along one side of the arc-shaped guide rail driven by the arc-shaped sliding part; the middle part of the bracket is fixed with a tie rod hinge support, and the tie rod hinge The support is fixedly connected with the oil cylinder support, and the oil cylinder support is rotatably connected with the end of the hydraulic cylinder. The piston rod of the hydraulic cylinder is hinged with the bucket, and the expansion and contraction of the piston rod in the hydraulic cylinder provides power for the sliding of the bucket. The arc-shaped sliding part includes two arc-shaped plates fixedly connected with the bucket, and the opposite side of the two arc-shaped plates is provided with an arc-shaped sliding head. The invention can improve the torque transmission efficiency when the side is released, and avoid repeated force fracture at the hinge of the pin shaft.

Owner:QINGDAO LOVOL EXCAVATOR

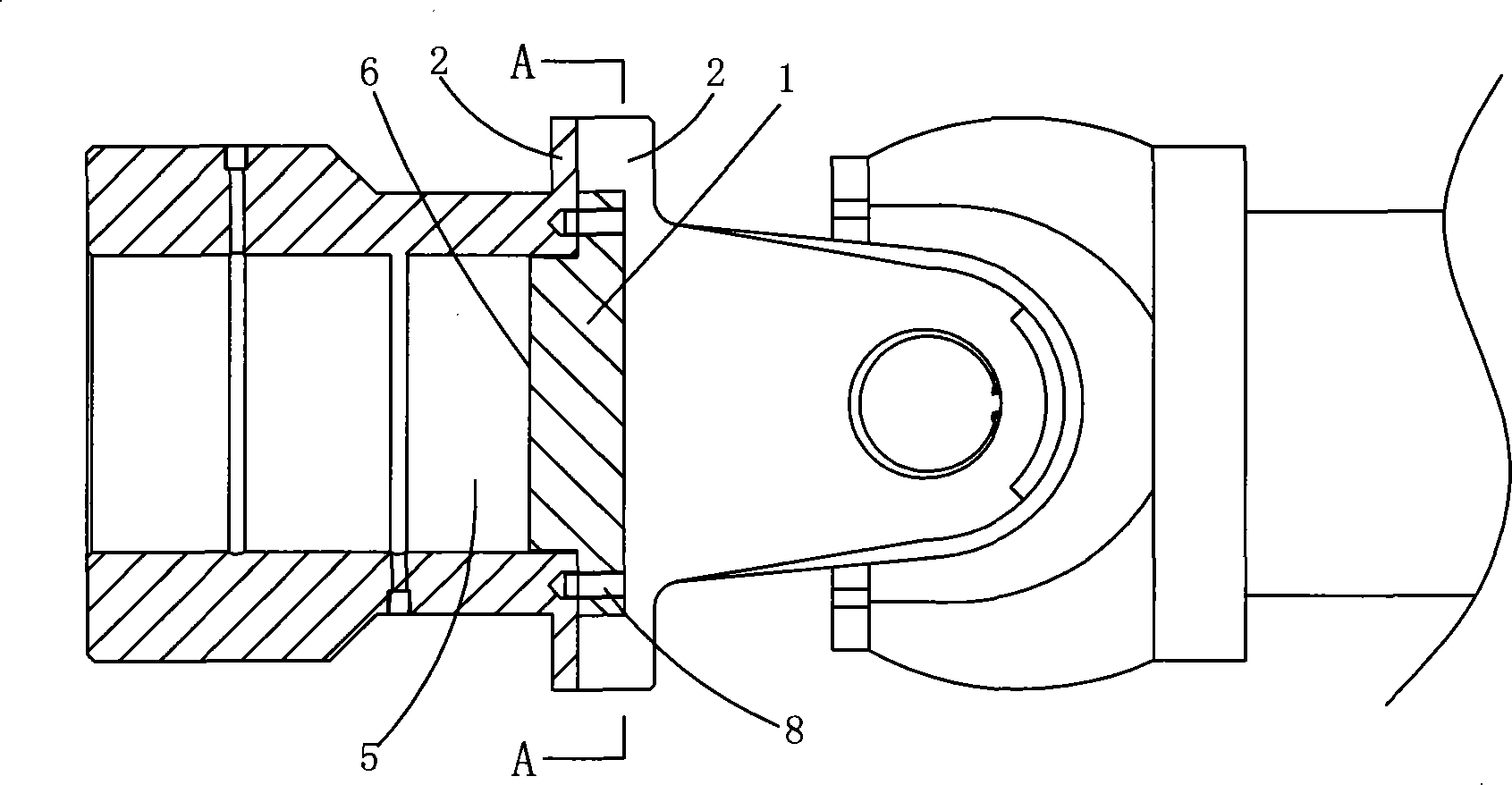

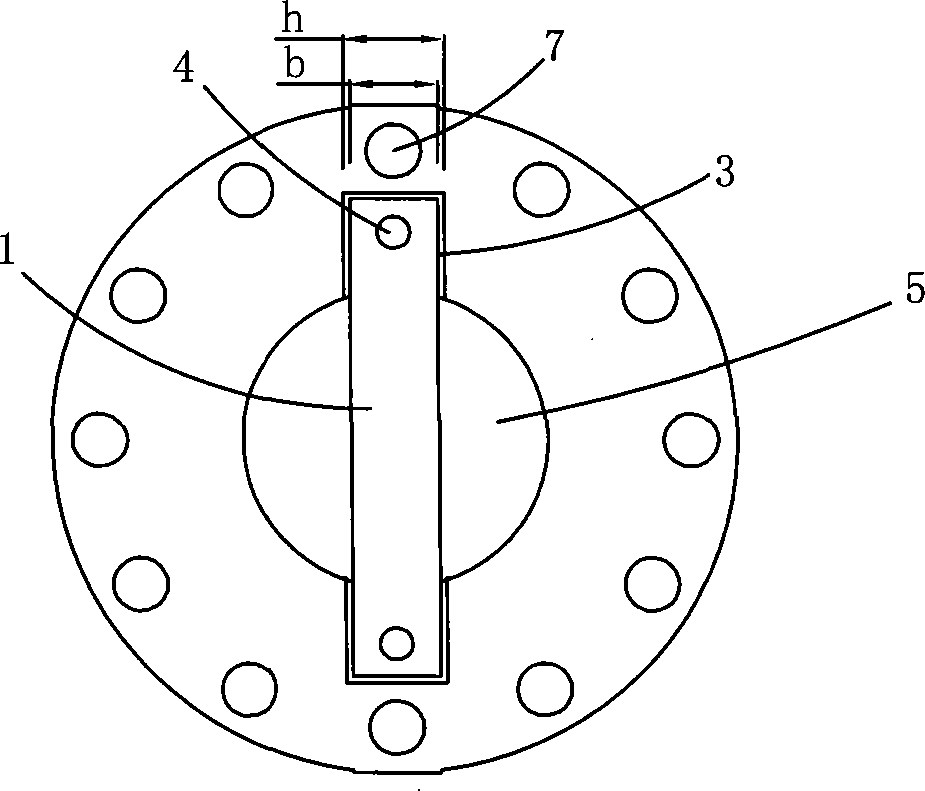

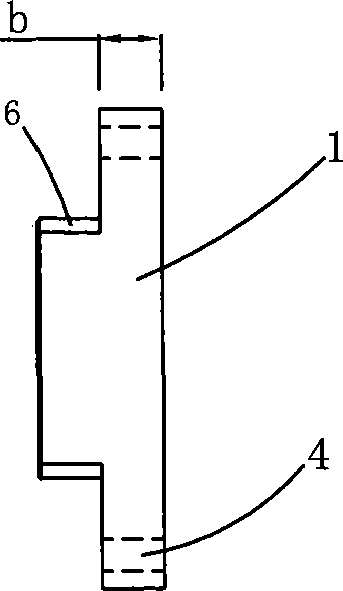

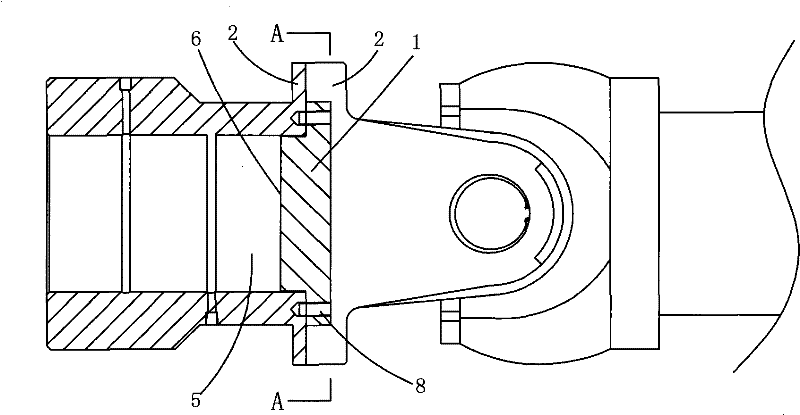

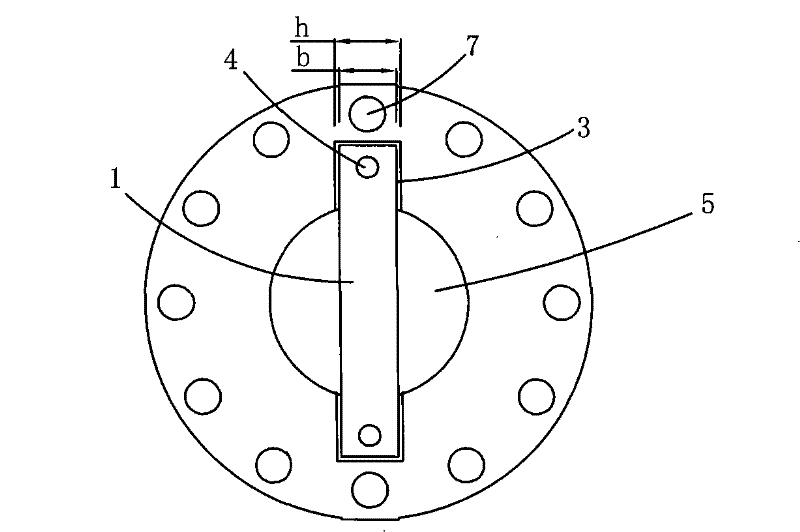

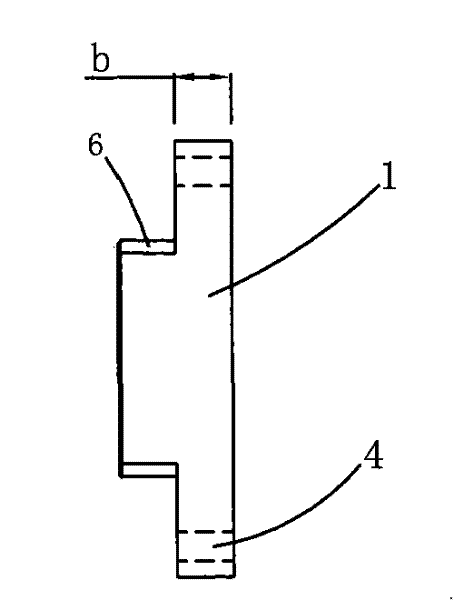

End-surface key structure for coupler

InactiveCN102478038BImprove torque transmission efficiencyImprove smoothnessYielding couplingKey type connectionsCouplingTorque transmission

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

End-surface key structure for coupler

InactiveCN102478038AImprove torque transmission efficiencyImprove smoothnessYielding couplingKey type connectionsCouplingTorque transmission

The invention relates to an end-surface key structure for a coupler, belonging to the technical field of key coupling pieces. The end-surface key structure comprises a key and a key groove manufactured on the end surface of a coupling flange; and the two ends of the key are manufactured with through holes in which fastening pieces for fixing the key and the coupling flange are arranged in a penetrating manner. The end-surface key structure leads the key to be embedded into a shaft hole of the coupling flange to be repositioned and fixed in the radial direction and increases the contact between the key and the coupling flange; therefore, the connection firmness between the key and the coupling flange is increased so as to ensure that the key does not deform and drop off to avoid failure; and the efficiency of torque transmission of the coupler is also improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

