Novel ratchet wheel driving type pneumatic motor

An air motor and driving technology, applied in the direction of engine components, variable capacity engines, machines/engines, etc., can solve the problems of poor durability, high blade speed, low work efficiency, etc., to improve torque transmission efficiency and power output The effect of improving efficiency and optimizing torque output curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

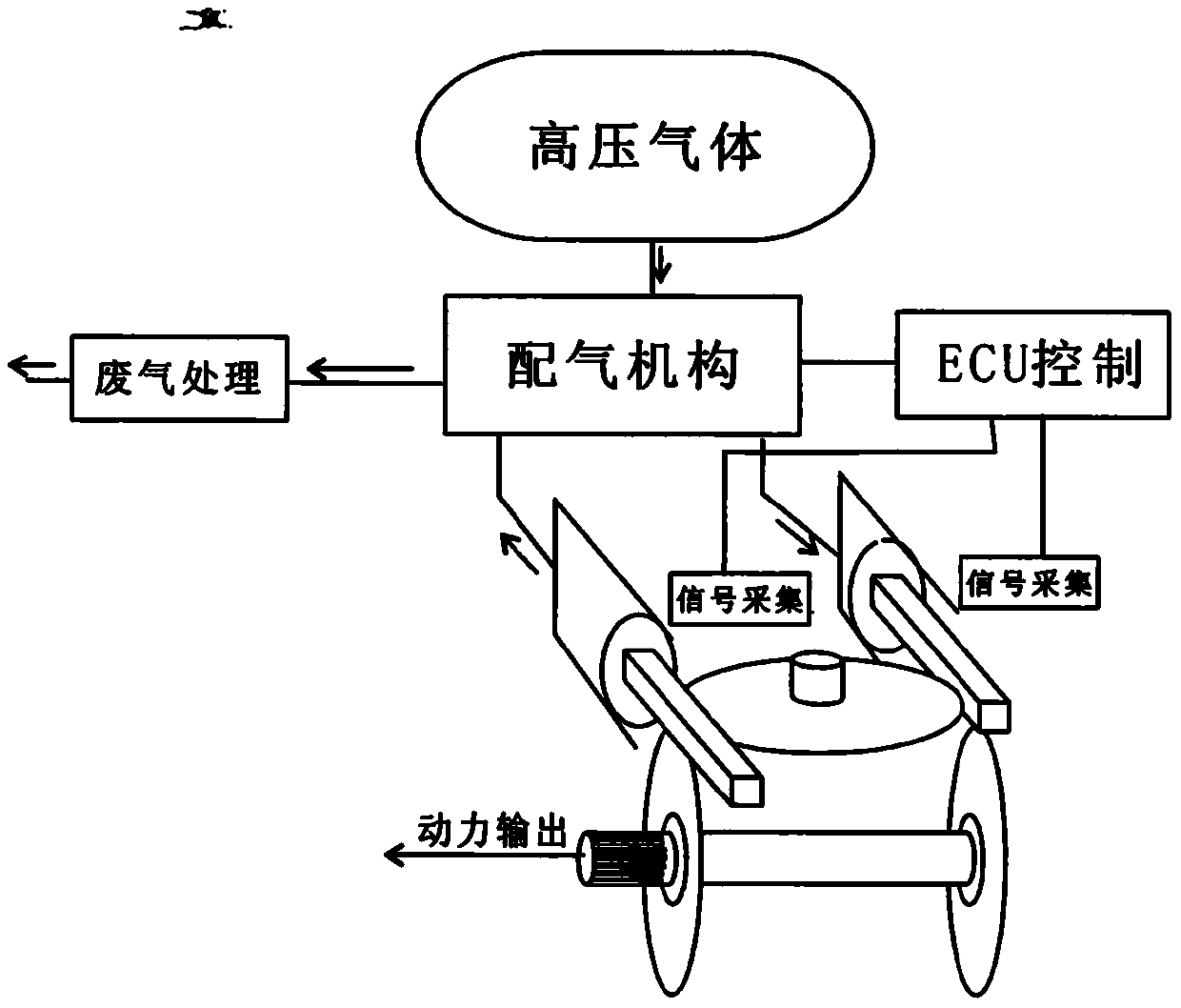

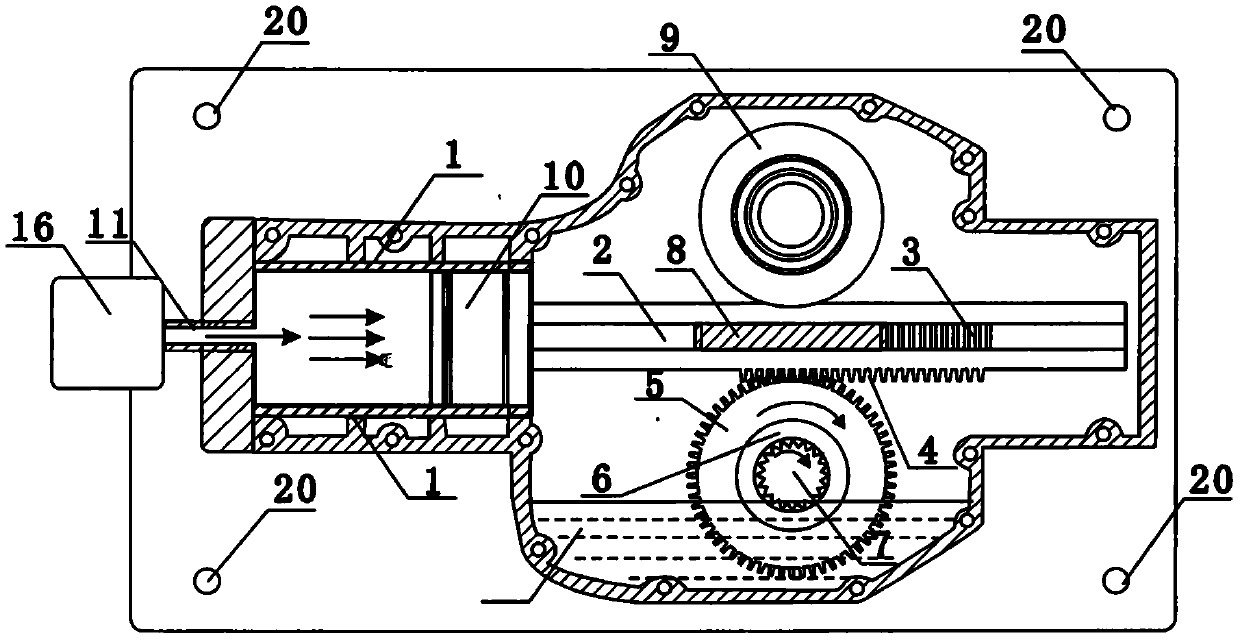

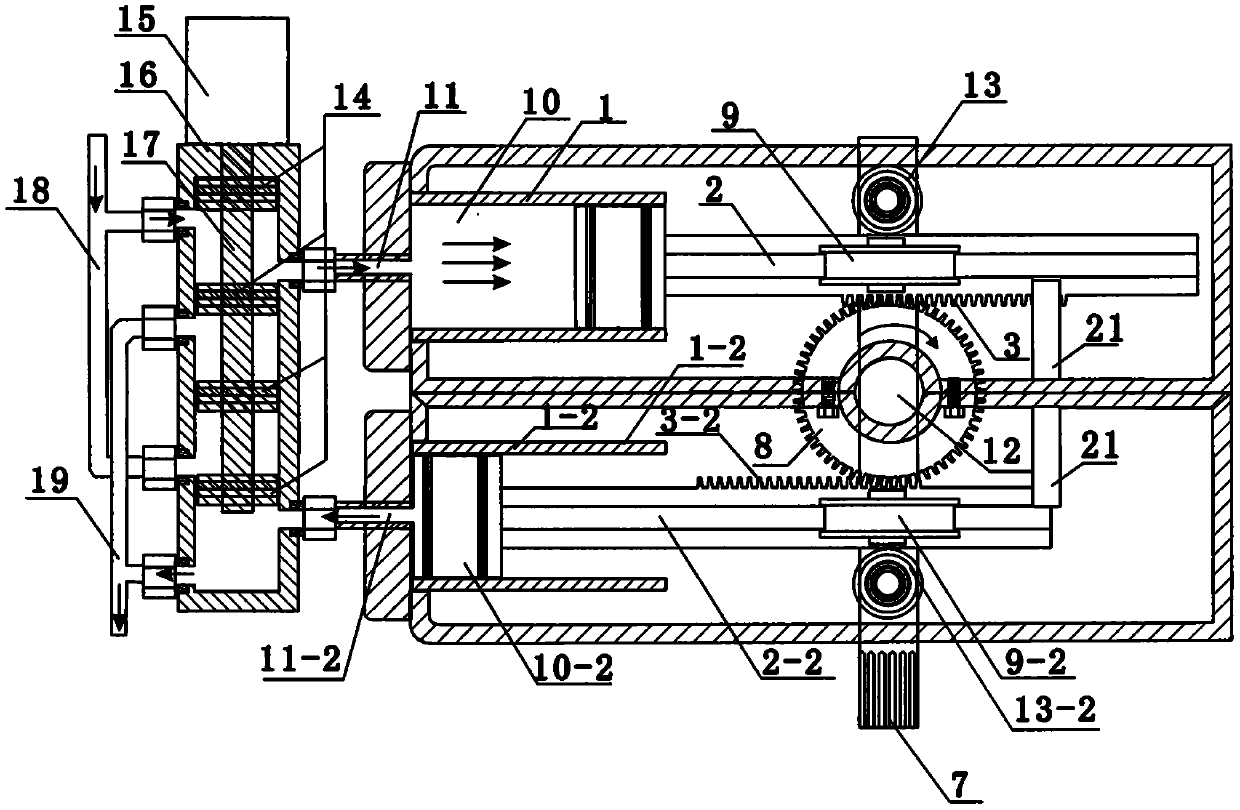

[0013] Such as figure 1 , 2 , 3, 4 design and manufacture a new type of wheel-driven air motor, the two motor cylinders A and B are arranged in parallel in parallel, and the two groups of working pistons A and B are respectively connected to the multi-faceted rack connecting rod 2, 2-2, two The racks 4 under the two connecting rods are respectively meshed with the output gear 5, and the two sets of output gears are respectively installed on the same output shaft 7 through the overrunning clutch 6. The push gear 8 meshes, and the position corresponding to the output gear on the multi-faceted rack connecting rod 2, 2-2 is provided with concave auxiliary wheels 9, 9-2 to maintain the linear motion of the multi-faced rack connecting rod 2, 2-2, and the gas distribution The mechanism is composed of a plurality of valve piston plates 14 in the gas distribution valve body 16 connected in series on a valve rod 17, the piston position sensor 21 provided on the body provides the ECU co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com