Fixed Constant Velocity Universal Joint

A constant velocity universal joint, fixed technology, applied in the direction of elastic couplings, mechanical equipment, couplings, etc., can solve the problems of not having track grooves, and achieve the effects of size reduction, rigidity improvement, and edge load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

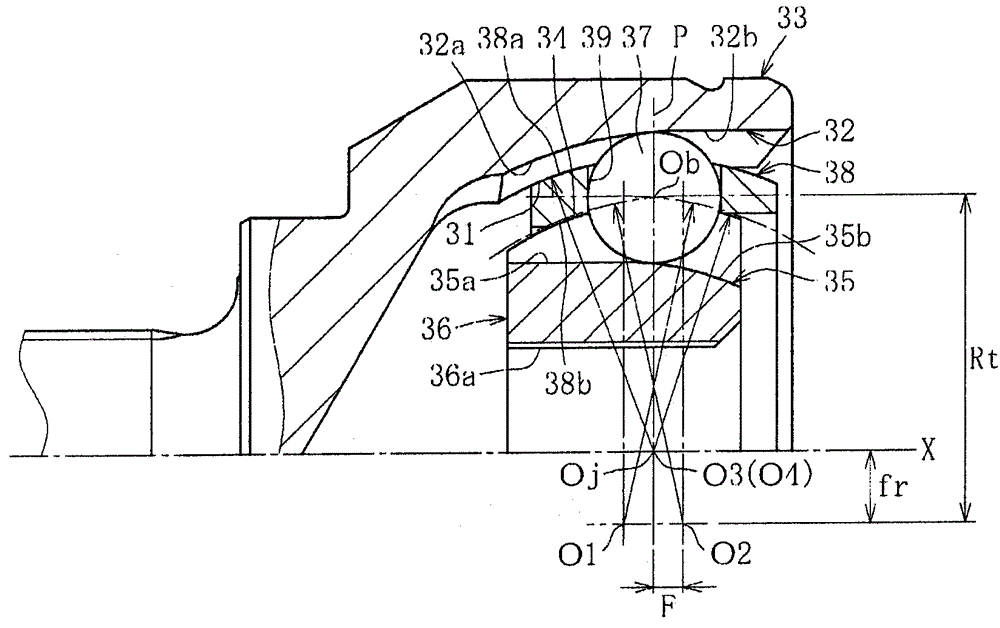

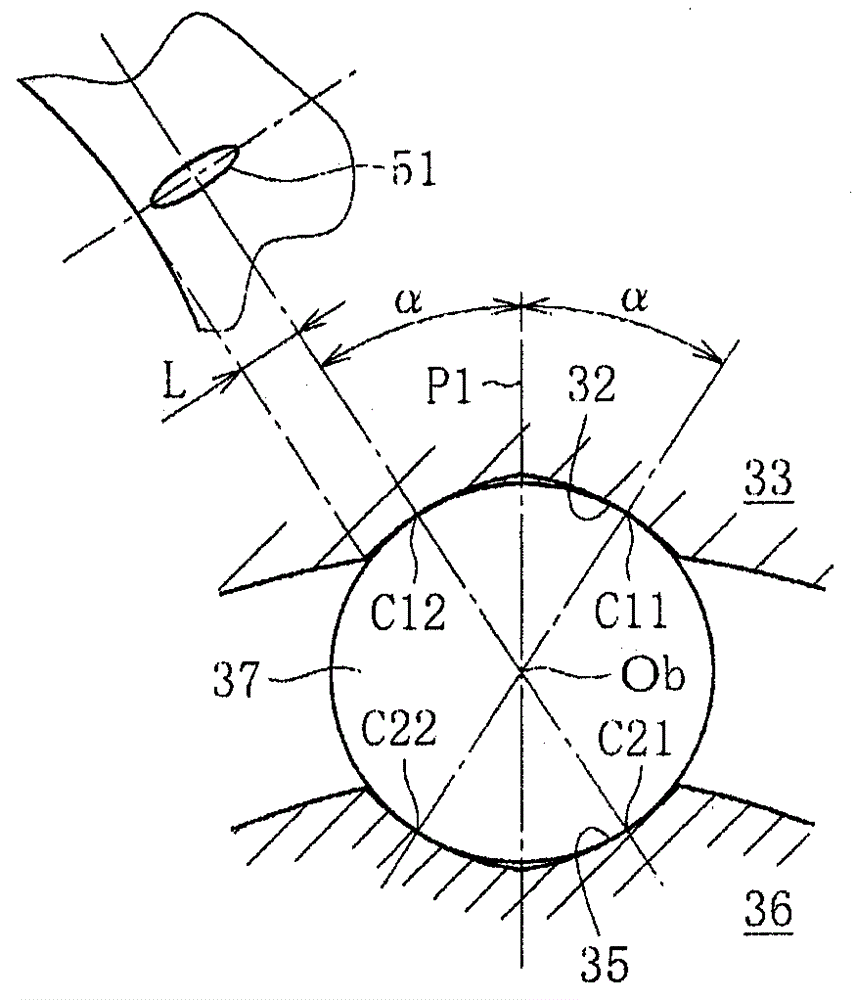

Embodiment 1

[0095] A common angle (operating angle of 6°) durability test was carried out under relatively large torque conditions, and the results are shown in Surface 2 below. In this case, two samples of conventional products (conventional product No.1, conventional product No.2), and two samples of the above-mentioned product A1 of the present invention (product A1 of the present invention, product A1 of the present invention No. 2 ), the samples of the product A2 of the present invention and the product B of the present invention are respectively made four (product A2No.1 of the present invention, product A2No.2 of the present invention, product A2No.3 of the present invention, product A2No.4 of the present invention, product A2No.4 of the present invention Product B1No.1, Product B1No.2 of the present invention, Product B1No.3 of the present invention, Product B1No.4 of the present invention). The durability test was performed under the conditions of a torque of 834 Nm and a rotatio...