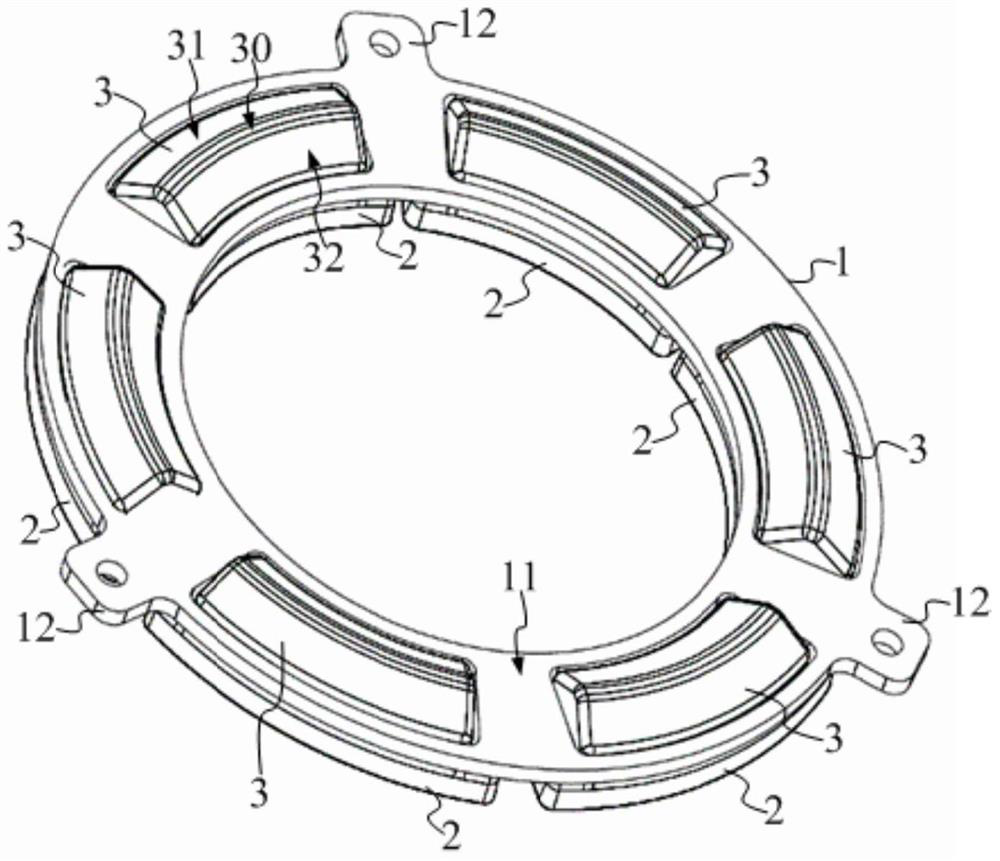

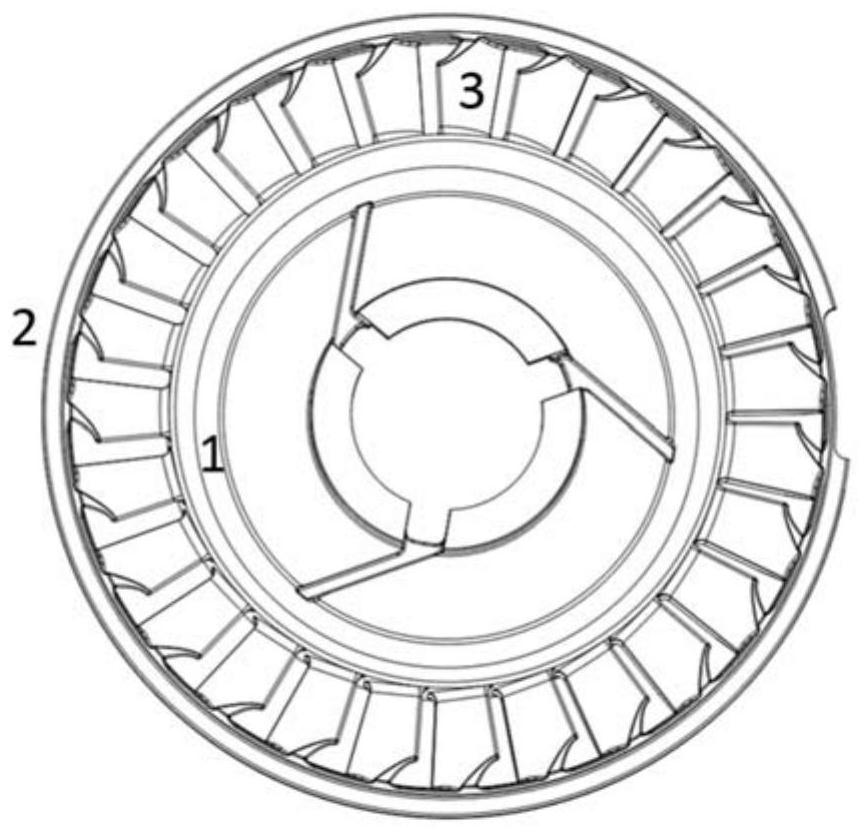

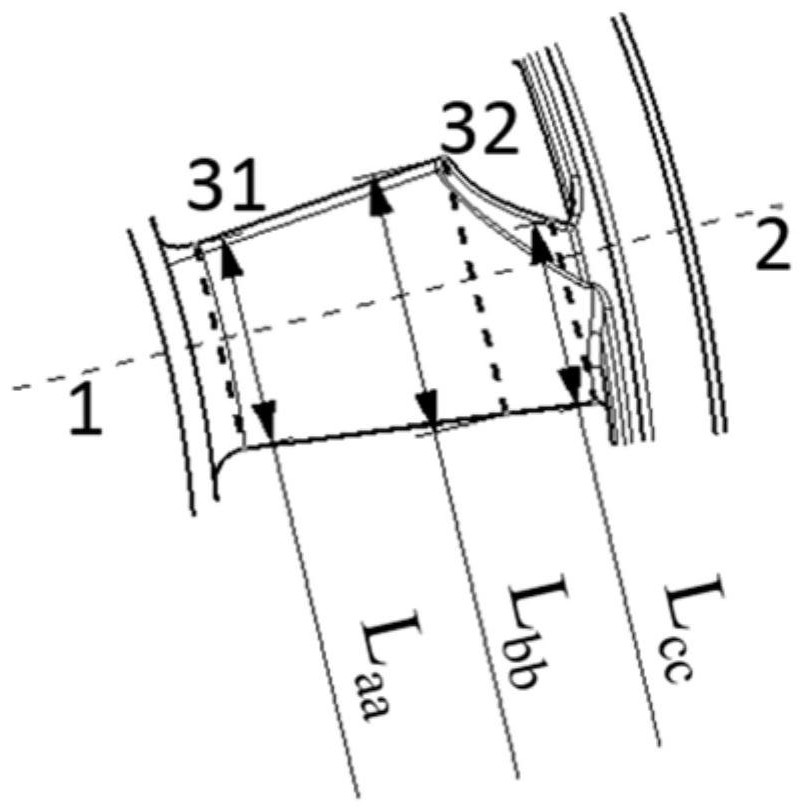

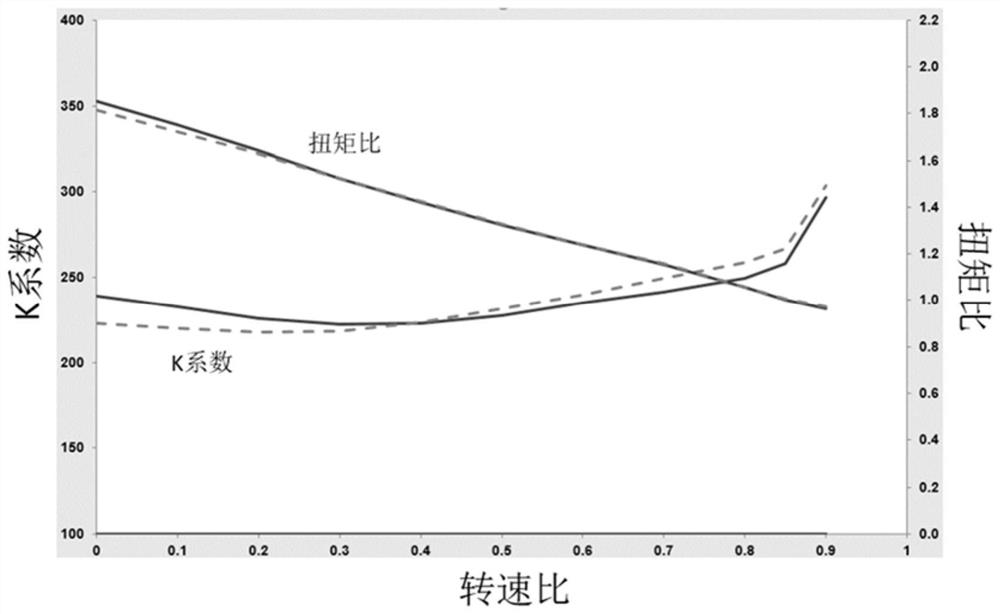

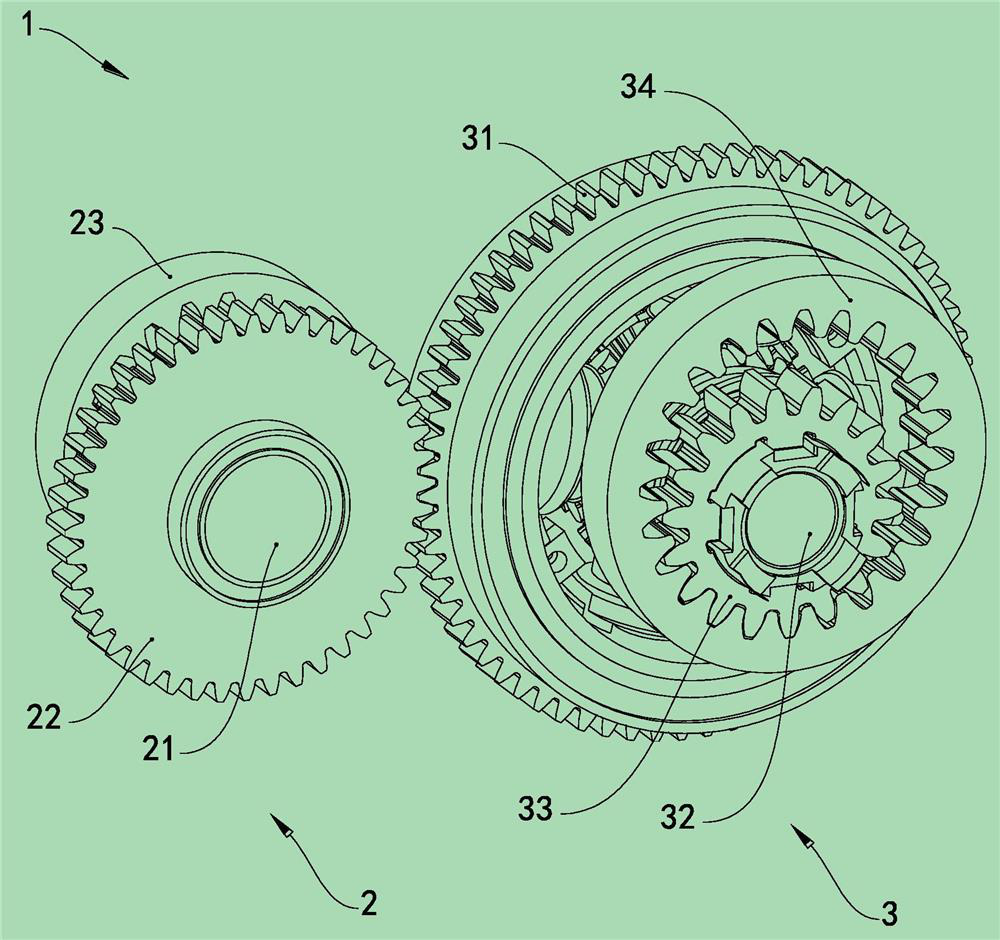

Stator of torque converter and torque converter comprising such stator

PendingCN111795127AImprove torque transmission efficiencyIncrease the areaFluid gearingsClassical mechanicsControl theory

The invention relates to a stator for a torque converter which includes a stator hub, a stator shroud, and a plurality of stator blades. The stator blades extend radially outward from the stator hub to the stator shroud and include a base intersecting the stator hub and an end intersecting the stator shroud. The base portion has a width Laa and the end portion has a width Lcc. In the direction inwhich the stator blades extend radially outward, the width of at least one of the plurality of stator blades is first gradually increased and then gradually decreased, and has a width Lbb, Laa < Lbb,and Lcc < Lbb at the widest thereof. The present disclosure also relates to a torque converter including the stator as described above.

Owner:VALEO KAPEC TORQUE CONVERTERS NANJING CO LTD

electric pruning tool

ActiveCN103327806BImprove torque transmission efficiencySimple structureCuttersCutting implementsAutomatic controlBevel gear

A cutting tool has a cutting head, a motor and a transmission means drivable by the motor. The cutting head comprises first and second cutting members, wherein the first cutting member is pivotably moveable with respect to the second cutting member. At least the first cutting member is drivable by the transmission means between a first angular position with respect to the second cutting member and a second angular position with respect to the second cutting member, in which a space between the respective cutting blades is closed. The transmission means is a bevel gear on the output shaft of a gearbox which conveys drive power from the