Clutches and Clutch Plates

A clutch and pressure plate technology, applied in the field of clutches, can solve the problems of torque transmission efficiency drop, low specific heat capacity, bursting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0033] In the clutch, the clutch pressure plate is arranged between the diaphragm spring and the clutch driven plate, exerts pressure on the diaphragm spring, and the diaphragm spring presses the clutch pressure plate to combine with the clutch driven plate. Release the pressure applied to the diaphragm spring, the diaphragm spring returns, and the clutch pressure plate is separated from the clutch driven plate.

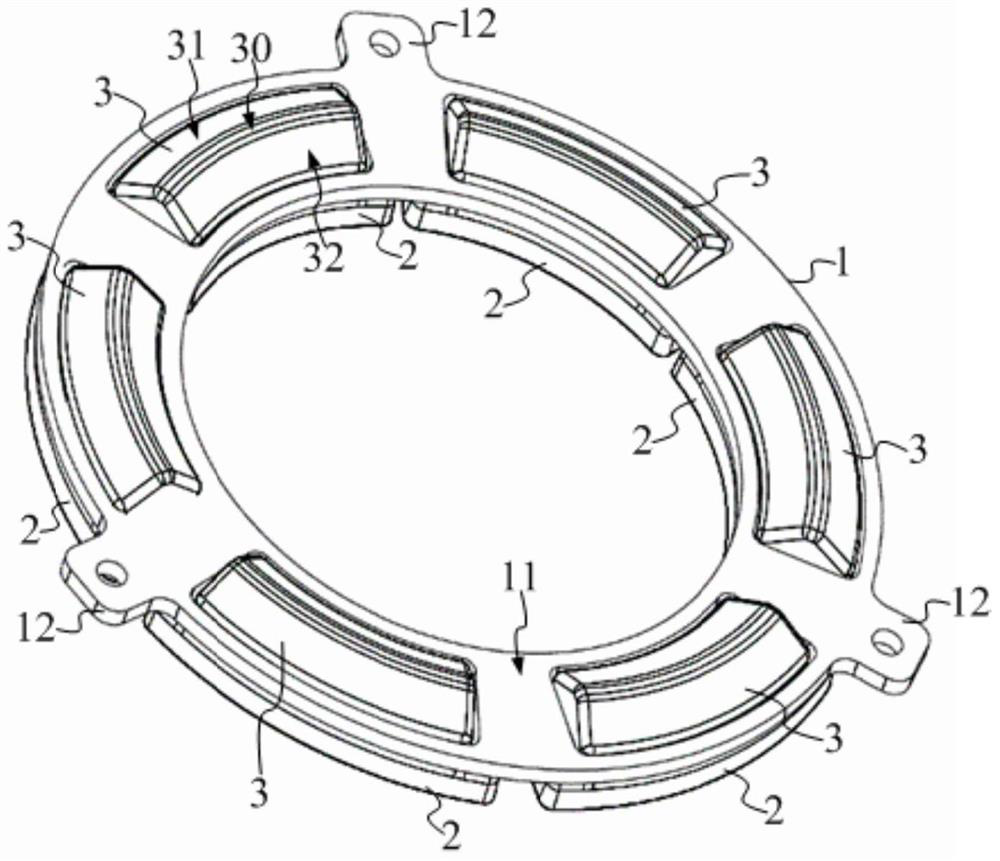

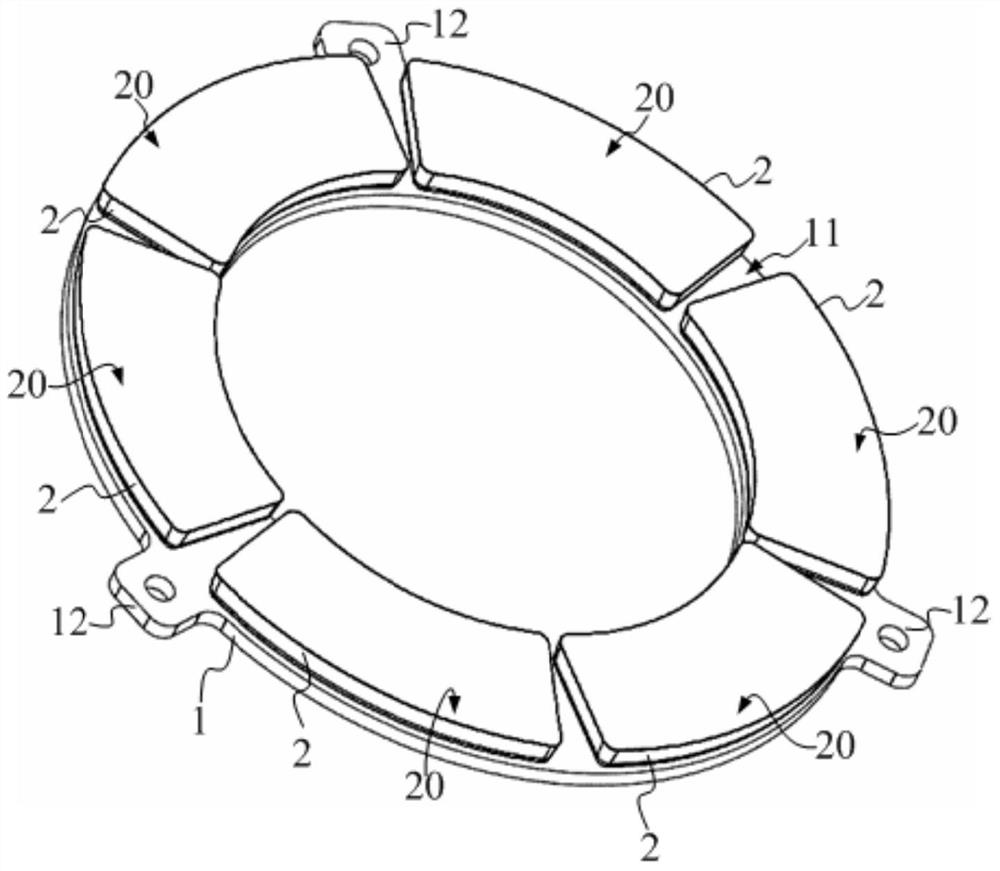

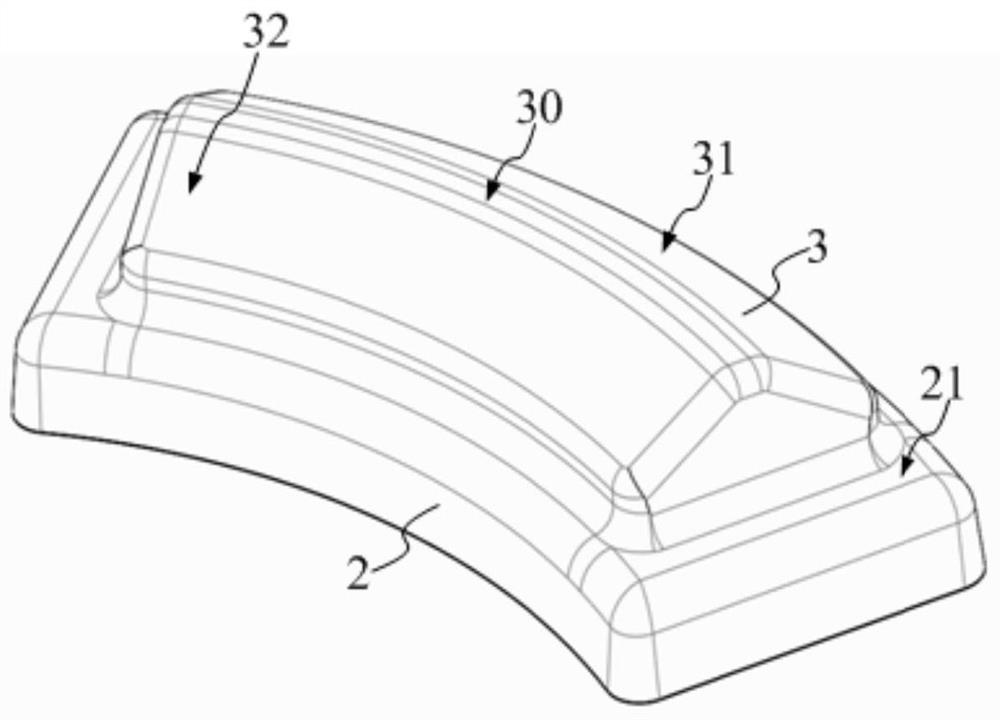

[0034] refer to figure 1 and figure 2 , the clutch pressure plate may include: a support disc 1, the material of which is steel; a friction member 2 arranged on the support disc 1 has a friction surface for frictional combination with the clutch driven disc (not shown in the figure) 20. The friction part 2 is made of cast iron.

[0035] In the clutch pressure plate of the technical solution, the support plate 1 and the friction member 2 are made of different materials, and the two form a split structure. Wherein, the friction surface 20 faces the clutch driven di...

no. 2 example

[0055] Compared with the first embodiment, the second embodiment differs in that:

[0056] refer to Figure 5 , the supporting member 4 and the friction member 5 are connected through the connecting portion 6;

[0057] combined reference Image 6 and Figure 7 , the support member 4 and the friction member 5 are respectively located on both axial sides of the support disc 7 and press the support disc 7 . The support member 4 and the friction member 5 clamp the support disc 7 to realize fixed installation. During assembly, the support member 4 and the friction member 5 can be clamped at the radially inner end of the support disc 7 first, and then the support member 4 and the friction member 5 are pressed into place along the radial direction of the support disc 7 from inside to outside.

[0058] In order to make the installation firm, the connecting part 6 can be provided to connect the support disc 7 in a clamping manner, which can enhance the firmness of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com