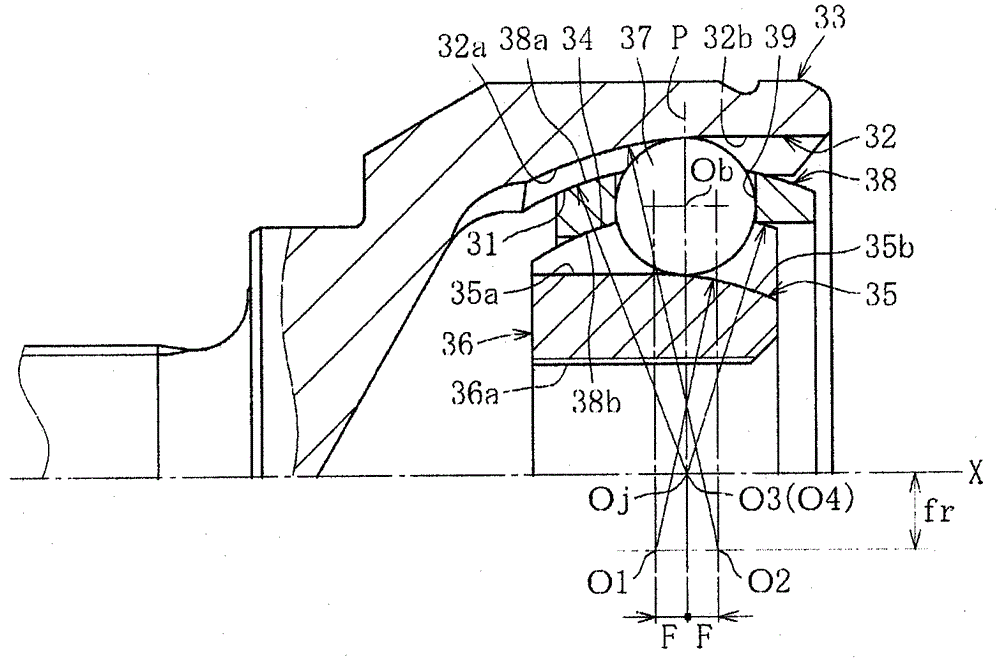

Embodiment 2

[0102] Next, a high-angle durability test was carried out, the results of which are shown in Table 3 below. In this case, two samples of the conventional product are made (conventional product No.1, conventional product No.2), and two samples of the product A1 of the present invention, product A2 of the present invention, and product B of the present invention are prepared respectively (product No. A1No.1, product of the present invention A1No.2, product of the present invention A2No.1, product of the present invention A2No.2, product of the present invention B1No.1, product of the present invention B1No.2). The durability test was carried out under the conditions of a torque of 549 Nm, an angle of 0 to 46° (swing), and a rotation speed of 80 r / min.

[0103] 〔table 3〕

[0104] [table 3]

[0105]

[0106] In the case of running time of 3.7 hours, conventional product No. 1 and conventional product No. 2 were on the inner side of the outer ring, and there was a defect due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com