motor to the drive gear. The bevel gear directly engages a bevel wheel member connected to the first cutting member and which swivels with the first cutting member about the same swivel point. A controller comprises main, first and second switches which control the motor to move the first cutting member (movable blade). The main switch acts as a main power switch whereas the first ad second switches act as limit switches detecting movement of said movable blade at the limits of its intended motion. The controller exerts automatic control over movement of the first cutting member in response to inputs from the first and second limit switches.

Owner:TECHTRONIC OUTDOOR PRODS TECH

Soil remediation device capable of simultaneously stirring and conveying soil

ActiveCN110238176APlay a cutting roleExtended service lifeContaminated soil reclamationSoil remediationEngineering

The invention discloses a soil remediation device capable of simultaneously stirring and conveying soil. The soil remediation device comprises a material inlet part, and the material inlet part comprises a first conveyor belt and a material inlet hopper; an outlet in the lower part of the material inlet hopper is arranged above the first conveyor belt, a screener covers an inlet in the upper part of the material inlet hopper, the upper surface of the screener has a predetermined slope, and the lower side of the upper surface of the screener extends to the outer side of the soil remediation device to intercept impurities exceeding a designed remediation maximum size or agglomerated soil to the outside of the soil remediation device; and the front and rear parts of the first conveyor belt are respectively provided with one power roller. The device provided by the invention has the following beneficial effects: one side, close to the middle of a stirring cabin, of each rotating shaft rotates from the bottom to the top, so that the soil accumulated in the middle of the conveyor belt is evacuated to two sides, a stirring tooth plate with an inclined angle is also used, so that the soil is pushed forwards, and the soil is conveyed by a second conveyor belt while the soil is stirred.

