Thread plug-in mounting type speed sensitive load control valve

A sensitive load, threaded insertion technology, applied in variable capacity pump components, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problems of high cost, achieve low cost, prevent overload flameout, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

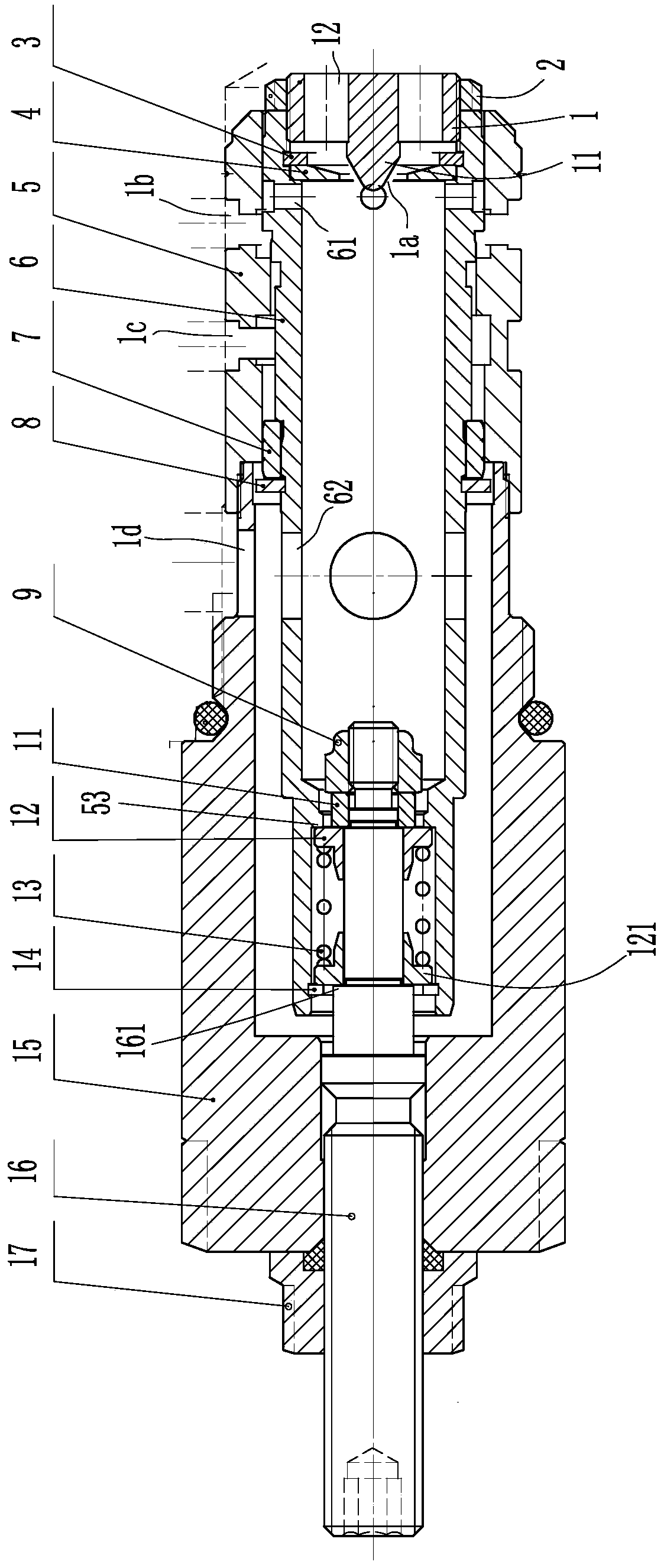

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 As shown, the threaded cartridge speed-sensitive load control valve in this embodiment includes a valve sleeve 5, a screw sleeve 15, an adjustment rod 16, a valve core 6, a throttle plate 4, a first spring seat 121, and a second spring seat 12. and spring 13.

[0024] The valve sleeve 5 is hollow in the axial direction, and the first oil port 1b and the second oil port 1c are opened in the lateral direction from front to back; A third oil port 1d is opened laterally.

[0025] The adjusting rod 16 is arranged in the screw sleeve 15 sealingly and the front end extends into the inner cavity formed by the screw sleeve 15 and the valve sleeve 5; the adjusting rod 16 can move forward and backward to adjust the stroke of the valve core 6.

[0026] The spool 6 is located in the inner cavity formed by the screw sleeve 15, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com