Star-type high-low pressure power device and work-doing method of star-type high-low pressure power device

A power equipment, high and low pressure technology, applied in mechanical equipment, variable capacity engines, machines/engines, etc., can solve the problems of high manufacturing cost, high cost, complex internal combustion engine radial engine structure, etc., and achieve maintainability and survivability. Good, light weight, great potential for power growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

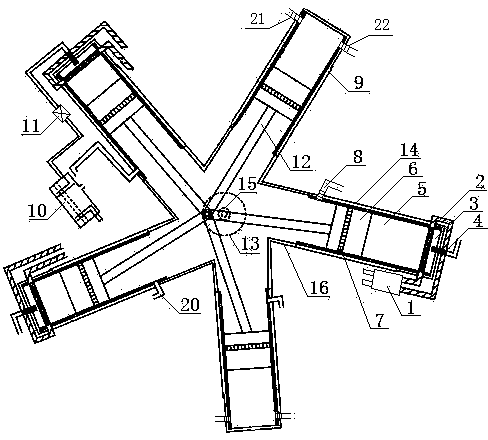

[0027] A star-shaped high and low pressure power equipment, including heat collector 1, heat preservation pipe 2, gasification reactor 3, atomizer 4, cylinder 5, piston 6, piston ring 7, automatic exhaust valve 8, radiator 9, Liquid storage tank 10, pressure valve 11, connecting rod 12, crankshaft 13, insulation layer 14, rotating shaft 15, casing 16 and buffer pipe 20; 6 is connected to the crankshaft 13 through the connecting rod 12, and the cylinder 5 is composed of three high-pressure cylinders and two low-pressure cylinders, of which two high-pressure cylinders are parallel, and the third high-pressure cylinder is set between the two low-pressure cylinders; the cylinder 5 is respectively equipped with Piston 6, piston 6 is provided with piston ring 7; crankshaft 13 is connected to rotating shaft 15, and rotating shaft 15 is fixed on the casing 16 through bearing; heat collector 1 is connected to gasification reactor 3 through insulation pipe 2, and gasification reactor 3 ...

Embodiment 2

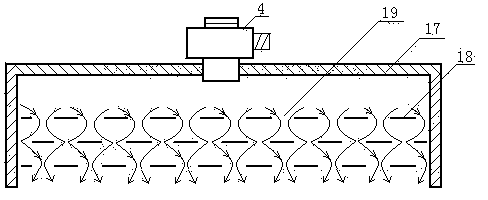

[0029] As in the star-shaped high and low pressure power equipment in Example 1, the gasification reactor 3 includes a pressure shell 17, a gasification heat conduction sheet 18, an air hole 19, and an atomizer 4, and the gasification heat conduction sheet 18 is arranged on the pressure shell 17 The air hole 19 is arranged in an array on the gasification heat conducting sheet 18, and the atomizer 4 is arranged at the inlet end of the pressure shell 17; the pressure valve 11 is associated with the crankshaft 13, and the pressure valve is opened and closed five times every time a cycle is completed; The structure of five cylinders is an example, five cylinders form a star structure, and five cylinders perform work in turn;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com