Owner:上海建工环境科技有限公司

Fixed Constant Velocity Universal Joint

Owner:NTN CORP

Tea picking machine with multi-wheel anti-bump walking mechanism

ActiveCN103766076BImprove torque transmission efficiencyLow anti-bounce performancePicking devicesControl devicesAgricultural engineeringFront-wheel drive

The invention belongs to the technical field of a tea picking machine,and particularly relates to a tea picking machine with a multi-wheel bump-proof walking mechanism.It comprises a door type structure machine frame, an engine on the machine frame, a gearbox, a tea picking mechanism, one front wheel is respectively arranged at the left and the right side of the machine frame, and more than one back wheel is respectively arranged at the left and the right side of the machine frame.The tea picking machine is characterized by also comprising two output shaft motive power driving transmission mechanisms, the front and back wheel motive power driving branched transmission mechanisms are connected with each output shaft motive power driving transmission mechanism, the front wheel motive power driving dump-proof vibration reduction transmission mechanism and the back wheel motive power driving transmission mechanism are connected with the front and back wheel motive power driving branched transmission mechanism,the front wheel driving transmission mechanism is connected with the front wheel motive power driving damp-proof vibration reduction transmission mechanism, and the back wheel dump-proof walking mechanisms are connected with the back wheel motive power driving damp-proof vibration reduction transmission mechanism.It has the advantages that the stable, efficient, quality-guaranteeing and quantity-guaranteeing tea picking on uneven hill ground can be realized.

