Unidirectional clutch type stepless speed change device for off-road motor vehicles

A continuously variable transmission device and motor vehicle technology, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of shoe wear life, reduced engine life, high cost, etc., and achieve high torque transmission efficiency, Stable and reliable performance, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

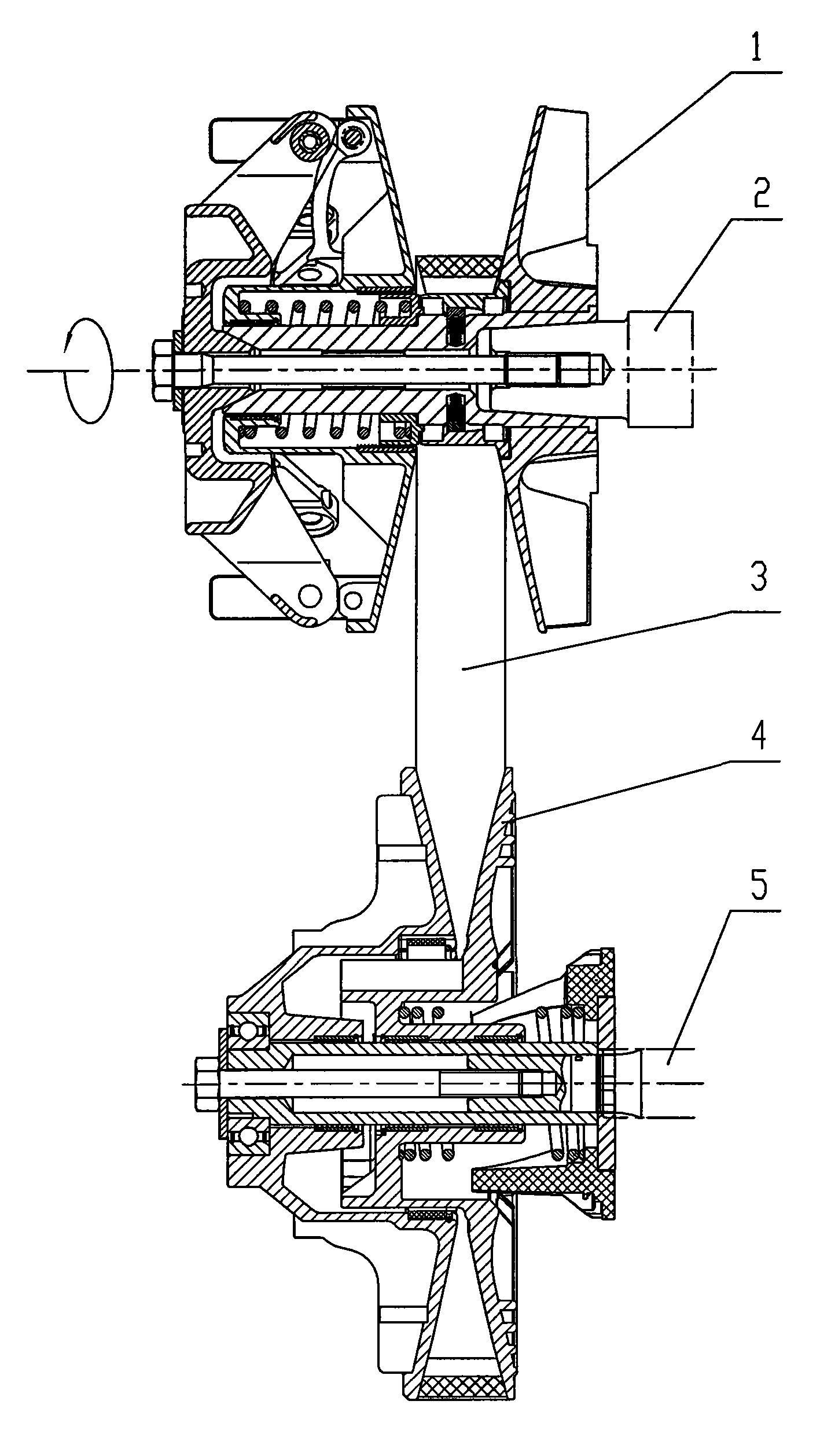

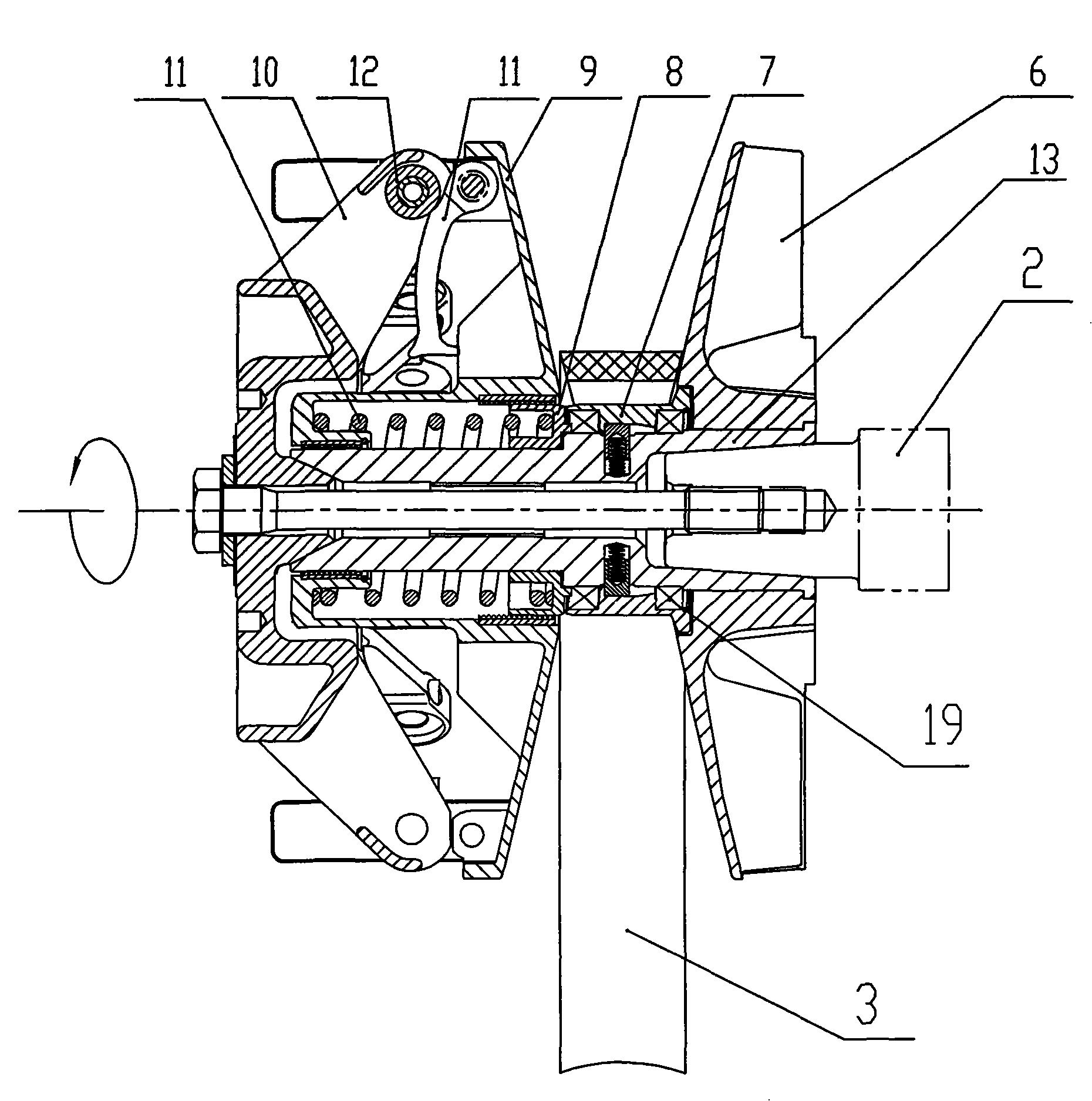

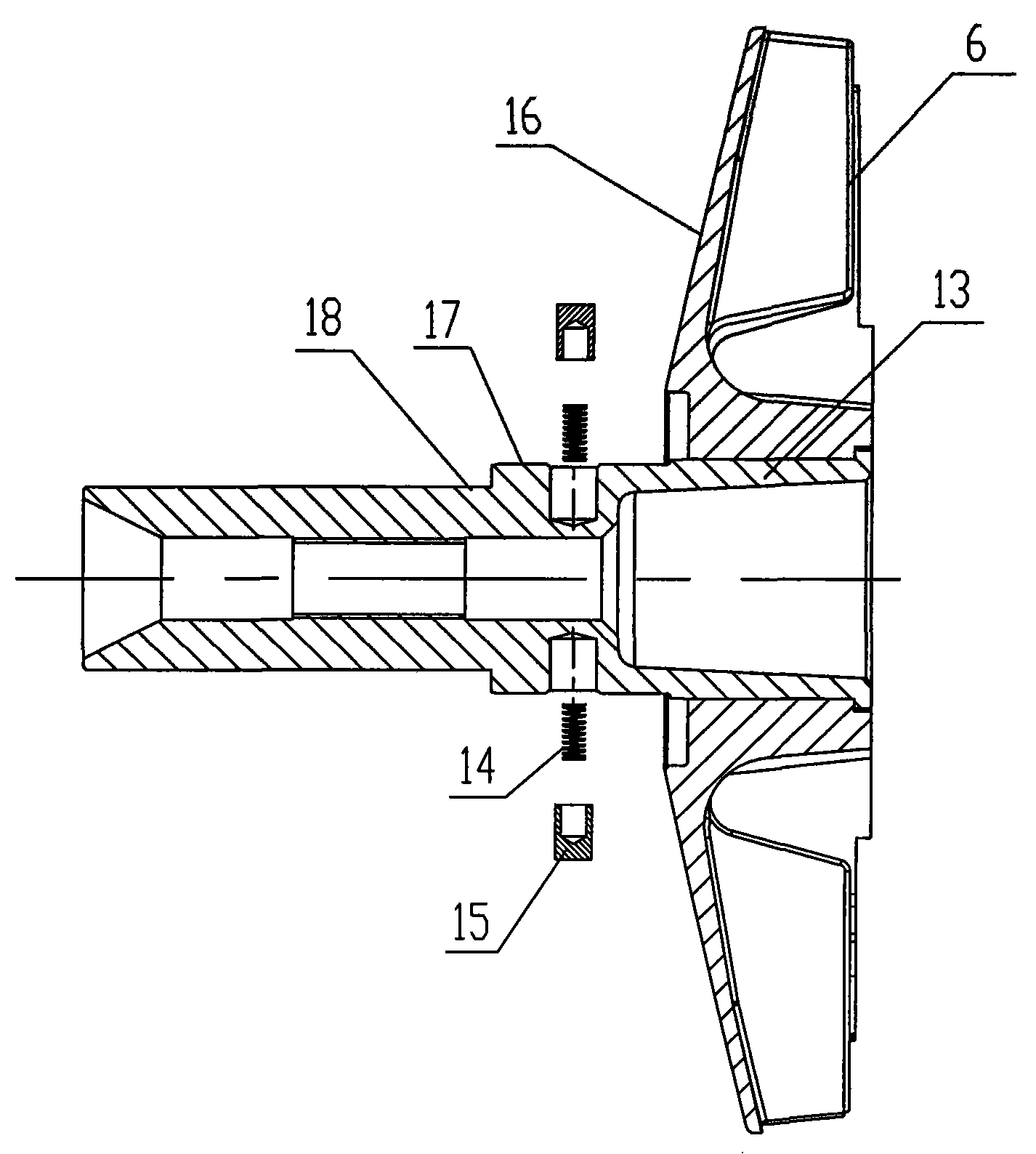

[0019] Figure 1 to Figure 6 As shown, the present invention creates a specific embodiment of the one-way clutch type continuously variable transmission device for non-road motor vehicles, which includes a driving wheel assembly 1 arranged on an input shaft 2, a driven wheel assembly 4 arranged on an output shaft 5, The driving wheel assembly 1 is connected with the driven wheel assembly 4 through the belt 3, and the driving wheel assembly 1 includes a pulley 6, an axle 13, a sliding sleeve 7, a spring seat 8, a pressure pulley 9, a driving wheel spring 11, a supporting wheel 10, The pulley 6 is fixed on the wheel shaft 13, the sliding sleeve 7, the spring seat 8, and the pressure pulley 9 are sequentially movably sleeved on the wheel shaft 13 and axially positioned by the support wheel 10, and the sliding sleeve 7 is arranged on the sliding sleeve mating surface 17 of the wheel shaft 13 Above, the spring seat 8 is arranged on the spring seat mating surface 18 of the wheel sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com