Polymethyl methacrylate monomer high-molecular polymer and preparation method thereof

A kind of technology of polymethyl methacrylate and methyl methacrylate, applied in the field of heat-resistant reinforced polymethyl methacrylate monomer and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

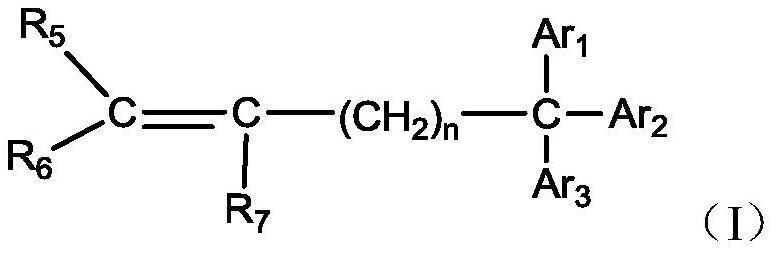

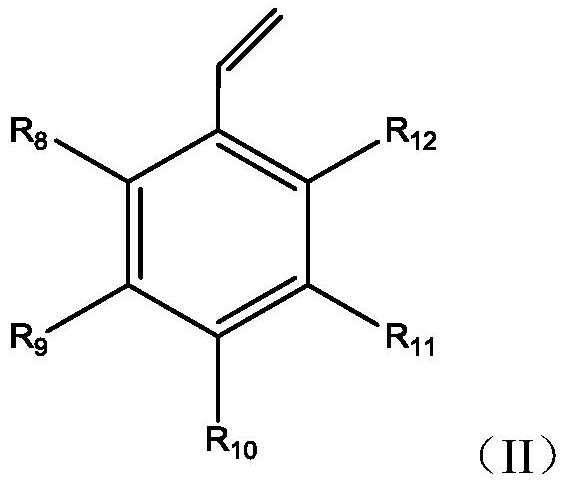

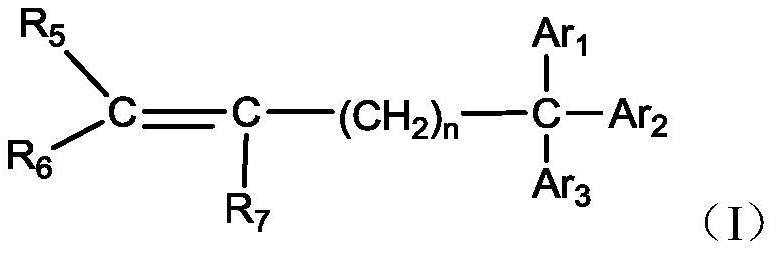

Method used

Image

Examples

Embodiment 1

[0058]Steps:

[0059](1) ingredient: 80 parts of methyl methacrylate, 14 parts of the monomer II contain a vinyl monomer of triphenyl structure, 6 parts of monomer III, 1 cellophilic, trigger, diodebenzene 0.18 pieces of formyl, 0.15 parts of the chain transfer agent, thirate thiol thiol, thoroughly stirred to mix uniform, adding the nitrogen gas to 20 min to remove oxygen dissolved therein;

[0060](2) Step-by-step polymerization: The reaction temperature is 90 ° C, reacted at 40 min under stirring, and the inner polymer is transferred into a cryogenic reaction vessel, and the reaction temperature is 50 ° C, the reaction time is 32 h, and the temperature is further warmed to 90 ° C, 105 ° C, 120 ° C, each temperature is reacted for 2 hours, and the polymerization conversion is increased, and the residual monomer is reduced.

Embodiment 2

[0062]Steps:

[0063](1) ingredient: 85 parts of methyl methacrylate, 9 parts of the monomer II contain a triphenyl structure, 3 parts of monomer III, 6 parts of Diethylbenzene, initiator-oxide diobenzene 0.18 pieces of formyl, 0.15 parts of the chain transfer agent, thirate thiol thiol, thoroughly stirred to mix uniform, adding the nitrogen gas to 20 min to remove oxygen dissolved therein;

[0064](2) Step-by-step polymerization: The reaction temperature is 90 ° C, reacted at 40 min under stirring, and the inner polymer is transferred into a cryogenic reaction vessel, and the reaction temperature is 50 ° C, the reaction time is 32 h, and the temperature is further warmed to 90 ° C, 105 ° C, 120 ° C, each temperature is reacted for 2 hours, and the polymerization rate is increased.

Embodiment 3

[0066]Steps:

[0067](1) ingredients: 90 parts of methyl methacrylate, 3 parts of the monomer II contain a triphenyl structure, 4 parts of the monomer III, 3, initiator, oxide diobenzene 0.18 pieces of formyl, 0.15 parts of the chain transfer agent, thirate thiol thiol, thoroughly stirred to mix uniform, adding the nitrogen gas to 20 min to remove oxygen dissolved therein;

[0068](2) Step-by-step polymerization: The reaction temperature is 90 ° C, reacted at 40 min under stirring, and the inner polymer is transferred into a cryogenic reaction vessel, and the reaction temperature is 50 ° C, the reaction time is 32 h, and the temperature is further warmed to 90 ° C, 105 ° C, 120 ° C, each temperature is reacted for 2 hours, and residual monomers are reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com