Owner:睢宁下邳农业有限公司

Numerical control machine tool with clamping tip

ActiveCN114101722AStable and enhanced clamping forceStable torque transmissionTailstocks/centresLarge fixed membersElectric machineryLeft lateral wall

The invention relates to the technical field of intelligent manufacturing, and discloses a numerical control machine tool with a clamping tip, the numerical control machine tool comprises a base, a first support, a second support, a motor and a grinding piece, a shaft sleeve is fixedly connected to the right side of the second support and located at the tail end of an output shaft of the motor, and a limiting column is fixedly connected to the left side wall of the first support; a center sleeve is fixedly connected to the right side wall of the shaft sleeve, a rotating column is fixedly connected to the center of the top wall of the center sleeve, a first protrusion is fixedly connected to the rotating column in the circumferential direction, and a permanent magnet is slidably connected to the interior of a limiting groove. Clamping of a part to be machined is achieved through the first protrusion on the tip, multi-stage switching of the protection mechanism is achieved through centrifugal force changes at different rotating speeds in the part machining process, the automation degree is high, torque is kept to be stably transmitted according to increase of the rotating speeds, multi-stage protection of the part is achieved, the machining efficiency is high, and the machining cost is low. The service life of the center is prolonged, and the defect rate of products is effectively reduced.

Owner:南通永锠数控机械科技有限公司

A high air pressure drill bit

The invention provides a high air pressure drill bit comprising a drill bit body and ally teeth. The drill bit body comprises a crushing head, a spline and a drill bit tail end. The alloy teeth are arranged on the crushing head with a length of L1. The length of the spline is L2. The length of the travel of the drill bit tail end is L3. The sum of L1, L2 and L3 is 230mm, L2 is greater than L1, and L2 is greater than L3. The loss of stress wave transmission of the drill bit body is reduced, so that the rotating torque transmission is more stable, the efficiency is higher and the service life is longer.

