Universal soft cable

A soft cable and soft casing technology, applied in the field of universal soft cables, can solve the problems of no similar products, limited use of electric cutting, complicated structure, etc., and achieve the effects of low cost, high torque transmission efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A universal flexible rope, comprising:

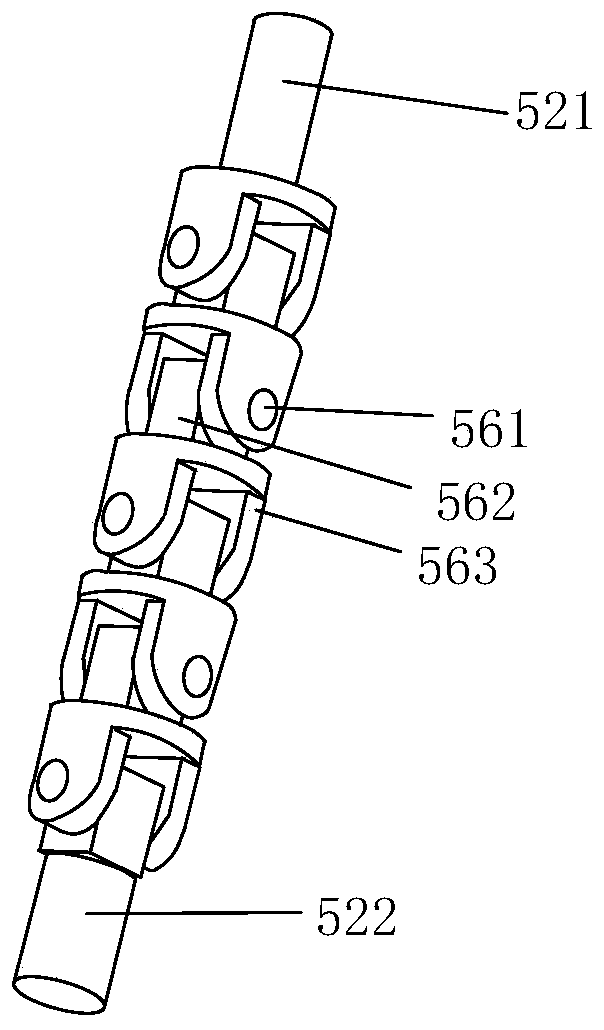

[0030] The first rotating shaft 521, a plurality of joints and the second rotating shaft 522 are sequentially hinged in series through the pin shafts 561, and the axis centers of the two pin shafts 561 on the same joint are not on the same plane;

[0031] The first joint 511 is sleeved on the outside of the first rotating shaft 521, and the first rotating shaft 521 can rotate in the first joint 511;

[0032] The second joint 512 is sleeved on the outside of the second rotating shaft 522, and the second rotating shaft 522 can rotate in the second joint 512;

[0033] When the first rotating shaft 521 rotates, the second rotating shaft 522 can be driven to rotate through a plurality of joint linkages.

[0034] In some usage environments, as long as the first joint 511 and the second joint 512 are fixed, the present invention can transmit power, and the soft sleeve 55 is an unnecessary part.

Embodiment 2

[0036] On the basis of embodiment 1, further comprising:

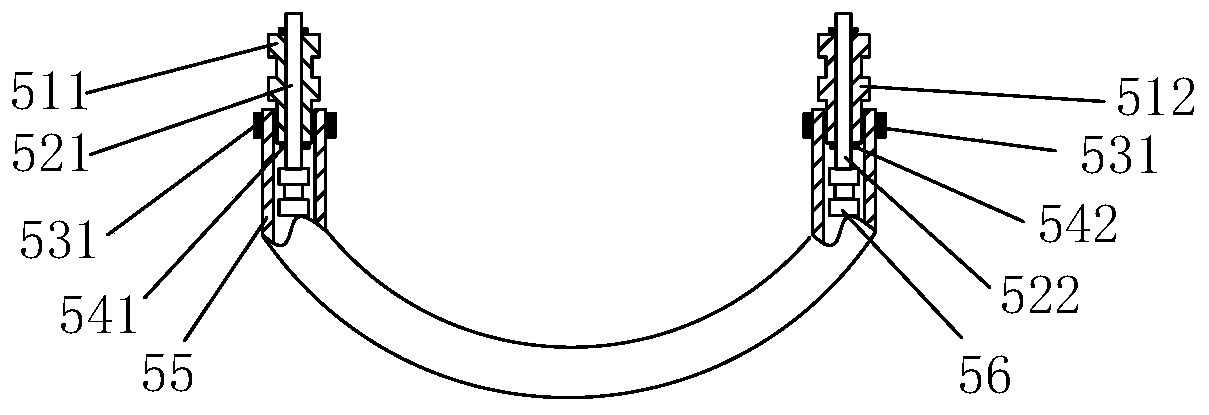

[0037] The two ends of the soft sleeve 55 are respectively fixed with the first joint 511 and the second joint 512 , and a plurality of joints penetrate the soft sleeve 55 .

[0038] The hoop 531 can compress the soft sleeve 55 outside the first joint 511 or the second joint 512 .

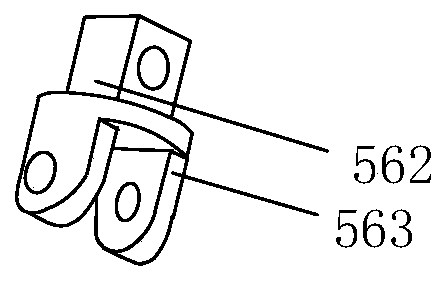

[0039] The axis centers of the two bearing pins 561 on the same joint 56 differ by 90 degrees.

[0040] The first rotating shaft 521 and the second rotating shaft 522 are provided with a limiting device 541, the limiting device 541 can limit the axial movement of the first rotating shaft 521 and the first joint 511, and can also limit the axial movement of the second rotating shaft 522 and the second joint 512. move.

[0041] The inner walls and / or joints of the soft sleeve 55 are coated with Teflon material.

[0042] The first joint 511 and the second joint 512 are provided with a convex ring and / or a concave ring.

[0043] In embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com