Power machine with two media conducting heat energy and work doing method thereof

A power machine and dual-medium technology, which is applied to combustion engines, machines/engines, mechanical equipment, etc., can solve the problems of high cost and high manufacturing cost, and achieve the effects of low noise, simple machine structure and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

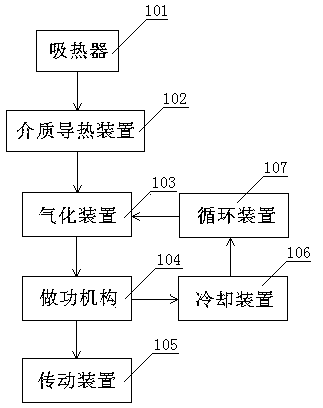

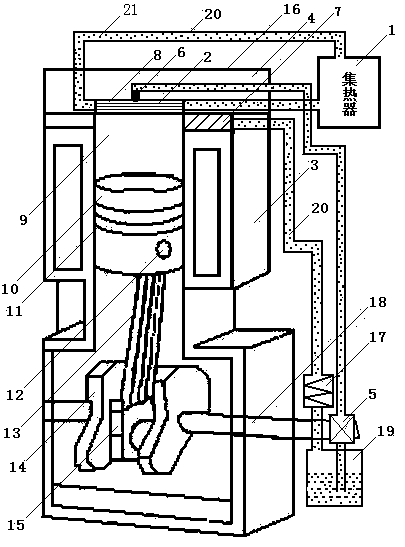

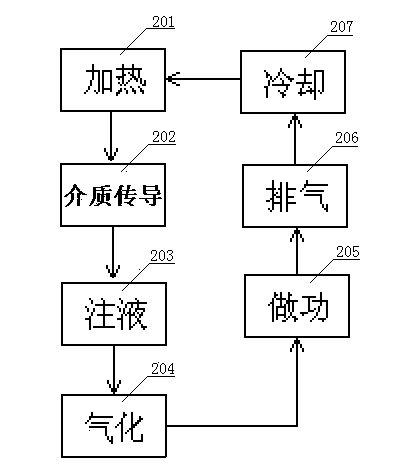

[0039] Refer to attached Figure 1-3, the embodiment of the present invention is:

[0040] A dual-medium conduction heat energy power machine, consisting of a heat absorber 1, a gasification heat conduction sheet 2, an insulation layer 3, a cylinder head 4, a pressure valve 5, an atomizer 6, an exhaust valve 7, a gasification reactor 8, and a cylinder 9. Piston 10, piston ring 11, connecting pin 12, connecting rod 13, crankshaft 14, bearing 15, casing 16, cooler 17, transmission shaft 18, liquid storage tank 19, medium heat conducting insulation pipe 20 and heat energy conducting medium 21, the cylinder 9 is provided with a piston 10, the piston 10 is provided with a piston ring 11, the piston 10 is connected to the connecting rod 13 through the connecting pin 12, the connecting rod 13 is connected to the crankshaft 14, the crankshaft 14 is provided with a bearing 15, and the bearing 15 is fixed on the transmission shaft 18, the transmission shaft 18 is fixed on the casing 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com