Owner:长沙天和钻具机械有限公司

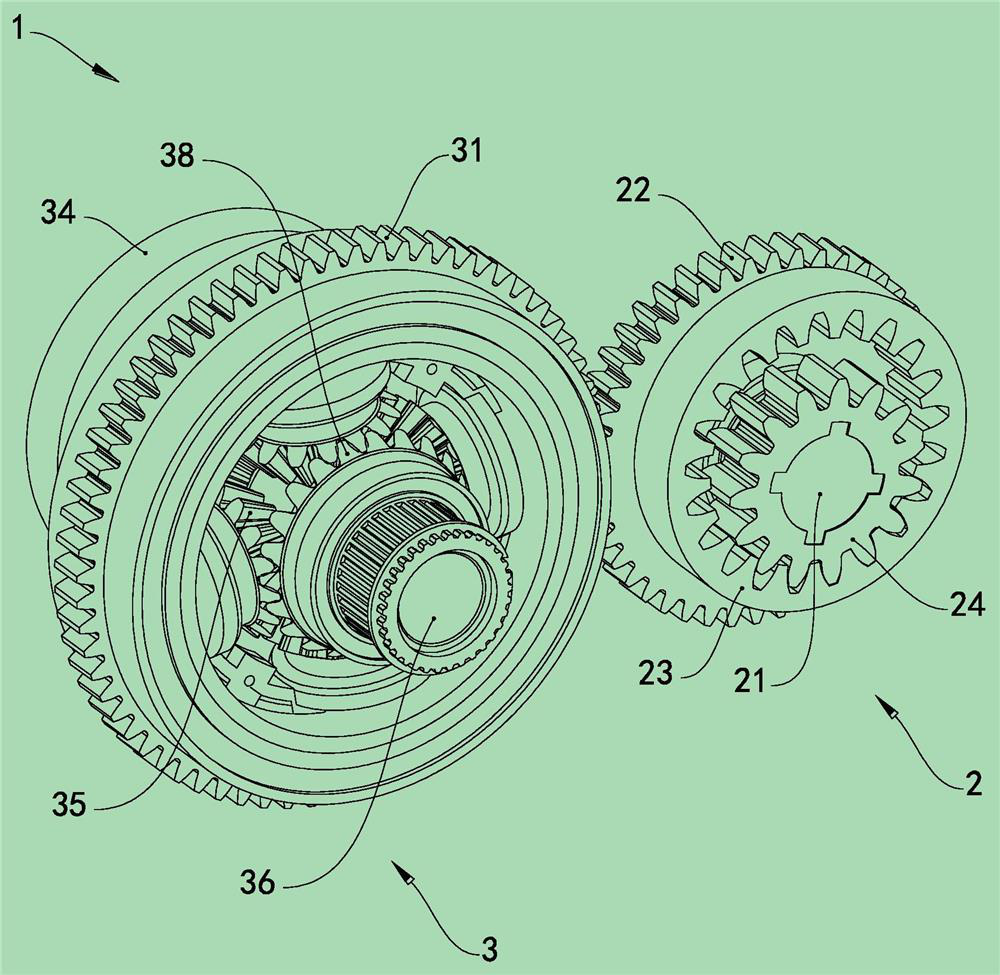

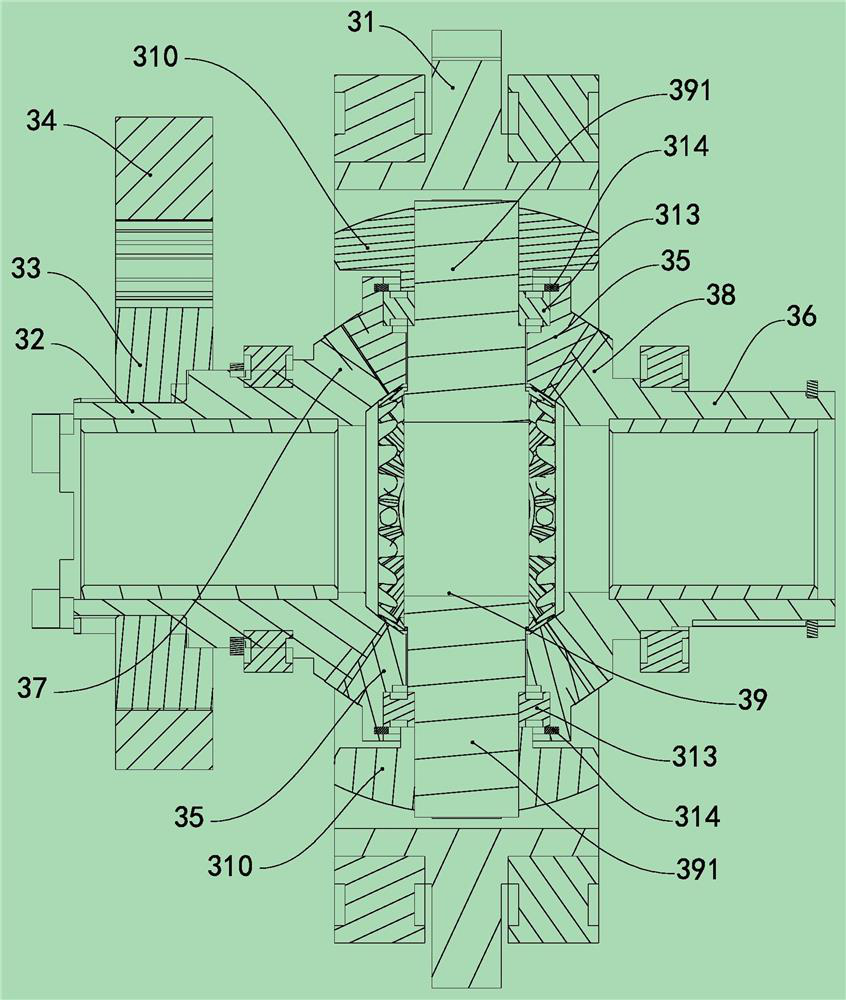

Multifunctional clutch and gearbox

PendingCN113513547ARealize automatic variable speed controlImprove torque transmission efficiencyFluid actuated clutchesGear lubrication/coolingClutchDriver/operator

The invention provides a multifunctional clutch and a gearbox. The clutch comprises a brake gear, a brake shaft, a brake oil pump and a pulse width modulation valve; the brake shaft can rotate around the axis of the brake shaft, and the first end of the brake shaft is coaxially sleeved with an inner rotor gear of the brake oil pump; and an outer rotor gear ring of the brake oil pump can rotate around the axis of the outer rotor gear ring and is connected to the inner rotor gear in a sleeving manner, the inner rotor gear is meshed with the outer rotor gear ring, the inner rotor gear and the outer rotor gear ring are eccentrically arranged, the brake gear is coaxially connected to the second end of the brake shaft in a sleeving manner, and the pulse width modulation valve is used for adjusting the oil pressure of the brake oil pump. The clutch has the functions of speed regulation and clutching, stepless speed regulation can be conducted on a transmission mechanism of the gearbox, torque fluctuation and anti-vibration of the gearbox can be actively absorbed, the problem of gear shifting jerking feeling of the gearbox is solved, the service life of the clutch is prolonged, work is reliable and high in precision, and the comfort experience of a driver is good.

Owner:深圳市雷圣特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com